Next Generation Continuous Process Improvement … Generation Continuous Process Improvement (CPI) A...

Transcript of Next Generation Continuous Process Improvement … Generation Continuous Process Improvement (CPI) A...

Next Generation Continuous Process Improvement

(CPI) A Breakout Session @ DoD Maint Symposium

Stu Paul Deputy, Aviation Fleet Readiness Branch of OPNAV N43

8-9:30 Tuesday 13Nov2012

FRC WESTPAC

NAF ATSUGI

Det Guam

Det Okinawa

Det Singapore

Det Korea

Det Iwakuni

FRC SEFAC

SOLOMONS

Naval Aviation Fleet Readiness Centers

FRC SOUTHWEST

NORTH ISLAND

SEAOPDET

Det Point Mugu

SEAOPDET

Det NAVCAL Lab

Futenma

Det NAVCAL Lab

Iwakuni

AFFILIATION WITH: MALS-39 Pendleton

MALS-13 Yuma

FRC WEST

LEMOORE

SEAOPDET Lemoore

Det Fallon

FRCSW Det

Det Fort Worth

Det China Lake

FRC SOUTHEAST

JACKSONVILLE

SEAOPDET

P-3 OPDET

Det Mayport

Det Key West

FRC NORTHWEST WHIDBEY ISLAND

ELU Det P3 OPDET SEAOPDET VANOPDET Det Everett FRCSW Det

FRC MID-ATLANTIC

OCEANA

SEAOPDET Oceana

Det Norfolk

SEAOPDET Norfolk

Det Pax River

Det New Orleans

Det NAF Washington

SEAOPDET Beaufort

FRCMA ACFT Dept

Voyage Repair Team

FRC EAST

CHERRY POINT Det McGuire

AFFLIATION WITH:

MALS-14 Cherry Point

MALS-26 & 29 New River

MALS-31 Beaufort

HMX-1 Quantico

MALS-49 Stewart

• 6,500+ Sailors & Marines

• 20 IMAs

• 6,000 Engine/Module/ Accessory Repairs

• 580,000 Component Repairs

• $2.0 Billion Operation Mission Funded

I-LEVEL • 11,500 Civilians

• 3 Depots + 1 GOCO Operation

• 1,500 Engine/ Module Repairs

• 70,000 Component Repairs

• 700 Aircraft Repairs

• $2.0 Billion Operation NWCF Funded

D-LEVEL

COMFRC HQ

PAX RIVER

Oct 2012

2

FRC NORTHWEST

AIRCRAFT (15) E/A-6B, E/A-18G, P-3 ENGINES (146) T56, J52 COMPONENTS (20,407) ALQ-99, E/A-6, canopies, components for above TMSs

FRC WEST

AIRCRAFT (31)

F/A-18 (PMI 2, AEPD),

E/A-18G

ENGINES (659)

F414, T56

COMPONENTS (28,690)

F/A-18 RADAR, composites,

components for above TMSs

FRC WESTPAC (Formerly NAPRA)

AIRCRAFT (30)

H-53, C-130, E/A-6B,

F/A-18, H-46, H-60, H-1

P-3, E-2, E/A-18G

FRC SOUTHWEST

AIRCRAFT (162)

F/A-18, E-2, C-2, H-1, H-60, AV-8 (PMI 2,3),

H-53 (PMID), (PMI 1N, 2N, PMI 2 Mods, P&E)

ENGINES (309)

LM2500, T700, T56

COMPONENTS (40,823)

Instruments, E-2 radar, composites, components

for above TMSs

FRC SOUTHEAST

AIRCRAFT (72)

E/A-6B (PMI 1, 2, 3, 4), P-3

(PH 1, 2, 3, SSI), F/A-18 (PMI

1, 2, 1M, 2M), H-60 (PMI 1N, 2N)

ENGINES (1280)

T56, J52, TF34, F414, T700, F404

COMPONENTS (50,956)

Electro-Optics, air refueling

stores, racks/launchers, components

for above TMSs

FRC EAST

AIRCRAFT (130)

AV-8B (PMI 1, 2, 3, 4, SWRK),

H-53 (AWI, SDML, PMID), H-1

(BSL, 1N, 2N, SDLM), EA-6B

(PMI 2, 3, 4), CH-46 (PMID,

SDLM, AWI)

ENGINES (144)

T58, F402, T64, T400, T56

COMPONENTS (26,395)

Dynamic components, rotor

blades, props, blades/vanes,

APU/GTC, components for

above TMSs as well as E-2

and P-3 props

MAINTENANCE LEVEL

D – DEPOT I – INTERMEDIATE

FRC MID-ATLANTIC

AIRCRAFT (85)

F/A-18 (PMI 2), E-2 (PMI 1),

C-2 (PMI 1, 2), H-53 (ISR),

H-60 (PMI 1N, 2N),

ENGINES (1,904)

F404, T56, T700, T64, T400

COMPONENTS (56,936)

F/A-18 Electro-Optics, Radar,

composites, E-2, C-2, H-60, H-1

C-130, EA-6B, Radar,

instruments, components for

above TMSs

VOYAGE REPAIR TEAM

Repair & Overhaul USN, USCG,

FMS air capable assets and

ALRE components

FRC Totals

Military: 6,293

Civilians: 9,349

Contractors: 2,314

Total Employees: 17,956

FRC Products (Last 12 Months)

FRC SEFAC

Repair, modification and overhaul of common and peculiar Support Equipment and Test Cells

Oct 2012 3

Maint Is Complicated and Interesting and possible to ‘BPR’ and ‘CPI’

4

Acft Inventory 2000-2019 Significant Intro of New T/M/S

DoN Aircraft Inventory Analysis

Aircraft Inventory for

T/M/S in Service

in FY00

Aircraft Inventory for

31 New T/M/S

since FY00

Inactive

107 107

101

96

92

9593

95

98

101103

101

98

93

90 90

85

81

78

107

0

500

1,000

1,500

2,000

2,500

3,000

3,500

4,000

4,500

2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019

To

tal

Air

cra

ft I

nve

nto

ry

0

10

20

30

40

50

60

70

80

90

100

110

120

# o

f T

yp

e/M

od

el/S

eri

es

107 T/M/S 78 T/M/S

4,055 A/C

410 A/C

1,901 A/C

2,053 A/C

5

Transition underway; NEPA/Basing decision complete

Projected transition timeline; NEPA and Basing decision required

PB12

07 08 09 10 11 12 13 14 15 16 17 18 19 20 22 23 24 25

EP-3A

FA-18C

P-3C

EA-6B EA-18G

BAMS UAS

P-8A

C-2A C-X ?

T-6AT-34C

Firescout

E-2C E-2D

EP-X ?

H-60B/F

F-35C JSF

MH-60R/S

FA-18E/F

T-45CT-39

EA-18G

F-14/18C FA18C

Naval Aviation Platform Introductions

6

Navy has a history of ‘CPI’ that causes ‘Cost Change’ with better ‘Readiness’ generation

10/17/11 Totals % ACTUAL TO:

$ K $

FY BRAC Plan FRC Projection ACTUAL BRAC Plan FRC Projection

COMFRC 07 $97,131 $94,833 $125,724 129.4% 132.6%

08 $164,367 $190,218 $208,484 126.8% 109.6%

09 $264,097 $287,324 $311,153 117.8% 108.3%

10 $311,231 $305,379 $326,835 105.0% 107.0%

Aug-11 11 $314,518 $347,837 $335,516 106.7% 96.5%

Completions FYDP $1,151,344 $1,225,592 $1,307,712 113.6% 106.7% F I N A L

MPN Interdiction Cost Avoidance AIRSpeed

$ K $ $ K $ $ K $

FY BRAC Plan FRC Projection ACTUAL FY BRAC Plan FRC Projection ACTUAL FY BRAC Plan FRC Projection ACTUAL

07 $3,395 $3,395 $3,395 07 $17,166 $25,505 $51,231 07 $65,617 $62,259 $62,259

08 $10,873 $10,873 $10,792 08 $60,999 $58,986 $82,290 08 $68,151 $97,302 $97,302

09 $16,549 $16,549 $16,549 09 $147,137 $59,055 $84,847 09 $68,730 $180,962 $185,239

10 $18,486 $18,486 $18,486 10 $202,905 $92,480 $129,802 10 $70,355 $175,079 $159,397

11 $19,135 $19,135 $19,135 11 $208,456 $127,056 $125,934 11 $72,147 $186,866 $175,498

FYDP $68,438 $68,438 $68,357 FYDP $636,662 $363,082 $474,104 FYDP $345,001 $702,469 $679,695

Source: FMB / N1 Source: NALCOMIS "Deckplate" Source: FCAP/CPIMS

Civilian Salary Supply ~ APN Base Oper. Support

$ K $ $ K $ $ K $

FY BRAC Plan FRC Projection ACTUAL FY BRAC Plan FRC Projection ACTUAL FY BRAC Plan FRC Projection ACTUAL

07 $7,280 $0 $5,165 07 $3,178 $3,178 $3,178 07 $496 $496 $496

08 $14,223 $12,936 $7,979 08 $9,021 $9,021 $9,021 08 $1,100 $1,100 $1,100

09 $16,309 $15,387 $9,146 09 $13,871 $13,871 $13,871 09 $1,501 $1,501 $1,501

10 $3,966 $3,814 $3,631 10 $13,939 $13,939 $13,939 10 $1,580 $1,580 $1,580

11 $449 $449 $618 11 $12,751 $12,751 $12,751 11 $1,580 $1,580 $1,580

FYDP $42,226 $32,586 $26,539 FYDP $52,760 $52,760 $52,760 FYDP $6,257 $6,257 $6,257

Source: NALCOMIS Deckplate / AIRSpeed workload

loss Source: FMB Source: CNI

MIL Personnel Actions CIV Personnel Actions CIV Personnel moves

FY BRAC Plan FRC Projection ACTUAL FY BRAC Plan FRC Projection ACTUAL FY BRAC Plan FRC Projection ACTUAL

07 -111 -111 -111 07 -108 -108 -83 07 87 58 50

08 -139 -139 -139 08 -211 -211 -125 08 67 44 24

09 -42 -42 -42 09 -236 -236 -134 09 0 0 26

10 0 0 0 10 -50 -50 -92 10 0 0 10

11 0 0 0 11 0 0 -124 11 0 0 0

FYDP -292 -292 -292 FYDP -605 -605 -557 FYDP 154 102 110

Source: FMB / N1

Source: NALCOMIS Deckplate

workload loss Source: TFM

Great, but what are you doing lately and

tomorrow?

$1.3B in past cost change carefully counted

7

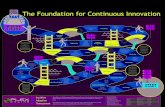

Numerous new CPI ideas in-work

Maint Optimization Event Based Maint ARAT BCM-I (more of it) I-level AIRSpeed w/ FCAP

ILSMS Ideas in ‘Imagineering’ phase

8

Maintenance Optimization Initiative Goal

• Aggregate repair capability & demand to the most successful, high throughput Level 2 sites

– Minimize redundant Level 2 capability (some consolidations)

– Allow potential to draw down some sites to mostly Flight-Line Services

– Use repair hub allowances to replenish sites without repair capability

• No item enters the wholesale system (Level 3) without passing through a Level 2 site that has established repair capability

If Level 2 capability exists, no component goes BCM without going through a site that has capability

9

Candidate Example – F/A-18 APU

Level 2 Repair Cost $1K AFM

BCM Repair Cost $32K AVDLR

Does not include

manpower, repair or

shipping costs

Potential $2M ROI

*Under PBL contract. Navy is charged by each item processed.

10

Potential $3.8M ROI in 05A

Site Example - Jacksonville

FRC Mayport (Only 20 Miles Away)

FRC SE North Island has 100% RFI Rate

11

NIIN

NIIN NIIN

NIIN

Work Center

Whole Site

NAS Fallon AT/FLIR W/C 610

Mitigation - Candidate Sequencing

Sequence 5

Sequence 4

Sequence 3

Sequence 1

Sequence 2

Sequence 5

Sequence 4

Sequence 3

Sequence 1

Sequence 2

No constraints – can be executed within 90 days

Simple constraints – can be executed within 180 days (SE, Allowance Relocation)

Moderate constraints – can be executed within 1 year (TRR Redux)

Difficult constraints – can be executed within 2 years (Manpower)

Extreme constraints – can be executed within 3 years (MILCON)

Candidate Sequencing

Ensures manpower, performance and

allowancing postures are fully capable prior

to implementation.

Candidate sequencing handbook available in Word

format.

12

NIINs: +615

Items: +1982 Man-Hours: +52924

NIINs: +273 Items: +518

Man-Hours: +14173

NIINs: +242

Items: +1439 Man-Hours: +13422

NIINs: +116 Items: +119

Man-Hours: +3100

NIINs: -15 Items: +2

Man-Hours: +2522

NIINs: +587

Items: +2250 Man-Hours: +38486

NIINs: +10 Items: +51

Man-Hours: +5041

NIINs: +643

Items: +2146 Man-Hours: +54570

NIINs: 0 Items: 0

Man-Hours: 0

NIINs: -185 Items: -343

Man-Hours: -762

NIINs: -81

Items: -110 Man-Hours: -748

NIINs: +477

Items: +1629 Man-Hours: +25218

Must take an ‘Enterprise’ view of the FRC’s Workload Net Changes (All Three Phases)

FRCSW PT Mugu

FRCSW North Island

FRCW Lemoore

FRCW Fallon

FRCNW Whidbey Is.

FRCSE Jacksonville

FRCMA Norfolk

FRCMA Oceana

FRCE M-D-L

FRCMA Pax River

NIINs: -15 Items: -27

Man-Hours: +77

FRCMA Washington

NIINs: -95 Items: -125

Man-Hours: -194

FRCW China Lake

NIINs: +38

Items: +402 Man-Hours: +2088

FRCW Fort Worth

Current manning levels support these changes

NIINs: -18 Items: -38

Man-Hours: -24

FRCSE Key West FRCSE Mayport

FRCMA New Orleans

13

EBM Concept

• EBM: a maintenance concept enabled by detailed RCM and maintenance task analysis data and a robust software application for efficient maintenance scheduling – Instead of packages (phases, specials, etc.) each maintenance

task and relevant aircraft usage parameters are tracked individually by their engineering derived intervals

– Tasks are grouped into preventive maintenance events whose content and schedule are based on: • Unique operating profile (usage and environment) of each aircraft • Planned operational schedules • Other planned “events” such as modifications (budget driven) • Unplanned “events” such as unscheduled down-time (random)

14

“What the aircraft needs, when it needs it, based on operating conditions and schedule”

14

EBM Benefits

• Anticipated cost savings – Decreased consumable demands for preventative maintenance

• Reduced maintenance burden (MMH) – Includes reduction from updated RCM analysis and EBM savings

• Improved planning capability – Better prediction of when maintenance is due based on planned usage (FH,

landings, cats / traps, etc.) – Improved knowledge of future maintenance resource requirements by

calculating the logistics requirements of each tasks as far into the future as needed

– Easier to adjust to changing operational requirements (e.g. Surge)

• Better aircraft material condition – Right maintenance at the right time as driven by the RCM interval for when

tasks should be done

• Improved aircraft availability – Decreased downtime for maintenance

15 15

16

Consumables Results

16

Savings / ac / year $25 K

Implementation Year +1 Implementation Year +2 Implementation Year +3 Implementation Year +4

TMS Fleet

Size

Savings TMS Fleet

Size

Savings TMS Fleet

Size

Savings TMS Fleet

Size

Savings

AH-1W 150 $3.7 M EA-6B 97 $2.4 M E-6 16 $0.4 M F-18 1056 $26.4 M

UH-1N 82 $2 M AV-8B 129 $3.2 M C-130 90 $2.2 M V-22 99 $2.5 M

E-2C 63 $1.6 M T-45 205 $5.1 M H-60 463 $11.6 M AH-1Z 8 $0.2 M

C-2A 35 $0.9 M P-3 169 $4.2 M H-53E 183 $4.6 M UH-1Y 26 $0.7 M

Imp. Yr. Total: $8.2 M Imp. Yr. Total: $14.9 M Imp. Yr. Total: $18.8 M Imp. Yr. Total: $29.8 M

Prior Yr. Total: $ 0 Prior Yr. Total: $8.2 M Prior Yr. Total: $23.1 M Prior Yr. Total: $41.9 M

FY Total: $8.2 M FY Total: $23.1 M FY Total: $41.9 M FY Total: $71.7 M

Five year savings total $216.6M

16

ARAT - Aviation Rapid Action Teams “Targeted, Applied, Direct Engineering and Logistics at Fleet Maint levels”

• ARAT mines Logistic data + talks to Fleet level Maintainers directly.

• ARAT musters hand picked Engineers, Super-techs and Loggee’s and ‘boots-on-the-deck’ investigates opportunities to resolve critical costs and readiness degraders.

• Enhance I-level repair capability

• Enhance I-level by imbedding D-level expertise (BCM-I’ish approach)

• Works with FST directly to resolve maintainability or even engineering deficiencies (ex PLCU A-7 SRA 35mA transformer)

• Challenges the ICRL’s, LORA, etc.

• Price challenges PLCU: a $52,515 consumable that could easily be repaired that we were using 1 per week 17

• COMFRC ARAT R-TOC Initiative surpassed it’s first year goal of $15.7M by more than $2M in FY12!

• Finalizing FY13 candidate list • September total cost avoidance by type / model

– V-22: $237,903 – F/A-18: $646,131 – Sep total: $884,034 – FY12 cumulative total: $17,850,604

COMFRC ARAT September 2012 Cost Avoidance Summary

18

BCM-I (more of it)

• BCM-I looks at the tens of thousands of AVDLR’s (LRU’s) coming off aircraft and going thru I-levels that can’t be repaired, then determines ‘if’ embedded D-level artisans are appropriate to effect repairs on site.

• ~$125M per year in ‘cost avoidance’ being achieved now; some possibility for expansion.

• Tangential technical rub-off and increased level II to level III to FST comms important.

• Readiness ‘lift’ important, but harder to measure.

D-level Artisan working with I-level MARINE

19

I-level AIRSpeed

• ‘Continuous’ Airspeed events and CPI pressure on all activities

• Examine differing RFI/BCM success rate from site to site and take steps to bring all retained repair sites to ‘best performance’ capability of most successful site.

20

FCAP Elements (Fleet Capability Alignment Program)

• The FCAP Process • Overall program involved NIIN Analysis, ‘FCAP Projects’ and reporting

– NIIN Analysis Tool

– Analysis & AIRSpeed project identification

– Enables sites to compare their repair success globally against all other ‘I’ level activities with like capabilities

– Identifies opportunities to improve repair success

– Target AIRSpeed events at those opportunities

– The FCAP software tool

– Measures the impact of improved repair processes & capabilities to the Flying Hour Program (FHP)

21

NIIN Analysis (Improve C1/C3 Capability)

Lemoore has avery successful repair rate. Large variation of repair success fleet-

wide. MALS-11 and Oceana could potentially save $1M on this NIIN through CPI.

22

Integrated Logistics Support Management System

( If You Can’t Scrutinize It, It’s Hard To CPI It )

23

• Standardized Data Triage Process, Tools and Language

– TMS Logistics Assessment enhanced by the implementation of Integrated Logistics Support Management System (ILSMS) • Exploit unprecedented access to maintenance and supply data • Advanced analytical and demand forecasting capability

• Improve Visibility of T/M/S Readiness & Cost Drivers • Root Cause Analysis of Identified Issues • Actionable Mitigation POA&M’s with provider organizations

Unprecedented Data Availability

ILSMS Aggregates Data

in One Tool

Logistics Assessment will be a key enabler in enhancing weapons system availability and reducing O&S cost 23

ILSMS DECK PLATE

AIRRS

TDSA

OOMA

NAVSUP WSS

DLA FRC

NAE

VAMOSC

CAVTS

N42

ILSMS Data Sources

Flight Records(NAVFLIRS)

Supply History (60 Series)

Maintenance Actions

X-ray data

Audited Flight Hours

RT-79 Records

Applicability List

Completed TD’s

WUC Baselines

Current Stock Posture

NIIN-PN/Cage Cross Reference

Allowances

Organic repair schedules

FRC G drivers

Backorders

ERP Schedule Board

(Due in/Projections)

Current Stock Posture

NIIN-WSDC Cross Reference

Backorders

Due in/Projected Procurement

Material Usage History

Current Readiness Metrics

Historical Fleet/Program Cost

Current FY Fleet Cost

AFAST

ICRL

Tracked Issues:

Program specific issues that require tracking/data or tie into

other decision processes i.e. (IMC/BULKHEADS/KAPTON)

Comments:

Allows for commenting by all stakeholders on most critical

areas- especially part number/NIIN and BUNOs

VAL/Reference Tables PN_NIIN_HOFNIIN_WUC_XREF ORG codes TEC Codes Supply Codes Most codes appx E of 4790

NAVAIR-6.8.2 / 6.8.4 ILSMS Analytic Module of DECKPLATE 24

Logistics Assessment

Readiness “Kill Chain”

25 UNCLASSIFIED / FOR OFFICIAL USE

ONLY

NAE Readiness &

Costs Metrics

Root Cause Analysis

Actionable POA&M

Issues Affecting Readiness & Cost

and more . . .

OPNAV / HQMC

Resource Sponsors

Provider Organizations

SURVEILLANCE DETECT TRACK ID/ENGAGE LAUNCH CONTROL LETHALITY ASSESS

Logistics Impacts Each Link of the “Kill Chain”

NAVSUP

T/M/S Data Driven

Analysis

CR

CFT

CURRENT READINESS & COST FUTURE READINESS: DESIGN FOR SUPPORTABILITY

Retail Supply

Support Equipment

Maintainer in Place

Execute Maintenance

Operate

Capture Data

CPI

Design for Supportability

Test

Support Concept

Wholesale Supply

Training

Tools/Tech Data

Readiness “Kill Chain”

25

Questions? Comments?

This was a fast raster scan of the CPI activities we in Naval Aviation are pursuing; I’ll be happy to talk to any of you off-line if you’d like more info. Stu Paul C:703.835.7558 [email protected] [email protected]