MTR, MTRE 1s,1, 3, 5,...

Transcript of MTR, MTRE 1s,1, 3, 5,...

MTR, MTRE 1s,1, 3, 5, 8Service instructions

GRUNDFOS INSTRUCTIONS

En

glis

h (G

B)

English (GB) Service instructions

Original service instructions

These service instructions cover the basic pump version (A) and the drainage-back-to-tank pump version (D) of MTR, MTRE 1s, 1, 3, 5, 8.

Note that some parts of the pump were replaced in August 2015 (week 32). These service instructions apply to pumps before and after this date. See section 6. Order of assembly for chambers and impellers.

CONTENTSPage

1. Type identification

1.1 Nameplate

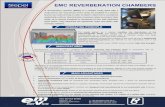

Fig. 1 Nameplate

1. Type identification 21.1 Nameplate 21.2 Type key 31.3 Code for shaft seal 4

2. Torques and lubricants 5

3. Service tools 63.1 Special tools 63.2 Torque tools 6

4. Dismantling and assembling pump version A 74.1 Dismantling the product 74.2 Assembling the product 74.3 Checking and replacing impellers or wear rings and

neck rings 8

5. Dismantling and assembling pump version D 95.1 Dismantling the product 95.2 Assembling the product 95.3 Checking and replacing impellers or wear rings and

neck rings 10

6. Order of assembly for chambers and impellers 116.1 Overview of chambers for MTR, MTRE 1s, 1, 3, 5

(before 1532, production year and week) 116.2 Overview of chambers for MTR, MTRE 1s, 1, 3, 5 (after

1532, production year and week) 126.3 Overview of chambers for MTR, MTRE 8 136.4 Overview of chambers for pump version D 146.5 Positioning of chambers 15

7. Drawings 367.1 MTR, MTRE 1s, 1, 3, 5, 8 (before 1532, production year

and week) 367.2 MTR, MTRE 1s, 1, 3, 5, 8 (after 1532, production year

and week) 387.3 MTR, MTRE 8 407.4 MTR, MTRE 1s, 1, 3, 5, 8 (pump version D). See section

1.2 Type key 42

TM

06

97

63

32

17

Pos. Description

1 Type designation

2 Model

3 Product number

4 Place of production

5 Production year and week

6 P2

7 Closed valve head

8 Head at rated flow rate

9Direction of rotationCCW: CounterclockwiseCW: Clockwise

10 Country of production

11 Frequency

12 Speed

13 Rated flow rate

14 Maximum pressure and temperature

15The number of the copy of the technical file kept at DEKRA (stated if the pump is ATEX classified)

16The serial number of the pump (stated if the pump is ATEX classified)

17 ATEX category (stated if the pump is ATEX classified)

Type

Model

f

n

Q

Hz

min -1

m3/h

P2

Hmax

H

kW

m

m

pmax/tmax bar/°C

Technical file no. XXXXXXXX XSerial No. Made in Taiwan

II 3 G Ex h IIB 125°C Gc

MEIDK - 8850 Bjerringbro, Denmark

0.7 --.-

111213

14151617

6789

10

1 2 3 4 5

9654

7135

MTR3-4/4 A-W-A-HUUVA 96515006 P1 0420

603500

3,6

0,5538

27,1CCW25/90

000001

2

En

gli

sh

(G

B)

1.2 Type key

Fig. 2 MTR pump

Example MTR E 32 (s) 2 /1 1 A F A H UU V

Pump type

Pump with integrated frequency control

Rated flow rate [m3/h]

All impellers with reduced diameter (only MTR 1s)

Number of chambers. See fig. 2.

Number of impellers. See fig. 2.

Number of impellers with reduced diameter

Pump version

A Basic version

B Oversize motor

C Inlet pipe

D Drainage back to tank

E Pump with certificate/approval

F 120 °C version

H Horizontal version

HS High pressure

J Pump with different maximum speed

P Undersize motor

T Double oversize

X Special version

Pipe connection

F DIN flange

G ANSI flange

J JIS flange

M Square flange with internal thread

W Internal thread

WB NPT internal thread

X Special version

Materials

A Basic version

I Wetted parts, EN/DIN 1.4301/AISI 304

N Wetted parts, EN/DIN 1.4401/AISI 316

X Special version

Shaft seal

A O-ring seal with fixed seal driver

H Balanced cartridge seal

Q Silicon carbide

U Tungsten carbide

B Carbon

E EPDM

F FXM

K FFKM

V FKM

TM

01

49

93

13

99

21

Pos. Description

1 Number of chambers

2 Number of impellers

3

En

glis

h (G

B)

1.3 Code for shaft seal

The code for shaft seal always consists of four letters:

The following codes are used:

Example H U U V

1Principal Grundfos type designation for shaft seal

2 Material, rotating seal face

3 Material, stationary seat

4 Material, secondary seal

Pos. Code Description

1

A O-ring seal with fixed seal driver

B Rubber bellows seal

C O-ring seal with spring as seal driver

D O-ring seal, balanced

E Cartridge seal with O-ring

F Cartridge seal with rubber bellows

H Balanced cartridge seal with O-ring

K Type M as cartridge seal

M Shaft seal with metal bellows

O Double seal, back-to-back

P Double seal, tandem

RO-ring seal, type A, with reduced sliding surfaces

X Special version

2 and 3

B Carbon, synthetic resin-impregnated

C Other types of carbon

S Chromium steel

HCemented tungsten carbide, embedded (hybrid)

U Cemented tungsten carbide

Q Silicon carbide

V Aluminium oxide

X Other ceramics

4

E EPDM

F FXM

P NBR (nitrile rubber)

T PFTE

V FKM

K FFKM

4

En

gli

sh

(G

B)

2. Torques and lubricantsThread-Eze, part No SV9997 (0.5 l).

Gardolube L 6034, part No SV9995 (1 l).

Pos. Designation Quantity Dimension Torque [Nm] Lubricant

7a Screw 4 M4 3 ± 0.25 -

9 Hexagon socket head screw 4

M6 13 ± 1.5

Thread-EzeM8 31 ± 3

M10 62 ± 6

36 Nut for strap

2 M8 18 ± 1

Gardolube4

M10 20 ± 4

M12 50 ± 5

36a Nut 4

M6 5 ± 1

Thread-EzeM8 12 ± 2

M12 30 ± 3

M16 40 ± 8

67 Lock nut 1M8 12 ± 2

GardolubeM12 40 ± 8

84b Screw for filter 1 M4 3 ± 0.25 -

105 Shaft seal 1 M28 35 ± 7 Soapy water

113 Set screw 3 M5 2.5 ± 0.25 -

5

En

glis

h (G

B)

3. Service tools

3.1 Special tools

3.2 Torque tools

A B C D

E F G H

Pos. Designation For pos. Description Part number

A Shaft holder for assembly SV0040

B Box spanner for shaft seal 105 SV2007

C Puller for neck ring 65 SV0239

D Punch for removing the shaft SV0238

E Mounting ring SV0872

F Mounting band SV0871

Pos. Designation For pos. Description Part number

G Torque wrench9, 26b, 28a, 36, 67,

105, 113

1-6 Nm SV0438

4-20 Nm SV0292

20-100 Nm SV0269

H Ratchet insert tool I 9 x 12, 1/2" x 1/2" SV0295

6

En

gli

sh

(G

B)

4. Dismantling and assembling pump version AFig. 3 Example of type key for pump version A (basic version)

Position numbers

Position numbers of parts (digits) refer to exploded views, sectional drawings and parts lists; position numbers of tools (letters) refer to section 3. Service tools.

Before dismantling the product

1. Disconnect the power supply to the motor.

2. Close the isolating valves, if fitted, to avoid draining the system.

3. Remove the electric cable in accordance with local regulations.

4. Note the centre of gravity of the pump to prevent it from overturning. This is especially important in the case of long pumps.

Before assembling the product

Always replace gaskets and O-rings when the pump is overhauled.

1. Clean and check all parts.

2. Order the necessary service kits.

3. Replace defective parts with new parts.

During assembly

4. Lubricate and tighten screws and nuts to the torque stated. See section 2. Torques and lubricants.

4.1 Dismantling the product

4.1.1 Removing the motor, coupling and shaft seal

1. Remove the screws (7a) together with the coupling guards (7).

2. Remove the screws (9) together with the coupling halves (10a) and the shaft pin (10).

3. Remove the screws (28).

4. Lift the motor off the pump head (2).

5. Loosen the three screws of the shaft seal (113) by approximately 1/4 of a turn.

6. Loosen the shaft seal (105) using the box spanner for shaft seal (B) until the thread is completely free of the pump head.

7. Pull the shaft seal off the shaft.

4.1.2 Dismantling the chamber stack

1. Remove the motor, the coupling and the shaft seal. See section 4.1.1 Removing the motor, coupling and shaft seal.

2. Place the shaft holder (A) in a vice, but do not tighten the vice.

3. Remove the nuts (36) together with the washers (66a).

4. Remove the straps (26a), the retainer for strainer (121) and the bottom chamber (5a).

5. Loosen the chamber stack with a light blow and pull it off.

6. Fit the shaft pin (10) into the shaft pin hole, place the chamber stack in the shaft holder (A) and tighten the vice.

Fig. 4 Fitting the chamber stack in the holder

7. Remove the nut (67), the washer (66), the priming screw (122) and the splined clamp (64c).

8. Remove the chamber stack parts: impellers, spacing pipes, chambers and bearing rings.

9. If the neck rings (45) in the chambers are worn, remove them by pressing off the neck ring retainer (65), using the puller for neck ring (C).

10. Remove the gasket (37).

4.2 Assembling the product

4.2.1 Assembling the chamber stack

1. Fit the neck rings into the chambers (45) if removed.

2. Place the shaft holder (A) in a vice, but do not tighten the vice.

3. Fit the shaft pin (10) into the shaft pin hole, place the shaft in the shaft holder and tighten the vice.

4. Fit the chamber stack parts on the shaft: chamber, spacing pipe, impeller and bearing ring. See section 6. Order of assembly for chambers and impellers.Note: When fitting the chamber stack, make sure that bearings and other rotating parts are not dropped on the shaft. They must be slid carefully over the shaft to prevent any damage to the bearings.

5. Fit the splined clamp (64c), the priming screw (122), the washer (66) and the nut (67) and tighten to the torque stated. See section 2. Torques and lubricants.

6. Fit the gasket (37).

7. Loosen the vice and fit the chamber stack on the pump head (2).

8. Fit the bottom chamber (5a), the retainer for strainer (121) and the straps (26a).Note: The holes for the straps in the retainer for strainer (121) are positioned asymmetrically.

9. Fit the washers (66a) and nuts (36), fixing the straps to the pump head.

10. Check that the straps are straight (parallel with the shaft), and tighten the screws alternately to ensure that the chamber stack is clamped straight.Tighten to the torque stated. See section 2. Torques and lubricants.

MTR E 32 (s) 2 /1 1 A F A H UU V

TM

02

95

59

32

04

7

En

glis

h (G

B)

4.2.2 Fitting the shaft seal, coupling and motor

1. Assemble the chamber stack. See section 4.2.1 Assembling the chamber stack.

2. If necessary, clean and smooth the shaft end using the holder with emery cloth supplied with the shaft seal kit.

3. Moisten the shaft end with soapy water.

4. Press the shaft seal on the shaft, screw it into the pump head and tighten it with 35 Nm using the box spanner for shaft seal (B).

5. Press home the shaft.

6. Fit the motor to the pump head.

7. Fit the screws (28), lubricate and tighten them diagonally to the torque stated. See section 2. Torques and lubricants.

8. Fit the pin (10) and the two coupling halves (10a).

9. Lubricate the four screws (9) with Thread-Eze and fit them.

10. Check that the gaps on either side of the coupling halves (10a) are equal.

Fig. 5 Gaps between coupling halves (10a)

11. Tighten the screws slightly.

12. Insert a suitable screwdriver between the bottom of the coupling and the shaft seal, and raise the shaft and coupling as far as possible.

Fig. 6 Raising the shaft

13. Lower the shaft and coupling to half the height.

14. Hold the shaft and coupling in this position and tighten the four screws in the coupling (9) diagonally to the torque stated. See section 2. Torques and lubricants. Check that the gaps on either side of the coupling halves (10a) are equal. See fig. 5.

15. Press the ring with the three set screws (113) against the hexagon plug.

16. Tighten the screws (113) with 2.5 Nm.

17. Check that the shaft rotates freely and noiselessly.

18. Fit the coupling guard (7) and the screws (7a).

4.3 Checking and replacing impellers or wear rings and neck rings

Impellers or wear rings

1. Check whether there is a visible groove in the impeller skirts. Use a finger nail.

2. If there is a groove, replace the impellers.

Neck rings

Always replace the neck rings (45) if the chamber stack has been dismantled.

1. Push the neck ring retainer (65) free of the chamber, using the puller for neck ring (C).

2. Remove the neck ring (45).

3. Fit a new neck ring in the chamber.

Fig. 7 Correct fitting of neck ring

4. Press the neck ring retainer (65) down on the neck ring (45) and make it engage with the chamber. It must be possible to move the neck ring freely sideways between the retainer and the chamber.

Bearing rings

1. Check whether there is a visible edge on the rotating bearing rings (47a). Use a finger nail.

2. The bearing rings (47a) and the chambers with bearing ring (4a) must be replaced at the same time.

TM

02

95

58

32

04

TM

02

96

03

35

040.5

xx

TM

02

11

82

06

01

8

En

gli

sh

(G

B)

5. Dismantling and assembling pump version DFig. 8 Example of type key for pump version D (drainage back to tank)

Position numbers

Position numbers of parts (digits) refer to exploded views, sectional drawings and parts lists; position numbers of tools (letters) refer to section 3. Service tools.

Before dismantling the product

1. Disconnect the power supply to the motor.

2. Remove the outlet pipe and the supply cable in accordance with local regulations.

3. Remove the bolts or screws holding the pump to a possible condensate tank.

4. Lift the pump out of the tank.

Before assembling the product

Always replace nut for shaft, gaskets and O-rings when the pump is overhauled.

1. Clean and check all parts.

2. Order the necessary service kits.

3. Replace defective parts with new parts.

5.1 Dismantling the product

5.1.1 Removing the motor, coupling and shaft seal

1. Remove the screws (7a) together with the coupling guards (7) or remove the coupling guards from the pump head (2) using a screwdriver.

2. Remove the screws (9), the coupling (8) and the shaft pin (10).

3. Remove the screws (28), holding the motor to the pump.

4. Remove the motor.

5. Remove the nuts (36) together with the washers (66a).

6. Remove these parts from the bottom of the pump:retainer for strainer (121), strainer (84) and screws (84b)

7. Remove these parts from the top of the pump:pump head (2) and gasket (37).

8. Pull the rotating shaft seal part free of the shaft.

Note: Do not expose the seal ring to blows or knocks.

9. Hold the shaft by means of a screwdriver inserted in the shaft pin hole while you loosen the nut (67)

10. Remove the nut, the washer (66) and the priming screw (122).

11. Place the shaft holder (A) in a vice and tighten it. Place the pump body in the shaft holder with the threaded shaft end pointing upwards.

12. Screw the punch for dismantling (D) on the threaded shaft end.

13. The first chamber to be removed is always a chamber with bearing ring (4a). See also section 6. Order of assembly for chambers and impellers. Note: Make sure that the chamber is positioned in the recess of the shaft holder and that the shaft can pass freely through and underneath the shaft holder.

14. If the impellers are stuck, use the punch to drive the shaft down through the impellers.

15. Remove the free parts from the shaft.

16. Repeat the procedure until the shaft passes through the shaft holder (A). Take care not to damage the shaft when you drive it free of the last impeller and the spacing pipe (69a).

17. Remove the punch (D) from the threaded shaft end.

Pump head

18. Prise the stationary shaft seal part out of the pump head, using a nylon punch or similar tool. Remove the lip seal (183). Do not expose the stationary shaft seal part to blows or knocks.

Neck ring

19. Release the neck ring (45) by pushing up the neck ring retainer (65), using the puller (C).

5.2 Assembling the product

5.2.1 Assembling the chamber stack

Bearing

The maximum permissible difference between the diameters of the bearing ring (47a) and the bearing in the chamber (4a) is 0.4 mm.

Pump head

1. Moisten the stationary seal ring with O-ring and the recess of the pump head with water. Place the lip seal (183) and press the seal ring home in the pump head with the O-ring against the pump head.

Note: Do not expose the seal ring to blows or knocks.

Impeller

2. Make sure that the impeller fits into the neck ring (45). If the clearance between neck ring and impeller is too large, replace the worn part.

Neck ring

3. Fit the neck ring (45) on the chamber. Then fit the retainer (65) on the neck ring and press it until it engages with the chamber.It must be possible to move the neck ring freely sideways between the retainer and the chamber.Note: No neck ring is fitted in the chambers (3, 3a and 5a).

4. Fit the shaft holder (A) in a vice.

5. Fit the shaft (51) in the shaft holder and tighten the vice. The threaded end of the shaft must be uppermost, and the opposite end must be flush with the lower edge of the shaft holder.

6. Continue the assembly. See section 6. Order of assembly for chambers and impellers.

7. Fit the nut (67) and tighten it to the torque stated. See section 2. Torques and lubricants.

8. Fit the straps into the slits of the retainer for strainer (121).

9. Fit the mounting band (F) in the middle of the pump and tighten it.

10. Loosen the vice and lift the pump body off the shaft holder.

11. Fit the pump body in the mounting ring (E) with the smooth shaft end pointing upwards.

12. Fit the rotating shaft seal part. Moisten the rubber part with water.

13. Fit the rotating seal ring so that the mark in the driving dog and the smooth, lapped face point upwards. Make sure that the O-ring is not damaged on the shaft pin hole and that the seal rings are not exposed to blows or knocks.

14. Before fitting the pump head (2), check that the stationary shaft seal part and the gasket (37) are positioned correctly. Take care not to damage the lip seal (183)

15. Lubricate the seal faces of the seal rings with silicone oil, type VO170038. Only lubricate the seal faces.

16. Fit the pump head to the pump body so that the threaded ends of the straps engage with the holes of the pump head.

17. Lubricate the nuts (36). Fit the nuts and tighten diagonally to the torque stated. See section 2. Torques and lubricants.

MTR E 32 (s) 2 /1 1 D F A H UU V

9

En

glis

h (G

B)

18. Fit the motor and turn it to the required terminal box position. Lubricate the screws (28). Fit the screws and tighten diagonally to the torque stated. See section 2. Torques and lubricants.

19. Fit the shaft pin (10) in the shaft. Fit the coupling (8). Lubricate the screws (9). Fit the screws, tighten and leave loose.

20. Check that the gaps on either side of the coupling halves (10a) are equal.

Fig. 9 Gaps between coupling halves (10a)

21. Raise the pump body as far as possible by means of a large screwdriver or a similar tool inserted underneath the coupling. Take care not to raise the motor shaft.

22. Lower the pump body 1 - 1.5 mm from its top position, and tighten the screws two and two (same side). See section 2. Torques and lubricants.

23. Check that the gaps on either side of the coupling halves (10a) are equal, and check the pump by turning the coupling. If the pump is tight or it cannot be rotated, adjust the pump once more.

24. Spring the two coupling guards (7) into place or secure them by means of the screws (7a).

25. Remove the mounting band (F).

26. The pump is now assembled.

5.3 Checking and replacing impellers or wear rings and neck rings

Impellers or wear rings

1. Check whether there is a visible groove in the impeller skirts. Use a finger nail.

2. If there is a groove, replace the impellers.

Neck rings

Always replace the neck rings (45) if the chamber stack has been dismantled.

1. Push the neck ring retainer (65) free of the chamber, using the puller for neck ring (C).

2. Remove the neck ring (45).

3. Fit a new neck ring in the chamber.

Fig. 10 Correct fitting of neck ring (45)

4. Press the neck ring retainer (65) down on the neck ring (45) and make it engage with the chamber. It must be possible to move the neck ring freely sideways between the retainer and the chamber.

Bearing rings

1. Check whether there is a visible edge on the rotating bearing rings (47a). Use a finger nail.

2. Replace the bearing rings (47a) and the chambers with bearing ring (4a) at the same time.

TM

02

95

58

32

04

TM

02

11

82

06

01

10

En

gli

sh

(G

B)

6. Order of assembly for chambers and impellers6.1 Overview of chambers for MTR, MTRE 1s, 1, 3, 5 (before 1532, production year and week)

The production year and week is printed on the nameplate. See section 1.1 Nameplate.

TM

02

89

64

12

04

84b

84

6766b

122

121

5a

64c

3a

47a

64a64

49d

4a

49

4

49

4a

64a

47a

69a

44

6969

3a

69a

11

En

glis

h (G

B)

6.2 Overview of chambers for MTR, MTRE 1s, 1, 3, 5 (after 1532, production year and week)

The production year and week is printed on the nameplate. See section 1.1 Nameplate.

TM

06

84

54

10

17

4

69a

64f

3a 4

69

4 4a

64g

47a

64g

4a

84b84c84

121

66b64e

64d

122

5a

49d

67

64h

47a

49

64

49

3a

6969a

64f

12

En

gli

sh

(G

B)

6.3 Overview of chambers for MTR, MTRE 8

TM

06

93

77

23

17

1b

1b

3

1e

4

8a

1d

4

1

5

2

8a

1f

7

8a

6

8a

1a

7

8c

2

6a

1f

7

8a

6

6a

1a

7

8c

2

151413

12

1110

9

8b

1c

2a

13

En

glis

h (G

B)

6.4 Overview of chambers for pump version D

See section 1.2 Type key

TM

02

89

64

12

04

84b

84

6766b

122

121

5a

64c

3a

47a

64a64

49d

4a

49

4

49

4a

64a

47a

69a

44

6969

3a

69a

14

En

gli

sh

(G

B)

6.5 Positioning of chambers

TM

06

93

80

23

17

MTR 1/1S/3 -

2 1 3 2 1 4 3 2 1 5 4 3 2 1 6 5 4 3 2 1 7 6 5 4 3 2 12/ 3/ 4/ 5/ 6/ 7/ 9/

3456789 2 1128 7 6 5 4 38/

268 286250232214196178160

1213/

567891011 4 31213

L87654

1

32

91011121314

MTR 1/1S/3 -

12 3411 10 9 8 7 6 512/

2 11211/

567891011 4 3129 8 7 6 5 4 310/

10

358

376

304 322 340

3411 10 9 8 7 6 514/

2 1121314

109

23

1

45678

LL

87654

1

32

91011121314

16

MTR 1/1S/3 -

15

394

3411 10 9 8 7 6 515/

2 112131415

17

412

16/3411 10 9 8 7 6 5 2 11213141516

3411 10 9 8 7 6 517/

2 1 1218/

567891011 4 31213

L

87654

1

32

91011121314

MTR 1/1S/3 -

141516171812131415

1516171819

1617

430 448

15

En

glis

h (G

B)

TM

06

93

81

23

17

1219/

567891011 4 31213

L

87654

1

32

91011121314

MTR 1/1S/3 -

1415161718

1516171819

19

20

466

1220/

567891011 4 31213141516171819

484

20

21

18 17 16 15 14

MTR 1/1S/3 -

13 12 3411 10 9 8 7 6 5 2 1192021

502

23

18171615

18 17 16 15 1422/

14131211109

23

1

45678

L

13 12 3411 10 9 8 7 6 5 2 119202122

22212019

520

21/

18 17 16 15 14

MTR 1/1S/3 -

MTR 1/1S/3 -13 12 3411 10 9 8 7 6 5 2 11920212223

538

23

18171615

18 17 16 15 1424/

14131211109

23

1

45678

L

13 12 3411 10 9 8 7 6 5 2 119202122

22212019

23

24

24

25

556

18 17 16 15 1426/25/

13 12 3411 10 9 8 7 6 5 2 119202122232425

574

18 17 16 15 14 13 12 3411 10 9 8 7 6 5 2 11920212223242526

592

23/

23

1817161514131211109

23

1

45678

L

22212019

24

2625

27

16

En

gli

sh

(G

B)

TM

06

93

82

23

17

23

18171615

18 17 16 15 14

MTR 1/1S/3 -27/

14131211109

23

1

45678

L

13 12 3411 10 9 8 7 6 5 2 119202122

22212019

23

24

2425

2625

2627

2827

610

18 17 16 15 14

MTR 1/1S/3 -28/

13 12 3411 10 9 8 7 6 5 2 1192021222324252627

628

8765

23242526

L

1211109

4

1

32

13141516171819202122

272829

28

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -29/

1819202122

19202122

27282930

272829

646

3130292827

22212019181716151413

23

1

4

9101112

L

26252423

5678

664

30 29 28 27 22 21 20 19 18

MTR 1/1S/3 -30/

17 16 3415 14 13 12 11 10 9 2 123242526 5678

17

En

glis

h (G

B)

TM

06

93

83

23

17

8 7 6 526 25 24 23 129101112131415 4 31617

MTR 1/1S/3 -31/

181920212227282930

682

31

8765

23242526

L

1211109

4

1

32

13141516171819202122

272829303132

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -32/

1819202122

19202122

27282930313233

272829303132

700

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -33/

1819202122

19202122

2728293031323334

27282930313233

718

18

En

gli

sh

(G

B)

TM

06

93

84

23

17

8 7 6 526 25 24 23 129101112131415 4 31617

MTR 1/1S/3 -34/

181920212227282930313233

736

8765

23242526

L

1211109

4

1

32

13141516171819202122

272829303132333435

34

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -35/

1819202122

19202122

27282930313233343536

272829303132333435

754

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -36/

1819202122

19202122

2728293031323334353637

27282930313233343536

772

19

En

glis

h (G

B)

TM

06

93

85

23

17

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -37/1819202122

19202122

27282930313233343536

38

27282930313233343536

790

37

37

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -38/1819202122

19202122

2728293031323334353637

27282930313233343536

808

3738

3839

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -39/1819202122

19202122

2728293031323334353637

27282930313233343536

826

373839

383940

20

En

gli

sh

(G

B)

TM

06

93

87

23

17

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -43/1819202122

19202122

272829303132333435363738

27282930313233343536

898

37

39

3839

4041

40

42

41

44

42

43

43

8 7 6 526 25 24 23 129101112131415 4 31617MTR 1/1S/3 -44/

181920212227282930313233343536

916

3738394041424344

8765

23242526

L

1211109

4

1

32

13141516171819202122

27282930313233343536373839404142

4443

45

8 7 6 526 25 24 23 129101112131415 4 31617MTR 1/1S/3 -45/

181920212227282930313233343536

934

373839404142434445

4645

4344

42414039383736353433323130292827

22212019181716151413

23

1

4

9101112

L

26252423

5678

21

En

glis

h (G

B)

TM

06

93

88

23

17

8 7 6 526 25 24 23 129101112131415 4 31617MTR 1/1S/3 -46/

181920212227282930313233343536

952

37383940414243444546

8765

23242526

L

1211109

4

1

32

13141516171819202122

27282930313233343536373839404142

4443

454647

8765

8 7 6 5

23242526

26 25 24 23 129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 1/1S/3 -47/1819202122

19202122

272829303132333435363738

27282930313233343536

970

37

39

3839

4041

40

42

41

44

42

43

43

45

44

46

45

47

46

48

47

22

En

gli

sh

(G

B)

TM

06

93

89

23

17

49

50

48

49

47

48

46

47

45

46

44

45

43

43

42

44

41

42

40

4140

39 38

39

37

1006

36 35 34 33 32 31 30 29 28 27

383736353433323130292827

22212019

22 21 20 19 18

MTR 1/1S/3 -49/

181716151413

23

1

4

9101112

L

17 16 3415 14 13 12 11 10 9 2 123242526

26252423

5678

5678

8 7 6 526 25 24 23 129101112131415 4 31617MTR 1/1S/3 -48/

181920212227282930313233343536

988

373839404142434445464748

8765

23242526

L

1211109

4

1

32

13141516171819202122

27282930313233343536373839404142

4443

4546474849

23

En

glis

h (G

B)

TM

06

93

90

23

17

LL

34

385

10 9 8 7 6 510/

2 1

MTR 5-

9/1234567

358

89

87654

1

32

910

412

3410 9 8 7 6 5 2 11111/

1212/

567891011

439

4 312 1213/

567891011

466

4 31213

87654

1

32

91011121314

MTR 5-169 196 223 250 277 304

2 1 3 2 1 4 3 2 1 5 4 3 2 1 6 5 4 3 2 1 7 6 5 4 3 2 12/ 3/ 4/ 5/ 6/ 7/ 8/

331

8 7 6 5 4 3 2 1

34

493

11 10 9 8 7 6 514/

2 1

MTR 5-

121314 34

520

11 10 9 8 7 6 515/

2 112131415 12567891011

547

4 31213

L

87654

1

32

91011121314

16/141516

151617

18171615

18 17 16 15 1418/

14131211109

23

1

45678

L13 12 3411 10 9 8 7 6 5 2 1

19

123456789101112131415161717/

MTR 5-574 601

24

En

gli

sh

(G

B)

TM

06

93

91

23

17

8765

8 7 6 5

232425

129101112131415

763

4 31617

L

1211109

4

1

32

131415161718

24/1819202122

19202122

24 23

8 7 6 5 129101112131415

790

4 3161725/

181920212224 2325

212019

2019 1819/

181716151413

23

1

4

9101112

L

17 16 34

655

15 14 13 12 11 10 9 2 15678

5678

21 20 19 1821/

17 16 34

682

15 14 13 12 11 10 9 2 15678

22212019

22 21 20 19 1822/

181716151413

23

1

4

9101112 L

17 16 34

709

15 14 13 12 11 10 9 2 1

23

5678

5678

22 21 20 19 1823/

17 16 34

736

15 14 13 12 11 10 9 2 1567823

18 17 16 15 14

MTR 5-

13 12 34

628

11 10 9 8 7 6 5 2 119

8765

8 7 6 5

23242526

129101112131415

817

4 31617

L

1211109

4

1

32

131415161718

26/1819202122

19202122

27

26 25 24 23

20/

MTR 5-

MTR 5-

MTR 5-

25

En

glis

h (G

B)

TM

06

93

92

23

17

8765

8 7 6 5

23242526

129101112131415

844

4 31617

L

1211109

4

1

32

131415161718

MTR 5-27/1819202122

19202122

27

26 25 24 2327

28

8765

8 7 6 5

23242526

129101112131415

871

4 31617

L

1211109

4

1

32

131415161718

MTR 5-28/1819202122

19202122

272829

28 27 26 25 24 23

8765

8 7 6 5

23242526

129101112131415 4 31617L

1211109

4

1

32

131415161718

MTR 5-29/1819202122

19202122

27282930

29 28 27 26 25 24 23

8765

8 7 6 5

23242526

129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 5-30/1819202122

19202122

27282930

29 28 27 26 25 24 2330

31

925

898

26

En

gli

sh

(G

B)

TM

06

93

93

23

17

232425262728293031

323130292827

22212019

22 21 20 19 18MTR 5-31/

181716151413

23

1

4

9101112

L

17 16 3415 14 13 12 11 10 9 2 1

26252423

5678

5678

8765

8 7 6 5

23242526

129101112131415 4 31617

L

1211109

4

1

32

131415161718

MTR 5-32/1819202122

19202122

27282930313233

32 31 30 29 28 27 26 25 24 23

34

33

8765

8 7 6 5

23242526

129101112131415

1006

4 31617

L

1211109

4

1

32

131415161718

MTR 5-33/1819202122

19202122

27282930313233

32 31 30 29 28 27 26 25 24 23

952

979

27

En

glis

h (G

B)

TM

06

93

94

23

17

MTR 8-196 223 250 277 304 331

2 1 3 2 1 4 3 2 1 5 4 3 2 1 6 5 4 3 2 12/ 3/ 4/ 5/ 6/ 7/

358

7 6 5 4 3 2 111/

439

3410 9 8 7 6 5 2 110/

1211/

567891011

466

4 3

MTR 8-

1212/

567891011

493

4 312

MTR 8-

34

547

11 10 9 8 7 6 514/

2 1121314 12567891011

574

4 3121315/

1415

17 16 15 1417/

13 12 34

628

11 10 9 8 7 6 5 2 1

MTR 8-

18171615

18 17 16 15 1418/

14131211109

23

1

45678

L13 12 34

655

11 10 9 8 7 6 5 2 1

2019

34

412

9 8 7 6 59/

2 18/

1234567

385

8

13 12 1213/

567891011

520

4 3

1234567891011121314151616/

601

1817161514131211109

23

1

45678

L

1514131211109

23

1

45678 L

L

87654

1

32

91011

28

En

gli

sh

(G

B)

TM

06

93

95

23

17

19 18 17 16 34

682

15 14 13 12 11 10 9 2 15678

22212019

2019 18

181716151413

23

1

4

9101112 L

17 16 34

709

15 14 13 12 11 10 9 2 15678

5678

21 20 19 18 17 16 34

736

15 14 13 12 11 10 9 2 15678

22212019

22 21 20 19 18

181716151413

23

1

4

9101112 L

17 16 34

763

15 14 13 12 11 10 9 2 1

23

5678

5678

24

8 7 6 5 129101112131415

790

4 31617181920212223

8765

8 7 6 5

232425

129101112131415

817

4 31617

L

1211109

4

1

32

131415161718

1819202122

19202122

24 23

26

8 7 6 5 129101112131415

844

4 31617181920212225 24 23

8765

8 7 6 5

23242526

129101112131415

871

4 31617

L

1211109

4

1

32

131415161718

1819202122

19202122

27

26 25 24 23

28

19/MTR 8-

20/

MTR 8-21/ 22/

MTR 8-23/ 24/

MTR 8-26/25/

29

En

glis

h (G

B)

TM

06

93

96

23

17

8765

8 7 6 5

23242526

129101112131415

898

4 31617

L

1211109

4

1

32

131415161718

MTR 8-27/1819202122

19202122

272829

27 26 25 24 23

8765

8 7 6 5

23242526

129101112131415

925

4 31617

L

1211109

4

1

32

131415161718

MTR 8-28/1819202122

19202122

27282930

28 27 26 25 24 23

8765

8 7 6 5

23242526

129101112131415

952

4 31617

L

1211109

4

1

32

131415161718

MTR 8-29/1819202122

19202122

27282930

29 28 27 26 25 24 23

31

8765

8 7 6 5

23242526

129101112131415

979

4 31617

L

1211109

4

1

32

131415161718

MTR 8-30/1819202122

19202122

272829303132

30 29 28 27 26 25 24 23

30

En

gli

sh

(G

B)

TM

06

93

97

23

17

8765

8 7 6 5

23242526

129101112131415

1006

4 31617

L

1211109

4

1

32

131415161718

MTR 8-31/1819202122

19202122

27282930313233

31 30 29 28 27 26 25 24 23

31

En

glis

h (G

B)

TM

06

93

98

23

17

L

MTR 8-223 250 277 304 331

2-1 3-1 2-1 4-1 3-1 2-1 5-1 4-1 3-1 2-1 6-1 5-1 4-1 3-1 2-1

2/ 3/ 4/ 5/ 6/ 7/

358

7-1 6-1 5-1 4-1 3-1 2-1

439

3-14-110-1 9-1 8-1 7-1 6-1 5-1 2-1

10/

87654

1

32

91011

L87654

1

32

91011121314

MTR 8-

15

547

14/2-15-16-17-18-19-110-111-1 4-1 3-112-113-114-1

2-1

11/5-16-17-18-19-110-111-1

466

4-1 3-1

MTR 8-

2-1

12/5-16-17-18-19-110-111-1

493

4-1 3-112-1

574

15/2-15-16-17-18-19-110-111-1 4-1 3-112-113-114-115-1

628

2-15-16-17-18-19-110-111-1 4-1 3-112-113-114-115-116-1

18171615

18-117-116-115-114-1

14131211109

23

1

45678

L

13-112-1 3-14-1

655

11-110-1 9-1 8-1 7-1 6-1 5-1 2-1

2019

3-14-1

412

9-1 8-1 7-1 6-1 5-1

9/2-1

8/2-13-14-15-16-17-1

385

8-1

520

13/2-15-16-17-18-19-110-111-1 4-1 3-112-113-1

16/

601

5-16-17-18-19-110-111-1 4-1 3-112-113-114-115-116-1 2-1

L

87654

1

32

9101112131415161718

18/17/MTR 8-

17-1

32

En

gli

sh

(G

B)

TM

06

93

99

23

17

26

22212019181716151413

23

1

4

9101112

L

817

252423

5678

790

736

22212019181716151413

23

1

4

9101112 L

23

5678

24

19/

682

8765

709

L1211109

4

1

32

131415161718

20/

19202122

MTR 8-

MTR 8-

MTR 8-

763

21/ 22/

23/ 24/

MTR 8-25/ 26/

8765

8-1

7-1

6-1

5-1

23242526

2-1

9-1

10-1

11-1

12-1

13-1

14-1

15-1

871

4-1

3-1

16-1

17-1

L

1211109

4

1

32

131415161718

18-1

19-1

20-1

21-1

22-1

19202122

27

26-1

25-1

24-1

23-1

8-1

7-1

6-1

5-1

2-1

9-1

10-1

11-1

12-1

13-1

14-1

15-1

4-1

3-1

16-1

17-1

18-1

19-1

20-1

21-1

22-1

24-1

23-1

28

23-1

24-1

25-1

22-1

21-1

20-1

19-1

18-1

17-1

16-1

3-1

4-1

844

15-1

14-1

13-1

12-1

11-1

10-1

9-1

2-1

5-1

6-1

7-1

8-1

19-1

18-1

17-1

16-1

3-1

4-1

15-1

14-1

13-1

12-1

11-1

10-1

9-1

2-1

5-1

6-1

7-1

8-1

20-1

19-1

18-1

17-1

16-1

3-1

4-1

15-1

14-1

13-1

12-1

11-1

10-1

9-1

2-1

5-1

6-1

7-1

8-1

21-1

20-1

19-1

18-1

17-1

16-1

3-1

4-1

15-1

14-1

13-1

12-1

11-1

10-1

9-1

2-1

5-1

6-1

7-1

8-1

21-1

20-1

19-1

18-1

17-1

16-1

3-1

4-1

15-1

14-1

13-1

12-1

11-1

10-1

9-1

2-1

5-1

6-1

7-1

8-1

23-1

22-1

21-1

20-1

19-1

18-1

17-1

16-1

3-1

4-1

15-1

14-1

13-1

12-1

11-1

10-1

9-1

2-1

5-1

6-1

7-1

8-1

33

En

glis

h (G

B)

TM

06

94

00

23

17

8765

8-1

7-1

6-1

5-1

23242526

2-1

9-1

10-1

11-1

12-1

13-1

14-1

15-1

898

4-1

3-1

16-1

17-1

L

1211109

4

1

32

131415161718

MTR 8-27/

18-1

19-1

20-1

21-1

22-1

19202122

272829

27-1

26-1

25-1

24-1

23-1

8765

23242526

925

L

1211109

4

1

32

131415161718

MTR 8-28/

19202122

27282930

27-1

26-1

25-1

24-1

23-1

22-1

21-1

20-1

19-1

18-1

17-1

16-1

15-1

14-1

13-1

12-1

11-1

10-1

9-1

8-1

7-1

6-1

5-1

4-1

3-1

2-1

28-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

9-1

10-1

11-1

12-1

13-1

14-1

15-1

16-1

17-1

18-1

19-1

20-1

21-1

22-1

23-1

24-1

25-1

26-1

27-1

28-1

29-1

3130292827

22212019

MTR 8-29/

181716151413

23

1

4

9101112

L

952

26252423

5678

34

En

gli

sh

(G

B)

TM

06

94

01

23

17

8765

23242526

10-1

11-1

12-1

13-1

14-1

15-1

1006

16-1

17-1

L

1211109

4

1

32

131415161718

MTR 8-31/18

-1

19-1

20-1

21-1

22-1

19202122

27282930313233

31-1

30-1

29-1

28-1

27-1

26-1

25-1

24-1

23-1

9-1

8-1

7-1

6-1

5-1

4-1

3-1

2-1

8765

8-1

7-1

6-1

5-1

23242526

2-1

9-1

10-1

11-1

12-1

13-1

14-1

15-1

979

4-1

3-1

16-1

17-1

L

1211109

4

1

32

131415161718

MTR 8-30/

18-1

19-1

20-1

21-1

22-1

19202122

272829303132

30-1

29-1

28-1

27-1

26-1

25-1

24-1

23-1

35

En

glis

h (G

B)

7. Drawings

7.1 MTR, MTRE 1s, 1, 3, 5, 8 (before 1532, production year and week)

See section 1.1 Nameplate.

7.1.1 Exploded view

TM

02

80

34

32

04

28

36a

28a

1

122

66

67

84

84b

64c

85

121

84c

69a

3a

76

3666a

26a

7a

375a

7a

7

7

2

113105

10a

8 9

10

4

65

45

64

49a

47a

51

49

64a

45

65

4a

49

76a

36

En

gli

sh

(G

B)

7.1.2 Sectional drawing

TM

02

80

33

35

04

84b 84

12185

84c26a

8 10

37

66a

2

36

9

10a

64a

65454

66

64

49

513a

69a

12264c

67

4a 4565

47a

113105

5a

7

7a

36a

1

49a

37

En

glis

h (G

B)

7.2 MTR, MTRE 1s, 1, 3, 5, 8 (after 1532, production year and week)

See section 1.1 Nameplate.

7.2.1 Exploded view

TM

06

87

46

10

17

38

En

gli

sh

(G

B)

7.2.2 Sectional drawing

TM

06

87

47

10

17

39

En

glis

h (G

B)

7.3 MTR, MTRE 8

7.3.1 Exploded view

TM

02

80

34

32

04

28

36a

28a

1

122

66

67

84

84b

64c

85

121

84c

69a

3a

76

3666a

26a

7a

375a

7a

7

7

2

113105

10a

8 9

10

4

65

45

64

49a

47a

51

49

64a

45

65

4a

49

76a

40

En

gli

sh

(G

B)

7.3.2 Sectional drawing

TM

02

80

33

35

04

84b 84

12185

84c26a

8 10

37

66a

2

36

9

10a

64a

65454

66

64

49

513a

69a

12264c

67

4a 4565

47a

113105

5a

7

7a

36a

1

49a

41

En

glis

h (G

B)

7.4 MTR, MTRE 1s, 1, 3, 5, 8 (pump version D). See section 1.2 Type key

7.4.1 Exploded view

TM

06

93

78

35

17

36a

1

28a10a

9

10

7a

7

2

76a

762836

26a

105

37

65

454

69a

64

64c

49

64

65

454

49

64a

65

454a

47a

64c

49

5a

51

64c

12266

67

85

121

84

84c

84b

3a

51

3a

8

766a

7a

183

42

En

gli

sh

(G

B)

7.4.2 Sectional drawing

TM

02

93

78

35

17

10a

10

9

2

8

105

26a84c 84b 84

85

121

49a

3a5169a

49

44565

64

4a4565

64a5a

47a

64c

122

66

67

7

36a

183

7a

36

66a

43

44

Gru

nd

fos

co

mp

anie

s

ArgentinaBombas GRUNDFOS de Argentina S.A.Ruta Panamericana km. 37.500 Centro Industrial Garin1619 Garín Pcia. de B.A.Phone: +54-3327 414 444Telefax: +54-3327 45 3190

AustraliaGRUNDFOS Pumps Pty. Ltd. P.O. Box 2040 Regency Park South Australia 5942 Phone: +61-8-8461-4611 Telefax: +61-8-8340 0155

AustriaGRUNDFOS Pumpen Vertrieb Ges.m.b.H.Grundfosstraße 2 A-5082 Grödig/Salzburg Tel.: +43-6246-883-0 Telefax: +43-6246-883-30

BelgiumN.V. GRUNDFOS Bellux S.A. Boomsesteenweg 81-83 B-2630 Aartselaar Tél.: +32-3-870 7300 Télécopie: +32-3-870 7301

BelarusПредставительство ГРУНДФОС в Минске220125, Минскул. Шафарнянская, 11, оф. 56, БЦ «Порт»Тел.: +7 (375 17) 286 39 72/73Факс: +7 (375 17) 286 39 71E-mail: [email protected]

Bosnia and HerzegovinaGRUNDFOS SarajevoZmaja od Bosne 7-7A,BH-71000 SarajevoPhone: +387 33 592 480Telefax: +387 33 590 465www.ba.grundfos.come-mail: [email protected]

BrazilBOMBAS GRUNDFOS DO BRASILAv. Humberto de Alencar Castelo Branco, 630CEP 09850 - 300São Bernardo do Campo - SPPhone: +55-11 4393 5533Telefax: +55-11 4343 5015

BulgariaGrundfos Bulgaria EOODSlatina DistrictIztochna Tangenta street no. 100BG - 1592 SofiaTel. +359 2 49 22 200Fax. +359 2 49 22 201email: [email protected]

CanadaGRUNDFOS Canada Inc. 2941 Brighton Road Oakville, Ontario L6H 6C9 Phone: +1-905 829 9533 Telefax: +1-905 829 9512

ChinaGRUNDFOS Pumps (Shanghai) Co. Ltd.10F The Hub, No. 33 Suhong RoadMinhang DistrictShanghai 201106PRCPhone: +86 21 612 252 22Telefax: +86 21 612 253 33

COLOMBIAGRUNDFOS Colombia S.A.S.Km 1.5 vía Siberia-Cota Conj. Potrero Chico,Parque Empresarial Arcos de Cota Bod. 1A.Cota, CundinamarcaPhone: +57(1)-2913444Telefax: +57(1)-8764586

CroatiaGRUNDFOS CROATIA d.o.o.Buzinski prilaz 38, BuzinHR-10010 ZagrebPhone: +385 1 6595 400 Telefax: +385 1 6595 499www.hr.grundfos.com

GRUNDFOS Sales Czechia and Slovakia s.r.o.Čajkovského 21779 00 OlomoucPhone: +420-585-716 111

DenmarkGRUNDFOS DK A/S Martin Bachs Vej 3 DK-8850 Bjerringbro Tlf.: +45-87 50 50 50 Telefax: +45-87 50 51 51 E-mail: [email protected]/DK

EstoniaGRUNDFOS Pumps Eesti OÜPeterburi tee 92G11415 TallinnTel: + 372 606 1690Fax: + 372 606 1691

FinlandOY GRUNDFOS Pumput AB Trukkikuja 1 FI-01360 Vantaa Phone: +358-(0) 207 889 500

FrancePompes GRUNDFOS Distribution S.A. Parc d’Activités de Chesnes 57, rue de Malacombe F-38290 St. Quentin Fallavier (Lyon) Tél.: +33-4 74 82 15 15 Télécopie: +33-4 74 94 10 51

GermanyGRUNDFOS GMBHSchlüterstr. 3340699 ErkrathTel.: +49-(0) 211 929 69-0 Telefax: +49-(0) 211 929 69-3799e-mail: [email protected] in Deutschland:e-mail: [email protected]

GreeceGRUNDFOS Hellas A.E.B.E. 20th km. Athinon-Markopoulou Av. P.O. Box 71 GR-19002 Peania Phone: +0030-210-66 83 400 Telefax: +0030-210-66 46 273

Hong KongGRUNDFOS Pumps (Hong Kong) Ltd. Unit 1, Ground floor Siu Wai Industrial Centre 29-33 Wing Hong Street & 68 King Lam Street, Cheung Sha Wan Kowloon Phone: +852-27861706 / 27861741 Telefax: +852-27858664

HungaryGRUNDFOS Hungária Kft.Park u. 8H-2045 Törökbálint, Phone: +36-23 511 110Telefax: +36-23 511 111

IndiaGRUNDFOS Pumps India Private Limited118 Old Mahabalipuram RoadThoraipakkamChennai 600 096Phone: +91-44 2496 6800

IndonesiaPT. GRUNDFOS POMPAGraha Intirub Lt. 2 & 3Jln. Cililitan Besar No.454. Makasar, Jakarta TimurID-Jakarta 13650Phone: +62 21-469-51900Telefax: +62 21-460 6910 / 460 6901

IrelandGRUNDFOS (Ireland) Ltd. Unit A, Merrywell Business ParkBallymount Road LowerDublin 12 Phone: +353-1-4089 800 Telefax: +353-1-4089 830

ItalyGRUNDFOS Pompe Italia S.r.l. Via Gran Sasso 4I-20060 Truccazzano (Milano)Tel.: +39-02-95838112 Telefax: +39-02-95309290 / 95838461

JapanGRUNDFOS Pumps K.K.1-2-3, Shin-Miyakoda, Kita-ku, Hamamatsu431-2103 JapanPhone: +81 53 428 4760Telefax: +81 53 428 5005

KoreaGRUNDFOS Pumps Korea Ltd.6th Floor, Aju Building 679-5Yeoksam-dong, Kangnam-ku, 135-916Seoul, KoreaPhone: +82-2-5317 600Telefax: +82-2-5633 725

LatviaSIA GRUNDFOS Pumps Latvia Deglava biznesa centrsAugusta Deglava ielā 60, LV-1035, Rīga,Tālr.: + 371 714 9640, 7 149 641Fakss: + 371 914 9646

LithuaniaGRUNDFOS Pumps UABSmolensko g. 6LT-03201 VilniusTel: + 370 52 395 430Fax: + 370 52 395 431

MalaysiaGRUNDFOS Pumps Sdn. Bhd.7 Jalan Peguam U1/25Glenmarie Industrial Park40150 Shah AlamSelangor Phone: +60-3-5569 2922Telefax: +60-3-5569 2866

MexicoBombas GRUNDFOS de México S.A. de C.V. Boulevard TLC No. 15Parque Industrial Stiva AeropuertoApodaca, N.L. 66600Phone: +52-81-8144 4000 Telefax: +52-81-8144 4010

NetherlandsGRUNDFOS NetherlandsVeluwezoom 351326 AE AlmerePostbus 220151302 CA ALMERE Tel.: +31-88-478 6336 Telefax: +31-88-478 6332E-mail: [email protected]

New ZealandGRUNDFOS Pumps NZ Ltd.17 Beatrice Tinsley CrescentNorth Harbour Industrial EstateAlbany, AucklandPhone: +64-9-415 3240Telefax: +64-9-415 3250

NorwayGRUNDFOS Pumper A/S Strømsveien 344 Postboks 235, Leirdal N-1011 Oslo Tlf.: +47-22 90 47 00 Telefax: +47-22 32 21 50

PolandGRUNDFOS Pompy Sp. z o.o.ul. Klonowa 23Baranowo k. PoznaniaPL-62-081 PrzeźmierowoTel: (+48-61) 650 13 00Fax: (+48-61) 650 13 50

PortugalBombas GRUNDFOS Portugal, S.A. Rua Calvet de Magalhães, 241Apartado 1079P-2770-153 Paço de ArcosTel.: +351-21-440 76 00Telefax: +351-21-440 76 90

RomaniaGRUNDFOS Pompe România SRLBd. Biruintei, nr 103 Pantelimon county IlfovPhone: +40 21 200 4100Telefax: +40 21 200 4101E-mail: [email protected]

RussiaООО Грундфос Россияул. Школьная, 39-41Москва, RU-109544, Russia Тел. (+7) 495 564-88-00 (495) 737-30-00Факс (+7) 495 564 8811E-mail [email protected]

Serbia Grundfos Srbija d.o.o.Omladinskih brigada 90b11070 Novi Beograd Phone: +381 11 2258 740Telefax: +381 11 2281 769www.rs.grundfos.com

SingaporeGRUNDFOS (Singapore) Pte. Ltd.25 Jalan Tukang Singapore 619264 Phone: +65-6681 9688 Telefax: +65-6681 9689

SlovakiaGRUNDFOS s.r.o.Prievozská 4D 821 09 BRATISLAVA Phona: +421 2 5020 1426sk.grundfos.com

SloveniaGRUNDFOS LJUBLJANA, d.o.o.Leskoškova 9e, 1122 LjubljanaPhone: +386 (0) 1 568 06 10Telefax: +386 (0)1 568 06 19E-mail: [email protected]

South AfricaGRUNDFOS (PTY) LTDCorner Mountjoy and George Allen RoadsWilbart Ext. 2Bedfordview 2008Phone: (+27) 11 579 4800Fax: (+27) 11 455 6066E-mail: [email protected]

SpainBombas GRUNDFOS España S.A. Camino de la Fuentecilla, s/n E-28110 Algete (Madrid) Tel.: +34-91-848 8800 Telefax: +34-91-628 0465

SwedenGRUNDFOS AB Box 333 (Lunnagårdsgatan 6) 431 24 Mölndal Tel.: +46 31 332 23 000Telefax: +46 31 331 94 60

SwitzerlandGRUNDFOS Pumpen AG Bruggacherstrasse 10 CH-8117 Fällanden/ZH Tel.: +41-44-806 8111 Telefax: +41-44-806 8115

TaiwanGRUNDFOS Pumps (Taiwan) Ltd. 7 Floor, 219 Min-Chuan Road Taichung, Taiwan, R.O.C. Phone: +886-4-2305 0868Telefax: +886-4-2305 0878

ThailandGRUNDFOS (Thailand) Ltd. 92 Chaloem Phrakiat Rama 9 Road,Dokmai, Pravej, Bangkok 10250Phone: +66-2-725 8999Telefax: +66-2-725 8998

TurkeyGRUNDFOS POMPA San. ve Tic. Ltd. Sti.Gebze Organize Sanayi Bölgesi Ihsan dede Caddesi,2. yol 200. Sokak No. 20441490 Gebze/ KocaeliPhone: +90 - 262-679 7979Telefax: +90 - 262-679 7905E-mail: [email protected]

UkraineБізнес Центр ЄвропаСтоличне шосе, 103м. Київ, 03131, Україна Телефон: (+38 044) 237 04 00 Факс.: (+38 044) 237 04 01E-mail: [email protected]

United Arab EmiratesGRUNDFOS Gulf DistributionP.O. Box 16768Jebel Ali Free ZoneDubaiPhone: +971 4 8815 166Telefax: +971 4 8815 136

United KingdomGRUNDFOS Pumps Ltd. Grovebury Road Leighton Buzzard/Beds. LU7 4TL Phone: +44-1525-850000 Telefax: +44-1525-850011

U.S.A.GRUNDFOS Pumps Corporation 17100 West 118th TerraceOlathe, Kansas 66061Phone: +1-913-227-3400 Telefax: +1-913-227-3500

UzbekistanGrundfos Tashkent, Uzbekistan The Repre-sentative Office of Grundfos Kazakhstan in Uzbekistan38a, Oybek street, TashkentТелефон: (+998) 71 150 3290 / 71 150 3291Факс: (+998) 71 150 3292

Addresses Revised 09.08.2017

99257005 1217

ECM: 1223821 The

nam

e G

rund

fos,

the

Gru

ndfo

s lo

go, a

nd b

e t

hin

k i

nn

ov

ate

are

regi

ster

ed tr

adem

arks

ow

ned

by G

rund

fos

Hol

ding

A/S

or G

rund

fos

A/S,

Den

mar

k. A

ll rig

hts

rese

rved

wor

ldw

ide.

© C

opyr

ight

Gru

ndfo

s H

oldi

ng A

/S

www.grundfos.com