National Aerospace University “Kharkiv Aviation Institute ... · the National Aerospace...

Transcript of National Aerospace University “Kharkiv Aviation Institute ... · the National Aerospace...

Aero

spa

ce

Re

sea

rch

and

Ed

uca

tion

at K

hAI

National Aerospace University

“Kharkiv Aviation Institute”

Knowledge to conquer the Sky

ContentWelcome from the Rector 1

Welcome from the Vice-Rector on Science 1

Section 1: General Information 3

Our History 4

University Today 5

University Academic Structure 6

University Training Programmes 7

KhAI in the World 8

Our Alumni 10

University Life 11

Section 2: KhAI Research 14

Research Environment 16

Research Centres and Laboratories 17

Research Profiles 18

University Research Facilities 50

University Experience in International Collaborative Research 52

Research Profiles Index 54

How to find us 55

Dear Readers,

I would like to welcome you on behalf of the staff and students community of the National Aerospace University “Kharkiv Aviation Institute”. We are happy to introduce you the only engineering University in Ukraine that provides a full cycle of higher education in the field of aerospace science.

The KhAI is proud of its old traditions in the training of high-qualified specialists. The University has numerous well-known Scientific Schools, which are recognised far beyond the Ukrainian borders thanks to successful collaborative projects with key aerospace design bureaus and industrial enterprises worldwide. Also, we are obliged to the thousands of KhAI’s alumni who maintain the high reputation of the Alma Mater and make valuable contribution to the global aerospace industry development.

I hope our collaboration to be fruitful and mutually beneficial and I also expect it will support the scientific and technical progress in our countries.

Rector of the UniversityProfessor Volodymyr Kryvtsov

Welcome to this overview of research at the National Aerospace University “KhAI” that describes our recent achievements in numerous research areas and informs of diverse collaborative opportunities offered by the University.

Ever since its establishment in 1930, in the very middle of Aviation’s Golden Age, KhAI has been playing an important role in aeronautics and space science development. KhAI’s role became fundamental through the persistent generation of new knowledge and their immediate transformation into advanced products and technologies relevant to the current market demands. We have a strong international reputation in various research areas ranging from the aerodynamics and material science basic research to the advanced space thrusters and communication systems development.

We pay high attention to the maintenance and facilitation of our vibrant research community. We offer a broad opportunities for our post graduate students and research fellows, provide them with a wide access to the University research facilities and support their involvement in multinational collaborative research teams. Furthermore, we also encourage our research and academic staff to share their advanced knowledge with today’s students to secure the next generation of talented young scientists and engineers.

Vice-Rector on Science Professor Olexandr Gaydachuk

Welcome from the Rector

Welcome from the Vice-Rector on Science

We hope this brochure provides you with a good insight into the research activities at KhAI and offers a good starting point for prospective collaborators from both national and international academic entities, research institutions and commercial organizations.

Ge

nera

l Inf

orm

atio

n

Our History 4

University Today 5

University Academic Structure 6

University Training Programmes 7

KhAI in the World 8

Our Alumni 10

University Life 11

Section 1: General Information

6

National Aerospace University "KhAI"

Our History

The KhAI was founded in 1930 as Kharkiv Aviation Institute and ever since its history has been linked to the global development of aircraft engineering and science. The first passenger airplane with retractable landing gear in Europe, called the «KhAI-1», and the first Soviet turbojet engine were designed and produced in KhAI at the beginning of the thirties. From 1937 an experienced team of KhAI researchers has been involved in the first Soviet jet rockets development. The airplanes and gliders designed by KhAI students and staff set up world records and even were produced serially and operated by USSR passenger airlines.

The rapid Institute development was interrupted by the World War II and KhAI evacuation to Kazan where the specialists’ training for aircraft industry was continued. More than 500 KhAI teachers and students went to the front, while many senior year students were employed by the Soviet defence enterprises as engineers. The Institute was moved back to Kharkiv only in 1944 after the

Ukraine is one of the few countries in the world involved in the aerospace structures and products development and manufacturing, and at the same time in highly qualified aerospace specialists training. Furthermore, the National Aerospace University “Kharkiv Aviation Institute” is the only engineering University in Ukraine that provides a full cycle of higher education in the field of aviation and aerospace science.

city was liberated by the Soviet Army. It took about 8 years to restore the completely ruined Institute buildings and facilities.

During the second half of the 20th

century the Institute’s research area was continually expanded simultaneously with regular educational process improvements. As a result, new Departments were set up and KhAI became the world leader in explosive forming, jet burners and pulse power sources development for research and industrial applications. The Students’ Design Bureau, founded in 1959, was deeply involved in design and manufacturing of new light and ultra-light airplanes, helicopters, autogyros, etc. In 1966 the KhAI was included in the list of 26 basic higher education institutions of the USSR.

In 1980s the Advance Wind Tunnels Complex and Strength Laboratory facilitated KhAI’s research in aerohydrodynamic and aircraft long-term structural strength areas. Aircraft Control Systems

and Rocket Engineering Faculties were established to meet the USSR industry’s demand for rocket engineers. The Faculty of Advanced Training was established for current aerospace industry employees.

In 1978 the KhAI was named after Nikolay Zhukovskiy and in 1980 it received the award - the Order of Lenin - for its great successes achieved in the training of highly qualified specialists and in research work realisation. Since Ukraine became an independent country in 1991, N. Ye. Zhukovskiy State Aerospace University “Kharkiv Aviation Institute” was founded on the basis of the KhAI and in 2000 the University received the status of the National Aerospace University.

Since its foundation in 1930, KhAI has trained more than 60 000 engineers. Our employees are proud of the achievements gained by our scientists in the fields of supersonic aerodynamics, aircraft structural strength, aircraft and rocket engine design, aircraft control systems, etc.

7

Section 1: General Information

University TodayStarting in 1930 with 2 departments, 12 teachers and 69 students, today KhAI is one of the leading Ukrainian technical universities and has the IV (highest in Ukraine) level of accreditation granted by the Ministry of Education and Science of Ukraine. The status of “National” certifies KhAI’s outstanding performance in education and scientific activity and ensures extended university rights and additional budget for research activities.

Every year we offer about 38 Bachelor’s, 54 Master’s and 14 Doctoral Degree Programmes in aerospace science and engineering for more than 2000 university entrants from Ukraine, Russia and other 45 countries all over the world.

KhAI is involved in global educational community though participation in IAU/UNESCO, PEGASUS, Magna Charta Universitatum, EASN, etc. and takes part in numerous international collaborative research projects in aeronautic and space areas with academic and industrial partners from Germany, France, UK, Italy, Sweden, Finland, Greece, Israel, USA, Japan, Mexico, S. Korea and China. Another KhAI’s peculiarity is its close connections to Ukrainian aerospace industrial enterprises that are directly involved in educational processes.

Today the KhAI campus occupies a separate area in the forest-park zone of the city (about 25 ha), and comprises 8 academic buildings, 2 research institutions, research laboratories, the library, sports complex, swimming pool, clinic of first medical aid, dining halls, etc.

Research grants and contracts

Research income by source

Based on 2011 data

Academic & Research Staff Students Population

Basic Research

Applied Research

State Financing for Basic Research

State Financing for Applied Research

External Financing for NII PFM

Ukrainian enterprises

Research Staff

Research Support Staff

Academic Teaching & Research Staff

Academic Support Staff

Undergraduate Students

Master's Degree Students

Postgraduate Students

Distant Students

218

640

826

124

4482

1513

251

2484

39.5%

13.6%5.7%

14.4%

13.6%

11.3% 1.9%

EU FP7 Programme

Foreign enterprises

Other

2007

2008

2009

2010

2011

Thousands UAH

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

7861 2718 9333.59

7495 2830

6790

6790

6220

4830.58

2422

2398

1173

6283.89

3409.92

4466.16

External Contacts

8

National Aerospace University "KhAI"

University Academic StructureThe KhAI’s academic structure has been developed for years – from 2 initial faculties in 1930 up to 41 departments referred to 10 currently existing faculties. Today KhAI’s academic structure is diverse, comprehensive and transparent. All our training programmes are provided by 7 basic Faculties, Distance Education Faculty, International Education Faculty, and Advanced and Pre-University Training Faculty.

Faculty of Aircraft Engineering The Aircraft Design Faculty was one of the 2 first KhAI faculties and its first alumni finished their education in 1935. Today, more than 1200 students of the Faculty acquire comprehensive knowledge and skills on modern aircraft, helicopters and complex engineering elements design under the guidance of the Faculty’s high qualified staff.

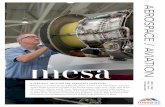

Faculty of Aircraft EnginesThe Faculty of Aircraft Engines is the oldest and the best equipped engine-building faculty in Ukraine. It was founded in 1930 simultaneously with the University’s establishment. Today about 1000 students from different countries study here the aircraft engines theory and design, specific manufacturing processes and maintenance procedures, aerospace heat engineering and robotics.

Faculty of Aircraft Control Systems The Faculty of Aircraft Control Systems was founded in 1959. Ever since its principal objective is to train specialists whose knowledge satisfies the modern specialized labour market demand. Trainings are performed by a teaching staff consisting of 90 persons who provide students and postgraduates with excellent engineering knowledge on aircraft control systems and information controlling systems.

Faculty of Space and Rocket EngineeringFor its 30-years history the Faculty of Space and Rocket Engineering has become the leader of aerospace engineers training. Today it is the only Faculty that trains experts on

electrojet engines in the former USSR. The Faculty’s educational and research labs are provided with modern facilities, unique test benches and equipment to ensure advanced education for more than 1000 students.

Faculty of Aircraft Radio Electronic SystemsThe Aircraft Radio Electronic Systems Faculty was founded in 1959 and now employs about 100 teaching and research staff and performs training on aircraft radio electronic systems design and production, computer systems and networks, etc. The Faculty alumni are highly appreciated not only in Ukraine, but in former USSR and all over the world.

Faculty of Economics and ManagementThe Faculty of Economics and Management was founded in 1991. Now the Faculty’s teaching staff trains Bachelors, Specialists and Masters according to 11 different training programmes in order to graduate highly-experienced economists, marketing managers, logisticians, financiers, etc., that are worthy of senior positions in high-level Ukrainian and international companies.

Faculty of HumanitiesThe youngest KhAI’s faculty was founded in 1999 to meet the demand for high-qualified and many-sided researchers and engineers. Specific training courses on philosophy, political science and history, psychology, foreign languages, and culture help our alumni to have clear mind, make well-considered decisions and find innovative, cutting-edge solutions in aerospace engineering.

Advanced and Pre-University Training FacultyFounded in 1985, this Faculty has different functions. It consists of a pre-university training school that has branches in 80 cities of Ukraine and helps more than 3000 school leavers to become KhAI students yearly. Also, it has a Lyceum for senior schoolchildren and provides several advanced postgraduate courses for hundreds of Ukrainian industrial aerospace enterprise employees and KhAI’s staff to enhance their professional skills and expertise.

Distance Education FacultyThe Distance Education Faculty was founded in 1996 to satisfy the emerging need for distance aerospace training. Today, there is a network of 22 KhAI tuition offices, which covers different Ukrainian regions and involves more than 4 000 distance students. The best lecturers from the 7 basic KhAI faculties are involved in distance education programmes for Bachelor, Specialist and Master Degrees on 15 key KhAI specialties.

International Education FacultyThe foreign students’ training in KhAI has begun in 1992 after the announcement of the Ukrainian independence. Since then over 1000 students from 45 different countries are yearly educated in our University. Foreign students study at the University according to the standard curriculum on 52 basic specialties. KhAI offers training courses in three languages: Ukrainian, Russian and English, and each year welcomes new foreign students entering the University.

9

Section 1: General Information

University Training ProgrammesAfter 4 years of education KhAI alumni obtain Bachelor of Science Degree (B.Sc) and have the opportunity to continue their education and choose one of the Specialist or Master of Science (M.Sc.) Degree Programmes. In Ukraine M.Sc. Training Programme, in contrast to the Specialist Programme, is characterized by a higher level of theoretical and practical knowledge. The difference is also in the entry requirements. The KhAI also provides 14 different Doctoral Degree Programmes and offers the opportunity to conduct advanced research within the University Departments, Research Labs and Centres and obtain Candidate of Science (equal to Ph.D.) and Doctor of Science Research Degrees. The majority of KhAI Training Programmes are provided in Ukrainian and Russian languages, but we also have a set of Bachelor and Master of Science Programmes in English for foreign students and specialized English-taught groups.

Training Programmes for Specialists and Masters

Airplanes and Helicopters

Aircraft and Aircraft Engine Service and Repair

Aircraft Testing and Certification

Machine Strength and Dynamics

Applied Fluid Mechanics and Mechanotronics

Information Technology Design

System Design

Ecology, Environmental Protection and Nature Management

Goods and Services Assessment

Road Transport

Aircraft Manufacturing Methods

Aircraft Engines and Power Plants

Aircraft Engines and Power Plants Manufacturing Methods

Gas-turbine Plants and Compressor Plants

Robotic Systems

Logistic Systems Engineering

Flight Control Systems

Systems for Air Navigation Service

Computer-assisted Command System and Automation

Information-Management Systems and Technologies

Metrology and Measurement Technology

Information and Measuring Systems

Quality, Standardization and Certification

Applied Mathematics

Mathematical and Computer-aided Modeling

Computer-Integrated Technical and Production Processes

Rocket and Space Complexes

Composite Structures Design and Manufacture

Rocket Engines and Power Plants

Packaging Technologies and Machines

Internal Combustion Engines

System Analysis and Management

Non-Conventional and Renewable Power Sources

Energy Management

Radioelectronic Instruments and Equipment

Biotechnical and Medical Devices and Systems

Radioelectronic Devices, Systems and Complexes

Information and Communication Networks

Telecommunication Facilities and Technologies

Computer Systems and Networks

Systems Programming

Specialized Computer Systems

Communication and Information Systems Safety

Geo Information Systems and Technologies

Enterprise Management and Administration

Management of External Economic Activity

Tourist Industry Management

Logistics

Project Management

International Projects and Programmes Management

International Economy

Business Economics

Marketing

Finance and Credit

Accounting and Audit

System Software

Software Engineering

Applied Linguistics

Psychology

Record Management and Information Activity

Bachelor Degree – 4 yearsSpecialist Degree – 1/1.5 years* after B.Sc.Master Degree – 1.5/2 years* after B.Sc.Candidate of Science (Ph.D.) – 3 years after M.Sc. or Specialist DegreeDoctor of Science – 3 years after Ph.D.

* depends on the specific training programme

Periods of study

10

National Aerospace University "KhAI"

KhAI in the WorldEuropean and Global International Associations and CommunitiesThe KhAI’s involvement into the global educational community started in 2003 with joining to the International Association of Universities (IAU/UNESCO) that facilitates experience exchange and fosters cooperation among its members.To provide advanced globally-recognized education and excellent employment prospects for our alumni KhAI became a member of Partnership of a European Group of Aeronautics and Space Universities (PEGASUS), The Magna Charta of the European Universities, International Association of Technical Universities from CIS Countries, Academic Association of CIS Countries Higher Education Institutions, etc. Active KhAI partnership with the European Aeronautic Science Network (EASN) supports the University‘s international research cooperation and provides excellent chances for efficient networking.

Bilateral cooperationKhAI is deeply involved in world-wide bilateral cooperation in high tech aerospace industry. We conduct collaborative research and implement joint R&D projects with leading research institutions and industrial enterprises from USA, France, Germany, UK, Sweden, Finland, Israel, Greece, Australia, Japan, Mexico, S. Korea ,China, etc. Among them are: the development of the unique test-bed for two-phase mechanically-pumped loop for the thermal control of telecommunication satellite for Thales Alenia Space; Egyptsat-1 basic design for Egyptian Council for Space Science and Technology Research; electric space thrusters self-heated hollow cathodes design and development for Technion Research and Development Foundation LTD (Israel), etc.

EU Framework ProgrammesSince 2006 the KhAI pays high attention to international collaborative research projects funded by European Commission within the 6th and the 7th Framework Programmes. Participation in these projects broadens KhAI’s researchers experience, stimulates further advanced developments and supports KhAI‘s further integration into the European research community. During the last 5 years KhAI has been involved in six FP6 and FP7 projects (SENARIO, ALCAS, HPH.com, WASIS, AERO-Ukraine and KhAI-ERA) focused on research and facilitation of international research cooperation.

11

Section 1: General Information

TEMPUS ProgrammeSince 2005 KhAI has been taking active part in the EU TEMPUS Programme aimed on higher education modernization through universities’ cooperation. Ever since KhAI has been a partner in 14 TEMPUS projects and as a result nu-merous training programmes were developed and implemented into KhAI’s curricula on the following topics: aviation engineering, engines and aircraft power systems, space technologies, critical computing, green computing and communication. Also a number of computer classes and laboratories were re-equipped with the modern facilities which help to bring the KhAI’s education onto European level.

Dual Degree Programmes with World Leading UniversitiesTo provide our students with the best knowledge and ensure their further successful career KhAI realizes Dual Degree Programmes with several world leading Universities. Since 2007 “2+2” Dual Degree B.Sc. and M.Sc. Programmes are available for Chinese students from Nanjing University of Aeronautics and Astronautics, who come to KhAI after 2 years of education in China.In 2011 KhAI started joint training of students with the University of Turin (Italy) on aerospace engineering and with the Otto von Guericke University of Magdeburg (Germany) on logistics. Following 3-years education in Ukraine, KhAI’s students spend 2 years in foreign higher education institutions and receive two universities’ diplomas at the end of their studies.In 2012 this programme was implemented for the KhAI and Bauman Moscow State Technical University (BMSTU) students as well. 1-year KhAI and 1-year BMSTU training programmes on Mechatronics and Robotics and Material Science (composite materials) are available for Master Students from both universities.

Working and Training Abroad for KhAI Students and StaffThe KhAI’s Bachelor, Master and Ph.D. students, research and academic staff are active in international mobility grant programmes for short- and long-term studies or trainings in the EU and around the world. KhAI is a national leader in the specific programme of the Cabinet of Ministers of Ukraine that provides individual scholarships to the best Ukrainian researchers and supports their study and training in the world leading research institutions and universities. Also, we are proud to have Fulbright, DAAD, ERASMUS-MUNDUS and Marie Curie Fellows among our students and staff.

Educational Programmes for Foreign CitizensTraining programmes for international students in KhAI were introduced in 1991. Every year more than 1100 young people from 45 countries all over the world select the National Aerospace University “KhAI” to receive advanced education in aerospace field. Today we offer full-time Bachelor and Master Degree Programmes on Aircraft and Spacecraft Design, Avionics and Computer Engineering in English as well as 1-year training at the Preparatory Department for further study in Russian. To support foreign citizens’ education in KhAI, we maintain and regularly update a dedicated web-site with all required information for foreign students in English, Russian, Arabic and Chinese.

12

National Aerospace University "KhAI"

Our AlumniThe Alumni of KhAI are of the highest caliber. For its long history our University has trained thousands of engineers, researchers and developers. We are justifiably proud of our graduates who have become excellent specialists and made their mark in aviation, rocket & space engineering and in other areas of life. KhAI education provides our students with a critical thinking and leadership skills to become successful in whatever path they choose.Those who graduated from the KhAI would never forget

Petro Balabuev

Graduated in 1954Doctor of Engi-neering, Professor, Honored Master of Science and En-gineering, Edward Warner Award Win-ner, Hero of Ukraine,

General Designer of the Antonov ASTC (1984-2005), leader of An-225 super-cargo airplane Design Group.

Fedir Muravchenko

Graduated in 1954“Eminent engineer of XX century” based on the Inter-national Engineer-ing Academy rank, Doctor of Engi-neering, Professor,

Hero of Ukraine, De-signer General of the State Enterprise “Ivchenko-Progress” Design Bureau (1994 – 2010).

Eminent graduates

Where are they now?

Viktor ChuykoGraduated in 1956Chairman of “International Association of Aero Engines Manufacturing”

Anatoliy MyalitsaGraduated in 1966

General Director of Kharkiv State-Owned Aircraft Production Enterprise; Honored

Mechanical Engineer of Ukraine

Vladimir VovkGraduated in 1978Doctor of Science, Professor of the Otto-von-Guericke-University Magdeburg, Institute of Manufacturing Technology and Quality Management

Ludmila ShvetsovaGraduated in 1973State Deputy of Russia Federation, 2001-2011 - Deputy-Mayor of Moscow-city

Oleg KononenkoGraduated in 1988

Russian Pilot-cosmonaut, Hero of the Russian Federation.

Performed 2 space flights in 2011

Oleksiy TorokhtiyGraduated in 2010Ukrainian weightlifter, European and World Championships multiple medalist. Won the gold medal at the London Olympic Games in 2012

their Alma Mater. KhAI, in turn, recognizes its alumni. Traditionally, the University graduates come to KhAI from all over the world in the late May to meet their friends and lecturers and to take a trip down the memory lane. Many of them are members of “International KhAI Alumni Association” whose principal objective is to consolidate KhAI graduates, students and academic staff to stimulate their cooperation and increase KhAI excellence.

Dmytro Kiva

Graduated in 1965Doctor of Engineer-ing, Professor, Hero of Ukraine, Honored Master of Science and Engineering. Current President and General De-

signer of the Antonov ASTC, member of the National Acad-emy of Sciences of Ukraine.

13

Section 1: General Information

University LifeThe National Aerospace University KhAI offers for its students, faculty and staff a unique atmosphere embracing a vast range of cultural, educational, athletic and social activities. There is an ample opportunity to nurture all kinds of talent in students.

Air SportAs an aviation University, KhAI encourages air sport growth and development. In our Hang Gliding Club, established in 1976, more than 50 hang gliders were designed and manufactured. Today it counts dozens of members, who constantly conduct trainings and perform flights. Experienced trainers of Paragliding Club provide training in paragliding for students and for anyone interested. Flights are performed almost each weekend in Kharkiv and twice a year in Carpathian Mountains.

Sport

KhAI has all necessary conditions to ensure its students with strong health and physical growth and development. Swimming pool, boxing, wrestling, sport games, weightlifting and body-building halls, climbing simulator and ski center accommodate various KhAI sport clubs. All clubs are under the supervision of high-qualified experienced sportsmen whose trainees have won more than 150 national, European and world championships and cups for the last 10 years. Also, indoor field-and-track and outdoor stadium equipped with all necessary facilities are opened all year round for everyone who desires to improve health or just play sport games.

MusicKhAI’s wind band amounts more than 40 musicians whose work constantly keeps students interested in music. The band’s wide-ranging repertoire includes famous pieces of classical music, different arrangements, modern jazz and symphonic compositions etc. Also, talented singers have the opportunity to join one of 2 KhAI choirs. For amateurs KhAI organizes different concerts, shows and competitions.

Dance

KhAI dancing has more than a 30-years history. Professional world-class dancers perform trainings in different dance styles, including Latin, European, Caribbean, belly-dance, contemporary, modern, cheerleading, tribal-dance, etc. Dance groups are organized by age and attainment level. The dancing team provides its members with warm and encouraging environment, bright emotions and individual approach and aims to share its love for dance through lessons, competitions and organizing shows.

Art

For all beauty and art lovers with creative thinking KhAI’s Art Studio and Fashion Theater are always opened. Admirable paintings of Art Studio members are presented at the local, regional, state and international exhibitions and festivals. The Fashion Theater members participate at different fashion projects, advertising actions, shows and festivals.

University festivalsEach May KhAI celebrates the University Day. The alumni from all over the world come to Alma Mater to meet their mates and visit academic buildings. The festive occasion begins with the parade of students, teaching staff and personnel accompanied by welcoming speeches and greetings from the University rector and special guests. At this event, KhAI stadium holds an exhibition of hang-gliders, autogyros and aircraft made by students and staff. The sky is filled with aircraft models and all comers can perform a short flight on a hot air balloon. In the evening KhAI’s creative groups (dancers, musicians, etc.) organise a great talent show. Traditionally, the day is finishing with festive fireworks. Another traditional festival is the annual freshmen “students initiation”. The event, which is similar to the University Day, takes place in late August. Also, for each national holiday gala concerts are given for all KhAI members.

KhAI

Re

sea

rch

Research Environment 16

Research Centres and Laboratories 17

University Research Profiles 18

University Research Facilities 50

University Experience in InternationalCollaborative Research 52

Section 2: KhAI Research

Ukraine is one of the nine world countries possessing the whole cycle of aerospace products design and manufacturing. Therefore the demand for high-qualified professionals and new emerging ideas and technologies is continuously growing.Since its establishment in 1930th the National Aerospace University has played an important role in aerospace S&T development due to its high-level staff’s and students’ potential and sustainable generation of new knowledge.We have strong international reputation in various research areas through our understanding of future needs and opportunities which are set to drive the KhAI’s interdisciplinary research and education strategies.Our R&D focus is generally aligned with the national goal of achieving technological excellence and self-reliance. The University has on-going academic and research collaborations with many national and international universities and industries, in order to remain abreast of current frontiers of knowledge and global developments, and also to be always aware of community needs.

Our S&T Labs and Centres carry out research in key areas of science and engineering, e.g. mathematics, solid state physics, fluid, gas and plasma mechanics, design and manufacturing of aerospace models, engines, various devices, radio electronic systems, information technologies, etc.Among the unique research facilities available at KhAI there are two having the status of National Heritage of Ukraine:•the Aerodynamic Complex,

consisting of supersonic wind tunnel, 5 subsonic wind tunnels and acoustics laboratory;

•the Inter-branch Research Institute of Aircraft Flight Modes Physical Modeling Problems.

KhAI research teams are always opened for starting new research collaborations in different types of projects and will be glad to become a part of consortia created to tackle problems arising in aerospace industry growth and development.

Key areas of KhAI researchbut not limited to•Aerodynamics,includingsubsonic,

supersonic, hypersonic fluid dynamics and wind tunnel tests

•CAD/CAM/CAE design ofaeronautic structures and elements

•StrengthanalysisandFEMsimulation•Aircraft structures full-scale

structural testing and durability study

•Advancedcoatingsdevelopment•High-strengthcompositestructures

design and simulation•Aircraft manufacturing and

assembly processes development•Advanced manufacturing tools

development for processes automation increasing

•Aircraftpropulsion•Gas-dynamicprocessessimulation•Aircraftcontrol systems, including:

avionics, dependable embedded systems and fault-tolerant adaptive systems

•Unmannedaerialvehicles•Remotesensingsystems

More specific information on these and other KhAI research directions is presented in the research profiles hereafter.

16

National Aerospace University "KhAI"

Research Environment

17

Section 2: KhAI Research

Research Centres and LaboratoriesUn

ive

rsity

Re

sea

rch

Stru

ctu

re

Research Institutes

Research centres

Research Laboratories

Departments’ Research Units

Design Bureaus

18

National Aerospace University "KhAI"

Aerodynamics and Aeroacoustics Research

Scale model of UAV in WT-4 operating section Scale model of vehicle

in WT-6 operating section Scale model of rolling stock on surface ground panel

in WT-4 operating section

The department of fluid mechanics was founded at the same time with the University in 1930 and was headed by the famous Ukrainian scientists Georgiy Proskura. In 1957, under the support of ANTONOV Design Bureau General Designer, the research laboratory of aeronautics and acoustics was organized. In 1975 the aerodynamic complex with supersonic wind tube began operating.Now the department includes the following laboratories and facilities:•SubsonicAerodynamicLaboratory•SupersonicAerodynamicLaboratory•Acoustics Laboratory equipped

with aeroacoustic chamber.Today the main area of our research is the interaction environment (air flow) and outer design of manmade structures (airplanes, helicopters, cars, trains, buildings, bridges etc.)Current investigations are focused on the decreasing of air drag for different transport modes. It leads to the decreasing of fuel consumption and exhaust gas emissions.

•Dr.Sc.,Prof.IuriiKrashantsa•Ph.D.,Ass.Prof.VitaliyChmovz•Ph.D.SergeyJeremenko•ResearchengineerViktorKuleshov•Researchengineer

Valentin Nuydovski•ResearchengineerIuriiGyrka

Principal Investigators

The research performed in the area of experimental aerodynamics is oriented towards the development of: (i) subsonic aerodynamics (WT-3 and WT-4 subsonic wind tunnels), including (i1) determination of total aerodynamic forces acting on the body; (i2) distribution of gage static pressure over a body surfaces; (i3) flow visualization (silk treads method for subsonic flow visualization, shadow method for supersonic flow visualization); (i4) ground surface aerodynamics; (ii) supersonic and transonic aerodynamics (WT-6 supersonic wind tunnel).Our research team had performed a lot of successful tests for USSR and Ukrainian design offices, such as Beriev, Antonov, Yuzhnoye, Luch, Kraz JSC, Motor Sich etc.The research carried out in the field of experimental aeroacoustics is oriented towards the development of noise and jet airframe interaction.Activities in the field of wind energy include the theoretical and experimental investigation of aerodynamic performance of wind turbine with the vertical axes. We are performing numerous tests of the scale models of vertical axes wind turbine in the wind tunnel test section. The research is focused on the optimization of turbine efficiency by the variation of wind turbine geometric parameters.Surface transport aerodynamic drag research include: (i) theoretical and experimental determination of vehicle aerodynamic drag and (ii) investigation of vehicle aerodynamic drag decreasing. In this field a number of successful projects together with USSR Ministry of Transport, Kraz JSC and Curtin University of Technology were performed.Activities in the field of aerodynamic efficiency and stability of airplanes and unmanned aerial vehicles are devoted to (i) theoretical and experimental determination of vehicle aerodynamic efficiency; (ii) investigation and development of methods of reducing vehicle aerodynamic drag; (iii) theoretical and experimental determination of aerodynamic longitudinal and lateral static airplane stability; (iv) investigation and development of methods for optimization of aerodynamic longitudinal and lateral static airplane stability in order to increase aircraft safety.Education and training: Theoretical knowledge gained as a result of performed R&D activities is widely used for education and training courses development. We have developed numerous training courses on hydraulics, theoretical and experimental aerodynamics, aerodynamics of vehicles, flight dynamics, hydrologic, space mechanics etc.

Contacts: Dr. Vitaliy Chmovzh (Head of the Fluid Mechanics Department)e-mail: [email protected]; phone: +38 (057) 788-41-01

19

Section 2: KhAI Research

In USSR, the Interbranch Research Institute of Aircraft Flight Modes Physical Modeling Problems (NII PFM KhAI) was the parent organization in the field of predictive flight researches of advanced aeronautical engineering using the dynamically similar, subscale pilotless airplane models. From 1976 till 1996 the institute has performed a range of flight tests of models of Su-27 and MiG-29 fighters and their modifications, and of some airplanes of Myasishchev and Antonov design offices and others. Since 1997 the general NII PFM field of activity has been the development of remotely piloted aircraft systems for civil and special applications. A great number of different types of remotely piloted aircraft were developed and tested. Currently, the Institute’s work is focused on the development and testing of new aerodynamic layouts, avionics, payloads and radio communication systems for aircraft.Principal Investigators•Dr.Sc.,Prof.YevgeniyDruzhinin•Dr.Sc.,Prof.AlexanderRyzhenko•Dr.Sc.,Prof.AlexanderBetin•DirectorofNIIPFMKhAI Anatoliy Smolyakov•HeadofNIIPFMdepartment

Sergey Yashin

Predictive flight researches with Free-flying Dynamically Similar ModelsThe large-scale Free-flying Dynamic Model (FDM) is a re-usable unmanned research aerial vehicle capable to perform remotely-piloted or automatic pre-programmed flights with the possibility of recording in-flight information. The FDM is geometrically similar to the investigated aircraft and has the same controls. Its weight, inertia moments, autopilot coefficients and other parameters ensure that the FDM flight performance conforms to the performance of a full-scale aircraft. When necessary the pilot actions (including possible pilot errors) are simulated by the model.The major part of the FDM structure is made of composites and aluminum al-loys. The FDM onboard systems include an automatic control system, flight pa-rameters measuring and recording system and recovery system. For the FDM development we used the modular approach providing model deep modifi-cation during the flight tests.The FDM can be applied for: (i) the investigation of the most effective aerodynamic layouts with the allowance for fixed and separated external stores effect; (ii) the study of critical flight modes related to complicated 3D aircraft movement; (iii) the investigation of aeroelasticity phenomena under the energetic maneuvering; (iv) the investigation of aircraft invulnerability and reconfigurable automatic control system efficiency.

Multi-purpose remotely piloted aircraft systems design and testingThe NII PFM conducts research, design, engineering and flight tests of specimens of multipurpose Remotely Piloted Aircraft Systems (RPAS) based on a different Remotely Piloted Aircraft (RPA) in consideration of flight safety requirements in the non-segregated aerospace.The modern RPAS based on the “ChiZh-L” small RPA is intended to perform: (i) real time aerial surveillance of territories, extensive objects and borders; (ii) aerial mapping; (iii) search and mapping of fossil fuel and mineral deposits; (iv) atmospheric investigations; (v) environmental monitoring etc.“ChiZh-L” RPAS has the following specifications: RPA take-off weight – 15 kg; RPA wing span – 2 m; flight endurance – 4 h; altitude ceiling – 5 000 m; operational range from Ground Control Station – up to 200 km; RPA quantity in one RPAS – 1÷5; RPA payload – 1.5 kg; RPA can be launch from and landed to the unprepared sites, including a board of small vessel.

Contact: Mr. Anatoliy Smolyakov (NII PFM KhAI Director)e-mail: [email protected], [email protected]; phone/fax: +38 (057) 315-11-34

Multi-purpose Remotely Piloted Aircraft Systems

“ChiZh-L” RPA “ChiZh-L” RPAS portable GCS“ChiZh-L” RPA preparation to flight

20

National Aerospace University "KhAI"

The CAD/CAM/CAE Educational Scientific and Research Centre of the National Aerospace University «Kharkiv Aviation Institute» was established in 1993. The scientific school of integrated aircraft design and simulation was established under the leadership of the Centre’s head DSc., Professor Alexander Grebenikov. The Centre provides education and scientific training for more than 100 students, young specialists, scientists, KhAI employees, production specialists from Ukraine and other countries yearly. Our staff is involved in international collaboration with colleagues from Russia, USA, Germany, Czech Republic, Canada, Japan, Iran, India, China, and Mexico.To perform scientific and research activities the Centre is equipped with modern computer integrated CAD\CAM\CAE\PLM systems: Siemens NX; CATIA, ANSYS, NASTRAN, COMPAS etc.

Principal Investigators•Dr.Sc., Prof. Alexander Grebenikov•Ph.D., Ass. Prof. Andrey Gumenny •Ph.D., Ass. Prof. Sergey Trubaev •Ph.D. Vadim Grebenikov •Researcher Dmitry Dmitrenko •Researcher Juriy Geremes•Researcher Alexander Serdukov •Researcher Vladimir Parfenuk •Researcher Anton Kalambet •Researcher Anton Chumak

Key areas of the Centre’s research activity are the development of methodology for integrated design of airplanes and helicopters, parametric simulation, engineering analysis and process engineering.

Our scientists have developed the concept, principles and methods for integrated design and simulation of long-lifetime aircraft. This approach will provide the reduction of costs and time required for transport airplanes production, also increase the competitiveness of aeronautic projects, ensure qualitative production and effective scientific and educational processes.

Also, we have developed methods for integrated design of airframe structural units and methods which allow us to achieve specified lifetime of zones around riveted and bolted joints. These methods are based on the application of modern computer systems. The introduction of assembly airframes integrated design with consideration for fatigue allows essential enhancing of durability of structural units under operational loads.

Others our activities include the analysis of local stress-strain state characteristics of zones around the fuel overflow holes and bolted and riveted joints in aircraft primary structural members. Developed approaches include machining process simulation. The application of these methods allow us to select the design and technological processing parameters in order to achieve specified lifetime characteristics without increasing structural weight and provide the possibility to predict fatigue characteristics at the design stage.

Proposed methods of integrated design and technological concepts are introduced into the theory and practice of assembly airframes development with the use of CAD/CAM/CAE integrated systems.

Integrated Aircraft Design

Contacts: Prof. Alexander Grebenikov (Head of the Centre)e-mail: [email protected]; phone: +38 (057) 315-08-87

21

Section 2: KhAI Research

The Scientific and Research Laboratory of Aircraft Structures Lifetime was established in 1978. Ever since that time our research activity has been focused on ensuring increased lifetime for aircraft structures joining elements. We have achieved the increasing of joints lifetime at operation loads by 7-11 times.Engineering solutions ensuring specified lifetime of bolted and riveted joints have been developed. Under the leadership of Professor Alexander Grebenikov the scientific school aimed at the development of design and engineering methods ensuring specified service lifetime characteristics of aircraft structural members was established.

Principal Investigators•Dr.Sc., Prof. Alexander Grebenikov •Ph.D., Prof. Sergey Bychkov •Ph.D., Ass. Prof. Yevgeniy Vasilevsky•Ph.D., Ass. Prof. Sergey Trubaev •Ph.D., Ass. Prof. Alexey Timchenko•Ph.D., Ass. Prof. Andrey Gumenny

Fatigue lifetime characteristics of aircraft structural membersUnder the Laboratory there is a research team which research activity is focused on the investigation of fatigue lifetime characteristics of aircraft structural members. The Laboratory is equipped with the machining facilities for samples manufacturing and test machines to conduct tests for the determination of fatigue lifetime characteristics of aircraft structural members.

Ensuring specified lifetime of assembly aircraft structuresUnder this topic the investigation of efficient design and engineering methods allowing to obtain specified lifetime characteristics of assembly aircraft structural members around the riveted and bolted jointing elements without structural mass increasing is being carried out.

New long-lifetime fasteners developmentThe laboratory staff develops new types of long-lifetime fasteners enabling to ensure specified characteristics of joints static strength, fatigue life, tightness and outer surface quality for transport aircraft airfoils. The application of such joining elements will provide reduced labor intensity for the assembly process.

Application of polymer fillers for manufacturing tolerances compensationThe application of polymer fillers when assembling the aircraft structural members allows to compensate the manufacturing tolerances and to reduce fretting corrosion intensity on contact surfaces of structural members under operational loads.

Performance restoration of thin-wall structures with fatigue cracksOn the basis of research results the recommendations for the load-carrying capacity restoration of aircraft structures with fatigue cracks were formulated. These recommendations and based thereon guiding engineering materials are approved by the leading experts of the Central Aerodynamic Institute and ANTONOV company and were introduced at aircraft manufacturing enterprises of Ukraine and CIS countries.

Aircraft Service Lifetime Research

Contacts: Prof. Alexander Grebenikov (Head of Airplanes and Helicopters Design Department)e-mail: [email protected]; phone: +38 (057) 788-41-03

22

National Aerospace University "KhAI"

KhAI Strength Laboratory has over 50 years of experience in strength and durability research. The Laboratory`s research topics are historically determined by requests of industrial partners such as Beriev, An-tonov, Tupolev, Ilyushin, Boeing etc.The Laboratory has a structural test hall of 10 m heights and 430 m2 area and equipped with hydraulic and electromechanical test machines, both static and fatigue, allowing us to offer a wide range of services for our partners in aerospace and engineering industries.Among our successful projects there are tests of Yak-40, “Shmel” 01-M, “Bekas” X-32, experimental wingbox of IL-86, fuselage of L-410 UVP-E, and other aircraft.The constant scientific progress helps us to solve offbeat and challenging problems, while maintaining the highest quality of our service.

Principal Investigators•Dr.Sc.,Prof.PeterFomichev•Ph.D.,Ass.Prof.AlexeyTretyakov•Ph.D.,Ass.Prof.TatyanaBoiko•Ph.D.,Ass.Prof.AlexeyChernykh•Ass.Prof.SergeyVakulenko

The scientists and researchers of the strength lab have developed the method of aircraft structures durability calculation. This method is based on energy fracture criterion, local stress-strain state and cyclic strain material data.In contrast to traditional methods, additional testing does not require the specific type of loading, operational conditions, flight profiles, or design solution. New material application can be studied without fatigue tests of structural elements, but on the basis of the cyclic strain material data tests only.Our method allows reducing required volume of fatigue testing and total costs for aircraft design, testing, modernization and operation.This method is applicable for:•calculation of damage equivalent for testing program or spectrum of

operational loads;•calculationofallowablestressesensuringthedurabilityofregularandirregular

structure zones;•processing and utilizing of loading data written by onboard recording

systems.We are opened for collaboration in the following areas: •Development and enhancement of strength and durability calculation

methods; •Airbornelifetimecountersscientificfoundationanddevelopment;•Fatigueandstaticstructuraltesting;•Anyotherproposalsinthefieldofaircraftstrength&durability.

Contacts: Dr. Sergey Vakulenkowebsite: www.khai.edu/prochnost; e-mail: [email protected]; phone: +38 (057) 788-43-28

Aerospace Structures Strength and Durability Analysis and Testing

23

Section 2: KhAI Research

The Research Laboratory of Gas-tur-bine Engines and Power Plants was cre-ated within the specific R&D Laboratory of USSR Ministry of Aircraft Production. The Laboratory had conducted ex-perimental, estimative and theoretical investigations of flow parameters in the areas of steady and unsteady modes of axial compressors. Currently the Laboratory carries out the research focused on (i) the development of mathematical models of gas-turbine engines for various applications, (ii) the development of design methods for numerical investigation of impeller machines performances, as well as (iii) the improvement of compressor aerodynamic calculation methods.We are involved in collaborative proj-ects together with well-known Ukrai-nian organizations, such as Ivchen-ko-Progress State-owned Company, «Motor Sich JSC», (Zaporozhye), “TUR-BOATOM JSC” (Kharkiv), PJSC «Sumy Frunze NPO» (Sumy), Gas Turbine Re-search & Production Complex Zorya-Mashproekt” (Nikolaev).Principal Investigators•Dr.Sc.,Prof.LudmilaBoyko•Dr.Sc.,Prof.VladimirGerasymenko•Ph.D.,SeniorresearcherAlexander

Dyomin•Ph.D., Senior researcher Elena

Barysheva•Ph.D., Senior researcher Elena

Karpenko

The Laboratory of Gas-turbine Engines and Power Plants carries out research focused on the development of mathematical models for gas-turbine engines for various applications, taking into account the geometrical parameters of its blade rows on the mean radius and the air-gas channel shape. In the frame of this research we had developed the calculation method for the turboshaft gas-turbine engine. This method includes the description of geometric parameters of the multistage axial compressor by each row. We are developing the calculation method for the multistage axial gas turbine in a wide range of flow patterns, including the transonic regimes taking into account the cooling. This approach provides the estimation of high-temperature gas-turbine engines product performance at given geometric parameters of blade rows and air-gas channel, as well as the evaluation of its influence on the thrust, power, fuel rate, efficiency and other engine parameters. The models of definite engines developed by our team give the opportunity to take into account the influence of propellant bleeding for the spacecraft needs and channel hot section cooling on flow parameters in different engine components and its performance characteristics. Such models practical application helps to improve an engine control system during its design and final adjustment. The approaches applied to the gas-turbine engines mathematical models formation provide the usage of considerably less number of adjustment coefficients during the specific models development and their identification. This helps to decrease a human factor influence on calculation results. Within the Laboratory of Gas-turbine Engines and Power Plants we develop the methods for design and performances numerical investigation of blade machines, high-pressure trans- and supersonic axial compressor stages, fans stages, multistage axial compressors, superchargers and high-pressure centrifugal compressor stages with high engine pressure ratio. The relevant software is developed. The proposed methods are based on the 1-D, 2-D and 3-D approaches used for the description of gas-dynamic processes and blade surfaces shapes.

Thermal Gas-Dynamic Processes Simulation

Contacts: Prof. Ludmila Boykoe-mail: [email protected]; phone: +38 (057) 788-42-01

Gas Turbine Engines Modelling Centrifugal High Pressure Rotors Flow ModelingAxial High Pressure Rotors and Multistage

Compressor Flow Modeling

24

National Aerospace University "KhAI"

We have developed the advanced approach for the increasing of gas turbine engine aerodynamics efficiency. It is based on the application of main parameters and operating tolerance new robust estimation methods at the development and operation stages using the inverse problem concept.Suggested methodology is based on system aggregation, decomposition and coordination of general problem principles. It assumes general problem solving by means of distributed solution of interrelated inverse (variational, optimal control) and optimal subproblems in determinate and stochastic problem definition. If feasible solution class limits are presented, system modification problem solution synthesis is realized on the basis of regularizing algorithms. The created modification problem numerical solution evolution method is based on the genetic algorithm application.Reconstruction (modification), control and turbojet engine technical state diagnostics problems were solved with the help of developed methodology.Also the information technology allowing computer support and decision-making systems was developed:1. Aerodynamic characteristic analysis and improvement of turbofan engine subsystem (two-shaft and three-shaft turbofan engine scheme) – methodology, methods, technique and realization of interactive computer support and decision-making system for turbojet engine image-building (main parameters of elements choice) TFE_1Dr Flow_Opt_Pr «Motor_Pro®».2. Aerodynamic performance analysis and improvement of multistage axial flow compressor – methodology, methods, technique and realization of interactive computer support and decision-making system for multistage axial flow compressor image-building (main blade rows parameters choice) MS_AFC_1DrFlow_Opt_Pr (figure 2).3. Aerodynamic performance analysis and improvement of axial flow compressor blade rows (on the base of turbomachine aerodynamics hybrid problem solution) – methodology, methods, technique and the realization of interactive computer support and decision-making system for multistage axial flow compressor blade rows image-building (parameters choice) 3Dr Flow_Hybrid_Pr (figures 1,3).4. Technical system element image-building based on the structural-parametric optimization methods – methodology, methods, technique and realization interactive computer support and decision-making system for technical system elements image-building (rational alternative parameters choice by artificial neuron networks and evolutional algorithms) “Concept_Pro®”.

Gas Turbine Engine Design and DiagnosticsThe research work of our team is mainly focused on the design and investigation of (i) new algorithms and methods for technical state diagnostics and control; (ii) the main parameters and operation tolerance based on the inverse problem concept.The following problems are solved:•characteristics analysis and

improvement of turbofan engine subsystem;

•performances analysis andimprovement of multistage axial flow compressor and compressor blade rows;

•systemelementimage-building;•technical system operational

condition diagnostics;•stochasticoptimizationproblems.System perfecting, methodology and main parameters robust estimation, and gas turbine engine elements operating tolerances information technology (based on the inverse problem concept) are developed by our research team.

Principal Investigators•Dr.Sc.,Prof.MykhayloUgryumov•Ph.D.YurijSkob•AssistantAlekseyTronchuk•AssistantVictoriaAfanasjevska

Contacts: Dr. Mykhaylo Ugryumov e-mail: [email protected]; phone: +38 (057) 788-43-62; +38 (057) 788-48-42

Figure 1 Figure 3Figure 2

25

Section 2: KhAI Research

At the Aircraft Engine Diagnostics Laboratory the following research activities are performed:•engine automatic control

algorithms and software synthesis;•engineparametricdiagnostics;•engine major components life-

time monitoring.The research activities are based on engine operation process static and dynamic models and engine units thermal and stress states.Thermodynamic models for engine static and dynamic performances analysis are based on the use of engine units’ characteristics, devices and sensors design. Engine operation and its automatic control system simulation (up to real-time and accelerated scaled-down tests) is provided.Parametric diagnostics is a set of universal adaptive algorithms includ-ing tolerance analysis, trend-analysis, state recognition and prognosis.Lifetime monitoring provides precise and effective determination of thermal-stress state taking into account real maintenance conditions.

Principal Investigators•Dr.Sc.,Prof.SergeyYepifanov•Dr.Sc.,Prof.DmytrySimbiskiy•Ph.D.,Ass.Prof.,SergeySukhovey

The experienced researchers of the Aircraft Engine Diagnostics Laboratory de-velop multilevel mathematical complex of gas turbine engines and models of their automatic control systems. This complex provides the simulation support in control and diagnostic systems design at all stages. Initial model is a ther-modynamic model of engine units coordinated by engine design bureau. Its adequacy is provided by experimental data with the help of parametric identifi-cation method. Then the model is transformed into a non-linear dynamic model taking into account rotors dynamics, gas cavities presence and heat exchange between propellant and structural elements. To allow radial clearances change during both active and passive methods of clearances control, this model is complemented with the dynamic model of parts heat expansion, which forms clearances, and appropriate correction of units’ performances. To obtain real-time and accelerated models, this model is simplified to the quasi-linear form with the factors depending on the operation mode and ambient conditions. To form models required for ACS elements testing, the model is complemented with the execution devices and sensors, and with the propellers and other driven devices for turboshaft and turboprop engines.This model can automatically calculate the working process parameters influence on the variable parameters of units’ performances.The following models have been already developed: (i) mathematical model of engine starting mode is formed by identification methods using experimental data, and also with the help of prior data (in this case this model is interfaced with the dynamic model in operating modes); (ii) mathematical model of oil supply system operation taking into account the two-phase propellant in discharge main.Based on these models, the methods of engine control algorithms synthesis and analysis, parametric diagnostics methods, and monitoring models of boundary heat exchange conditions for different parts were developed.Also, the approach to the analysis of algorithmic detection methods of engine and its systems parameters changing was developed. Using routine flight parameters registration data and proposed method, the most efficient criteria of parameters faulty values and trend detection were substantiated.To calculate parts residuary lifetime, the method of stress-stain state monitoring models formation was developed. This method ensures formation of models with high computing power but high temperature and stresses calculation tolerance in the most heavy-loaded parts zones in real maintenance conditions. Stress and temperature are determined in real time and can be implemented in onboard systems or realized as on-ground software (fig. 3).

Gas Turbine Control and Health Monitoring Systems

Contacts: Prof. Sergiy Yepifanov e-mail: [email protected]; phone: +38 (057) 719-05-40

Fig. 1 Thermodynamic model of engine unitsFig. 3 Stress-stain state monitoring models

formationFig. 2 Trend analysis method

26

National Aerospace University "KhAI"

Aircraft design with new materials and subject to manufacture, opera-tional and ecological conditionsCurrent research is focused on the synthesis of the modern concepts for optimal project implementation in order to create aerospace structures made of polymer composite materials. Its concepts are based on integrated computing of the entire life cycle of the aircraft.Design of optimal composite structuresMethods and algorithms for the design of basic structure elements (rods and bars, shells, spars and beams, flat, stiffened and sandwich panels) in consideration of strength, buckling and stiffness constraints are developed. They are based on solving of design problems of composite structures. Strength analysis of composite structuresThe following issues are developed and are currently under research:•method of prediction of strength properties of textile and 3D-woven

composites, composite physical and mechanical characteristics variation coefficients on the results of standard tests. According to this method values of an additional safety factor are determined;

•experimentalensuringsystemofstrengthcalculationofmechanicaljointsatthe best fit test condition and nature of loading in real structure;

•FEMmodelingof2Dand3Dwovencompositestrengthandelasticproperties;•methodofdefinitionofphysicalandmechanicalpropertiesofcomposites

reinforced by woven sleeves. Joints of high-loaded polymer composite parts and structuresNew structural and technological solutions of joints of high-loaded composite structural components (embedded longitudinal and transverse fastening microelements, semi-loop joints) are developed.Prediction of structural element stress-strain state under thermome-chanical loadingThe mechanism of skin panel and stiffener thermal deformation is theoretically and experimentally grounded. On this base a method of assembly stresses and strains prediction that occurs during panel installation and manufacture processes with minimum thermal and shrinkage deformation are developed; structural and technological solutions of thick skins interlaminar strength increasing to prevent delamination due to thermal and shrinkage stresses are suggested.Cost-efficient composite structures repair and curing processes Problem of energy saving during composite structure manufacture is solved by the selection of curing process optimal parameters and by using of a heating tool.

Composites Structures Design, Manufacturing and TestingThe outstanding aircraft designer, academician of the Academy of Sciences of Ukraine Oleg Antonov led the creation and development of the Laboratory of Composite Materials. The Laboratory was established in 1971, after the successful static testing of the An-2M fuselage, which was the first large-scale aircraft unit made of polymeric composite materials in the Soviet Union.

Currently, the actual problems of design and manufacture of polymeric composites for aviation, rocket and space structures are under the research of our Laboratory.

Since the Laboratory establishment its scientific supervisor is Professor Vitaliy Gaydachuk, doctor of Science, Laureate of State Prize of Ukraine, and Honored Scientists of Ukraine. At the beginning of the 90’s Prof. Yakov Karpov, doctor of Science, Laureate of State Prize of Ukraine have become the head of research in the area of composite structures design and manufacturing.

Principal Investigators•Dr.Sc.,Prof.VitaliyGaydachuk•Dr.Sc.,Prof.YakovKarpov•Ph.D.,Ass.Prof.MarynaShevtsova

Model of 3D fabric Heating toolMetal- composite joints

Contacts: Dr. Maryna Shevtsova e-mail: [email protected]; phone: +38 (057) 788-42-25

27

Section 2: KhAI Research

The Problem-Oriented Research Laboratory of Radio and Navigation Systems has been carrying out research in the field of applying IT-technologies in radio-electronic systems, mainly in unmanned aerial vehicle complexes, polarimetric radars for remote sensing, geo-information systems and technologies for more than 30 years. Leading scientists of the Laboratory have developed new techniques for environmental remote sensing from aerospace carriers and unmanned aerial vehicles as well as new hardware and software for remote sensing complexes. The developed methods and equipment allow the estimation of electro-physical properties and geometrical characteristics of remote sensing objects and imply usage of new information technologies for remote sensing data in geo-information systems. The results of our research were published in more than 20 monographs, numerous articles in world-known scientific journals and international scientific and technical conferences papers.Principal Investigators•Dr.Sc.,Prof.ViktorIlushko•Dr.Sc.,Prof.VyacheslavKortunov•Dr.Sc.,Prof.ValeryVolosuk•Dr.Sc.,Prof.GrigoryKrasovsky•Ph.D.,Ass.Prof.AnatolyPopov

Unmanned aerial vehicle complexes are developed and produced on the basis of three electric aircraft platforms: aeroplane, helicopter and sixcopter. The complexes are constructed on the basis of original airborne radio and navigation systems and allow running UAV flights with high accuracy (up to 2 meters) in a fully-automatic regime according to the preset program. The complexes also provide programme change during the flight. The airborne systems are unified and a change of a carrier requires only changes in software. The developed UAV participated in the military exercises “Adaptive Reaction - 2011” and got high appraisal during the cross-validation testing.Areas of UAV application:•protectionofstateborders;•search-and-rescueapplications;•monitoringoftechnicalobjects’(buildings,tubings,power lines,damsetc.)

state;•aerialobservationandmapping;•environmentalqualitymonitoring.

Polarimetric radar systems and new methods of object’s detection, automatic classification and recognition are developed to receive fully polarimetric information on remote sensing objects and solve tasks of detection and recognition of small ground and sea-surface objects with predefined properties against a background of intensive clutter. Areas of polarimetric radar systems application:•maintenanceofrescueworks;•protectionofstateborders;•automatictargetlocation;•providingsafetyofplaneflightsandseashipsnavigation;•radarmeteorologyandstormprediction;•radarmapping;•environmentalqualitymonitoring.

The newly developed methods of information processing in geoinformation systems provide utilizing data of aerospace remote sensing in order to solve such tasks as prediction of emergency situations and aftermaths of anthropogenic accidents, environmental quality monitoring, land mapping etc.

Radio and Navigation Systems

Contacts: Prof. Viktor Ilushko (Head of the Department of Aircraft Radio Systems)e-mail: [email protected]; phone: +38 (057) 788-43-53

28

National Aerospace University "KhAI"

Principal Investigators•JSDBChiefGennadyKhmyz•SeniorresearcherBorisVirsky•EngineerAlexeyTihovsky•EngineerAlexeyRakov•LaboratoryHeadNikolayBagach

The JSDB’s research team of piloted airplanes has a vast experience in design, manufacturing, testing and operation of light single and double ground planes, hydroplanes, gliders and motor gliders, hang-gliders, paragliders, motor paragliders and hovercraft. We carry out work on the development and construction of rotary-wing aircraft, such as viroplans, gyroplanes and helicopters. We were the first in Ukraine who raised into the air the KhAI-49 gyroplane. Also the full-scale aircraft flying copies of Nieuport IV, Po-2, Farman IV an M-9 hydroplane were created.The Hovercraft Research Team designs and manufactures the light amphibious vehicles, as well as produces a hovercraft for transportation, installation, connection, testing, shipping and other purposes, where the use of traditional equipment is impractical or impossible.The Equipment Research Team has a practical experience in the development of competitive electronics for microlight aircraft. The Team works on the design, manufacturing, installation and maintenance service of the secured power supply systems based on the wind turbines and PV modules. We have developed a series of controllers for battery charge from the wind turbines and PV modules, uninterruptible power supplies, inverters supplying the power of 220V (50Hz) from the batteries, allowing to create standalone systems with installed capacity of up to 50 kW. A few types of LED projectors allowing substantial decreasing of energy consumption and operating costs were designed.In the Airplane Model Laboratory we develop and investigate modern models of unmanned aerial vehicles made of composite materials, such as gliders, electric aircraft, helicopters and their micro engines. The high-class equipment allows our sportsmen and aircraft modelers to place high on the different competitions.The JSDB’s clubs involve hundreds of KhAI students, PhDs and staff annually who master different technical sports under the supervision of experienced trainers and Masters of Sports of International Class.Auto Club members are participating in a numerous competitions on auto-cross on different upgraded vehicles. The members of paragliding and hang-gliding clubs have an opportunity to design their own flying devices, to conduct research of a flexible wing, to develop methods of flight training and improve flying skills. We perform constant trainings and flights, consisting of weekly prac-tices and lectures on different subjects.JSDB members take part in different competitions and championships on various certified vehicles and regularly place high positions.

Contacts: Mr. Gennady Khmyze-mail: [email protected]; phone: +38 (057) 788-43-72

Students’ Design Bureau Research OutputThe Joint Students’ Design Bureau (JSDB) was founded in 1959. Nowa-days JSDB consists of the following units:•Research Laboratory, including (i)

Research Team of Piloted Airplanes; (ii) Hovercraft Research Team; (iii) Equipment Research Team; (iv) Air-plane Model Laboratory.

•Students’ Laboratory, including (i) Auto Club, (ii) Paragliding Club and (iii) Hang-gliding Club.

The Laboratory is equipped with the design halls, computers and modern software. Assembly shops allow performing an assembly of full scale aircraft.Among our facilities are metal-working and wood-working machining equipment, including the precision one, equipment for composites manufacturing, test-benches etc.Our research activities are carried out with the help of other facilities and on the base of research results available at the University and at different Ukrainian organizations.The scientific supervision of our work is performed by the experienced KhAI staff and our students are constantly filled with new ideas.

29

Section 2: KhAI Research

The Subdivision of Power Engineering of STC SPE works on the development and experimental testing of new schemes and technical solutions of space and rocket technics power supply systems. We investigate and prepare the recommendations for optimization of the structures of promising space-rocket complex and spacecraft power supply systems based on power system components mathematical modeling and possible in-operation failures analysis.

By means of mathematical and physical modeling of power supply systems of space-rocket products and autonomous objects we have carried out system modeling and performance improvement of photoelectric and electrochemical batteries through the increased informativity of its ground bench tests.

The Subdivision of Power Engineering have developed a set of methods and algorithms for diagnostics, rehabilitation, accelerated testing and resource prediction of electrochemical accumulators. These methods and algorithms allow performing of the full-range experimental researches in the area of electrochemical accumulators of different electrochemical systems used in space power plants.

Our team has also developed the automated experimental stands, bench tools, simulators and physical models for space power plants and its components testing. We have created and applied a few stands for modeling, research and testing of power plants, photoelectric batteries and electrochemical accumulators. The stand contains specialized digital devices and the devices developed in KhAI, providing special modes of objects operation. The equipment allows to perform the full scale tests and investigation of chemical and photoelectric batteries and its individual elements, and also to replace full scale tests with model tests and reduce material and time expenses while.Also our staff provides training, educational, scientific and industrial practice for B.Sc., M.Sc., young specialists and scientists who specialize in the field of autonomous power supply systems of space-rocket technics and autonomous objects. We hold scientific seminars and perform graduate students and Ph.D. students training.

Space Power EngineeringThe subdivision of Power Engineering was founded in January 15, 1995 on the basis of Scientific and Technical Centre of Space Power and Engines (STC SPE).For a 16-years period the Depart-ment of Power Engineering of STC SPE have performed numerous research activities in the field of power supply systems design for modern space-rocket complexes and spacecraft.

Among the research projects performed in collaboration with the leading Russian and Ukrainian organizations we have the following ones: “Base”, “Start”, “Sich”, “Sich-1M”, “AUOS CM-CI”, “Lybid”, “Poperedjennia”, “Mikrosuputnik», «Egyptsat» and “A18M missile power supply lifetime improvement” projects.

Within our subdivision 2 doctors, 11 PhDs and over 70 M.Sc. and B.Sc. have been prepared.

Principal Investigators•Dr.Sc., Prof. Konstantin Bezruchko•Ph.D. Albert Davidov•Ph.D. Semen Shirinskiy•Alexander Azarnov•Svetlana Sinchenko

Contacts: Prof. Konstantin Bezruchko (STC SPE Deputy Director)e-mail: [email protected]; phone/fax: +38 (057) 788-40-65, phone: +38 (057) 788-44-28

30

National Aerospace University "KhAI"

KhAI’s Center of Technical Physics is the unit of Aerospace Heat Engineering Department. The Center’s research is focused on the development of complex thermal engineering systems and technologies generally based on the heat transfer loops and heat-exchangers with condensation/evaporation and two-phase flows (water, freon, ammonia, carbon dioxide, cryogenic fluids, air-water mixtures). The Center’s researchers have a broad experience in the development of software for analyses of thermal hydraulic process in thermal engineering for different applications, including refrigeration and conditioning systems. Moreover, we perform testing and updating of the software designed by other developers of the heat exchange devices. The Center has the experimental base and high-skilled staff capable to design, manufacture and test equipment of different complexity as well as to study the thermal hydraulic processes for future design optimization. Principal Investigators•Prof. Gennady Gorbenko •Ass. Prof. Pavel Gakal•Senior researcher Vasily Ruzaykin•Senior researcher Dmitry Chayka•Senior researcher Konstantin

Epifanov•Researcher Nina Ivanenko

Design, manufacture and test of two-phase mechanically pumped loops for space and general applications. Design and adjustment of testing facilities to study the thermophysical phenomena in thermal engineering.Since 1980th KhAI’s Center of Technical physics has been solving tasks related to the development of thermal control systems based on the two-phase Mechanically Pumped Loop (MPL) concept. Together with the RSC “Energia” our staff took part in the development of two-phase thermal control system for the Russian segment of International Space Station. Also, we participated in MPL prototype flight tests (performed on the “Mir” Space Station) planning and results processing. Since 2001 the Center has been performing collaborative researches with Thales Alenia Space (France) focused on the development of thermal control system based on MPL and heat pump concept for powerful telecommunication platform. 6kW full-scale MPL prototype and its special testing facilities were designed and manufactured In 2011 the Center‘s researchers in the frame of joint project with Thales Alenia Space designed and manufactured the components for 10 kW thermal control system on the base of heat pump concept. Development and design of thermal regulation system for space rocket complexes of different applicationsSince 2004 the Center together with the “Yuzhnoye” Design Office have been providing the scientific guidance for the development of stationary air thermal regulation system for “Cyclone 4” space rocket complex. This work has been performed in the framework of collaborative Ukraine-Brazil project aimed at “ Tsyklon 4” launch complex construction in the Alcântara Launch Center. KhAI’s Center of technical physics has designed, manufactured and tested the functional analogue of thermal regulation system.Other Center activities are dealing with:•non-standardrefrigerantandconditioningsystemsdevelopment;•energysavingsolutions;•energyauditandmanagementofindustrialenterprises;•technical and economical justifications of for enterprise refrigerant supply

concepts.

Advanced Thermal Engineering Systems and Technologies

Contacts: Dr. Pavel Gakal e-mail: [email protected]; phone: +38 (050) 641-53-66

31

Section 2: KhAI Research