NAQN March 2014

-

Upload

janet-stanley -

Category

Documents

-

view

214 -

download

0

description

Transcript of NAQN March 2014

Volume 18 No. 8 March 2014

PRSRT STDUS POSTAGE PAID

UTICA,NYPERMIT #55Haul Trucks / Show Issue: Hard Hat

Expo / Show Issue: Con Agg / Con Expo

Quarry experiences production leap afterswitch to Flex-Mat 3

Haul Trucks / Show Issue: Hard HatExpo / Show Issue: Con Agg / Con Expo

2 • March 2014 NORTH AMERICAN QUARRY NEWS

NORTH AMERICAN QUARRY NEWS March 2014 • 3

4 • March 2014 NORTH AMERICAN QUARRY NEWS

NORTH AMERICAN QUARRY NEWS March 2014 • 5

ichigan based Great Lakes AggregatesInc. produces approximately a milliontons of limestone per year at its SylvaniaMinerals Quarry located in SouthRockwood. As the quarry increased the

number of saleable products that it produced, itencountered screening challenges along the way suchas limited open area, screen breakage and severeblinding. “With only nine months of production timeeach year it’s important that we keep production ontrack,” says Bill Begley, quarry manager at SylvaniaMinerals Quarry.

The quarry’s goal was to increase its throughput onall three decks of the wash screens, while producingfour different product sizes from clean, high qualityminus 3/4-inch material. After several failedattempts with other products to achieve these results,Begley meet with Kevin Hinkley at ConveyallIndustrial Supply, Inc. and Brad Rice from MajorWire who recommended they try Major Wire’s Flex-Mat® 3 screen media.

Competitor’s poor screen media hindersproduction

All three decks of both screen boxes were originallyfitted with modular polyurethane panels. The topdeck screen had a 1/2-inch opening, the middle deckhad a 3/8-inch opening and the bottom deck screenhad a .212-inch opening. This system worked fine aslong as the load of base materials and washedproducts were split equally. However, as the quarryincreased the amount of washed products, the resultswere poor quality and lower production rates. Thescreens needed more open area.

To achieve more open area, the previous screenmedia provider then suggested changing to theirdiamond shaped (“D” style) wire openings andsupplied urethane bucker bar covers for the flat deckrail bars on the screen boxes to create a crown for theside tensioned panels. These new panels wereinstalled on the top and middle decks of both screenplants. After running for only a few days the screenmedia panels broke apart causing production to come

to a halt.Flex-Mat 3 quickly makes an impact

Hinkley from Conveyall visited the quarry to takemeasurements of the screen boxes to ensure every-thing would fit correctly. Next, they installed MajorWire’s Flex-Mat 3 Tensioned Series D, a diamondshaped media that works well for most standardapplications, on both the top and middle decks of onescreen box. On their second screen box, for compari-son, they installed more of the competitive “D” stylescreen panels that they had been using previously onthe top and middle decks as well.

After just a few days of production, the screen boxwith the previous screen media on it broke again butthe Flex-Mat 3 screen media lasted nearly four more

GreatLakes 6

MA Komatsu WA800 loads shot rock into a CAT 775F haul truck headed to the primary.

Quarry experiences production leap Quarry experiences production leap after switch to Flex-Mat 3after switch to Flex-Mat 3

by Gary Pederson, VP of sales for Major Wire Industries Limited- Candiac, Quebec, Canada.

From this elevated view, Great Lake's stockpile of material is very impressive.

Bill Begley shows how consistant in size the material is.

GreatLakes from 5

months. Following that, they installed it on the comparison screen and increased production on bothscreens. “We were really impressed with the wear lifeof Flex-Mat 3 and excited about the extra production.The other self-cleaning screen media we used didn’thave enough open area and didn’t screen as well asMajor Wire’s Flex-Mat 3,” comments Begley. “It hasbeen a good product, very reliable and the price iscompetitive with other self-cleaning screen media,but Flex-Mat 3 has a longer wear life.”

Flex-Mat 3 Tensioned Series D is now installed onboth of Sylvania Minerals’ triple deck wash screenboxes. Production has gone from 39 tons per hour toan impressive 80-85 tons per hour, more thandoubling the production of minus 1/2-inch by plus3/8-inch limestone, which is a premium productused in asphalt. The production of other washedproducts also increased.

“The durability of Flex-Mat 3 screen media hasmeant far less time performing maintenance andchanging screens, saving valuable operating hours,”says Begley. The plant can now run fewer hours andstill put more material on the ground. “The only chal-lenge now is that the tertiary crusher feeding thewash screens can’t feed material fast enough to keepup with the new Flex-Mat 3 screen media.”

Problem solvingBegley wasn’t completely surprised by the perform-

ance of Flex-Mat 3 as he had experience with theproduct while working in one of Great LakeAggregates’ other quarries a few years earlier. “Wewere experiencing severe blinding; it was so bad thatevery 90 minutes the operation would shut down for20-30 minutes to beat the blinded material out of thescreen media with a hammer. The quarry switched toFlex-Mat 3 and never had a problem with blindingagain.”

Another challenge faced by Sylvania Minerals wastheir overflowing settling ponds. Their initial solutionwas just to build another settling pond but the$100,000 price tag made exploring other optionsmore appealing. In another area of the plant, theyinstalled Major Wire’s HyperSlot screen media. It is aslotted screen media with unique alternating crimpedand straight wires. These provide an uneven surfacewith one straight wire followed by one crimped wire.The crimped wire causes the material to slow downgiving the material more time to pass over the open-ings, resulting in better fines removal.

Since installing HyperSlot screen media on thebottom deck, quarry personnel have noticed a 50percent decrease in material entering the settlingpond, down from the former 220 tons per hour toonly 110 tons per hour. The change to HyperSlotscreen media has allowed the quarry to delay the cre-ation of an additional settling pond while providinganother saleable product. For more product informa-tion visit www.majorwire.cc .

A blast produces new shot rock ready for crushing.

Great Lake Aggregates installed Flex-Mat 3 TensionedSeries D on both the top and middle screen decks toimprove throughput and for its longer wear life.

One of two screen decks at Great Lakes Aggregates screens limestone flawlessly using Major Wire's Flex-Mat 3 screenmedia.

Great Lakes Aggregates' South Rockwood, Michigan facility produces nearly 1 million tons of limestone products eachyear.

6 • March 2014 NORTH AMERICAN QUARRY NEWS

R E S E R V E ,LOUISIANA — Louisianabased DSC Dredge, LLCwill have its experts inindustry-leading cus-tomized dredge tech-nologies available atCONEXPO-CON/AGG2014 for questions anddiscussion in booth30040 in Central Hall 1.For over 20 years thecompany has been fo-cusing its expertise onthe design and manufac-ture of customizedportable cutter suctiondredges of all sizes andapplications for thedredging markets. DSCDredge units are in usethroughout the world inconstruction, environ-mental, mining, naviga-tional, recreational,restoration and specialtyapplications.

Since every applicationhas unique characteris-tics, DSC Dredge has de-veloped its specializationin customizing standarddredge platforms to meet

the challenges of eachcustomer. Prior to mak-ing any recommenda-tions, the company goesthrough a rigorousprocess of establishingthe application parame-ters. This informationmay include factors suchas dredging depths,types of materials, dis-tance and elevation todischarge, portability re-quirements and accessto power grids. Only thenwill the company recom-mend a specific solutionbased on the actual ap-plication and customerrequirements. Units arethen built to order in oneof three manufacturingfacilities to the exactspecifications required.Customers are encour-aged to visit the facilityat any time in the buildprocess and to followtheir unit through man-ufacturing, delivery,commissioning and on-site training completion

DSC Dredge’s dredg-

ing solutions are basedon a number of applica-tion specific platformsthat are then cus-tomized to match thespecific application. TheMarlin Class deep min-ing dredge has been de-signed as an efficientmethod for excavatingdeep mining depositswith its underwaterpump system and hightorque cutter drive. TheShark Class cutter suc-tion dredge is a tough,yet portable design mostcommonly used in thesand and aggregate pro-duction arena. Oftencalled the contractor’s“dream machine,” theBarracuda Class dredgefeatures a swinging lad-der design used most of-ten in waterway mainte-nance and lake revital-ization projects. DSC’sMoray Class convention-al/swinging ladderdredge was designedaround the concept of aversatile design in a

smaller portable pack-age unmatched in theindustry, often used inthe environmentalcleanup and irrigationapplications. Roundingout the line are the Bad-ger Class and theWolverine Class dredges,designed for the contrac-tor with a compact yetportable design that isfully functional by oneoperator. Several of theDSC Dredge platformsare available with elec-tric power for applica-tions requiring sustain-able attributes.

DSC Dredges are inuse throughout theworld, from Chile to theCanadian Oil Sands,from the rivers of Nigeriato the heartland of Amer-ica, helping their cus-tomers to achieve maxi-mum dredging efficiencythrough customized de-sign to exacting specifi-cations. Stop by thebooth and visit with theexperts in customizedsolutions for your dredg-ing challenges.

DSC Dredge, LLC ad-vances the engineering,automation, manufac-turing and quality ofcutter suction, clamshelland underwater pumpmining dredges. Thecompany operates fromthree major manufactur-ing facilities located inReserve, LA, Poplarville,MS and Greenbush, MI.For more informationabout the company andits products and servic-es, please visit www.dsc-dredge.com .

NORTH AMERICAN QUARRY NEWS March 2014 • 7

Experts in customized solutions for dredging challenges to exhibit at CONEXPO-CON/AGG 2014

DSC Dredge units are in use throughout the world in construction, environmental,mining, navigational, recreational, restoration and specialty applications.

Since every application has unique characteristics,DSC Dredge has developed its specialization incustomizing standard dredge platforms to meet thechallenges of each customer.

DSC Dredge, LLC advances the engineering,automation, manufacturing and quality of cuttersuction, clamshell, and underwater pump miningdredges

The Barracuda Class dredge features a swingingladder design used most often in waterwaymaintenance and lake revitalization projects.

8 • March 2014 NORTH AMERICAN QUARRY NEWS

FEATURE STORIESQuarry experiences production leap after switch to Flex-Mat 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

by Gary Pederson, VP of sales for Major Wire Ind. Limited

Experts in customized solutions for dredging challenges to

exhibit at CONEXPO-CON/AGG 2014 . . . . . . . . . . . . . . . . . . . . 7

Paladin Attachments tools and coupler systems at CONEX-

PO-CON/AGG 2014 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Superior Industries highlights conveyor component innova-

tions at CONEXPO-CON/AGG 2014 . . . . . . . . . . . . . . . . . . . . 18

BMC Rock uses mobile equipment to develop granite quarry

in Southside Virginia. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-23

by Karl H. Kazaks

Classifieds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-26North American Quarry News is published monthly by

Lee Publications, P.O. Box 121, 6113 St. Hwy. 5,

Palatine Bridge, NY 13428

Standard Class Postage Paid at Palatine Bridge, NY 13428

POSTMASTER: Send address changes to: Lee Publications, P.O. Box

121, Palatine Bridge, NY 13428.Publisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Frederick W. LeeVice President, Production . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mark Lee Vice President and General Manager . . . . . . . . . . . . . . . . . . Bruce ButtonEditor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Jon M. CaseyEditorial Assistant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Kathleen LeeComptroller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Robert MoyerProduction Coordinator. . . . . . . . . . . . . . . . . . . . . . . . . . . Jessica MackayPage Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Alison SwartzShop Foreman. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Harry DelongSubscriptions/Circulation . . . . . . . . . . . . . . . . . . . . . . . . . . 888-596-5329

MAIN OFFICE: Palatine Bridge, NY 13428

518-673-3237 - FAX# 518-673-2381Wendell Jennings (Sales Manager) . . . . . . . . . . . . . . . . . . . . 518-673-0114Janet Stanley. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315-679-3588Michelle Kruglak . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518-673-0135Brian Johnson . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518-673-0161Tina Krieger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518-673-0108Jan Andrews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518-673-0110

REGIONAL SALES OFFICES

Scott Duffy (NH, VT, ME) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 802-484-7240Ian Hitchener (So. NE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 518-210-2066Wanda Luck (Carolinas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336-416-6198

NATIONAL TRADE SHOW SALES Ken Maring, Trade Show Manager

888-355-5080 or 518-673-0103

North American Quarry News will not knowingly accept or publish advertising which is fraudulent or misleadingin nature. The publisher reserves the sole right to edit, revise or reject any and all advertising - with or withoutcause being assigned - which, in his judgement, is unwholesome or contrary to the interest of this publica-tion. North American Quarry News assumes no financial responsibility for typographical errors in advertise-

ments; but, if at fault, will reprint that portion of the ad in which the error appears. Publisher accepts no finan-cial responsibility for ads which do not appear due to any circumstance.

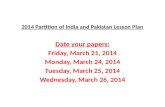

ADVERTISE!All advertising materials must be submitted on or before the advertising deadlineslisted below. North American Quarry News is published monthly. In the event thatcopy changes are not received by the ad deadline, contracted advertiser’s copythe previous issue will be inserted.

April/May 2014Advertising Deadline:

April 4, 2014

June/July 2014Advertising Deadline:

May 30, 2014

CONTRIBUTE!North American Quarry News is circulated to 20,000 mine and quarry owners

and operators by Lee Publications, Inc. Designed to bring news to those involvedin the aggregate industry from the mines and quarries to the end users, NorthAmerican Quarry News includes new products, technology updates, associationnews, people in the news, company profiles, and current events.

We invite you to send us your news! Send your news by mail, fax, or e-mail to:

Jon M. Casey, EditorNorth American Quarry News6113 State Highway 5Palatine Bridge, NY 13428FAX: 518-673-2699E-MAIL: [email protected]? Call 717-258-6775

Stories on quarries from

coast to coast will be

featured! If you’d like us to

do a story on your

operation, call the editor to

set up an interview!

Cover Caption: Quarry Manager, Bill Begley and Major WireManager Brad Rice worked together to improve production atGreat Lakes Aggregates.

TABLE OF CONTENTS

NORTH AMERICAN QUARRY NEWS March 2014 • 9

PEORIA, IL — JoshSwank, vice presidentof sales and marketingfor Philippi-Hagenbuch,Inc. (PHIL) is happy toannounce the signing ofa licensing agreementwith Mr. Håkan Johan-nesson, vice president

of CeDe Group ofMalmö, Sweden thatcommenced on Dec. 6,2013. Under the termsof this partnership,PHIL is licensing itsRear Eject Technologyfor use in off highwaybody applications with-

in the construction andmining sectors to CeDefor use in Europe, theMiddle East, Africa andAustralia. Rear ejectbodies manufacturedunder this licensingagreement by CeDe andshipping into Europe,

the Middle East andAfrica will be brandedas CeDe products andbodies shipped intoAustralia will be brand-ed under the PHILbrand name.

“The CeDe Group isan outstanding compa-

ny that engineers andmanufactures a diverseline of equipment forthe construction andmining industries. Be-cause of its close prox-imity to the Port ofMalmö and close coop-eration with Volvo CE,CeDe is able to buildcustomized equipmentfor Volvo CE products,install its products onthe prime machinesand ship them as aturn key solution directto the dealer or enduser globally. Thisagreement will helpPHIL expand into theEuropean, Middle Eastand African marketswith our rear eject bod-ies, and it will helpCeDe further expandinto customized articu-lated hauler solutions”said Swank.

PHIL Engineering,headed by its Chief En-gineer LeRoy Hagen-buch, P.E. has led theglobal off-highwayhaulage industry inrear eject technology. In1985, PHIL released itsfirst rear eject productfor use in a landfill en-vironment, hauling re-fuse. Since this time,PHIL and Mr. Hagen-buch have amassedmultiple U.S. and glob-al patents on rear ejecttechnology.

CeDe Group is a fastgrowing engineeringcompany with its headoffice in Malmö, Swe-den. Development andproduction are strongly

linked, as the whole op-eration is under thesame roof. This con-tributes to dynamic andinnovative solutionswhere ideas are shapedinto ready to use ma-chines. In the expansiveÖresund region of Swe-den, CeDe develops andmanufactures specialapplications and com-plete machines. Themajority of its cus-tomers are world lead-ing companies withinthe mining, construc-tion and offshore indus-tries throughout Eu-rope, the Middle East,Africa, and Australia.

Located in Peoria, Ill.,Phi l ippi-Hagenbuch,Inc. has been buildingequipment for off-high-way haul trucks since1969, and become theglobal leader in off high-way truck customiza-tion. In addition to cus-tom trailers, truck bod-ies, lowboy trailers, ve-hicle recovery tools(VRTs) and rear ejectbodies, Philippi-Hagen-buch designs andbuilds tailgates and wa-ter tanks for nearlyevery make and modelof articulated and rigidframe off highway truckavailable.

For more information,contact Philippi-Hagen-buch, 7424 W PlankRd., Peoria, IL 61604.Call 309-697-9200, tollfree 800-447-6464, e-mail [email protected] or visitwww.philsystems.com .

Philippi-Hagenbuch licenses rear eject body technology to CeDe Group of Sweden

Featuring safety, stability and increased productivi-ty as hallmarks of its design, Philippi-Hagenbuch’spatented line of rear eject bodies offer the idealsolution for challenging hauling applications.

10 • March 2014 NORTH AMERICAN QUARRY NEWS

Hard Hat Expo is Produced by the Trade Show Division of Lee Newspapers, Inc.

Publishers of Hard Hat News • P.O. Box 121, 6113 St Hwy. 5, Palatine Bridge, NY 13428

FOR MORE INFORMATION CALL 1-800-218-5586

NEW LARGER BUILDING !!NEW DATES !!

NOW HELD IN THEEXHIBIT CENTER!!

MARCH 19-20MARCH 19-20

20142014NEW YORK STATE FAIRGROUNDS

SYRACUSE, NY WEDNESDAY 8-4 • THURSDAY 8-3

28thConsecutiveYear

HARD HAT EXPOHARD HAT EXPO

NORTH AMERICAN QUARRY NEWS March 2014 • 11

A non-fatal accident occured whena bulldozer overturned on an em-bankment, rolling onto a bench be-low. Low temperatures and frozenground created the condition, whichled to the accident.

Best Practices1. Conduct adequate examinations

of working areas especially during ad-verse weather conditions. Additionalexaminations may be needed wherefrozen ground exists;

2. Train examiners to know the haz-ards of frozen ground (equipment canslide and sudden ground failures canoccur);

3. Correct hazardous conditions be-fore equipment is operated or groundis travelled upon;

4. Operate equipment within its de-sign limitations;

5. Clear outslopes of large rock orstumps where track mounted equip-ment will operated;

6. Install roll over protection (ROPS)and wear seatbelts at all times;

7. Install adequate lighting on mobileequipment that operates at night orduring adverse weather conditions;

1. Conduct pre-operational checksbefore mobile equipment is operated.Report hazards to management; and

8. Maintain two way radio commu-nications between mobile equipmentoperators and all personnel in the

vicinity.A non-fatal accident occurred when

a bulldozer broke into a cavity in araw coal stockpile above the feeder.The bulldozer cab was completely cov-ered and the operator was entrappedfor approximately four hours beforebeing rescued.

Best Practices1. Use enclosed cabs with rollover

protection in stockpile areas;2. Install two means of two way

communication in the bulldozer, withone powered by an independent pow-er source;

3. Maintained communication at alltimes with the feeder control roomand the bulldozer operator;

4. Install two 60 minute oxygen gen-erating SCSRs in the bulldozer andinspect them during pre-operationalchecks. Mount the SCSRs overheadand train operators in their use;

5. Install an independent lightsource;

6. Install 40 psi cab window glass orchemically treat with a proper windowsupport system;

7. Provide a remote controlled stopdevice in the cab that can shut off re-claim feeders and belt conveyors; abd

8. Mark feeder areas of the coalstockpile with a suspended markernear the center of each feeder.

MSHA Safety: Bulldozer accidentprevention alert

www.quarrynews.com

12 • March 2014 NORTH AMERICAN QUARRY NEWS

Central Hall Booth #51829

Your Trade Newspapers for

Heavy Construction, Quarry &

Aggregate Production,

Waste Reduction and Recycling

Central Hall Booth #51829

Come See Us At

- Safe andEasy to Use

- Economical- Reliable

RockFrac® Rock Splitting Mortar is the answer when your job calls for thedemolition of rock or concrete by non-explosive or low vibration means. RockOutcroppings, Boulders or reinforced concrete can be easily split and fractured,speeding its removal.• Eliminate: vibration from blasting, fly rock, permitting, seismic and

explosives monitoring.• Minimize vibration from large breakers.• Exploits the Tensile strength of even the hardest rock.• Reduces removal time, saving time and money.• The Fracturing increases productivity of equipment.• Environmentally friendly.

Visit Us At CONEXPO-CON/AGG • Booth 51403 Central Hall

ENTERPRISING EUROPA, INC., 439 ROUTE 17N, MAHWAH, NJ 07430 USAPHONE: 201-236-0969 FAX: 201-584-0229

WEB SITE: ROCKFRAC.COM EMAIL: [email protected]

DEXTER, MI — Paladin Attachmentswill showcase their market leading cou-pler systems and attachment tools atCONEXPO-CON/AGG 2014 in Booth12203, North Hall. The Paladin leadingbrands include Bradco, CP, Custom-Works, FFC, Harley, JRB, McMillen andSweepster. With these eight leadingbrands and four primary manufactur-ing operations in the US, the companyhas more than 300 years of combinedexperience in the design and manufac-ture of hundreds of attachments andcouplers for the construction, roadbuilding, aggregate, excavation, land-scaping, agricultural, forestry, vegeta-tion management, municipal and utilitymarkets. With more than 20 territorymanagers actively supporting morethan 2,000 dealer and rental store loca-tions, and with the active support ofleading OEM partners, Paladin isuniquely positioned to provide thebroadest product line and market sup-port in North America.

Paladin will spotlight the newest ad-ditions to the company’s product line-up, which join an arsenal of hundredsof attachments and coupler systems.Paladin’s extensive JRB product linewill be represented with the popular

PowerLatch™ coupler with new Power-Fill™ bucket, the Grapple and theSmartLoc™ couplers for excavators,the new Cast wheel joader coupler, thenew Roll Out bucket and the new Tiltbucket for wheel loaders. The Bradcoproduct line will be represented by thenew FME40 Flail Mower mini-excava-tor attachment, the new Extreme DutyGround Shark™ Brush Cutter, theRock Trencher and the Cold Planer.The Sweepster Heavy Duty HopperBroom and VCS Vacuum Sweeper willbe displayed along with a Harley Pow-er Box Rake and a McMillen Augersystem. The company’s CustomWorkscapabilities will be highlighted toround out the booth.

Paladin Attachments is a leadingmanufacturer of couplers and attach-ments throughout North America andparts of the world for the construction,aggregate, agriculture, landscaping,land clearing, recycle, mining, demoli-tion, utility, and municipal market seg-ments. For more information about Pal-adin’s entire coupler and attachment of-fering, call 800-456-7100, fax 734-996-9014, e-mail [email protected] or visit www.paladinat-tachments.com.

Paladin Attachments tools and coupler systems at CONEXPO-CON/AGG 2014

The Atlas Copco HS1 screeningplant is built for high productivitywith its sorting efficiency, mobilityand easy maintenance. Supplement-ing the Atlas Copco range of crush-ers, the single deck HS1 screener en-ables customers to produce two sal-able products or to run the crusherin closed circuit with a recirculatingconveyor. In certain applications thisincreases the quality and shape ofthe material.

The screen box has large clear-ances to help eliminate blockageseven when the crusher is producinghigh output volumes. The re-circu-lating conveyor option deposits over-size materials directly back into thehopper of the crusher.

At just 22-feet 9-inches long by 6-feet 6-inches wide, it has superiortransport capability. Since the HS1is mounted on the crusher, it movesaround the jobsite with ease, en-abling quick and easy onsite grading.

Atlas Copco HS1 screener

Atlas Copco HS1 screener.

Neponset, IL — Bulkmaterial handlers nowhave a proven solutionfor blocked vessels andplugged dischargechutes, one that will re-move buildups, reclaimlost material and restoredesign capacity and flow

rates. In most casesMartin® Silo Solutionseliminate the need forconfined space entry andhazardous cleaningtechniques such as ex-plosives, water and airlancing, typically allow-ing the material to be re-

captured and returnedto the process stream.

Technicians from Mar-tin Engineering use re-mote controlled equip-ment from the top of thevessel to safely addressblockages. With nearly70 years of experience in

solving material flowproblems, the companyemploys highly trainedspecialists who are safe-ty certified to currentOSHA and MSHA stan-dards.

Most cleaning projectsare performed with the

Martin® Heavy DutyWhip, a portable, remotecontrolled tool that canbe lowered into storagevessels through a man-hole opening. Poweredby compressed air, theHeavy Duty Whip can beequipped with a varietyof flails and cuttingedges to knock down ac-cumulated materialwithout damaging stor-age vessels. Abrasion re-sistant steel chain isbest suited for most ap-plications, with non-sparking brass chain forcombustible materials.Urethane flails can also

be employed to protectlined vessels that couldbe susceptible to damagefrom metal tools.

“With this technology,the need for confinedspace entry is greatly re-duced,” observed MartinEngineering Silo SalesSpecialist Marty Yepsen.“The equipment can beset up quickly outsidethe vessel, and it’sportable enough to moveeasily around variousbin sizes and shapes.”

The Martin HD Whipuses a modular boom

NORTH AMERICAN QUARRY NEWS March 2014 • 13

WEAR PARTS FOR EAGLE IRON WORKS® EQUIPMENT

FOR YOUR EAGLE IRON WORKS® EQUIPMENTREQUIREMENTS, WE SUPPLY QUALITY AFTERMARKETCASTINGS, MACHINED COMPONENTS, OUTBOARDBEARING ASSEMBLIES, SEAL KITS AND MUCH MORE!!

TOLL FREE: [email protected]

4530 Andrews Street, Suite LNorth Las Vegas, NV 89081

Local: 702-643-6888 Fax: 702-643-6898

AGGREGATEEQUIPMENT SALES

Equip Sales & Leas-ing Corp. and its em-ployees have a com-bined 50 years of expe-rience in the crushing,screening and recyclingindustry. They have op-erated and sold variousmakes of crushers andscreeners, but when itcame to the decision ofwhich machine thecompany wanted torepresent and add to itsrental fleet, the Rock-ster Duplex System wasthe ideal fit.

The unique DuplexSystem was a strong

argumentJoe Collazo, sales

manager of Equip Salessays: "Rockster crushershelped fill the void in thefleet as we didn't have aclosed circuit machinecapable of producingspec material, and thefact that the machinecan be switched fromJaw to Impactor made it

an even easier decisionfor our company. Theunique design of the du-plex system allowed usto get maximum utiliza-tion of the machine, as itcan be used in variousapplication from virginstone to recycled asphaltand concrete." Rocksterhas developed the du-plex system which hasbeen patented for al-ready eight years now. Itenables the exchange ofimpact crusher and jawcrusher and vice versaon one basic chassiswithin a few hours. Thistechnology allows flexi-ble recycling, operatingwith hard stone, as-phalt, concrete or anyother C&D. The hydro-static drive system pro-vides the technical basefor this highly sophisti-cated system: It allows acontinuous variation ofthe crusher speed aswell as a clockwise or

anti-clockwise operationof the crusher (or viceversa). Through thisdrive system Rockster'scustomers have the ad-vantages of a great oper-ation convenience, anddue to the absence of aconventional clutch it isfree of wear. Moreoverthe maintenance is sim-ple and high perform-ance across all applica-tions due to an optimal

adaptation to the vari-ous requirements isguaranteed.100 percent defined

final grainMoreover the ideal

measures of the ma-chine which allow totransport the crusherincluding the screeningbox and the return beltwith one truck were im-portant for choosingRockster machines.

Equip Sales putsgreat emphasis on goodperformance and needshigh value, cubic finalgrain so they chose theoptional screening boxand the return belt towork with a closed cir-cuit and produce 100percent definable finalgrain. Additionally youhave the possibility touse it as stockpile

conveyor with a dis-charge height of up to 4meters.

Mr. Collazo is verysatisfied with Rockster:"Three years and almost4000 hours later themachine continues toperform and shock ourcustomers with its pro-duction and materialquality despite its com-pact size."

Equip Sales’ customers are highly satisfied with performanceand material quality

Equip Sales crusher Rockster R900 in operationwith demolition debris. With the additional screen-ing system you get 100% defined final grain.

Equip Sale's owns the first Rockster R800/900DUPLEX in the USA.

Silo cleaning solutions without confined space entry

Silo 14

arrangement that extends from 7-feet up to 28-feet and can clean ves-sels up to 60-feet in diameter and225-feet tall from a single centralopening of just 18-inches. The pneu-matic cutting head delivers powerfulwhip action from the rotating head toremove buildup from walls. The hosereel easily separates from the boomassembly for transportation and set-up in tight spaces.

“There are competing systems thatutilize hydraulics, but they tend to beheavy and cumbersome,” said MartinEngineering Territory Manager JimDensberger. “And they present thepossibility of a fluid leak, which couldcontaminate otherwise-salvageablematerial. The whip requires no hy-draulics; it needs just 90 PSI and 100CFM, which can usually be suppliedfrom a plant’s existing air system.”

Densberger added that some pneu-matic cleaning systems require veryhigh air volumes, often as much as

1,200 CFM. “To achieve that kind ofpressure, the diesel compressorrental alone can be more than $1,000a day, and the fuel bill for a full day’swork could be half again as much,”he said. “Then there’s the cost to ac-tually do the work.”

Potential damage to the storagevessel can also be an issue. Somecleaning technologies use the veryhigh pressure to blow air through ahose that’s simply dropped into anaccess hole at the top of the vessel.At the end of the hose is a tool with arestricted nozzle, which causes the“cleaning head” to thrash about ran-domly. While this technique worksin large blockages, it provides littleor no control, and as the head getscloser to the vessel wall, it has anequal chance of taking out a chunkof the silo as it does hitting materialfor removal.

For extreme blockages where hard-ened lumps of material have pluggeddischarge chutes, silo cleaning tech-nicians also use the Martin® Buster,

which safely dislodges blockages bythe powerful force of expanding CO2gas. The technique employs non-ex-plosive generators that cause rapidgas expansion to fracture chunks andcompacted material, opening the dis-charge and restoring normal flow.

When bridged or arched materialcreates a no flow condition, techni-cians can rely on the Martin Drill tobore through tough clogs. The drill’spowerful hydraulic action drives itsway through blockages, clearing apathway at depths up to 150-feet.

Martin Engineering’s Silo Solutionsare provided as a turnkey service.The company’s fully-equipped teamsbring all required equipment and per-sonnel directly to customer sites.Many facilities are able to remain inoperation during vessel cleaning, butwhen conditions require a shutdown,technicians work evenings, weekendsor holidays to accommodate cus-tomer schedules.

Silo cleaning services from MartinEngineering are backed by the com-

pany’s total satisfaction guarantee.If any customer is dissatisfied afterone full shift, the crew will return toheadquarters without charge.

Founded in 1944, Martin Engineer-ing is the world leader in makingbulk materials handling cleaner,safer and more productive. The com-pany supplies flow aids and conveyorproducts around the world for a widevariety of bulk material applications,including coal, cement / clinker,rock / aggregate, biomass, grain,pharmaceuticals, food and other ma-terials. The firm is headquartered inNeponset, IL, offering manufactur-ing, sales and service from factoryowned business units in Brazil, Chi-na, France, Germany, Indonesia,Mexico, South Africa, Turkey, Indiaand the UK, and under exclusive li-cense with ESS Australia. For moreinformation, visit www.martin-eng.com or call 309-852-2384. Glob-al representatives for Martin Engi-neering can be found at www.martin-eng.com/rep-finder.

14 • March 2014 NORTH AMERICAN QUARRY NEWS

CAPITAL EQUIPMENT COMPANY9714 Ensley Lane

Leawood, KS 66206

John Mabry816-830-6421

KORTE BROS., INC.620 W. Cook Rd.

Fort Wayne, IN 46825

260-497-0500email:

MEAD EQUIPMENT, INC.16659 Stonecrest Dr.

Conroe (Houston), TX 77302

TX, LA, NM

SWANSTON EQUIPMENT CORP.3450 Main Ave.

Fargo, ND 58103

701-293-7325

REQUIP MACHINERY LTD.Camrose, Alberta, Canada

702-423-1500 • 780-226-9223email:

Silo from 13

Avoid the pitfalls of buying or sellingequipment yourself!

What to look for:

1) A large company with a sound trackrecord of success:• Apollo Equipment.net has over 16 years of experience, is family-owned, and is part of a group of companies—Grinder Wear Parts and Grinder Rebuild Specialists—specializing inserving the wood waste industries.

2) A company which has an excellent multichannel marketing system:• Apollo Equipment.net has an award-winning website withglobal exposure. Our equipment specialists are trained andknowledgeable, not only in equipment but in buying and selling strategies. We have a database of over 9000 wood wasteindustry clients that we are in constant contact with. We alsopromote our equipment through many channels: email, flyers,webinars, videos, blogs, social media, trade shows, face-to-faceand, of course, through phone communication. We are active,not passive!

3) Unbiased representation:• Apollo Equipment.net brokers all the major wood wasteequipment brands which allows our clients a large selection ofmachines as well as the ability to find the best fit to help reduce your operating costs, increase production, and grow yourbusiness.

FEATURED LISTING:

2005 Express Blower TM-20 Roll-off

with 1999 International 9400 Daycab/Trailer $109,900

NORTH AMERICAN QUARRY NEWS March 2014 • 15

HAYDEN-MURPHY EQUIPMENT COMPANY

2013 DOPPSTADT SM720 S/N 655. 100 HOURS, 1/2” DRUM& 1 1/2” DRUM, STOCK NUMBER0018883. CALL FOR PRICING.

2008 FACTORY RECONDITIONEDDOPPSTADT AK630 HIGH SPEEDSHREDDER WITH 6 MO. P&LWARRANTY, AND NEW MERCEDESENGINE WITH FULL WARRANTY.

2011 DOPPSTADT 3060 K S/N 121. SLOW SPEED SHREDDER. CALL FOR PRICING.

Serving Our Customers For 57 Years

www.hayden-murphy.comMinneapolis, MN 55420

(800) 352-2757

16 • March 2014 NORTH AMERICAN QUARRY NEWS

(1) 36”x60’ Truss Conv, complete, less supp. $8,500; (2) 36”x70’ Truss Conv, complete, less

supp. $9,500/ea.; (1) P-Screen 36”x90’Truss, complete, less supp. $17,500; (1) 36”x100’Truss

Conv, complete, less supp. $19,500; (2) 36”x140’Truss Conv, complete, less supp. $22,500/ea.;

(1) 36”x150’Truss Conv, complete, less supp. $22,500; (1) 42”x50’Truss Conv, complete, less

supp. $10,500

GROVE RT 522 RT Crane, 22 ton cap, Det Dsl 453 eng. 4x4 drive, 4

way steer, 20.5x25 tires @50%, 70’ boom, 23’ jib, Hook Block, new

paint. . . engine rebuilt . . . F.O.B. Sylacauga, Alabama . . . . .$32,500

KOLBERG 44”X32’ Single Screw Sand Washer, outboardgrease bearing, NEW Urethane liners, elec drive, new paint,stand (98) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$29,500

Custom built 30 x 50 Towable Channel Frame Conveyor

with 5th wheel towing, dual tired, axle assembly with belting

and electric drive. F.O.B. Sylacauga, AL . . . . . . . . . . .$23,500

(2) each DUNBAR model Z160 Clamshell Loaders 15’ reach, 1 cubic

yd hyd clamshell bkt, rated 10,600 lb @ 10’ radius, elect hyd driven,

pedestal mount ..............................................................$15,000 each

(4) 36”x80’ Portable Conveyor, complete, truss . . . . . .$17,500/ea.

(1) 36”x85’ Portable Conveyor, complete truss . . . . . . . . . .$18,500

(1) 30”x50’ Portable & Roadable, fifth wheel, weigh scale, complete

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$18,500

KOMATSU WA600-6 Wheel Loader, 6,900 hours, with encl cab, air

cond, 65/36-33 L5 tires ranging from 20% WR to 50% WR, 8.5 Yd

Bkt w/teeth, excellent cond (08) . . . . . . . . . . . . . . . . . . .$325,000

Falling Model 1500 Truck Mounted Combination Rotary Drill/Well Drill,

SN:999-563, with 20’ mast, 2-3/4” drill steel - 30’, bit sub, casing pusher,

and air injection system, mounted on a 1989 FORD F700 Chassis with

diesel engine, 5 speed automatic transmission, 167,000 miles showing on

odometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F.O.B. $23,500

KOMATSU PC 1250LC-7 Excavator, 17,000 hours, NEW UNDER-CARRIAGE, FOPS Cab, Std Boom/Stick, 9.5 Yd. bkt w/teeth, air cond,nice machine (05) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $475,000

EAGLE IRON WORKS 44”x32’ Sand Screw, Elec, New Outboard bearing, NEWLINERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$28,500EAGLE IRON WORKS Twin 36”x25’ Sand Screw, elec, urethan liners, speedreducer, hydrotex bearing, support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$28,500EAGLE IRON WORKS Twin 36”x25’ Sand Screw, elec, steel liners, open geardrive, hydrotex bearing, support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$16,500

GROVE RT 65S Hydraulic RT Crane, SN: 31415, Cat dsl.eng., 35 ton cap., 104’ bm., 32’ jib, hook blk., ball, 29.5x25tires (70%), block & ball, painted (74) . . . . . . . . . . .$39,500

STAMFORD

165KW Diesel

Generator, Iveco

dsl eng, 1,800 hrs,

with power control

center with circuit

breaker/starters,

inside 45’ van with

fuel tank and

exhaust . . .$28,500

EARTHMOVING EQUIPMENT(2) DUNBAR 1 Cu. Yd. Articulating Clamshell Machines, 15’ reach, 1.0 yd. clamshell

bkt., stationary mount, electric/hydraulic drive & controls ................$15,000 EachEFFICIENCY 3,000 Gal. Water Tanker w/ gasoline fill pump for insert into 16 yd. dump

body ..............................................................................................................$9,500FRUEHAUF 3,500 Gal. Water Tanker w/ gasoline fill pump on two axle carrier w/ fifth wheel ..

......................................................................................................................................$9,500KOMATSU PC 48R-8 Excavator, 10,000 Lb., 3,400 Hrs, 24” bucket, OROPS, level blade

(00)..............................................................................................................$28,500KOMATSU PC 1250LC-7 Excavator, 17,000 hrs, NEW UNDERCARRIAGE, FOPS Cab,

Std Boom/Stick, 9.5 Yd bkt w/teeth, air cond, nice machine (05) ............$475,000KOMATSU WA600-6 Wheel Loader, 6,900 hrs, with encl cab, air cond, 65/36-33 L5

tires ranging from 20% WR to 50% WR, 8.5 Yd Bkt w/teeth, excellent condition(08)............................................................................................................$325,000

LIEHBERR R974HD Hydraulic Excavator, Liehberr dsl. engine, mass excavat boom/tip,6.0 cu. yd. bucket w/ teeth, A/C ..................................................................$75,000

TEREX 3305B Hauler, Det. dsl., bed liners, good tires (77) ..............................$26,500(2) Lube/Fuel Bodies w/ (5) each lube/oil tanks w/ air discharge, air comp., 600 gal. dsl.

tank ......................................................................................................$9,500 EachWORTHINGTON 600CFN Portable Air Compressor, Cum diesel, runs good (70) ........

......................................................................................................................$8,500CRANES & LIFT EQUIPMENT

CLARK 250 30,000 lb. Forklift, gas/propane, 15’ & 21’ mast ............................$25,000GROVE RT 65S Rough Terrain Crane, 35 ton cap., Detroit diesel eng., 4x4 drive, 4 way

steer, one winch, 104’ boom, 32’ jib, blk. & ball (74)..................................$39,500GROVE RT58 RT Crane, 14 ton cap., Detroit diesel, 4x4x4, 60’ bm, 30’ jib, blk. (74)....

....................................................................................................................$15,000GROVE RT 522 RT Crane, 22 ton, Detroit diesel, 70’ + 23’ (79)........................$32,500MANITOWOC 2900 T Series II Lattice Trk Crane, 8x4, rated 70 ton cap., Cummins

diesel up/Cummins diesel down, 2 drums, 160’ boom, 50’ jib, blk.............$79,500NATIONAL 6T56 Boom Truck, 10 ton cap, 56’ boom, rear out, on Ford F800 chassis, Dsl

(78) ..............................................................................................................$16,500

ASPHALT EQUIPMENT

BEARCAT 2,500 Gal. Asphalt Distributor, hydrostatic drive (PTO) air controls, 14’ spray

bar, on Ford F800 w/ V8 gas engine (78) ..................................................$18,500

CONCRETE EQUIPMENT & PLANTS

(30) Used Ready Mix Trucks - Macks, Volvos, Int’l - front & rear discharge - various ages

................................................................................................................................P.O.R.

(3) Stationary Baghouses, 5,000 CFM to 7,500 CFM ..........................................P.O.R.

FEEDERS

ALLIS CHALMERS 54" X 20' Vibrating Grizzly feeder, on stand, with electric motor

(1994)..........................................................................................................$28,500

SAUNCO 36S Feeder, electric w/ box ................................................................$12,500

Four (4) SYNTRON 36” High Frequency Feeders, complete w/controls (94) $9,500/Ea.

18”/24”/30” Belt Feeders up to 20’ long, electric ..................................................P.O.R.

(3) 36”x90’ Channel Conv, complete, less supp & belt ............................$13,000/ea.

(1) 36”x100’ Channel Conv, complete, less supp & belt ................................$15,000

(1) 36”x120’ Channel Conv, complete, less supp & belt ................................$18,500

(1) 36”x200’ Channel Conv, complete, less supp & belt ................................$22,500

KOLBERG MODEL 2516T Crawler Mounted Direct Feed Screening

Plant, 1,233 hours John Deere dsl. eng., feeder with fold down hopper,

5’x16’ DD Incl Screen, two sided foldable discharge conveyors and one

rear 48” discharge conveyor, ground controls, remote tram controls

(08) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$95,000

FINLAY Model 8B30 Port Screening Plant, electric with a feed

hopper, 30” feed belt, 4’x8’ DD Incl Vib Screen, highway towable, good

condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$28,500

SUGGSEQUIPMENTSALES, INC.

Yard Location: 45245 U.S. Highway 280, Sylacauga, Alabama 35150

Mailing Address: P.O. Box 381116, Birmingham, Alabama 35238-1116

877-241-7756 Fax: 205-980-5766 • [email protected]

Celebrating Our 19th Year in Business

Domestic Sales Representative

Christopher A. “Chris” Suggs

45245 U.S. Highway 280

Sylacauga, AL 35150

Phone: 205-470-5161

Email: [email protected]

Manager of Logistics

and Internet Sales

Janice Folden

Phone: 205-240-9635

Email: [email protected]

International Sales

Representative

Bobby G. Suggs

P.O. Box 381116

Birmingham, AL 35238-1116

Phone: 205-281-9370

Email: [email protected] site: www.suggsequip.com

All Prices are F.O.B stocking location and are subject to prior sale. Prices do not include disassembly and loadout of the equipment. Equipment is representedas accurately as possible but specifications are not guaranteed. All equipment is offered “AS IS” with no warranty and is subject to applicable sales tax.

CATERPILLAR 400KW (500KVA) Diesel Generator, Cat 3208B Dsl. eng.,

enclosed, on skid, 240/480V-3PH-60HZ, end controls (photo). . . .$28,500

CATEPILLAR 105KW 3304 dsl eng, open with lift bale, on skid, with fuel

tank, 240V 1PH and 3PH, 480V-3PH. . . . . . . . . . . . . . . . . . . . . . . $11,500

DETROIT DIESEL 125KW, Det 4-71 eng, on skid with tank, 240/480V-

3PH-60HZ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . $12,500

NORTH AMERICAN QUARRY NEWS March 2014 • 17

EAGLE IRON WORKS 36”x8’ Portable Pugmill Mixing Plant, Detroit 6-71

diesel engine, hyd. elevating legs/stabilizers, spray bar system, NEW radial

tires, lights, rated 350-750 TPH, new paint . . . . . . . . . . . . . . . . . . . .$58,500

TRIO “Triton” 3242 Port Jaw Crushing Plant, 40”x16’ VGF, 3242 Jaw Crusher

w/200 HP motor, Disch conv w/elec, on three axle carrier w/fifth wheel, very good

cond, in process of new paint, parts & man (2000) . . . . . . . . . . . . . . . . . . . .$155,000

KOLBERG 271B Port. Screening Plant, JD dsl engine, 2,811 hours,feed hopper, transfer belt, 4’x8’ DD Incl screen, direc chutes, fines collhopper, new paint (97) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$45,000

36”x150’Tunnell Conveyor, 10’ diameter tunnell, 3/8” steel, galva-nized, 6 feed points, four (4) each Syntron feeders, complete withbelt, stands, 6” trough/return idlers, GOOD CONDITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$75,000

CAT TH 63 Telehandler Forklift, 6,600 hrs, Cat 3054 dsl eng, rated at acapacity of 6,000 Lbs. and a lift height of 41’ 15.5 Pneum tires @ 50% range,5’ forks, hydraulic outriggers on front, OROPS, parts and operating manuals,good operating condition and appearance . . . FOB. Sylacauga, Alabama . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$22,500

STEDMAN Model

GS 4860AR HC

Stationary HSI

Crusher, NEW

Blow Bars, good

liners, 250 HP,

1,185 RPM, 3ph

motor, V-belts, hyd

adjustment, lube

system, new paint

(90). . . . . . $58,500

TELSMITH 2536 Stationary Jaw Crusher, jaw dies @ 80% plus,

150HP elec motor, 1,185 RPM, 3PH, V-belts . . . . . . . . . .$48,500

TELSMITH 489S PortCone Crusher, SN: 7428, 4’ standard cone

crusher with deep throat, 150 HP elec motor, lube system . .$68,500

TEREX/SIMPLICITY 8’x20’ TD Incline Screen, twin drives w/ 25 HPmotors, support stands, catwalks/handrails, screen cloth, excellent (01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$75,000

SIMPLICITY 8’X20’ 4 Deck Incline with motor, stand, fines conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .$38,500

GIW 8”x8” LSA25 Sand

Pump with Denver Speed

Reducer . . . . . . . . . . . . . .

. . . . .Price On Request

Galigher VAC Seal 8”x8”

N8-VPC-207 Sand Pump,

125HP Electric Motor . . .

. . . . . . . . . . . . . .$16,500

EL JAY 5’x16’TD Port Horizontal Screening Plant, SN:1574, mounted on

single axle carrier, with elec motor drive, screen cloth on one deck .$28,500

GATOR PEX 1252 Portable Jaw Crushing Plant, w/ a 4 step 44”x16’ vib

Grizzly feeder w/ 25 HP motor, a 12x52 jaw crusher w/ a 75 HP motor, rear

discharge conveyor, can accept 10” feed & crush to -1” (99) . . . . .$58,500

PIONEER SPOKANE Model 74EV (2500) VSI Crusher, 300 HP elec motor, support stand

with feed box, cooler/lubricator, in good condition with new shaft and bearings on 12/11; has

new turntable that comes with it...not installed (2000) . . . . . . . . . . . . . . . . . . . . . . . . .$78,000

All Prices are F.O.B stocking location and are subject to prior sale. Prices do not include disassembly and loadout of the equipment. Equipment is representedas accurately as possible but specifications are not guaranteed. All equipment is offered “AS IS” with no warranty and is subject to applicable sales tax.

SCREENS... PORTABLEEL JAY 5' X 16' TD Hor. Port Screen Plant, elec, single axle, fifth wheel, fines belt ..........$ 28,500FINLAY 8E30 Portable Wet Screening Plant, all elec., 4’x8’ DD incl. wet screen, new paint ............

....................................................................................................................................$28,500KOLBERG 271B Port Screen Plant, JD dsl, 2,800 hrs, hopper, 30" feed belt, 4' X 8' DD incl screen,

roadable (97) ................................................................................................................$45,000SCREENS... STATIONARY

ALLIS CHALMERS 6’x16’ DD Incl Screen, complete on frame (88) ....................................$15,000EL JAY 6’x20’ Triple Deck Horizontal Vib. Screen, w/ electric drive, screen cloth, mounted on frame,

complete (88) ..............................................................................................................$25,000HARTL 4’x8’ Double Deck Incline Vibrating Screen, w/ two side discharge conveyors, one rear dis-

charge fines conveyor, hydraulic driven ......................................................................$23,500HEWITT ROBINS 5’x16’ TD Incline Screen ............................................................................$9,500HEWITT ROBINS 5’x16’ 3.5 Deck Incl Screen, on stand, less motor ..................................$18,500SIMPLICITY 8’x20’ Four Deck Incline Screen, elec drive, on frame, with fines collection chute, fines

discharge conveyor, screen cloth (85)..........................................................................$38,500SIMPLICITY 5’x14’ TD Incline Screen, support ..................................................................$12,500TEREX/SIMPLICITY 8' X 20' TD Incl Screen, elec, with support stand, motor, cloth, Exc. (2000) ..

....................................................................................................................................$75,000CRUSHERS... PORTABLE

GATOR PEX 1252 Portable Jaw Crusher, can accept up to 10” feed & crush to -1”, w/ 75 HP motor,44”x16’ four stage vib. Grizzly feeder w/ 25 HP motor, prod. discharge conveyor (99) ................................................................................................................................................$58,500

TRIO 3242 Port Jaw Crusher, 3 axle, hopper, 40" X 16' VGF, 3242 Jaw Crusher w/200 HP mtr, Dischconveyor (00) ............................................................................................................$155,000

CRUSHERS... STATIONARYGUNDLACH 56” Double Roll Coal Crusher, (2) 25 HP motor ..............................................$18,500STEDMAN GS R4860AR HC Horizontal Shaft Impact Crusher, 250 HP elec motor, 3 row hammer

setup, NEW BLOWBARS, impact plates at 60-70% remaining, elec hydraulic kit, new paint(98) ..............................................................................................................................$48,500

CONVEYORS... RADIAL36”x100’ Radical Stacker, elec., power rad, truss frame, w/motor & belting (99) ..............$38,50042”x90’ Radial Stacker, elec., w/ man. rad., man. raise/lower, 3 ply belt (98) ....................$38,500MORGAN 54”x250’ Truss Frame Rad Stacker, elec, man rad, hyd raise/lower..(84)............$75,000

CONVEYORS... STATIONARYCUSTOM BUILT 30”x90’ Truss Frame Conveyor, elec, belting (94) ....................................$22,500CUSTOM BUILT (3) 36”x140’ Truss Frame Conveyors, elec, belting, catwalks & handrails (94)......

............................................................................................................................$38,500 EachCUSTOM BUILT 42”x40’ Channel Frame Conveyor, elec, belting (94) ................................$12,500CUSTOM BUILT 42”x50’ Truss Frame Conveyor, elec, belting (94) ....................................$15,000POWERSCREEN 36”x90’ Truss Frame Conveyor, elec, belting, catwalks & handrails (94) ..............

....................................................................................................................................$26,000SAND & GRAVEL EQUIPMENT

EAGLE IRON WORKS Portable 36” Twin Shaft Pugmill, Detroit 6-71 diesel, w/ water ........$58,500EAGLE IRON WORKS 36”x25’ Twin Screw Washers, open drive, hydrotex bearings ..........$16,500EAGLE IRON WORKS 36”x25’ Twin Screw Washer, enclosed drive, hydrotex bearings ........$23,500EAGLE IRON WORKS 36”x24’ Logwasher, open drive, greast lub bearings ........................$28,500

EAGLE IRON WORKS 10’x24’ Sand Classifying Tank, 7 station, 2 cell, rising current, Auto SpecControls (74) ................................................................................................................$29,500

EAGLE IRON WORKS 8’x32’ Stationary Classifyer, 9 stat, 3 cell, rising current, MK V computer con-trols (99) ......................................................................................................................$65,000

KOLBERG 10’x40’ Sand Classifyer, 11 station, 3 cell, rising current, legs & supports, ComputerControls (00) ................................................................................................................$95,000

DIESEL GENERATORSCAT 105KW Diesel Generator, on skid, side controls, 3 ph and 1 ph connectors, painted ..........

....................................................................................................................................$12,500CAT 400KW (500KVA) Dsl Gen, Cat 3208B dsl eng, 240/480V-3PH-60HZ, encl, on stand, end cont,

less fuel tank ................................................................................................................$28,500DETRIOT DIESEL 125 KW Diesel Generator, Det. 6-71 diesel engine, on support frame, open, w/

controls & gauges, switch box ......................................................................................$9,500 STAMFORD 160 KW Diesel Generator, Iveco diesel engine, 1,435 hrs., in enclosed trailer w/ switch

boxes, circuit breakers/starters (99) ............................................................................$28,500PARTS MACHINES & ATTACHMENTS

GROVE RT65S RT Crane, Det Dsl, 104’ boom, good machine, missing hyd tank ..............$18,00010’x10’ Crushing Plant Control House, A/C, push button controls, w/ electric control center w/

switches, breaker & starter boxes ..............................................................................$140,000Skidder Tires with rims for VOLVO L90E Wheel Loader, tires 50% ................................$4,500/setQuick Attach with bucket & forks for a VOLVO L90E Wheel Loader ......................................$9,500Three each 23.5x25 Tires, Bias, 60% WR........................................................................$4,500/set

KOLBERG 10’x40’ Sand Classying Tank 11 station, 3 cell, rising current,

Computer Controls, with supports, parts and op man (98) (SAND SCREW

NOT INCLUDED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . $75,000

36”x100’ Radial Stacker, Power Radial . . . . . . . . . . . . .$28,500

42”x90’ Radial Stacker, Manual Radial . . . . . . . . . . . . .$22,500

EAGLE IRON WORKS 8’x32’ Stationary Sand Classifying Plant, 9 station, 3 cell flume,Mark V Computer controls, supports (99) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..$65,000EAGLE IRON WORKS 10’x24’ Stationary Sand Classifying Plant, 7 station, 2 cell, Auto Spec. .$29,500

SUGGSEQUIPMENTSALES, INC.

Yard Location: 45245 U.S. Highway 280, Sylacauga, Alabama 35150

Mailing Address: P.O. Box 381116, Birmingham, Alabama 35238-1116

877-241-7756 Fax: 205-980-5766 • [email protected]

Celebrating Our 19th Year in Business

Web site: www.suggsequip.com

Domestic Sales Representative

Christopher A. “Chris” Suggs

45245 U.S. Highway 280

Sylacauga, AL 35150

Phone: 205-470-5161

Email: [email protected]

Manager of Logistics

and Internet Sales

Janice Folden

Phone: 205-240-9635

Email: [email protected]

International Sales

Representative

Bobby G. Suggs

P.O. Box 381116

Birmingham, AL 35238-1116

Phone: 205-281-9370

Email: [email protected]

MORRIS, MN — Supe-rior Industries, the Mor-ris, MN based manufac-turer of conveyor sys-tems and components,will highlight its latestconveyor component in-novations at ConExpo-Con/Agg 2014 in LasVegas, with an indoorsite in Central Hall(Booth No. 51838); andan outdoor site in thebrand new Platinum Lot(Booth No. 7602).

Chevron® PulleyVersus traditional

wing pulleys that trapfugitive material andcause wings to tip orbend, the Superior In-dustries Chevron Pulleydeflects fugitive materi-al out and away, pre-venting costly belt dam-age. Also, with its evenwearing rounded con-tact bars, its continu-ous belt contact re-duces beating actionand vibration for quietoperation. The ChevronPulley will be displayednext to a traditionalwing pulley; and salesand engineering repre-sentatives will be onhand to discuss the keydifferences in operationbetween the two.

Navigator® ReturnTrainer

Effective in both wetand dry conditions, theSuperior IndustriesNavigator Return Train-er idler maintains prop-er belt tracking by usingthe gravity of the beltweight to make theroller shift and thustrack the belt. The mis-aligned belt puts pres-sure on one side of thetraining idler, causingthe training idler to tilt

and guide the belt backto center. Designed as acontact-free product,the return trainer is freeof wear parts and anyside contact to the belt,leading to longer wearlife and less mainte-nance. Additionally, itsrubber lagging shedsmaterial and increasesfriction, keeping thebelt aligned and pre-venting belt damage.

Exterra® Belt Cleaners

The Superior Indus-tries line of Exterra beltcleaners features apatented blade designthat’s manufacturedwith a thicker profileand a beefier tip formore material at ascraper’s point of at-tack. At ConExpo-Con/Agg, Superior willhighlight its ExterraSFL Dual Belt Cleaner,the first and only com-bination primary andsecondary cleaning sys-tem to feature twoblades on one mountingpole. Also, the systemfeatures a one-time ten-sioning system at setup,requiring no furthertensioning during thelife of the blade.

Complete solutionsAt the show, Superior

Industries will also dis-play a representation ofits complete line of con-veyor pulleys; and itscomplete line of CEMArated idlers which in-cludes its Moxie Rollsthat shed sticky materi-als and prevent trackingissues; and its UrathonReturn Rolls that pre-vent material buildupand significantly in-crease wear life. Superi-

or will also highlight itsSealing System thatprevents materialspillage in load zones;and engineers will ad-dress the company’sCore System® Design, apackage that delivers asingle source for power

transmission compo-nents, while eliminatingthe headaches of onsiteassemblies and reduc-ing installation time.

Join Superior Indus-tries at ConExpo-Con/Agg in Las Vegasfrom March 4-8, 2014!

Headquartered inMorris, MN, SuperiorIndustries manufac-tures a full line ofportable and stationaryconveying equipmentincluding telescopingconveyors; truck un-loading systems, feed

systems, design-buildconveyor systems andportable plants; and acomplete line of idlers,pulleys and other con-veyor components. Formore information, call800-321-1558 or visitwww.superior-ind.com .

18 • March 2014 NORTH AMERICAN QUARRY NEWS

Superior Industries highlights conveyor component innovations at ConExpo-Con/Agg

The Chevron Pulley will be displayed next to atraditional wing pulley.

NORTH AMERICAN QUARRY NEWS March 2014 • 19

DON’T MISS YOUR CHANCE TO ATTENDthe Largest Construction Show East of The Mississippi

2 Buildings & Outside Exhibit Space • Skid Steer Rodeo

FILL OUT THE TICKETBELOW FOR FREE ADMISSION

NYS FAIR

GROUNDSSYRACUSE, NY

in the Exhibit Center

ADMISSION TICKET • ADMISSION TICKET • ADMISSION TICKET •

2014 New YorkHARD HAT EXPO

Wed. March 19th • 8 am - 4 pmThurs. March 20th • 8 am - 3 pm

28thANNUAL

Name Badge MUST BE WORN

at all times while at the show.Sponsored by the Trade Show Division of Lee Publications

Publishers of HARD HAT NEWS, the Northeast’s Leading Heavy Construction Equipment Trade Newspaper.

Name_

____

____

____

____

____

____

____

__

Title

____

____

____

____

____

____

____

___

Co.__

____

____

____

____

____

____

____

__

2014

HAR

DH

ATEX

POSp

onso

red

by H

ARD

HAT

NEW

S • L

ee P

ublic

atio

ns

DOOR PRIZE TICKETName:________________________

Phone: _______________________Deposit at the Hard Hat News Booth in The Center of Progress Building

Registration tickets valid only if all requested information is provided below. Please Print Legibly. No-one under 18 yrs of ageadmitted without supervision. One Winner Per Day. Need not be present to win. Must be 18 years or older to be eligible to win.

TITLE1 � President / CEO2 � Manager / Supervisor3 � Other

FULL-TIME EMPLOYEES1 � 1 - 52 � 6 - 253 � 25+

NUMBER YOUR PRIMARYBUSINESS #1, SECONDARY #2 ETC.1 � Asphalt Paving ___2 � Concrete Paving ___3 � Oil & Stone Paving ___4 � Bridge Construction ___5 � Excavating ___6 � Utility / Underground ___7 � Construction Demolition ___8 � Landscaping ___9 � Land Clearing ___10� Logging ___

HOW MANY OF THE FOLLOWING TYPES OFEQUIPMENT DO YOU OWN OR LEASE?

1 � Excavators ___2 � Dozers ___3 � Track / Wheel Loaders ___4 � Trucks ___5 � Backhoes, TLB’s ___6 � Other Heavy Equipment ___

NAME

COMPANY

ADDRESS

CITY

TELEPHONE

FAX

STATE ZIP

AREA CODE

AREA CODE

#

#

-

-

Plea

se P

rint W

ithCa

pita

l Let

ters

YES NO

FIRST LAST

Would you Like a FREE SUBSCRIPTION to Hard Hat?

If Yes, Please Sign and Date to Receive your Free Subscription Signature ______________________________________Date________

20 • March 2014 NORTH AMERICAN QUARRY NEWS

)

Are You Involved In More Than One Industry?We Are Here to Help You.

FREE SUBSCRIPTIONS BY REQUEST *

Name _______________________________________________

Farm/Business Name ___________________________________

Address______________________________________________

______________________________________________

City________________________ State _____ Zip __________

County ____________________Email _____________________

Phone ( ) _______________Fax ( ) _________________

Date___________Signature______________________________

LEE PUBLICATIONS, INC.PO Box 121, 6113 State Hwy., Palatine Bridge, NY 13428

800-218-5586 • FAX 518-673-2381SUBSCRIPTIONS

888-596-5329email: [email protected]

National Aggregate (bi-monthly)

Regional Heavy Construction (monthly)

TITLE

1 � President/CEO 2 � Manager/Supervisor 3 � OtherNUMBER YOUR PRIMARY BUSINESS #1, SECONDARY #2, ETC.

1 Asphalt Paving_____________________ 7 Construction Demolition _________________2 Concrete Paving ___________________ 8 Landscaping __________________________3 Oil & Stone Paving__________________ 9 Land Clearing _________________________4 Bridge Construction ________________ 10 Logging _____________________________5 Excavating ________________________ 11 Other _______________________________6 Utility/Underground _________________

Hard Hat News focuses on heavy equipment construction including excavating, construction/dem-

olition, paving, bridge building, and utility construc-tion in the northeastern third of the United States.

� YES - Send me Hard Hat News!

1 � Crushed stone and sand & gravel2 � Crushed stone3 � Sand and gravel4 � Recycled materials, concrete/asphalt5 � Lime

6 � Industrial minerals7 � Machinery/equipment manufacturer8 � Equipment dealer/distributor9 � Drilling

10 � Blasting

North American Quarry News covers quarries, sand and gravel pits, HMA and ready mix concrete operations in the United States. NAQN provides a

combination of strong editorial and advertising for industry professionals.

� YES - Send me North American Quarry News!

Your company produces these products or services:(Check All That Apply)

Regional Agriculture

� Dairy � Beef � Poultry � Horse � Goat� Sheep � Alfalfa � Corn � Soybeans

� YES - Send me Country Folks!

Business Type: (Check All That Apply)

Our premier weekly agricultural newspaper has four editions covering agriculture from Maine

through North Carolina. Every issue is loaded with national,

regional and local agricultural news,

equipment, service advertising and auctions.

*This publication costs $50 for one year. *This publication costs $85 for two years.

Regional/National Solid Waste Recycling(monthly)

TITLE

� Owner/President/VP � Operations Manager � Other

TYPE OF BUSINESS (Check all that apply)

Recycling professionals involved in the wood waste,C&D, scrap metal, asphalt & concrete, and

compost recycling industries will find Waste Handling Equipment News a valuable source of

new products, product innovation and site adaption.

� YES - Send me Waste Handling Equipment News!

� Construction Demolition Recycling� Construction Demolition Landfill� Woodwaste Recycling/Land Clearing� Composting

� Asphalt/Concrete Recycling� Scrap Metals Recycling

� Ferrous � Non-Ferrous

Paid Subscriptionweekly( )

Our premier weekly agricultural newspaper has four editions covering agriculture from Maine

Regional Horticulture

� YES - Send me Country Folks GROWER!

� Greenhouse � Tree Fruit � Nursery

� Farmers Market� Direct Market� Vegetable

� Small Fruit � Christmas � Garden Center� Supplier

Business Type: (Check All That Apply)

Country Folks Grower is the regional newspaper for all segments of commercial horticulture.

Each issue is filled with important information for the Greenhouse, Nursery,

Garden center, Landscaper, Fruit, Vegetable Grower and Marketers.

*This publication costs $24 for one year.*This publication costs $40 for two years.

Paid Subscriptionmonthly

National Vineyard Paid Subscriptionbi-monthly( )

Wine & Grape Grower offers features, news and informationon growing grapes, and making and selling wines.

Learn tips on how to start or improve your business.

� Grape Grower � Wines� Vineyard � Supplier

Business Type: (Check All That Apply)

Northeast Equine Market (monthly)Mane Stream is a monthly horse publication reaching Maine

to Northern Pennsylvania, and New Jersey.Not only does Mane Stream go to horse owners who request

it, but it goes to all of our Affiliated Horse AssociationMembers.....29 Associations Strong and Growing! In addition,issues of Mane Stream are shipped to tack shops, feed stores,

stables, auction barns, and where horse people frequent.

How Many Horses Do You Have?_____

NORTH AMERICAN QUARRY NEWS March 2014 • 21

Tough enough to use asa primary crusher, theAtlas Copco PC3 impactcrusher is an all in onereduction plant. Thehighly productive PC3has single pass capabilityto simultaneously pro-duce two salable frac-tures to spec. Applica-tions include naturalstone crushing, miningand quarrying, construc-tion and demolition jobsof soft to medium-hardmaterials.

The PC3 impact crush-

ers’s key features are theresult of years of in thefield use and customerinput on desirable attrib-utes such as productivi-ty, low operating costs,availability and safety.

The PC3 increases pro-duction capacity with alarge crusher inlet openingwith wide clearance be-tween crusher and outlet.

The PC3 is capable ofmultiple uses for a loweroverall operating cost. Itcombines a conveyormounted HS1 screen box

with closed circuit con-veyor so it can create twoquality controlled salablecommodities in one pass.

Oversized rock is noproblem. The primarychamber is designed toproduce greater reduc-tions and maintainsmooth running materi-al throughput. Twin hy-draulically adjustablecurtains enable fastCSS adjustment andtune reduction ratios toyield higher quality cu-bical product from just

one crusher.In recycling operations,

the PC3 impact crusher’sreversible permanentmagnet removes metalfrom crushed product. Alarge discharge openingfrom crusher base to itsendless rip stop conveyorbelt creates ample clear-ance for rebar.

Long life and availabili-ty is designed into thesystems themselves. Theendless rip stop conveyorbelt ensures a longer beltlife, and the feeder and

hopper are lined withHardoz to protect themfrom wear. The transfluidcrusher drive systemmakes for soft starts andgentler engine load.

A radial piston pumpproduces lower workingtemperatures with lessdrop off in the hydraulicsystem. A side dischargebelt beneath the grizzlyremoves fines, extendingthe life of wear compo-nents and producingcleaner fracture. And afull impact slider bed un-der the crusher dis-charge also contributes

to longer belt life andlower operational costs.

Easy access to key areasin the machine makesmaintenance easier, keep-ing the PC3 available andproductive. Plug and playcomponents are easy tomaintain or replace. Longlife symmetrical wearplates located in high wearareas are interchangeable.

Keeping safety in mind,the PC3 has a full func-tion wireless remote con-trol for maneuvering andpermits one man crusheroperation from a loaderor excavator cab.

Atlas Copco Powercrusher PC3 impact crusher

Atlas Copco PC3 Impact Crusher.

MORRIS, MN — Superior Industries, Inc., the Morris,MiN based manufacturer of material handling systemsand components, takes on big game hunting at ConEx-po-Con/Agg 2014. Donning camouflage wear and orangevests, the Superior Industries team heads into the deepwoods of Central Hall (Booth No. 51838) and will bravethe brand new Platinum Lot (Booth No. 7602) whereequipment hunters will meet with sales and engineersatop the show’s largest deer stand.

Leading the show’s fearless pack of hunters is NorthAmerican hunting legend — Bullseye — who hasachieved reality star infamy of late in a series of videoblogs on the Superior Industries website at www.superi-or-ind.com . The eight episode show preview series, fea-turing Bullseye and his BFF, Norm the Deer, guidesequipment hunters as they track innovative materialhandling solutions behind every tree, while bagging thebest value for the buck.

Throughout the show, Bullseye and Norm will be greet-ing fellow equipment and component hunters at both theindoor and outdoor booths. “And if you’re nice, I mayeven autograph your idlers,” says Bullseye.

While visiting either Superior Industries booth, equip-ment hunters are invited to take a shot and test theirskills at the Big Buck Video Arcade — a contest that willcrown the three highest scoring marksmen by theshow’s end. Each winner will receive one of Bullseye’sspecially designed hunting trophies, and one of threegrand prizes: First Place — a Weatherby VanGuard Se-ries Rifle; Second Place — Leupold BX-4 McKinley HDBinoculars; and Third Place — a GoPro HERO3 Hunt-ing Camera.

Join the Superior Industries Big GameHunt at ConExpo-Con/Agg in Las Ve-

gas from March 4-8, 2014.Headquartered in Morris, MN, Su-

perior Industries manufactures afull line of portable and stationaryconveying equipment including tele-scoping conveyors, truck unloading

systems, feed systems, and de-sign-build conveyor systems;and a complete line of idlers,pulleys and other conveyorcomponents. For more infor-mation, call 800-321-1558 orvisit www.superior-ind.com .

Superior Industries takeson big game hunting at

Conexpo-Con/Agg

Bullseye

RAKES BRANCH, VA — BMC Rock, a familypartnership between Curtis Tharpe’s threechildren Beverly Kunath, Mike Tharpe andChris Tharpe, opened for business onAugust 29, 2005. With eleven employees

from pit to scale, the business is firmly and proudly afamily operation.

According to Tharpe, the family got into the quarrybusiness quite by accident. Curtis had bought afarm, timbered it, and was cutting a fire trail to burnthe cutover stand and turn the land into pasture. “Wekept hitting rock,” he said. So he moved the fire trail,and hit rock again. Eventually he decided to test therock, dynamite it to see how good it was. It was goodenough for them to decide to start sample drilling. Asa result, they found a seam of very hard granite thatextends to a depth of over 400-feet in some places. Anengineering survey estimated that at 24 tons per load,100 loads per day, five days per week, the quarry willlast 120 years. In some places, the overburden is asmuch as 40-feet, in others as little as eight feet.

BMC started by digging where the overburden was

greatest, because when they opened they were sellinga lot of dirt. They also sold a lot of rock. Today, themain pit already has a 60-foot granite face exposed.“When we first got into it we thought we might growto 100 loads a week,” said Curtis. “We’ve done asmany as 200 loads a day.”

Within the first year, the quarry had three statejobs. One was to provide 3,000 tons of pug mill mate-rial per day. “We started crushing at 4 a.m.,” saidMike, recalling that project. “Those first few yearswere “very, very productive.” Then the economysagged.

EquipmentThe quarry relies upon mobile equipment entirely.

The quarry’s primary jaw crusher is a Terex PegsonPremiertrak 1180 located in the pit. It feeds a lineconveyor, which goes to the top of the quarry. There,material enters the quarry’s secondary crusher, aPowerscreen 1500 Maxtrak. The 1500 Maxtrack, oneof the largest mobile cone crushers available, usesTerex® Automax cone crusher technology.

BMC also has two other cone crushers, a 1300

Maxtrak (like the 1500, with Terex® Automax tech-nology) and a Terex 1000SR, which combines crush-ing and screening capabilities. The 1000SR has a twodeck screen with an 11-foot x 5-foot screen box.

BMC does most of its screening with a PowerscreenH6203 three deck horizontal screen (with a 6-foot x20-foot screen box) and a Powerscreen Warrior 1800,a two deck screen with a 16-foot x 5-foot screen boxall of it purchased Powerscreen Mid-Atlantic in NorthCarolina. (It did open with a small electric crusherand a screen, but those quickly wore out.)