MT543LOGV01-04T-12430-FORMATO PARA INTERNET

Transcript of MT543LOGV01-04T-12430-FORMATO PARA INTERNET

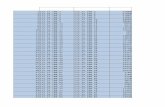

Datalogger operation mode

Datalogger sampling interval

Variation of the temperature to force data recording

Variation of the outputs to force data recording

Overwrite records in the memory when it is full?

Intensity of the digital filter

Network address RS-485

F36

F37

F38

F39

F40

F41

F42

2

999

18

1

1

9

247

2

999

10

1

1

9

247

-

sec.

ºC

-

-

-

-

-

sec.

ºF

-

-

-

-

2

30

0

0

1

0

1

0

1

0

0

0

1

0

1

0

0

0

1

THREE OUTPUT DIGITAL CONTROLLER

WITH ALARM, CYCLICAL TIMER AND

SERIAL COMMUNICATION

Ver.01

1 - DESCRIPTIONMT-543Ri LOG has three outputs of temperature control and a internal buzzer. Because of its versatility, it allows that the second stage works as clyclical timer and the third as alarm, the second stage can work with the first stage in systems that need minimum ventilation. The unit is equipped with a clock and an internal memory (datalogger). The MT-543Ri LOG can store the temperature data for certain periods of time, temperature variations and events such as sensor error, alarms and output changes. It also has an internal rechargeable battery that permits data recording even during a power outage.Through the serial output RS-485, it permits communication with SITRAD software.

2 - APPLICATION• Blood banks• Multistage temperature system• Air conditioning• Data centers

3 - TECHNICAL SPECIFICATIONS- Power Supply: MT-543Ri LOG: 90 ~ 264Vac (50/60Hz)

MT-543RiL LOG: 12/24 Vac/dc- Control Temperature: NTC:-50 to 105°C(*) / -58 to 221°F(*)

®

- Dimensions: 71 x 28 x 71 mm- Operating temperature: 0 to 50 ºC / 32 to 122ºF- Operating humidity: 10 to 90% RH (without condensation)- Maximum Load Current: OUT 1, OUT 2 and OUT 3 (NO) - 5(3)A / 250 Vac 1/8HP per output

OUT 3 (NC) - 3A/250Vac - Resistive load- Digital input: Switch - input for detection of open door (dry contact type)

(*) This instrument can measure and control up to 200°C (392°F) temperatures, since used with silicone cable sensor (ex.: SB59).

5 PARAMETERS DESCRIPTION - F01 - Offset indicationIt allows to compensate eventual shunting lines in the reading of ambient temperature proceeding from the exchange of the sensor or cable lenght alteration.

F02 - Operation mode of first stage- Refrigeration- Heating

F03 - Minimum setpoint allowed to the end user (first stage)F04 - Máximum setpoint allowed to the end user (first stage)Electronic limits whose purpose is prevent that too high or too low setpoint temperatures are regulated.

F05 - Control differential (hysteresis) of first stageIt is the difference of temperature(hysteresis) between turn ON and turn OFF the OUT1 output.

F06 - Minimum delay to turn on the first stage output It is the minimum time that OUT1 will keep turned off, it means, the amount of time between the last stop and the next start.

2

30

0

0

1

0

1

Operation mode of third stage

Minimum setpoint allowed to the end user (third stage)

Maximum setpoint allowed to the end user (third stage)

Control differential (hysteresis) of third stage

Minimum delay to turn on the third stage

Delay to enable the alarm when the instrument is powered on

Reactivation time of alarm when inhibited manually

Alarm Time (on cycle)

Alarm Time (off cycle)

Enables F24 and F25 on easy access menu

Operation mode of Buzzer

Acting point of Buzzer (inferior limit)

Acting point of Buzzer (superior limit)

Buzzer time on

Buzzer time off

Inhibition time of Buzzer during electrical supply

Reactivation time of Buzzer when inhibited manually

Time for the open door alarm

Digital input operation mode

F17

F18

F19

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

F31

F32

F33

F34

F35

6(*)105(*)105

20

999

999

999

999

999

1

2(*)105(*)105

999

999

999

999

999

1

-

ºC

ºC

ºC

sec.

min.

min.

sec.

sec.

-

-

ºC

ºC

sec.

sec.

min.

min.

min.

-

6(*)221(*)221

36

999

999

999

999

999

1

2(*)221(*)221

999

999

999

999

999

1

-

ºF

ºF

ºF

sec.

min.

min.

sec.

sec.

-

-

ºF

ºF

sec.

sec.

min.

min.

min.

-

5

21

27

1

0

0

1

1

0

1

21

27

1

1

0

5

0

3

70

81

2

0

0

1

1

0

1

70

81

1

1

0

5

0

0

-50

-50

0.1

0

0

0

0

0

0

-50

-50

0

0

0

0

0

-58

-58

1

0

0

0

0

0

0

-58

-58

0

0

0

0

CELSIUS FAHRENHEIT

4.2 - Parameters table

MinMin MaxMax Standard UnitUnit

5.0

1(*)105(*)105

20

999

4(*)105(*)105

20

999

1

999

999

999

4

9

1(*)221(*)221

36

999

4(*)221(*)221

36

999

1

999

999

999

4

DescriptionFun

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

F13

F14

F15

F16

Offset indication

Operation mode of first stage

Minimum setpoint allowed to the end user (first stage)

Maximum setpoint allowed to the end user (first stage)

Control differential (hysteresis) of first stage

Minimum delay to turn on the first stage output

Operation mode of second stage

Minimum setpoint allowed to the end user (second stage)

Maximum setpoint allowed to the end user (second stage)

Control differential(hysteresis) of second stage

Minimum delay to turn on the second stage output

Time base of second stage cyclical timer

Activation time for second stage cyclical timer

Cyclical timer on second stage - time ON

Cyclical timer on second stage - time OFF

Operation mode of cyclical timer

°C

-

°C

°C

°C

sec.

-

ºC

ºC

ºC

sec.

-

sec.

s/m

s/m

-

°F

-

°F

°F

°F

sec.

-

ºF

ºF

ºF

sec.

-

sec.

s/m

s/m

-

-5.0

0

-50

-50

0.1

0

0

-50

-50

0.1

0

0

0

0

0

0

-9

0

-58

-58

1

0

0

-58

-58

1

0

0

0

0

0

0

Standard

F12 -Time base of second stage cyclical timer- seconds- minutes

F13 - Activation time of second stage cyclical timerThis function depends of F16. Every time that the temperature reach the configured value in , the configured time in this function is respected, to be activated the cyclical timer after. To activate the timer when is reached just set “0” in this function.

F14 - Cyclical timer on second stage - time ONIt is the time that the timer will be turned ON.

F15 -Cyclical timer on second stage - time OFFIt is the time that the timer will be turned OFF.

F16 - Operation mode of cyclical timer- Independent cyclical timer- Cyclical timer started by the first stage setpoint- First stage linked with cyclical timer (Timer starts ON)- First stage linked with cyclical timer (Timer starts OFF)- Cyclical timer output turned on whenever the the first stage output is turned ON

F07 - Operation mode of second stage- Refrigeration (controlled by )- Heating (controlled by )- Refrigeration (controlled by )- Heating (controlled by )- Cyclical timer

F08 - Minimum setpoint allowed to the end user (second stage)F09 - Maximum setpoint allowed to the end user (second stage)Electronic limits whose purpose is prevent that too high or too low setpoint temperatures are regulated.

F10 - Control differential(hysteresis) of second stageIt is the difference of temperature(hysteresis) between turn ON and turn OFF the output OUT2.

F11 - Minimum delay to turn on the second stage output the minimum time that the output OUT2 will remain turned off, in other words, the amount of time between the last startup and the next startup. Only if programmed in F07 = 0, 1, 2 or 3.

F17 - Operation mode of third stage - Refrigeration ( )- Heating ( )- Refrigeration ( )- Heating ( )- Intra range alarm (F18 and F19)

- Extra range alarm (F18 and F19)- Extra range alarm relative to the 1st stage setpoint ( - F18 and + F19), it is considered the absolute values of F18 and F19.

F18 - Minimum setpoint allowed to the end user (third stage)F19 - Maximum setpoint allowed to the end user (third stage)Electronic limits whose purpose is prevent that too high or too low setpoint temperatures are regulated. When the third stage is defined as alarm ( F17=4, 5 or 6 ), the acting points are defined in F18 and F19.

F20 - Control differential (hysteresis) of third stageIt is the difference temperature (hysteresis) between turn ON and turn OFF the output OUT3.

controlled by controlled by

controlled by controlled by

(*) This parameter allows adjustments up to 200ºC (392°F), but to work on these conditions it has to be used with silicone cable sensor (ex.: SB59).

4 - CONFIGURATIONS

4.1 - Control temperature adjust (SETPOINT)- Press for 2 seconds unti appears ,then release it. will appear and the temperature will be adjusted for the first stage.- Use and to change the value and then press when ready.- Adjust in the same way (2nd estage) and (3rd stage).- The adjustment and will only be displayed if F07 and F17 are configured with 0 or 1 values. - If the 3rd stage is configured as an alarm (F17 = 4, 5 or 6) and F26 = 1, the alarm time on and off ( ) will be permitted.

MT-543Ri LOG

0.0

1

-50

105

1

0

0

-50

105

1

0

0

5

0

0

0

0

1

-58

221

2

0

0

-58

221

2

0

0

5

0

0

0

SET

SET

MT

54

3L

OG

V0

1-0

4T

-12

43

0

7 FUNCTIONS WITH FACILITATED ACCESS

7.1 Register of minimum and maximum temperatures

Press , appear the minimum registered temperatures. Soon will apears the the maximum registered temperature.Note: To reset the registers, keep the key pressed during the visualization of minimum and maximum registers until to be showed.

-

-

- 7.2 Viewing current date and time:You can press the key shortly to view the date and time set in the controller. The display shows the current day, month, year, hours and minutes, in this order. Ex: 03/17/2006 12h43min

F22 - Delay to enable the alarm when the instrument is powered onDuring this time the alarm is kept turned off waiting that the system reaches the working control temperature (only if F17= 4,5 or 6).

F23 -Reactivation time of alarm when inhibited manuallyThis function allows three different settings (only if F17= 4,5 or 6):

- The alarm is inhibited by an indefinite period or until the temperature range in normal working condition and return the alarm again;

- The alarm can not be inhibited by facilitating access keys; to - The alarm will be inhibited during this period (in minutes), returning the call if the

alarm condition persists;

F24 - Alarm time (on cycle)It allows to adust the time that OUT3 output will keep turned on (only if F17= 4,5 or 6).

F25 - Alarm time (off cycle)It allows to adust the time that OUT3 output will keep turned off (only if F17= 4,5 or 6).

F26 - Enables F24 and F25 on easy access menuEnables the time setting alarm ON and OFF in the easy access menu, if the 3rd stage is configured as an alarm (F17=4, 5 or 6).

- Disabled- Enabled

F27 -Operation mode of Buzzer - Intra-range alarm (F28 and F29)

- Extra-range alarm (F28 and F29) - Extra-range alarm relative to the 1st stage setpoint ( - F28 and + F29), It is

considered the absolute values of F28 and F29)

F28 - Acting point of Buzzer (inferior limit)It is the inferior value of temperature to the buzzer alarm act as the configured Operation Mode of Buzzer (F27).

F29 - Acting point of Buzzer (superior limit)It is the superior value of temperature to the buzzer alarm act as the configured Operation Mode of Buzzer (F27).

F30 - Buzzer time onIt is the time that the Buzzer will be turned on (cycle on). To turn it off the sonore alarm (Buzzer) adjust the value “0” to this function.

F31 - Buzzer time offIt is the time that the buzzer will be turned off (cycle off). To turn it off the sonore alarm (Buzzer) adjust the value “0” to this function.

F32 - Inhibition time of Buzzer during electrical supply It is the time were the alarm will kept turned off even if in alarm contitions. It serves to inhibit the buzzer during the time while the system do not reaches the working control temperature.

F33 -Reactivation time of Buzzer when inhibited manuallyThis function allows three different settings:

- The Buzzer is inhibited by an indefinite period or until the temperature range in normal working condition and return the alarm again;

- The Buzzer can not be inhibited by facilitating access keys; to The Buzzer will be inhibited during this period (in minutes), returning the call if the

alarm condition persists.-

F34 - Time for the open door alarm When the door open alarm is enabled, the buzzer will be triggered after the door has been left open for the programmed amount of time. The time the buzzer is on and off is set with F30 and F31.

- Disabled to - Minutes to activate the open door alarm

F35 - Digital input operation modeThis function allows to configure what status of digital input will indicate that the door is open:

- Closed contact indicates that the door is open- Open contact indicates that the door is open

F36 - Datalogger operation mode Allows to choose between the following operation modes of the datalogger:

- Always OFF- Always ON- Manual operation

F37 - Datalogger sampling interval Time period in which the controller will register a sample of the temperature and the control outputs status.

F38 - Variation of the temperature to force data recording Temperature difference to forces the recording of data in the memory, independently of the sampling time configured at F37. To desable this function, just decrease the value until the message appears in the display.

F39 - Variation of the outputs to force data recording Indicates whether the change in the control outputs (configured as cooling or heating) will force the recording of data in memory regardless of the time of sampling set in F37. Data recording will also occur if the device enters or exits the alarm condition (for OUT3 and buzzer) and lack of and return electricity (if the battery is connected as described on item 10.1)

- OFF- ON

F40 - Overwrite records in the memory when it is full This function indicates whether the controller should start writing the new data at the beginning of the datalogger's memory when it is full. This prevents that the latest data recorded from controller be erased first.

F41 - Intensity of the digital filter This filter aims at simulating an increase of the mass of sensor , thus increasing its response time (thermal inertia). The larger the value adjusted in this function, the longest the response time of sensor.

A typical application requiring this filter is the freezer for ice cream or frozen goods, because when the door is opened a hot air mass reaches the sensor directly, causing the indication of the measured temperature to rise quickly and the compressor to be activated unnecessarily.

F42 - Network address RS - 485 Each controller connected to the RS-485 network must have its own address different from the others so that the computer will be able to identify it.Attention: To avoid communication problems, make sure that there are no controllers with the same address.

6.2 Functions -

- To enter the access code- Advanced setting functions- Date and time setting

6 - PARAMETERS ALTERATION

6.1 - To enter the function menuPress and simultaneously for 2 seconds to display and release the keys. When is displayed, press (shortly), and enter the code (123) through the and keys. Press to confirm. Use the and keys to access the other functions and proceed the same way to adjust them. Press (long touch) until is displayed to exit the menu and return to normal operation.

SET SET

SET

SET

7.3 - Clearing datalogger memory

Press the and keys for 2 seconds to display . The LCD then displays . If you

don't want to clear the memory and cancel the operation press . To clear the memory press until is displayed and press to confirm and exit the function.

- With F36 set to value 2 and the and keys pressed simultaneously for 10 seconds one can enable or disable the operation of data recording (datalogger). The message will be shown, then when the datalogger is activated and when it is deactivated. If F36 is set to 0 or 1 the messages and will be displayed respectively.

-

7.4 Manual datalogger activation

7.5 Alarm and Buzzer inhibition To inhibit the OUT3 press the and keys simultaneously . To inhibit the Buzzer press the and keys simultaneously.- The inhibition of alarm and buzzer can be configured by the functions F23 and F33, respectively.

SET

SET

SET

SET

SET

8 - SIGNALING

Invalid parameters configurationThe outputs are turned off automatically in this situationPlease check which parameters have invalid data configured and correct them to return to normal operation.

-

OUT 1 - Output 1 turn onOUT 2 - Output 2 turn onOUT 3 - Output 3 turn onBUZZ - Internal buzzer activated - Detached temperature sensor or outside the specified range.

9 SELECTION OF THE UNIT (ºC / ºF)In order to define the unit that the instrument will operate in, enter function with the access code 231 and confirm with the key. Press the key and the indication will appear. Press to choose between or and confirm. After selecting the unit the message will appear, and the instrument will return to the message . Every time that the unit is changed, the parameters should be reconfigured, since they assume the “standard” values.

- Deprogram clock ®- Communication with SITRAD

- Open door- Alarm of datalogger memory full- Alarm of datalogger memory corrupted-

SET

SET

F21- Minimum delay to turn on the third stageIt is the minimum time that the output OUT3 will keep turned off, it means, the amount of time between the last stop and the next start. Only if programmed in F17 = 0, 1, 2 or 3.

6.3 - Adjustment of the date and timeInside the functions menu, press the key until the message appears in the visor.Hit key . The settings will appear in the following order: DAY MOUTH YEAR HOURS MINUTES

Ex.: 17/03/2006 12h43min

SET

- Day- Month- Year- Hours- Minutes

- Day- Month- Year- Hours- Minutes

PROTECTIVE :VINYL

This adhesive vinyl (included inside the packing) protects the instruments against water drippings, as in commercial refrigerators, for example. Do the application after finishing the electrical connections.

Remove the protective paper and apply the vinyl on the entire superior part of the device, folding the flaps as indicated by the arrows.

72 mm

Dimension of the clipping for setting of the instrument

in panel 29 m

m

®

12 - INTEGRATING CONTROLLERS, RS-485 SERIAL INTERFACE AND

COMPUTER

11 - WIRING DIAGRAM

ENVIRONMENTAL INFORMATIONPackage:The packages material are 100% recyclable. Just dispose it through specialized recyclers.

Products:The electro components of Full Gauge controllers can be recycled or reused if it is disassembled for specialized companies.

Disposal:Do not burn or throw in domestic garbage the controllers which have reached the end-of-life. Observe the respectively law in your region concerning the environmental responsible manner of dispose its devices. In case of any doubts, contact Full Gauge controls for assistance.

10.3 - Data recording in the event of a power outageWith the battery connected, as described in item 10.1 and the datalogger activated, the MT-543Ri LOG will record the temperature in the internal memory even in the event of a power outage. These records can be configured to be recorded at preset time intervals (F37) and/or with the temperature variation (F38). If the temperature variation data record is disabled, the device will read the temperature sensor only at the set time intervals, therefore using less energy. With the temperature change recording activated, the sensor will be constantly read, using more energy, but recording all the details of the temperature variation.

10.4 - Battery Precautions- Avoid unnecessarily draining the battery;- If the appliance is not in use, the battery should be disconnected;- If a greater time interval between each sample is set, the datalogger will use less battery power;- If not required, disable the F38 function to avoid wasting the energy used in reading the temperature sensor.

OU

T 1

OU

T 2

C2C1

CO

MM

ON

OU

T 1

AN

D 2

OU

T 3

NO

OU

T 3

NC

C3BC3A

Loadssupply

C3A and C3B

S1 (b

lack

)S

enso

r

4 5 6 7 8 9 10 11 12321 21

Serial communication RS-485

Digital input

A B

CO

MM

ON

OU

T 3

Loadssupply

C1 and C2

Powersupply

IMPORTANT

According to the chapters of norm IEC 60364:

1: Install protector against overvoltage on the power supply

2: Sensor cables and signal cables of the computer may be joined, but not in the same electric conduit

through which the electric input and the activation of the loads run

3: Install transient suppresors (RC filters) parallel to the loads as to increase the product life of the

relays.

Schematic for the connection of supresors to contactors

Sup

pres

or

A1

A2

A1 and A2 are the contactor coil terminals.

Schematic for the connection of supresors to direct activation loads

Load

Sup

pres

or For direct activation the maximumspecified current should be takeninto consideration.

A B

RS-485 Network

RS-485 Serial Interface

®

Device used to establish the connection Full Gauge Controls’ instruments with the Sitrad .

Instrument

RS-485 Network

ExternalmeshAB

A AB B

A B

A AB B

A B

A AB B

A B

AB AB

A AB B

A B

Serial interface RS-485

Full Gauge

MOD 64

A AB B

A B

terminal grounded

Distribution Box Used to connect more than one instrument to the Interface. The wire's connections must be made in agreement with the following rules: terminal A of the instrument connects to the terminal A of the distribution box, that must be connected with the terminal A of the Interface. Repeat the action for terminals B and , being the cable shield. The terminal of distribution box must be connected to the respective terminals of each instrument.

Battery connection (*)

Above specified current use a contactor.

Note 1: Sensor cable length can be increased by the user until 200 meters, using 2 x 24 AWG cable. For

immersion in water use thermometric well.

(*) The MT-543Ri LOG comes with an internal battery disconnected for storage. Before installing

the instrument, connect it to the terminals 2 and 3 through a wire, as shown.

Note 2: After connecting the terminals as indicated, keep the instrument powered on for at least

ten hours for battery charging.

4 - 54 - 6

12V24V

MT-543Ri LOG-

90 ~ 264V

MT-543RiL LOG

0 (12V ) (24V )

90 ~ 264V

10 - INTERNAL BATTERY

10.1 - Battery connectionThe MT-543Ri LOG has an internal rechargeable battery. This battery provides the power to operate the clock and record the data in the memory in the event of a power outage. The device leaves the factory with the battery disconnected for storage. Before installing the instrument, the battery must be connected using terminals 2 and 3, using a wire as shown in the wiring diagram.

10.2 - ClockThe MT-543Ri LOG has an internal clock to record data in its memory. To continue operation, even in the event of a power outage, the battery must be connected as described in item 10.1. If the battery is disconnected or discharged, when energizing the device, the following message will appear indicating that the date and time should be set.

PUMP AUX 1 AUX 2

MIC

RO

SO

L I

I pl

us

OUT 1 OUT 2 OUT 3

PC

T-4

00

R

plus

OUT 4 ALMR