NFVA22512NP2T - ASPM34 Series Automotive 3-Phase 1200 …

Transcript of NFVA22512NP2T - ASPM34 Series Automotive 3-Phase 1200 …

© Semiconductor Components Industries, LLC, 2019

May, 2020 − Rev. 01 Publication Order Number:

NFVA22512NP2T/D

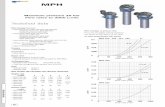

ASPM34 SeriesAutomotive 3-Phase 1200 V25 A IGBT Intelligent PowerModule

NFVA22512NP2TGeneral Description

NFVA22512NP2T is an advanced Auto IPM module providing afully−featured, high−performance inverter output stage for hybrid andelectric vehicles. These modules integrate optimized gate drive of thebuilt−in IGBTs to minimize EMI and losses, while also providingmultiple on−module protection features including under−voltagelockouts, over−current shutdown, thermal monitoring of drive IC, andfault reporting. The built−in, high−speed HVIC requires only a singlesupply voltage and translates the incoming logic−level gate inputs tothe high−voltage, high−current drive signals required to properly drivethe module’s internal IGBTs. Separate negative IGBT terminals areavailable for each phase to support the widest variety of controlalgorithms.

Features• Automotive SPM®

in 34 Pin DIP Package

• AEC & AQG324 Qualified and PPAP Capable

• 1200 V − 25 A 3−Phase IGBT Inverter with Integral Gate Driversand Protection

• Low−Loss, Short−Circuit Rated IGBTs

• Very Low Thermal Resistance Using Al2O3 DBC Substrate

• Built−In Bootstrap Diodes and Dedicated Vs Pins Simplify PCBLayout

• Separate Open−Emitter Pins from Low−Side IGBTs for Three−PhaseCurrent Sensing

• Single−Grounded Power Supply Supported

• Built−In NTC Thermistor for Temperature Monitoring andManagement

• Adjustable Over−Current Protection via Integrated Sense−IGBTs

• Isolation Rating of 2500 Vrms / 1 min

• This is a Pb−Free Device

Applications• Automotive High Voltage Auxiliary Motors

♦ Climate E−Compressors♦ Oil / Water Pumps♦ Super / Turbo Chargers♦ Variety Fans

• Motion Control♦ Industrial Motor

www.onsemi.com

See detailed ordering and shipping information on page 14 ofthis data sheet.

ORDERING INFORMATION

MARKING DIAGRAM

3D Package Drawing(Click to Activate 3D Content)

DIP34 80x33, AUTOMOTIVE MODULECASE MODGL

XXXXXXXXXXXX = Specific Device CodeZZZ = Lot IDAT = Assembly & Test LocationY = YearW = Work WeekNNN = Serial Number

NFVA22512NP2T

www.onsemi.com2

Related Resources• AN−9075 − Users Guide for 1200V SPM®

2 Series

• AN−9076 − Mounting Guide for New SPM® 2 Package

• AN−9079 − Thermal Performance of 1200 V MotionSPM®

2 Series by Mounting Torque• Integrated Power Functions

• Integrated Drive, Protection, and System ControlFunctions

Integrated Power Functions• 1200 V - 25 A IGBT inverter for three−phase DC / AC

power conversion (Please refer to Figure 1)

Integrated Drive, Protection and System ControlFunctions• For inverter high−side IGBTs: gate drive circuit,

high−voltage isolated high−speed level shiftingcontrol circuit Under−Voltage Lock−Out Protection(UVLO)

• For inverter low−side IGBTs: gate drive circuit,Short−Circuit Protection (SCP)control supply circuit Under−Voltage Lock−OutProtection (UVLO)

• Fault signaling: corresponding to UVLO (low−sidesupply) and SC faults

• Input interface: active−HIGH interface, works with 3.3 /5 V logic, Schmitt−trigger input

PIN CONFIGURATION

Figure 1. Pin Configuration − Top View

(34) VS(W)

(33) VB(W)

(31) VDD(WH)

(30) IN(WH)

(29) VS(V)

(28) VB(V)

(26) VDD(VH)

(25) IN(VH)

(24) VS(U)

(23) VB(U)

(21) VDD(UH)(20) COM (H)

(19) IN(UH)

(18) RSC

(17) CSC

(16) CFOD

(15) VFO

(12) IN (UL)

(13) IN (VL)

(14) IN (WL)

(10) VDD(L)

(11) COM (L)

(22) VBD(U)

(27) VBD(V)

(32) VBD(W)

(1) P

(2) W

(3) V

(4) U

(5) N W

(6) N V

(7) N U

(8) RTH

(9) VTH

Case Temperature (TC)Detecting Point

NFVA22512NP2T

www.onsemi.com3

PIN DESCRIPTION

Pin Number Pin Name Pin Description

1 P Positive DC−Link Input

2 W Output for W Phase

3 V Output for V Phase

4 U Output for U Phase

5 NW Negative DC−Link Input for W Phase

6 NV Negative DC−Link Input for V Phase

7 NU Negative DC−Link Input for U Phase

8 RTH Series Resistor for Thermistor (Temperature Detection)

9 VTH Thermistor Bias Voltage

10 VDD(L) Low−Side Bias Voltage for IC and IGBTs Driving

11 COM(L) Low−Side Common Supply Ground

12 IN(UL) Signal Input for Low−Side U Phase

13 IN(VL) Signal Input for Low−Side V Phase

14 IN(WL) Signal Input for Low−Side W Phase

15 VFO Fault Output

16 CFOD Capacitor for Fault Output Duration Selection

17 CSC Shut Down Input for Short−Circuit Current Detection Input

18 RSC Resistor for Short−Circuit Current Detection

19 IN(UH) Signal Input for High−Side U Phase

20 COM(H) High−Side Common Supply Ground

21 VDD(UH) High−Side Bias Voltage for U Phase IC

22 VBD(U) Anode of Bootstrap Diode for U Phase High−Side Bootstrap Circuit

23 VB(U) High−Side Bias Voltage for U Phase IGBT Driving

24 VS(U) High−Side Bias Voltage Ground for U Phase IGBT Driving

25 IN(VH) Signal Input for High−Side V Phase

26 VDD(VH) High−Side Bias Voltage for V Phase IC

27 VBD(V) Anode of Bootstrap Diode for V Phase High−Side Bootstrap Circuit

28 VB(V) High−Side Bias Voltage for V Phase IGBT Driving

29 VS(V) High−Side Bias Voltage Ground for V Phase IGBT Driving

30 IN(WH) Signal Input for High−Side W Phase

31 VDD(WH) High−Side Bias Voltage for W Phase IC

32 VBD(W) Anode of Bootstrap Diode for W Phase High−Side Bootstrap Circuit

33 VB(W) High−Side Bias Voltage for W Phase IGBT Driving

34 VS(W) High−Side Bias Voltage Ground for W Phase IGBT Driving

NFVA22512NP2T

www.onsemi.com4

INTERNAL EQUIVALENT CIRCUIT AND INPUT/OUTPUT PINS

Figure 2. Internal Block Diagram

NOTES:1. nverter low−side is composed of three IGBTs, freewheeling diodes for each IGBT, and one control IC. It has gate drive and protection

functions.2. nverter power side is composed of four inverter DC−link input terminals and three inverter output terminals.3. Inverter high−side is composed of three IGBTs, freewheeling diodes, and three drive ICs for each IGBT.

LVIC

COM

VDD

IN

IN

IN

VFO

CSC

OUT

OUT

OUT

W (2)

P (1)

(24) VS(U)

(23) VB(U)

(29) VS(V)

(28) VB(V)

(17) CSC

(15) VFO

(14) IN(WL)

(13) IN(VL)

(12) IN(UL)

HVIC OUT

(25) IN(VH)

(10) VDD(L)

(19) IN(UH)

(34) VS(W)

(33) VB(W)

(21) VDD(UH)

(30) IN(WH)

Thermistor

VS

(11) COM (L)

VDDCOM

HVIC OUT

VS

VDD

COM

HVIC

VB

OUT

VS

VDD

COM

CFOD

NU (7)

NV (6)

NW (5)

U (4)

V (3)

RTH (8)

VTH (9)

(16) CFOD

(18) R SC

(20) COM (H)

(22) VBD(U)

(26) VDD(VH)

(27) VBD(V)

(31) VDD(WH)

(32) VBD(W)

IN

IN

IN

VB

VB

NFVA22512NP2T

www.onsemi.com5

ABSOLUTE MAXIMUM RATINGS (Tj = 25°C unless otherwise noted)

Symbol Rating Conditions Rating Unit

INVERTER PART

VPN Supply Voltage Applied between P − NU, NV, NW 900 V

VPN(Surge) Supply Voltage (Surge) Applied between P − NU, NV, NW 1000 V

VCES Collector − Emitter Voltage 1200 V

±IC Each IGBT Collector Current TC = 100°C, TJ ≤ 150°C, VDD ≥ 15 V (Note 4) 25 A

±ICP Each IGBT Collector Current (Peak) TC = 25°C, TJ ≤ 150°C, Under 1 ms Pulse Width (Note 4)

50 A

PC Collector Dissipation TC = 25°C per One Chip (Note 4) 154 W

TJ Operating Junction Temperature VCES = 960 V −40~150 °C

VCES = 1200 V −40~125 °C

CONTROL PART

VDD Control Supply Voltage Applied between VDD(H), VDD(L) − COM 20 V

VBS High−Side Control Bias Voltage Applied between VB(U) − VS(U), VB(V) − VS(V), VB(W) − VS(W)

20 V

VIN Input Signal Voltage Applied between IN(UH), IN(VH), IN(WH), IN(UL), IN(VL), IN(WL) − COM

−0.3~VDD + 0.3 V

VFO Fault Output Supply Voltage Applied between VFO − COM −0.3~VDD + 0.3 V

IFO Fault Output Current Sink Current at VFO pin 2 mA

VSC Current Sensing Input Voltage Applied between CSC − COM −0.3~VDD + 0.3 V

BOOSTSTRAP DIODE PART

VRRM Maximum Repetitive Reverse Voltage 1200 V

IF Forward Current TC = 25°C, TJ ≤ 150°C (Note 4) 1.0 A

IFP Forward Current (Peak) TC = 25°C, TJ ≤ 150°C, Under 1 ms Pulse Width (Note 4)

2.0 A

TJ Operating Junction Temperature (Note 6) −40~150 °C

TOTAL SYSTEM

tSC Short Circuit Withstand Time VDD = VBS ≤ 16.5 V, VPN ≤ 800 V, TJ = 150°CNon−repetitive

3 �s

TSTG Storage Temperature −40~150 °C

VISO Isolation Voltage 60 Hz, Sinusoidal, AC 1 minute, Connection Pins to Heat Sink Plate

2500 Vrms

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionalityshould not be assumed, damage may occur and reliability may be affected.4. These values had been made an acquisition by the calculation considered to design factor.

THERMAL RESISTANCE

Symbol Parameter Conditions Min Typ Max Unit

Rth(j−c)Q Junction to Case Thermal Resistance (Note 5)

Inverter IGBT part (per 1 / 6 module) − − 0.81 °C/W

Rth(j−c)F Inverter FWD part (per 1 / 6 module) − − 1.58 °C/W

L� Package Stray Inductance P to NU, NV, NW (Note 6) − 32 − nH

5. For the measurement point of case temperature (TC), please refer to Figure 1. DBC discoloration and Picker Circle Printing allowed, pleaserefer to application note AN−9190 (Impact of DBC Oxidation on SPM® Module Performance).

6. Stray inductance per phase measured per IEC 60747−15.

NFVA22512NP2T

www.onsemi.com6

ELECTRICAL CHARACTERISTICS

Symbol Parameter Conditions Min Typ Max Unit

INVERTER PART (Tj as specified)

VCE(SAT) Collector −Emitter Saturation Voltage

VDD = VBS = 15 V, VIN = 5 V, IC = 25 A, TJ = 25°C − 1.90 2.50 V

VDD = VBS = 15 V, VIN = 5 V, IC = 25 A, TJ = 150°C − 2.35 2.95 V

VF FWDi Forward Voltage VIN = 0 V, IF = 25 A, TJ = 25°C − 2.00 2.60 V

VIN = 0 V, IF = 25 A, TJ = 150°C − 1.95 2.55 V

HS tON High Side Switching Times VPN = 600 V, VDD = 15 V, IC = 25 A, TJ = 25°C VIN = 0 V ↔ 5 V, Inductive Load See Figure 4 (Note 7)

0.60 1.10 1.70 �s

tC(ON) − 0.25 0.65 �s

tOFF − 1.15 1.75 �s

tC(OFF) − 0.15 0.55 �s

trr − 0.20 − �s

LS tON Low Side Switching Times VPN = 600 V, VDD = 15 V, IC = 25 A, TJ = 25°C VIN = 0 V ↔ 5 V, Inductive Load See Figure 4 (Note 7)

0.45 0.95 1.55 �s

tC(ON) − 0.30 0.70 �s

tOFF − 1.10 1.70 �s

tC(OFF) − 0.15 0.55 �s

trr − 0.20 − �s

ICES Collector − Emitter Leakage Current

Tj = 25°C, VCE = VCES − − 3 mA

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Productperformance may not be indicated by the Electrical Characteristics if operated under different conditions.7. tON and tOFF include the propagation delay time of the internal drive IC. tC(ON) and tC(OFF) are the switching time of IGBT itself under the given

gate driving condition internally. For the detailed information, please see Figure 3.

Figure 3. Switching Time Definition

(a) turn-on (b) turn-off

VCE IC

VIN

tON

tC(ON)

VIN(ON)

10% IC

10% VCE90% IC

100% IC

t rr

100% IC

VCEIC

VIN

tOFF

tC(OFF)

VIN(OFF) 10% VCE 10% IC

NFVA22512NP2T

www.onsemi.com7

Figure 4. Example Circuit of Switching Test

One−Leg Diagram of ASPM34

P

N

IC

U,V,W

Inductor

HS Switching

LS Switching

V600 V

V

V15 V

5 V

4.7 kΩ

CBS

HS Switching

LS Switching

V

0 V

5 V

RBS

IN

VDD

IN

COM

VB

OUT

VS

VDD

IN

COM

OUT

CSC

CFOD

VFO

U,V,W

RSC

VDD

VPN

Sw

itchi

ng L

oss,

ES

W [�

J]

Collector Current, IC [A]

Inductive Load, VPN = 600 V, VCC = 15 V, Tj = 25�C

Collector Current, IC [A]

Inductive Load, VPN = 600 V, VCC = 15 V, Tj = 150�C

Figure 5. Switching Loss Characteristics

Sw

itchi

ng L

oss,

ES

W [�

J]

Figure 6. R−T Curve of Built−in Thermistor

0

4

8

12

16

20

−20 −10 0 10 20 30 40 50 60 70 80 90 100 110 120

Res

ista

nce

[k�

]

Temperature [°C]

50 60 70 80 90 100 110 120

R−T Curve in 50�C ~ 125�C

R−T Curve

0

50

100

150

200

250

300

350

400

450

500

550

600

Temperature [°C]

Res

ista

nce

[k�

]

NFVA22512NP2T

www.onsemi.com8

ELECTRICAL CHARACTERISTICS

Symbol Parameter Conditions Min Typ Max Unit

BOOTSTRAP DIODE PART (Tj as specified)

VF Forward Voltage IF = 1.0 A, TJ = 25°C − 2.2 − V

trr Reverse−Recovery Time IF = 1.0 A, dIF / dt = 50 A/ms, TJ = 25°C − 80 − ns

CONTROL PART (Tj = 25°C unless otherwise noted)

IQDDH Quiescent VDD Supply Current

VDD(UH,VH,WH) = 15 V, IN(UH,VH,WH) = 0 V

VDD(UH) − COM(H), VDD(VH) − COM(H), VDD(WH) − COM(H)

− − 0.15 mA

IQDDL VDD(L) = 15 V, IN(UL,VL, WL) = 0 V VDD(L) − COM(L) − − 4.80 mA

IPDDH Operating VDD Supply Current

VDD(UH,VH,WH) = 15 V, fPWM = 20 kHz, Duty = 50%, Applied to one PWM Signal Input for High−Side

VDD(UH) − COM(H), VDD(VH) − COM(H), VDD(WH) − COM(H)

− − 0.30 mA

IPDDL VDD(L) = 15V, fPWM = 20 kHz, Duty = 50%, Applied to one PWM Signal Input for Low−Side

VDD(L) − COM(L) − − 15.5 mA

IQBS Quiescent VBS Supply Current

VBS = 15 V, IN(UH,VH,WH) = 0 V VB(U) − VS(U), VB(V) − VS(V), VB(W) − VS(W)

− − 0.30 mA

IPBS Operating VBS Supply Current

VDD = VBS = 15 V, fPWM = 20 kHz, Duty = 50%, Applied to one PWM Signal Input for High−Side

VB(U) − VS(U), VB(V) − VS(V), VB(W) − VS(W)

− − 12.0 mA

VFOH Fault Output Voltage VDD = 15 V, VSC = 0 V, VFO Circuit: 4.7 k� to 5 V Pull−up 4.5 − − V

VFOL VDD = 15 V, VSC = 1 V, VFO Circuit: 4.7 k� to 5 V Pull−up − − 0.5 V

ISEN Sensing Current of Each Sense IGBT

VDD = 15 V, VIN = 5 V, RSC = 0 �, No Connection of Shunt Resistor at NU,V,W Terminal

IC = 25 A − 23 − mA

VSC(ref) Short Circuit Trip Level VDD = 15 V (Note 8) CSC − COM(L) 0.43 0.50 0.57 V

ISC Short Circuit Current Level for Trip

RSC = 27 � (±1%), No Connection of Shunt Resistor at NU,V,W Terminal (Note 8)

− 50 − A

UVDDD Supply Circuit Under−Voltage Protection

Detection Level 10.3 − 12.8 V

UVDDR Reset Level 10.8 − 13.3 V

UVBSD Detection Level 9.5 − 12.0 V

UVBSR Reset Level 10.0 − 12.5 V

tFOD Fault−Out Pulse Width CFOD = Open (Note 9) 50 − − �s

CFOD = 2.2 nF 1.7 − − ms

VIN(ON) ON Threshold Voltage Applied between IN(UH,VH,WH) − COM(H), IN(UL,VL,WL) − COM(L)

− − 2.6 V

VIN(OFF) OFF Threshold Voltage 0.8 − − V

RTH Resistance of Thermistor at TTH = 25°C See Figure 6 (Note 10)

− 47 − k�

at TTH = 100°C − 2.9 − k�

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Productperformance may not be indicated by the Electrical Characteristics if operated under different conditions.8. Short−circuit current protection functions only at the low−sides because the sense current is divided from main current at low−side IGBTs.

Inserting the shunt resistor for monitoring the phase current at NU, NV, NW terminal, the trip level of the short−circuit current is changed.9. The fault−out pulse width tFOD depends on the capacitance value of CFOD according to the following approximate equation:

tFOD = 0.8 x 106 x CFOD [s].10.TTH is the temperature of thermistor itself. To know case temperature (TC), conduct experiments considering the application.

NFVA22512NP2T

www.onsemi.com9

RECOMMENDED OPERATING RANGES

Symbol Parameter Conditions Min Typ Max Unit

VPN Supply Voltage Applied between P − NU, NV, NW 300 600 800 V

VDD Control Supply Voltage Applied between VDD(UH,VH,WH) − COM(H), VDD(L) − COM(L)

14.0 15.0 16.5 V

VBS High−Side Bias Voltage Applied between VB(U) − VS(U), VB(V) − VS(V), VB(W) − VS(W)

13.0 15.0 18.5 V

dVDD / dt,dVBS / dt

Control Supply Variation −1 − 1 V/�s

tdead Blanking Time for Preventing Arm − Short For Each Input Signal 2.0 − − �s

fPWM PWM Input Signal −40°C ≤ TC ≤ 125°C, −40°C ≤ TJ ≤ 150°C − − 20 kHz

VSEN Voltage for Current Sensing Applied between NU, NV, NW − COM(H, L) (Including Surge Voltage)

−5 − 5 V

PWIN(ON) Minimum Input Pulse Width VDD = VBS = 15 V, IC ≤ 50 A, Wiring Inductance between NU,V,W and DC Link N < 10 nH (Note 11)

2.0 − − �s

PWIN(OFF) 2.0 − −

TJ Junction Temperature −40 − 150 °C

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyondthe Recommended Operating Ranges limits may affect device reliability.11. This product might not make output response if input pulse width is less than the recommended value.

MECHANICAL CHARACTERISTICS AND RATINGS

Parameter Conditions Min Typ Max Unit

Device Flatness See Figure 7 0 − +200 �m

Mounting Torque Mounting Screw: M4 See Figure 8

Recommended 1.0 N ⋅ m 0.9 1.0 1.5 N ⋅ m

Recommended 10.1 kg ⋅ cm 9.1 10.1 15.1 kg ⋅ cm

Terminal Pulling Strength Load 19.6 N 10 − − s

Terminal Bending Strength Load 9.8 N, 90 degrees Bend 2 − − times

Weight − 50 − g

(+)

(+)

Figure 7. Flatness Measurement Position

NFVA22512NP2T

www.onsemi.com10

Figure 8. Mounting Screws Torque Order

NOTES:12.Do not over torque when mounting screws. Too much mounting torque may cause DBC cracks, as well as bolts and Al heat−sink

destruction.13.Avoid one−sided tightening stress. Figure 8 shows the recommended torque order for the mounting screws. Uneven mounting can cause

the DBC substrate of package to be damaged. The pre−screwing torque is set to 20~30% of maximum torque rating.

Pre − Screwing: 1 → 2Final Screwing: 2 → 1

1

2

TIME CHARTS OF SPMs PROTECTIVE FUNCTION

Figure 9. Under-Voltage Protection (Low-Side)

a1: Control supply voltage rises: after the voltage rises UVDDR, the circuits start to operate when the next input is applied.a2: Normal operation: IGBT ON and carrying current.a3: Under-voltage detection (UVDDD).a4: IGBT OFF in spite of control input condition.a5: Fault output operation starts with a fixed pulse width according to the condition of the external capacitor CFOD.a6: Under-voltage reset (UVDDR).a7: Normal operation: IGBT ON and carrying current by triggering next signal from LOW to HIGH.

Input Signal

Output Current

Fault Output Signal

ControlSupply Voltage

RESET

UV

ProtectionCircuit State SET RESET

a1a3

a2a4

a6

a5

a7

DDR

UVDDD

NFVA22512NP2T

www.onsemi.com11

Figure 10. Under-Voltage Protection (High-Side)

b1: Control supply voltage rises: after the voltage reaches UVBSR, the circuits start to operate when the next input is applied.b2: Normal operation: IGBT ON and carrying current.b3: Under-voltage detection (UVBSD).b4: IGBT OFF in spite of control input condition, but there is no fault output signal.b5: Under-voltage reset (UVBSR).b6: Normal operation: IGBT ON and carrying current by triggering next signal from LOW to HIGH.

Input Signal

Output Current

Fault Output Signal

Control

Supply Voltage

RESET

UV

Protection

Circuit State SET RESET

UVb1b3

b2b4

b6

b5

High−level (no fault output)

BSD

BSR

NFVA22512NP2T

www.onsemi.com12

Figure 11. Short-Circuit Current Protection (Low-Side Operation Only)

(With the external sense resistance and RC filter connection)c1: Normal operation: IGBT ON and carrying current.c2: Short-circuit current detection (SC trigger).c3: All low-side IGBTs gate are hard interrupted.c4: All low-side IGBTs turn OFF.c5: Fault output operation starts with a fixed pulse width according to the condition of the external capacitor CFOD.c6: Input HIGH: IGBT ON state, but during the active period of fault output, the IGBT doesn’t turn ON.c7: Fault output operation finishes, but IGBT doesn’t turn on until triggering the next signal from LOW to HIGH.c8: Normal operation: IGBT ON and carrying current.

Lower ArmsControl Input

Output Current

Sensing Voltageof Sense Resistor

Fault Output Signal

SC reference voltage

RC filter circuittime constantdelay

SC current trip level

ProtectionCircuit state SET RESET

c6 c7

c3

c2

c1

c8

c4

c5

Internal IGBTGate−Emitter

Internal delayat protection circuit

Input Voltage

INPUT/OUTPUT INTERFACE CIRCUIT

Figure 12. Recommended MCU I/O Interface Circuit

NOTE:14.RC coupling at each input might change depending on the PWM control scheme used in the application and the wiring impedance of the

application’s printed circuit board. The input signal section of the Motion SPM 2 product integrates 5 k� (typ.) pull−down resistor. Therefore,when using an external filtering resistor, please pay attention to the signal voltage drop at input terminal.

MCU

COM

VFO

4.7 k� ASPM

IN(UH), IN(VH), IN(WH)

IN(UL), IN(VL), IN(WL)

+5 V (MCU or control power)

NFVA22512NP2T

www.onsemi.com13

Figure 13. Typical Application Circuit

NOTES:15.To avoid malfunction, the wiring of each input should be as short as possible (less than 2 − 3 cm).16.VFO output is an open−drain type. This signal line should be pulled up to the positive side of the MCU or control power supply with a resistor

that makes IFO up to 2 mA. Please refer to Figure 13.17.Fault out pulse width can be adjust by capacitor C5 connected to the CFOD terminal.18. Input signal is active−HIGH type. There is a 5 k� resistor inside the IC to pull−down each input signal line to GND. RC coupling circuits

should be adopted for the prevention of input signal oscillation. R1C1 time constant should be selected in the range 50~ 50 ns(recommended R1 = 100 �, C1 = 1 nF).

19.Each wiring pattern inductance of point A should be minimized (recommend less than 10 nH). Use the shunt resistor R4 of surface mounted(SMD) type to reduce wiring inductance. To prevent malfunction, wiring of point E should be connected to the terminal of the shunt resistorR4 as close as possible.

20.To insert the shunt resistor to measure each phase current at NU, NV, NW terminal, it makes to change the trip level ISC about theshort−circuit current.

21.To prevent errors of the protection function, the wiring of points B, C, and D should be as short as possible. The wiring of B between CSCfilter and RSC terminal should be divided at the point that is close to the terminal of sense resistor R5.

22.For stable protection function, use the sense resistor R5 with resistance variation within 1% and low inductance value.23. In the short−circuit protection circuit, select the R6C6 time constant in the range 1.0~1.5 �s. R6 should be selected with a minimum of

10 times larger resistance than sense resistor R5. Do enough evaluaiton on the real system because short−circuit protection time mayvary wiring pattern layout and value of the R6C6 time constant.

24.Each capacitor should be mounted as close to the pins of the ASPM34 product as possible.25.To prevent surge destruction, the wiring between the smoothing capacitor C7 and the P & GND pins should be as short as possible. The

use of a high−frequency non−inductive capacitor of around 0.1~0.22 �F between the P & GND pins is recommended.26.Relays are used in most systems of electrical equipments in industrial application. In these cases, there should be sufficient distance

between the MCU and the relays.27.The Zener diode or transient voltage suppressor should be adapted for the protection of ICs from the surge destruction between each pair

of control supply terminals (recommended Zener diode is 22 V / 1 W, which has the lower Zener impedance characteristic than about 15 �).28.C2 of around seven times larger than bootstrap capacitor C3 is recommended.29.Please choose the electrolytic capacitor with good temperature characteristic in C3. Choose 0.1~0.2 �F R−category ceramic capacitors

with good temperature and frequency characteristics in C4.

Fault

C3 C4

C3 C4

C3 C4

C2 C4

R3

C1

R1

M

VDCC7Gating UH

Gating VH

Gating WH

Gating WL

Gating VL

Gating UL

C1

MCU

R4

R4

R4

W−Phase Current

V−Phase CurrentU−Phase Current

R6C6

R1

R1

R1

R1

R1

R1

C1C1C1

C1 C1 C1

R7

5V line

LVIC

COM

VDD

IN

IN

IN

VFO

CSC

OUT

OUT

OUT

W (2)

P (1)

(24) V S(U)

(23) V B(U)

(29) V S(V)

(28) V B(V)

(17) C SC

(15) V FO

(14) IN (WL)

(13) IN (VL)

(12) IN (UL)

HVIC

VB

OUT

IN

(25) IN (VH)

(10) V DD(L)

(19) IN (UH)

(34) V S(W)

(33) V B(W)

(21) V DD(UH)

(30) IN (WH)

Thermistor

VS

(11) COM (L)

VDD

COM

CFOD

NU (7)

NV (6)

NW (5)

U (4)

V (3)

(8) R TH

(9) V TH

(16) C FOD

RSC (18)

(20) COM (H)

(22) V BD(U)

(26) V DD(VH)

(27) V BD(V)

(31) V DD(WH)

(32) V BD(W)

HVIC

VB

OUT

IN

VS

VDD

COM

HVIC

VB

OUT

IN

VS

VDD

COM

15V line

C5

5V line

Temp.Monitoring

R5

E

C4

C4

C4R2

R2

R2

SenseResistor

ShuntResistor

A

B

C

D

ControlGND Line

PowerGND Line

NFVA22512NP2T

www.onsemi.com14

PACKAGE MARKING AND ORDERING INFORMATION

Device Device Marking Package Shipping

NFVA22512NP2T NFVA22512NP2T ASPM34−CAA(Pb−Free)

6 Units/Tube

SPM is registered trademarks of Semiconductor Components Industries, LLC (SCILLC) or its subsidiaries in the United States and/or other countries.

DIP34 80x33, AUTOMOTIVE MODULECASE MODGL

ISSUE ODATE 19 OCT 2018

XXXX = Specific Device CodeZZZ = Lot IDAT = Assembly & Test LocationY = YearW = Work WeekNNN = Serial Number

*This information is generic. Please refer todevice data sheet for actual part marking.Pb−Free indicator, “G” or microdot “�”, mayor may not be present. Some products maynot follow the Generic Marking.

GENERICMARKING DIAGRAM*

XXXXXXXXXXXZZZ ATYWWNNNNNNN

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regardingthe suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specificallydisclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor therights of others.

98AON97156GDOCUMENT NUMBER:

DESCRIPTION:

Electronic versions are uncontrolled except when accessed directly from the Document Repository.Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1DIP34 80x33, AUTOMOTIVE MODULE

© Semiconductor Components Industries, LLC, 2018 www.onsemi.com

onsemi, , and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliatesand/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to anyproducts or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of theinformation, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or useof any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its productsand applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications informationprovided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance mayvary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any licenseunder any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systemsor any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. ShouldBuyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or deathassociated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an EqualOpportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATIONTECHNICAL SUPPORTNorth American Technical Support:Voice Mail: 1 800−282−9855 Toll Free USA/CanadaPhone: 011 421 33 790 2910

LITERATURE FULFILLMENT:Email Requests to: [email protected]

onsemi Website: www.onsemi.com

Europe, Middle East and Africa Technical Support:Phone: 00421 33 790 2910For additional information, please contact your local Sales Representative

◊