NEW APPROACH FOR ENGINE CONTROL SYSTEM SOFTWARE … · Typical control systems for large engines:...

Transcript of NEW APPROACH FOR ENGINE CONTROL SYSTEM SOFTWARE … · Typical control systems for large engines:...

AVL Software and Functions

NEW APPROACH FOR ENGINE

CONTROL SYSTEM SOFTWARE

DEVELOPMENT

6th CIMAC CASCADES 2015

Borja Pintos

| | 27 February 2015 | 2

AGENDA

1. Engine control software development: Concept

2. Engine control software development over time

3. New approach: Model based development

a. Model based development: phases

b. Model based development: advantages

c. Model based development: example

4. Conclusions

| | 27 February 2015 | 3

ENGINE CONTROL SOFTWARE DEVELOPMENT-CONCEPT

Software to control the complete powertrain system

Includes: sensors and actuators needed for control strategies

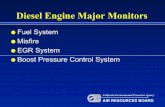

Typical control systems for large engines:

CLOSED LOOP CONTROL

Rotational engine speed control Rail pressure control Boost pressure control

Monitoring and diagnosis Emissions optimization Consumption optimization

| | 27 February 2015 | 4

ENGINE CONTROL SOFTWARE DEVELOPMENT-CONCEPT

Typical example for a large engine: rotational engine speed control

A lever sets an engine speed set point

The Engine Control Unit (ECU) functionality shall keep the engine speed constant to the demand value

Engine

ECU Control Functionality

Engine speed

OutputVisualization

Speed Controller Fuel mass

Input

Engine speedset point

| | 27 February 2015 | 5

ENGINE CONTROL SOFTWARE DEVELOPMENT OVER TIME

Mayor software improvements over time allowing for: shorter development time, reduce costs and increased quality

1 2

• Very time consuming• Poor overview• Need software experts

100%0% Time consuming

• Open loop test• Graphical model overview• Need software experts

100%0% Time consuming

~70%

+

Manual code generation

No test of requirements

Manual code generation

+Open loop test

| | 27 February 2015 | 6

Auto code generation

+

ENGINE CONTROL SOFTWARE DEVELOPMENT OVER TIME

3 4

0% 100%Time consuming

~30%

• Open loop test• Graphical overview• Fast code generation. Code

generated without errors

100%0% Time consuming

~50%

• Closed loop test• Graphical overview• Fast code generation. Code

generated without errors

Auto code generation

+Open loop test

| | 27 February 2015 | 7

Working flow:

1. Development of software functions using a graphical programming language (e.g. Simulink) according to the customer requirements

2. Test the software functions in Simulink using a virtual engine model (closed loop test)

3. Generate C code and flash it into the ECU

4. Verification of software functions at engine test bench (closed loop test)

OutputVisualization

Input

Stimuli

NEW APPROACH: MODEL BASED DEVELOPMENT

Engine

ECS Control Functionality

Speed Controller

Engine speedset point

Fuel mass

Engine speed

| | 27 February 2015 | 8

NEW APPROACH: MODEL BASED DEVELOPMENT

Detailed engine model: Crank angle resolution for cylinder and gas path

Innovative, numerically-optimized approach and advanced solver technology allows real-time capability

Multiple applications of real-time engine models in the software development process

| | 27 February 2015 | 9

MODEL BASED DEVELOPMENT: PHASES

Simulink

Model-in-the-Loop (MiL)

ECU concept

Functions and ECU development

Engine test bench

Verification

Refinement Simulink

ECU

HiL

Hardware-in-the-Loop (HiL)

ECU development

Pre-calibration, Monitoring, OBD

Hardware-TestsSimulink

ECU

| | 27 February 2015 | 10

MODEL BASED DEVELOPMENT: PHASES

Simulink

Model-in-the-Loop (MiL)

ECU concept

Functions and ECU development

Entire Simulink environment

Development of functions

Virtual engine model interface

available for Simulink

Closed loop test using virtual

engine models

Motor model

State of the Art:

No model or very simple model (mean model, map)

AVL-Proposal:

Physical Model (Cylinder and air path in CRK angle

resolution)

| | 27 February 2015 | 11

MODEL BASED DEVELOPMENT: PHASES

HiL

Hardware-in-the-Loop (HiL)

ECU development

Pre-calibration, Monitoring, OBD

Hardware-TestsSimulink

ECU

Real time PC ~ Virtual engine

ECU

Actuators

Wiring harness

Computer for data analysis

Lever

| | 27 February 2015 | 12

MODEL BASED DEVELOPMENT: ADVANTAGES

• Higher maturity of engine

control achieved earlier in

the development

• No risk of engine-

component damage in MiL

& HiL environment

• Pre-calibration and

validation of control

functionality are developed

in MiL & HiL environment

• Model based software

development saves time

and money and improves

quality of the software

| | 27 February 2015 | 13

MODEL BASED DEVELOPMENT: EXAMPLE

Motor type (~ 1 MW per Cyl.)

Bore > 300 mm

Dual Fuel (Diesel, Gas)

One stage turbo with

wastegate

Motor bypass and compressor

bypass valve developed for fine

-control

Variable valve timing

Generator operation, ship

propulsion

| | 27 February 2015 | 14

MODEL BASED DEVELOPMENT: EXAMPLE

Air path (incl. Wastegate,

Compressor-Bypass and Motor-Bypass)

Charging & Intercooling

Fuel supply(Gas & Diesel)

Cylinder & Motor (Wall heattransfer, combustion

characteristics, valve lift, flowcharacteristics, moment of

inertia…)Variable valve

timing

Brake, external load

Building the model Software development Closed loop test (HiL)

| | 27 February 2015 | 15

MODEL BASED DEVELOPMENT: EXAMPLE

Plant ModelECS Control Functionality

Speed Controller

BoostPressureController

PBoost

Demand

EngineEngine speed

Lambda

Boost pressure

Fuel mass

Waste gate

Bypass valve

Engine speedset point

Boost pressureset point

Lambdaset point

Operating point

Building the model Software development Closed loop test (HiL)

| | 27 February 2015 | 16

MODEL BASED DEVELOPMENT: EXAMPLE

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Zeit [s]

Moto

rdre

hzahl [

Upm

]

450

500

550

600

650

700

750

Ein

spritz

menge [g/H

ub]

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

Last ist konstant (100%).

Engin

e s

peed [

rpm

] Load is constant (100%)

Fuel quantity

[g/s

tk]

Building the model Software development Closed loop test (HiL)

| | 27 February 2015 | 17

MODEL BASED DEVELOPMENT: EXAMPLE

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Zeit [s]

Moto

rdre

hzahl [

Upm

]

450

500

550

600

650

700

750

Lam

bda [-]

1.0

1.5

2.0

2.5

3.0

3.5

Ladedru

ck [bar]

2.5

3.0

3.5

4.0

4.5

5.0

5.5

Wate

gate

-Ste

llung [%

]

0

20

40

60

80

100

-Sollwert

-Istwert

Ladedruck-SollwertLadedruck-Istwert

Last ist konstant (100%).Load is constant (100%)

Building the model Software development Closed loop test (HiL)

Lam

bda [

-]W

gpositio

n [

%]

Boost

pre

ssure

[bar]

Setpoint

Actual

Boost pressure

actual value

Boost pressure

setpoint

| | 27 February 2015 | 18

CONCLUSIONS

Model based software development saves time and money and

improves software quality

Innovative, physical real-time engine models (simulation in crank

angle resolution, 0D gas dynamics) allow the observation of various

motor phenomena that can not be considered with mean value models

www.avl.com

THANK YOU