MOXY ADT Full Line

Transcript of MOXY ADT Full Line

-

8/12/2019 MOXY ADT Full Line

1/24

ARTICULATED DUMP TRUCKS

PRODUCT INFORMATIONmachinery for challenging conditions

-

8/12/2019 MOXY ADT Full Line

2/24

WIN-WIN PARTNERSHIP BETWEEN DOOSANINFRACORE AND MOXY TRUCKS

BUILT BY MOXYS TECHNOLOGY AND PRESENTED BY DOOSAN INFRACORE.

GROWING, ENHANCING TECHNOLOGY, INCREASING THE PRODUCT OFFERING AND PROVIDING A

BIGGER OPPORTUNITY FOR CUSTOMERS.

-

8/12/2019 MOXY ADT Full Line

3/24

THE NEXT GENERATION OF ARTICULATED DUMP TRUCKS OFFERSRELIABLE MACHINERY FOR CHALLENGING CONDITIONS

DOOSAN MOXY strives to be a pioneer in the field of product development and performance.

With the new generation of DOOSAN MOXY articulated dump trucks, the product features

have been refined and innovated to meet the tough demands of the future. Our philosophy

is to stay one step ahead of the competition and always deliver a full-range of articulated

dump trucks to the market.

ADT RANGE 3

-

8/12/2019 MOXY ADT Full Line

4/24

DOOSAN MOXY PLUS 1 CONCEPT

Our goal has been to develop a new line of advanced reliable and cost effective articulated dump trucks, loaded with significant

competitive advantages.

With the new, modern product design and sophisticated technical features, DOOSAN MOXY is proud to introduce the unique

MOXY Plus 1 concept with the folowing benefits:

Plus 1Productivity Plus 1StabilityPlus 1Power Plus 1ReliabilityPlus 1Traction Plus 1Comfort

-

8/12/2019 MOXY ADT Full Line

5/24

-

8/12/2019 MOXY ADT Full Line

6/24

Power

Plus1

DOOSAN MOXY Plus 1 Concept

DOOSAN MOXY uses proven, reliable and

powerful diesel engines with excellent torque

which achieves low fuel consumption and

fulfills Tier 3 US/EPA regulation guidelines.

DOOSAN MOXY utilizes reliable transmissions

that feature smooth gear shifting abilities.

These features result in the maximum net

power transmission to the wheels, resulting in

maximum fuel efficiency.

-

8/12/2019 MOXY ADT Full Line

7/24

Plus1

Productivity

The DOOSAN MOXY Plus 1 concept offers a larger

load capacity in all weight class categories.

Additional load capacity, combined with superior

power and traction allow for improved

productivity. The unique advantages of

DOOSAN MOXYS permanent six-wheel drive,

free-swinging rear tandem articulation hinge

system, independent front wheel suspension

system and sloping rear frame provide excellent

driving stability with equal weight distribution and

wheel power. The DOOSAN MOXY articulated

dump truck is designed to work under rough

conditions and can also travel at speeds up to

31 mph.

Engine

MT 31 Scania Engine

Power rating: (1kW=hp/1.36)

(ISO 3046) 347 (255 kW)

(ISO 9249) 336 (247 kW) No. of cylinders: 5 (in line)

Cylinder volume: 549 cubic inches (9.0 liters)

Air filter: Dry type

MT 41 Scania Engine

Power rating: (1kW=hp/1.36)

(ISO 3046) 450 (331 kW)

(ISO 9249) 438 (322 kW)

No. of cylinders: 6 (in line)

Cylinder volume: 714 cubic inches (11.7 liters)

Air filter: Dry type

-

8/12/2019 MOXY ADT Full Line

8/24

DOOSAN MOXY Plus 1 Concept

Stability

Plus1

DOOSAN MOXYS free-swinging rear tandem

bogie and the special articulation system offer

excellent performance and the best possible

ground contact in soft and difficult terrain. The

sloping rear frame, in combination with the

track width, ensures a lower center of gravity

and class-leading sideways stability, which

removes the need for wide, low profile tires.

One of the main highlights of the DOOSAN MOXY

concept is the location of the turning ring in

relation to the swing point which always ensures

equal weight distribution to the front wheels.

Equal distribution to the front wheels makes it

possible to use the differentials while

maintaining maneuverability. DOOSAN MOXYS

unique independent front wheel suspension

allows for maximum ground contact and shock

absorption.

-

8/12/2019 MOXY ADT Full Line

9/24

ADT RANGE 9

Traction

Plus1

The unique DOOSAN MOXY concept

offers permanent six-wheel drive which

ensures stability and equal distribution to

accommodate all job applications.

DOOSAN MOXYS superior driveline ensures

maximum traction performance and durability.

-

8/12/2019 MOXY ADT Full Line

10/24

DOOSAN MOXY Plus 1 Concept

Reliability

Plus1

DOOSAN MOXY has one of the most reliable

dump trucks in the industry because of its

strong and reliable system solutions. The

automatic central lubrication system is

standard on all DOOSAN MOXY models. With

over thirty years dedicated to product

development, the new generation of

DOOSAN MOXY trucks provides innovative

drive train and fatigue-proof structure.

-

8/12/2019 MOXY ADT Full Line

11/24

ADT RANGE 11

Comfort

Plus1

The cabin is equipped with air-conditioning

and an operator seat with air suspension to

provide excellent operator comfort. Precise

steering, good visibility and low noise levels

provide a comfortable cabin environment.

The tip-tronic gearshift feature enables

the operator to run the truck in bothautomatic and manual gears to ensure the

smoothest possible gear-shifts and

momentum while operating the truck.

The sloping hood provides an excellent

view from the operators position combined

with good rear visibility. DOOSAN MOXY

cares about the environment and aims

to set the best possible standards in the

manufacturing of our products. DOOSANMOXY utilizes industry leading engines that

achieve low fuel consumption and fulfill the

latest Tier 3 US/EPA regulations in addition

to all noise regulations.

DOOSAN MOXY provides exceptional

operator comfort with low cabin vibration

levels. Minimal fuel consumption is

achieved while lock-up clutch is engaged in

mechanical mode.

-

8/12/2019 MOXY ADT Full Line

12/24

MT51Line Up

DOOSAN MOXY Plus 1 Concept

Highline Equipment MT26, MT31, MT36, MT41 (MT51)

Standard

Tiltable cabin with hydraulic pump Cabin top hat Instructor seat with safety belt Radio / CB-player Front wheel mudflaps Front mudguards extension Mudflaps in front of bogie Working light / Extra high beam Automatic lubrication system

ROPS / FOPS safety cabin Cabin heater and defroster Air conditioner (refrigerant R134a) Adjustable air - suspended operator seat with

armrest and headrest

Safety belt on operator seat Tilt and height adjustable steering column Comprehensive instrumentation Speedometer Cigarette lighter and ashtray Retractable roller sunblind Tinted safety glass Sliding window left-hand side Windshield wiper and washer

Four exterior mirrors Protective grille for rear window Emergency steering Air cleaner service indicator Protection under engine and transmission

Towing hook-front/rear Exhaust brake Retarder brake Parking brake alert system Directional and warning lights Brake lights Head lights (H3/H7) Parking lights Diode rear light

Back-up light and alarm Cabin interior light Instrument and switch lighting Front light protection Battery main switch

-

8/12/2019 MOXY ADT Full Line

13/24

MT41 MT36 MT3 MT26

ADT RANGE 13

1

Heated operator seat

Sliding window, front, right-hand side

Sliding window, rear, right-hand side

Sliding window, door, right-hand side Radio / Cassette-player Heated mirrors

Rotating beacon

Extra back-up light (work light on mirror arms)

Rear view system

First aid kit

Options

Fire extinguisher

Warning triangle

Body lining (plates)

Protection in front of body (spillguard) Top tailgate kit Wheel chocks (set of 2)

Exhaust heated body kit

Electrical engine coolant heater

Tool kit (spanners, socket etc.)

Low profile tires

-

8/12/2019 MOXY ADT Full Line

14/24

Top 10 Advantages of

DOOSAN MOXY Articulated Dump Trucks

- Low operating cost

- Excellent performance in difficult terrain

- Independent front suspension ensures

maximum ground contact and stability

- The sloping rear frame ensures low center of

gravity, good stability and excellent weight

distribution to the front axle

- Improved driver comfort and easy operation

- Tier 3 of USA/California regulations (ISO

8178) for emissions

- Free-swinging rear tandem bogie ensures

the best possible ground contact

- Articulation hinge system ensures equal

weight distribution to the front axle in all

situations

- Permanent 6-wheel drive, a significant

advantage in rugged terrain

- Easy maintenance

Best Structure for All-Condition Terrain

DOOSAN MOXY articulated dump trucks have

permanent 6-wheel drive for equal power distri-

bution while the free-swinging rear tandem bogie

and the special articulation system offer excellent

driving performance. The articulation hinge is po-

sitioned behind the turning ring to ensure equal

weight distribution. The sloping body design fur-

ther enhances Doosan Moxy stability and ensures

fast and easy tipping for increased productivity

in even the most demanding conditions. Many

DOOSAN MOXY machines have worked more than

25,000 hours without any major overhaul of the

engine. Fully automatic transmission control unit

and smooth gear-shifting abilities enable the op-

erator to concentrate on working conditions with

maximum comfort.

Unique Concept of DOOSAN MOXYADT

Disc brakes

Rear axle housing

Rear axle differential

Gear-drive, free swingingtandem housing

Parking brake

Articulation hinge

Sloping rear frame

Concept

-

8/12/2019 MOXY ADT Full Line

15/24

Engine

Configuration

Gross Power

Net Power

Gross Torque

Load Index

Capacity

Body Volume

Density Index

Gross Weight

Net Weight

Payload Kg

Power to Weight

Empty

Loaded

Transmission

Speeds

Travel Speed

Brakes

Front

Rear

Retarder

Body

Dimensions

Tot Lenght

Width

Load over Height

Turning Radius

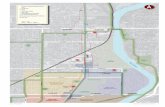

Moxy MT26-lll

Scania DC9

5 in Line / 9.0 liter

228 kw @2200 Rpm

224 kw @2200 Rpm

1345 Nm @1500 Rpm

25.33 kw / liter

SAE 2:1

14.7m3

1.64 t/m3

44.95 tons

20.4 tons

24100

Net Power vs Tons

10.98 kw/t

5.03 kw/t

ZF 6WG260 RPC Countershaft

6F - 3R

51.0/33.0 km/h

Wet Multiple Disc

Wet Multiple Disc

Exhaust Brake & T/M Retarder

Hardo x 400

9816 mm

2750 mm

2864 mm

8.9 m

Moxy MT31-lll

Scania DC9

5 in Line / 9.0 liter

255 kw @2200 Rpm

247 kw @2200 Rpm

1455 Nm @ 1500 Rpm

28.33 kw//liter

SAE 2:1

17.6m3

1.62t/m3

49.8 tons

21.3 tons

28,500

Net Power vs Tons

11.60 kw/t

4.95 kw/t

ZF 6WG260 RPC Countershaft

6F - 3R

51/33 km/h

Wet Multiple Disc

Wet Multiple Disc

Engine Exh &T/M Ret Brake

Hardox 400

9857 mm

2990 mm

2946 mm

8.7 m

Moxy MT36

Scania DC12

6 in Line /11.7 liter

294 kw @2200 Rpm

285 kw @ 2200 Rpm

1854 Nm @1500 Rpm

25-13 kw/liter

SAE2:1

20.1m3

1.64t/m3

61.4 tons

28.8 tons

Net Power vs Tons

9.90 kw/t

4.63 kw/t

ZF 6WG310 RPC Countershaft

6F - 3R

51.0 / 31.0 km/h

Wet Multiple Disc

Wet Multiple Disc

Engine Brake & T/M Retarder

Hardox 400

10450 mm

3275 mm

3440 mm

8.85 m

Moxy MT41

Scania DV12

6 in Line / 11.7 liter

331 kw @2200 Rpm

322 kw @2200 Rpm

1854 NM @1200 Rpm

28.29 kw/liter

SAE 2:1

22.7m3

1.64t/m3

66.4 tons

29.2 tons

Net Power vs Tons

10.82 kw/t

4.76 kw/t

ZF 6WG310 RPC Countershaft

6F - 3R

53.0/34.0 km/h

Wet Multiple Disc

Wet Multiple Disc

Engine Brake & T/M Retarder

Hardox 400

10445 mm

3460 mm

3185 mm

8.8 m

Ultimate Efficiency

Lower power curve when empty plus reduced weight

achieved through state of the art design and lightweight, highgrade, wear resistant steel.

Ultimate Safety

Superior visibility because of new front wagon design.

Ultimate Traction & Stability

Sloping Frame, well positioned turning ring and excellent

weight distribution remove the need for wide, low profile

tires, significantly reducing running costs. New skip design

further improves stability while tipping.

Ultimate Comfort

Fully independent nitrogen suspension and new, highly

specified cabin offer unparalleled levels of comfort.

Ultimate Service Access

Remote mounted service points mean general servicing

can be completed at ground level. Excellent access is

?offered by the side tilting cabin. Hood design capable of

opening to 83 for the improved access.

Ultimate Power/Weight Ratio

Class-leading power to weight ratio of 6.48hp per ton

The DOOSAN MOXY Concept -

ADT RANGE 15

-

8/12/2019 MOXY ADT Full Line

16/24

45

Unique Concept of DOOSAN MOXYADT

One of the main points in the Doosan Moxy concept is

the location of the turning ring in relation to the swing

point. The turning ring is located in front of the swingpoint which always ensures equal weight distribution

to the front wheels in all situations, also during maxi-

mum turning. Equal weight distribution to the front

wheels makes it possible to use the differential with

only 45% locking value. This provides drive to both

wheels in all situations without completely locking up

the wheels. Our competitors have located the turning

ring behind the swing point giving different weight

distribution to the front wheels. Due to differentials

on the front wheels, our competitors use 100%differential lock causing steering difficulties. A dif-

ferential lock of 100% creates more force on the

driveline in all turns resulting in a higher amount of

wear on the tires.

Forward mounted turning ring

Moxys philosophy on frame design is generally the

same as manufacturers of rigid dump trucks. The

frame is inclined (sloped) downward from the hinge

points to obtain equal weight distribution on all axles

while fully-loaded. As a result, lower center of gravity

is obtained giving better stability.

Unique Frame Sloping forWeight Distribution

Transferred andFront unit

weight50%

weight50%Transferred and Front unit

weight100%Transferred and Front unit weight0%

Transferred andFront unit

weight50%

Weight Distribution Articulation System

The hood has a wide opening to provide

accessibility to the engine for easy maintenance

The tilting cabin allows the same clear access to the

transmission and hydraulic components

All electrical and AC connections are at the rear of

the cabin. This allows tilting of the cabin without

disconnecting.

Excellent Service Accessibility

DOOSAN MOXY

Competitors

New weight - saving bogie designoil immersed brakes front & rear

Improvements of III Series

Moxys unique independent front suspension allows

for free movement on one side movement contact

and shock absorption. Our competitors use rigid axles

which cause movement on the opposite side of the

axle which results in driver discomfort.

Front Wheel Suspension

DOOSAN MOXY Competitors

DOOSAN MOXY Competitors

Free - swinging Tandem Housing

Competitors

45

DOOSAN MOXY

-

8/12/2019 MOXY ADT Full Line

17/24

DOOSAN MOXY Drive Line Competitors Drive Line

Excellent Tire Wear Prevention

More efficient braking under load, which means less

brake fade because of the oil cooling plus more

brake force

Less servicing intervals, brake discs last longer -

In very adverse conditions like deep mud and

water, the dry disc brakes cause the brake pads

and discs to have a very short service life - Wet

brakes are not affected by these conditions

because they are fully encased in Oil

Reduced maintenance cost

NAF system in MT26/31 III has a big advantage.

It does not require forced cooling ike most

competitors.

There is no danger of sparks

Wet Disk Brake in Whole Line Up

Cabin is equipped with air-conditioning and an operator

seat with air-suspension

Sloping hood provides an excellent view from the

operators position combined with good rear visibility

Rubber suspension mounted for CABIN lead to low

vibration levels

Tip-tronic gearshift feature enables the operator to

run the truck in both automatic and manual gear to

ensure the smoothest possible gear-shift

Operators Comfort

Operating in Tough Conditions Operating on Extreme Terrain Dumping Hauling

Best Ground Contact in All Condition Terrain

New weight - saving bogie designno need for tail gate increased payload

DOOSAN MOXY driveline only requires 1 diff lock/

limited slip diff mounted on the rear tandem

Competitors drive line requires 2 units on

the rear axles

Competitorsrear diffs get a lot of wear because

of the nature of the operation between the

middle axle and rear axle because a inter axle

lock unit between the 2 rear axle diffs

ADT RANGE 17

-

8/12/2019 MOXY ADT Full Line

18/24

BODY

Material: Hardened abrasion-resistant steel plates Tilt cylinders: Single stage, double-acting Tipping time: Up: 11sec. / Down 10sec. The body is designed for exhaust heating Sloping body down from the hinge point

Level capacity : Heaped capacity : (Acc. SAE J 1363, 2:1) Heaped capacity : (Acc. SAE J 1363, 1:1)

WEIGHTS

Empty: Front axle

Rear axle

Loaded: Front axleRear axle

Pay loadTotal weight (loaded)

NOTE: All weights include a full fuel tank and operator

GROUND PRESSURES

Standard 23.5x 25tires with 15% sinkage

Empty: Front axleRear axle

Loaded: Front axleRear axle

CAPACITIES

Fuel TankHydraulic System Engine Cooling System Transmission DropboxEngine Crankcase Front Reduction GearRear DifferentialTandem Housing

SPEEDS1st

2nd3rd

4th5th

6th

SUSPENSION

Front: Independent with long life rubber springs and hydraulic shock absorbers Rear: Free-swinging tandem housing

ARTICULATION HINGE AND STEERING

Articulation hinge with forward mounted turning ring Steering cylinders (two): Double-acting The steering is approved according to ISO 5010 Max. steering angle: 45 Ground driven emergency steering pump

DRIVE LINE

Full-time 6x 6drive with two transverse differentials and one longitudinal Front axle transverse differential: Limited-slip with45% locking ratio Rear axle transverse differential: Limited slip with45% locking ratio Inter-axle longitudinal differential: Torque-proportioning differential, integrated into

Torque distribution: 1/3to the front axle2/3to the rear axle100% lockable

Tandem housing: Gear driven, free-swinging.Provides equal drive to rear wheels and ensures the best possible ground contact

- whatever the ground conditions

Cubic Yards Cubic Meters

16 12

20 15

24 18

LB KG

24,640 11,200

21,230 9,650

32,164 14,620

66,726 30,330

53,020 24,100

98,890 44,950

PSI kPa

15.52 107

6.53 45

20.02 138

20.89 144

U.S. GALLONS LITERS

84.5 320

36.4 13811.9 45

15.1 57

8.7 33

3.5 13.2

2 X 0.80 2 X 3

8.5 32

2 X 19.8 2 X 75

MPH KMH4 6

6 9

7 14

14 22

20 33

32 51

ENGINE

Scania DC 9, water-cooled, unit injected diesel engine with turbo chargerand air to air intercooler Complies with Stage 3of EU Directive 97/68/-EC

and Tier 3of USA/California regulations (ISO 8178) for emissions Power rating: (1.36 hp = 1 kW)

(ISO 3046) 310hp (228kW)

(ISO 9249) 299hp (220kW) No. of cylinders: 5(in line)Cylinder volume: 549cubic inches (9.0 liters) Air filter: Dry type

TRANSMISSION

ZF 6 WG 260Dash 4electronically-controlled automatic transmission

the torque converter has automatic lock-up in all gears

BRAKE SYSTEM

Dual circuit braking system acting on all six wheels Approved according to ISO 3450 All hydraulic operated brakes with enclosed oil-cooled wet multiple discs all round Spring actuated hydraulic released parking brake, mounted on propeller shaft Max. gradient, parking brake: 20 Automatic engine brake as standard Automatic transmission retarder as standard

HYDRAULIC SYSTEM

Pumps: 2 variable displacement piston pumps : for steering & tipping -

for cooling, fan, brakes & auxilaries Delivery: 60.8gallon/min(230l/min) @2200 rpm Filtration: One return flow filter & high pressure filter Pressure-setting, main safety valves:Tipping Circuit: 4,061 PSI (280bar)Steering Circuit: 3,046 PSI (210bar)

ELECTRICAL SYSTEM

Alternator: 28V 100A Batteries: (two): 12V 140Ah

(series connected to give 24V) Starter: 5.4 HP (4.0kW)

CAB

Approved to ROPS/FOPS standards (ISO 3471, ISO 3449, SAE J 231and SAE J1040 April88) Low interior sound level 74 dB(A) (ISO 6394) The cab is centrally located on rubber mountings Hand and arm vibrations are less than 2.5 m/s according to ISO 5349-2 Whole body vibration is less than0.5m/s according to ISO 2631-1 Superior visibility - for safer operation Superior operating controls location Adjustable suspended operator seat Adjustable steering column Heater and Air Conditioning Tilting for service access

TIRES

Standard 23.5R25two star radial

Turning radius according to

ISO 7457: 24.8feet (7.56 m) PERFORMANCE DIAGRAM

millimeter (inches)

MT 26 III2916 (114.8)

9816 (386.4)

1 76 8 ( 69 .6 ) 1 35 7 ( 53 .4 )2650 (10 4.3) 1125 (44. 3)

3530(

130)

3354(

132) 6

0

40(

237.7)

565

(22.2

)

700

(27.5)

2854(

112.7

)

70

2130 (83.9)

2750 (116.1)

2473(

97.3

)

576

(22.7

)

2625 (103.3)

Dimensions&Technical specifications

-

8/12/2019 MOXY ADT Full Line

19/24

237.0 (93.3)

2990 (117.7)

2100(

82.7)

576

(22.7

)

2875 (113.2)

BODY

Material: Hardened abrasion-resistant steel plates Tilt cylinders: Single stage, double-acting Tipping time: Up: 11sec. / Down 10sec. The body is designed for exhaust heating Sloping body down from the hinge point

Level capacity : Heaped capacity : (Acc. SAE J 1363, 2:1) Heaped capacity : (Acc. SAE J 1363, 1:1)

WEIGHTS

Empty: Front axle

Rear axle

Loaded: Front axleRear axle

Pay loadTotal weight (loaded)

NOTE: All weights include a full fuel tank and operator

GROUND PRESSURES

Standard 23.5x 25tires with 15% sinkage

Empty: Front axleRear axle

Loaded: Front axleRear axle

CAPACITIES

Fuel TankHydraulic System Engine Cooling System Transmission DropboxEngine Crankcase Front Reduction GearRear DifferentialTandem Housing

SPEEDS1st

2nd3rd

4th5th

6th

SUSPENSION

Front: Independent with long life rubber springs and hydraulic shock absorbers Rear: Free-swinging tandem housing

ARTICULATION HINGE AND STEERING

Articulation hinge with forward mounted turning ring Steering cylinders (two): Double-acting The steering is approved according to ISO 5010 Max. steering angle: 45 Ground driven emergency steering pump

DRIVE LINE

Full-time 6 x 6 drive with two transverse differentials and one longitudinal Front axle transverse differential: Limited-slip with 45% locking ratio Rear axle transverse differential: Limited slip with45% locking ratio Inter-axle longitudinal differential: Torque-proportioning differential, integrated into

Torque distribution: 1/3to the front axle 2/3to the rear axle 100% lockable

Tandem housing: Gear driven, free-swinging.Provides equal drive to rear wheels and ensures the best possible ground contact

- whatever the ground conditions

Cubic Yards Cubic Meters

18 14

24 18

29 22

LB KG

25,135 11,425

25,300 11,500

36,300 16,500

75,735 34,425

61,600 28,000

112,035 50,925

PSI kPa

15.37 106

7.83 54

22.34 154

0.24 163

U.S. GALLONS LITERS

92.4 350

39.6 15011.9 45

15.1 57

8.7 33

3.5 13.2

2 X 0.8 2 X 3

8.5 32

2 X 19.8 2 X 75

MPH KMH4 6

6 9

9 14

14 22

20 33

32 51

ENGINE

Scania DC 9, water-cooled, unit injected diesel engine with turbo chargerand air to air intercooler Complies with Stage 3of EU Directive 97/68/-EC

and Tier 3of USA/California regulations (ISO 8178) for emissions Power rating: (1.36 hp = 1 kW)

(ISO 3046) 347hp (255kW)

(ISO 9249) 336hp (247kW) No. of cylinders: 5(in line)Cylinder volume: 549cubic inches (9.0 liters) Air filter: Dry type

TRANSMISSION

ZF 6WG 260Dash 4electronically-controlled automatic transmission

the torque converter has automatic lock-up in all gears

BRAKE SYSTEM

Dual circuit braking system acting on all six wheels Approved according to ISO 3450 All hydraulic operated brakes with disc brakes all round Spring actuated hydraulic released parking brake, mounted on propeller shaft Max. gradient, parking brake: 20 Automatic engine brake as standard Automatic transmission retarder as standard

HYDRAULIC SYSTEM

Pumps: 2variable displacement piston pumps : for steering & tipping -

for cooling, fan, brakes & auxilaries Delivery: 60.8gallon/min(230l/min) @2200 rpm Filtration: One return flow filter & high pressure filter Pressure-setting, main safety valves:Tipping Circuit: 3,046 PSI (280bar)Steering Circuit: 4,061 PSI (210bar)

ELECTRICAL SYSTEM

Alternator: 28V 100A Batteries: (two): 12V 140Ah

(series connected to give 24V) Starter: 5.4 HP (4.0kW)

CAB

Approved to ROPS/FOPS standards (ISO 3471, ISO 3449, SAE J 231and SAE J1040 April88) Low interior sound level 74 dB(A) (ISO 6394) The cab is centrally located on rubber mountings Hand and arm vibrations are less than 2.5m/s according to ISO 5349-2 Whole body vibration is less than 0.5m/s according to ISO 2631-1 Superior visibility - for safer operation Superior operating controls location Adjustable suspended operator seat Adjustable steering column Heater and Air Conditioning Tilting for service access

TIRES

Standard 23.5R25two star radial

PERFORMANCE DIAGRAM

Turning radius according to

ISO 7457 : 25.2feet (7.68 m)

MT 31 III2916 (114.8)

9857 (388)

1768 (69. 6) 1398 (55)2650 (104.3) 1125 (44 .3)

3530(

139)

3436(

135.3

)60

52(

238.3)

571

(22.5

)

625

(24.

6)

2946(

116)

70

Dimensions&Technical specifications

millimeter (inches)

-

8/12/2019 MOXY ADT Full Line

20/24

2130 (83.9)

2750 (116.1)

2473(

97.3

)

576

(22.7

)

2625 (103.3)

BODY

Material: Hardened abrasion-resistant steel plates Tilt cylinders: Single stage, double-acting Tipping time: Up: 11sec. / Down 10sec. The body is designed for exhaust heating Sloping body down from the hinge point

Level capacity : Heaped capacity : (Acc. SAE J 1363, 2:1) Heaped capacity : (Acc. SAE J 1363, 1:1)

WEIGHTS

Empty: Front axle

Rear axle

Loaded: Front axleRear axle

Pay loadTotal weight (loaded)

NOTE: All weights include a full fuel tank and operator

GROUND PRESSURES

Standard 23.5x 25tires with 15% sinkage

Empty: Front axleRear axle

Loaded: Front axleRear axle

CAPACITIES

Fuel TankHydraulic System Engine Cooling System Transmission DropboxEngine Crankcase Front Reduction GearRear DifferentialTandem Housing

SPEEDS1st

2nd3rd

4th5th

6th

SUSPENSION

Front: Independent with long life rubber springs and hydraulic shock absorbers Rear: Free-swinging tandem housing

ARTICULATION HINGE AND STEERING

Articulation hinge with forward mounted turning ring Steering cylinders (two): Double-acting The steering is approved according to ISO 5010 Max. steering angle: 45 Ground driven emergency steering pump

DRIVE LINE

Full-time 6x 6drive with two transverse differentials and one longitudinal Front axle transverse differential: Limited-slip with45% locking ratio Rear axle transverse differential: Limited slip with45% locking ratio Inter-axle longitudinal differential: Torque-proportioning differential, integrated into

Torque distribution: 1/3to the front axle 2/3to the rear axle 100% lockable

Tandem housing: Gear driven, free-swinging.Provides equal drive to rear wheels and ensures the best possible ground contact

- whatever the ground conditions

Cubic Yards Cubic Meters

16 12

20 15

24 18

LB KG

24,640 11,200

21,230 9,650

32,164 14,620

66,726 30,330

53,020 24,100

98,890 44,950

PSI kPa

15.52 107

0.53 45

20.02 138

20.89 144

U.S. GALLONS LITERS

84.5 320

36.4 13811.9 45

15.1 57

8.7 33

3.5 13.2

2 X 0.80 2 X 3

8.5 32

2 X 19.8 2 X 75

MPH KMH4 6

4 9

9 14

14 22

21 33

32 51

ENGINE

Scania DC 9, water-cooled, unit injected diesel engine with turbo chargerand air to air intercooler Complies with Stage 3of EU Directive 97/68/-EC

and Tier 3of USA/California regulations (ISO 8178) for emissions Power rating: (1.36 hp = 1 kW)

(ISO 3046) 310hp (228kW)

(ISO 9249) 299hp (220kW) No. of cylinders: 5(in line)Cylinder volume: 549cubic inches (9.0 liters) Air filter: Dry type

TRANSMISSION

ZF 6 WG 260Dash 4electronically-controlled automatic transmission

the torque converter has automatic lock-up in all gears

BRAKE SYSTEM

Dual circuit braking system acting on all six wheels Approved according to ISO 3450 All hydraulic operated brakes with enclosed oil-cooled wet multiple discs all round Spring actuated hydraulic released parking brake, mounted on propeller shaft Max. gradient, parking brake: 20 Automatic engine brake as standard Automatic transmission retarder as standard

HYDRAULIC SYSTEM

Pumps: 2 variable displacement piston pumps : for steering & tipping -

for cooling, fan, brakes & auxilaries Delivery: 60.8gallon/min(230l/min) @2200 rpm Filtration: One return flow filter & high pressure filter Pressure-setting, main safety valves:Tipping Circuit: 4,061 PSI (280bar)Steering Circuit: 3,046 PSI (210bar)

ELECTRICAL SYSTEM

Alternator: 28V 100A Batteries: (two): 12V 140Ah

(series connected to give 24V) Starter: 5.4 HP (4.0kW)

CAB

Approved to ROPS/FOPS standards (ISO 3471, ISO 3449, SAE J 231and SAE J1040 April88) Low interior sound level 74 dB(A) (ISO 6394) The cab is centrally located on rubber mountings Hand and arm vibrations are less than 2.5 m/s according to ISO 5349-2 Whole body vibration is less than0.5m/s according to ISO 2631-1 Superior visibility - for safer operation Superior operating controls location Adjustable suspended operator seat Adjustable steering column Heater and Air Conditioning Tilting for service access

TIRES

Standard 23.5R25two star radial

Turning radius according to

ISO 7457: 24.8feet (7.56 m) PERFORMANCE DIAGRAM

millimeter (inches)

MT 262916 (114.8)

9816 (386.4)

1 76 8 ( 69 .6 ) 1 35 7 ( 53 .4 )2650 (10 4.3) 1125 (44. 3)

3530(

130)

3354(

132) 6

0

40(

237.7)

565

(22.2

)

700

(27.5)

2854(

112.7

)

70

Dimensions&Technical specifications

-

8/12/2019 MOXY ADT Full Line

21/24

2575(101.4)

3275(128.9)

2325(91.5

)

641

(25.2

)

3195 (125.8)

PERFORMANCE DIAGRAM

Turning radius according to

ISO7457: 27.5 feet (8.37 m)

BODY

Material: Hardened abrasion-resistant steel plates Tilt cylinders: Single stage, double-acting Tipping time: Up: 12sec. / Down 11sec. The body is designed for exhaust heating Sloping body down from the hinge point

Level capacity : Heaped capacity : (Acc. SAE J 1363,2:1) Heaped capacity : (Acc. SAE J 1363, 1:1)

WEIGHTS

Empty: Front axle

Rear axleLoaded: Front axle

Rear axlePay load

Total weight (loaded)NOTE: All weights include a full fuel tank and operator

GROUND PRESSURES

Standard 26.5x 25tires with15% sinkageEmpty: Front axle

Rear axleLoaded: Front axle

Rear axle

CAPACITIES

Fuel TankHydraulic System Engine Cooling System Transmission DropboxEngine Crankcase Front Reduction GearRear DifferentialTandem Housing

SPEEDS

1st2nd

3rd

4th5th

6th

SUSPENSION

Front: Independent with long life rubber springs and hydraulic shock absorbers Rear: Free-swinging tandem housing

ARTICULATION HINGE AND STEERING

Articulation hinge with forward mounted turning ring Steering cylinders (two): Double-acting The steering is approved according to ISO 5010 Max. steering angle: 45 Ground driven emergency steering pump

DRIVE LINE

Full-time 6x 6drive with two transverse differentials and one longitudinal Front axle transverse differential: Limited-slip with 45% locking ratio Rear axle transverse differential: Limited slip with45% locking ratio Inter-axle longitudinal differential: Torque-proportioning differential, integrated into

Torque distribution: 1/3to the front axle 2/3to the rear axle 100% lockable

Tandem housing: Gear driven, free-swinging.

Provides equal drive to rear wheels and ensures the best possible ground contact- whatever the ground conditions

Cubic Yards Cubic Meters21 16

27 21

34 26

LB KG

29,480 13,400

29,260 13,300

42,900 19,500

87,780 39,900

71,940 32,700

130,680 59,400

PSI kPa15.66 108

8.99 62

23.21 160

24.66 170

U.S. GALLONS LITERS112.2 425

66.0 250

13.2 50

14.5 55

9.0 34

3.5 13.2

2 X 2 2 X 7.5

12.1 46

2 X 40 2 X 150

MPH KMH

4 6

6 9

9 14

14 22

20 32

32 51

ENGINE

Scania DC 12, water-cooled, unit injected diesel engine with turbo charger

and air to air intercooler Complies with Stage 3of EU Directive 97/68/-EC

and Tier 3of USA/California regulations (ISO 8178) for emissions Power rating: (1.36 hp = 1 kW)

(ISO 3046) 400hp (294kW)(ISO 9249) 388hp (285kW)

No. of cylinders: 6(in line)Cylinder volume: 714cubic inches (11.7 liters) Air filter: Dry type

TRANSMISSION

ZF 6 WG 310Dash 4electronically-controlled automatic transmissionthe torque converter has automatic lock-up in all gears

BRAKE SYSTEM

Dual circuit braking system acting on all six wheels Approved according to ISO 3450 All hydraulic operated brakes with enclosed oil-cooled wet multiple discs all round Spring actuated hydraulic released parking brake, mounted on propeller shaft Max. gradient, parking brake: 20 Automatic engine brake as standard Automatic transmission retarder as standard

HYDRAULIC SYSTEM

Pumps: 2variable displacement piston pumps :

for steering & tipping - for cooling, fan, brakes & auxilaries Delivery: 84.5gallon/min(320l/min) @2200 rpm Filtration: One return flow filter & high pressure filter Pressure-setting, main safety valves:Tipping Circuit: 4,061 PSI (280bar)Steering Circuit: 3,046 PSI (210bar)

ELECTRICAL SYSTEM

Alternator: 28V 100A Batteries: (two): 12V 225Ah (series connected to give 24V) Starter: 9 HP (6.7kW)

CAB

Approved to ROPS/FOPS standards (ISO 3471, ISO 3449, SAE J 231and SAE J1040 April88) Low interior sound level 74 dB(A) (ISO 6394) The cab is centrally located on rubber mountings Hand and arm vibrations are less than 2.5m/s according to ISO 5349-2 Whole body vibration is less than0.5m/s according to ISO 2631-1 Superior visibility - for safer operation Superior operating controls location Adjustable suspended operator seat Adjustable steering column Heater and Air Conditioning Tilting for service access

TIRES

Standard 26.5R25two star radial

MT 36

millimeter (inches)

3170 (124.8)

10450 (411.5)

1960 (77.2) 1270 (50)2835 (111.6) 1210 (47.6)

3735(

147)

3040(

119.7

)

6450(

253.9

)

587

(23.1

)

3040(119.7

)

652(25.7

)

70

Dimensions&Technical specifications

-

8/12/2019 MOXY ADT Full Line

22/24

2690(105.9)

3475(136.8)

2390(94.1

)

706

(27.8

)

3395 (133.6)

PERFORMANCE DIAGRAM

Turning radius according to

ISO 7457: 27.6feet (8.42 m)

ENGINE

Scania DC 12, water-cooled, unit injected diesel engine with turbo chargerand air to air intercooler Complies with Stage 3of EU Directive 97/68/-EC

and Tier 3of USA/California regulations (ISO 8178) for emissions Power rating: (1.36 hp = 1 kW)

(ISO 3046) 450hp (331kW)

(ISO 9249) 438hp (322kW) No. of cylinders: 6(in line)Cylinder volume: 714cubic inches (11.7 liters) Air filter: Dry type

TRANSMISSION

ZF 6WG 310 Dash 4 electronically-controlled automatic transmissionthe torque converter has automatic lock-up in all gears

BRAKE SYSTEM

Dual circuit braking system acting on all six wheels Approved according to ISO 3450 All hydraulic operated brakes with enclosed oil-cooled wet multiple discs all round Spring actuated hydraulic released parking brake, mounted on propeller shaft Max. gradient, parking brake: 20 Automatic engine brake as standard Automatic transmission retarder as standard

HYDRAULIC SYSTEM

Pumps: 2variable displacement piston pumps : 1for steering & tipping -

1for cooling, fan, brakes & auxilaries Max Capacity : 84.5gallon/min (320l/min) @ 2200rpm Filtration: One return flow filter & high pressure filter Safety valve settings: Steering: 3,046PSI (210bar)

Tipping: 4,061 PSI (280bar)

ELECTRICAL SYSTEM

Alternator: 28V 100A Batteries: (two): 12V 225Ah (series connected to give 24V) Starter: 9.1 HP (6.7kW)

CAB

Approved to ROPS/FOPS standards (ISO 3471, ISO 3449, SAE J 231and SAE J1040 April88) Low interior sound level 74 dB(A) (ISO 6394) The cab is centrally located on rubber mountings Hand and arm vibrations are less than2.5m/s according to ISO 5349-2 Whole body vibration is less than0.5m/s according to ISO 2631-1 Superior visibility - for safer operation Superior operating controls location Adjustable suspended operator seat Adjustable steering column Heater and Air Conditioning Tilting for service access

TIRES

Standard 29.5R25two star radial

BODY

Material: Hardened abrasion-resistant steel plates Tilt cylinders: Single stage, double-acting Tipping time: Up: 12sec. / Down 11 sec. The body is designed for exhaust heating Sloping body down from the hinge point

Level capacity : Heaped capacity : (Acc. SAE J 1363, 2:1) Heaped capacity : (Acc. SAE J 1363, 1:1)

WEIGHTS

Empty: Front axle

Rear axleLoaded: Front axle

Rear axlePay load

Total weight (loaded)

NOTE: All weights include a full fuel tank and operator

GROUND PRESSURES

Standard 29.5x 25tires with 15% sinkage

Empty: Front axleRear axle

Loaded: Front axleRear axle

CAPACITIES

Fuel TankHydraulic System Engine Cooling System Transmission DropboxEngine Crankcase Front Reduction GearRear DifferentialTandem Housing

SPEEDS1st

2nd3rd

4th5th

6th

SUSPENSION

Front: Independent with long life rubber springs and hydraulic shock absorbers Rear: Free-swinging tandem housing

ARTICULATION HINGE AND STEERING

Articulation hinge with forward mounted turning ring Steering cylinders (two): Double-acting The steering is approved according to ISO 5010 Max. steering angle: 45 Ground driven emergency steering pump

DRIVE LINE

Full-time 6x 6drive with two transverse differentials and one longitudinal Front axle transverse differential: Limited-slip with45% locking ratio Rear axle transverse differential: Limited slip with45% locking ratio Inter-axle longitudinal differential: Torque-proportioning differential, integrated into

Torque distribution: 1/3to the front axle 2/3to the rear axle 100% lockable

Tandem housing: Gear driven, free-swinging.Provides equal drive to rear wheels and ensures the best possible ground contact

- whatever the ground conditions

Cubic Yards Cubic Meters

24 18.5

31 24

38 29

LB KG

30,690 13,950

29,038 13,200

44,000 20,000

97,568 44,350

81,840 37,200

141,568 64,350

PSI kPa12.76 88

6.96 48

18.85 130

22.05 152

U.S. GALLONS LITERS

129 490

73 27513 50

14.5 55

9 34

3.5 13.2

2 X 2 2 X 7.5

12 46

2 X 40 2 X 150

MPH KMH4 6

6 9

9 15

14 23

21 34

33 53

MT 41

millimeter (inches)

3170 (124.8)

10450 (411.5)

1960 (77.2) 1270 (50)2835 (111.6) 1210 (47.6)

3745(

147)

3040(119.7)

6450(

253.9

)

587

(23.1

)

3040(119.7

)

652(25.7)

70

Dimensions&Technical specifications

-

8/12/2019 MOXY ADT Full Line

23/24

NOTES

-

8/12/2019 MOXY ADT Full Line

24/24

Doosan Infracore Middle East Center (Dubai)

P.O.Box 183127, Al-Serkal Building, Air Port Road,Dubai, U.A.ETel : +971-4-295-2781~2 Fax :+971-4-295-2783

Doosan Infracore do Brasil ServiCos de Suporte Comercial Ltda.

Alameda Santos 2222 Cj52 CEP 01418.200 Sao Paulo, SP, BrasilTel : +55-11-3061-3227 Fax : +55-11-3061-2731

Doosan Infracore India Pvt.Ltd

Plot No. 34, Door No. 1/61-19, Palwels street, Ravi Colony,St. Thomas Mount, Chennai-600 016Tel : +91-44-4222-3900 Fax : +91-44-4222-3905

Doosan Infracore U.K., Ltd.

Doosan House, Unit 6, 3 Heol Y Gamlas, Parc Nantgarw, Nantgarw,Cardiff. CF15 7QU, U.K.

Tel :+44-1443-84-2273

Fax : +44-1443-84-1933

Doosan Infracore France

ZAC de La Clef Saint Pierre - Buroplus 2 1A Avenue Jean dAlembert78990 Elancourt, FranceTel : +33-(0)1-30-16-21-41 Fax : +33-(0)1-30-16-21-44

Doosan Infracore Europe S.A. Germay

Heinrich-von- Stephan str. 2 40764 Langenfeld, GermanyTel : +49-2173-2035-210 Fax : +49-2173-2035-219

Doosan Infracore Russia

123242, Moscow, Kapranova Lane, bld.3, office 402, 4-th floorBusiness Centre Premier Plaza

Tel: +7 (495)663 82 38

/(499) 923 12 55

Fax: +7 (495) 663 82 39

Doosan Infracore Europe S.A.

1A, Rue Achille Degrace, 7080 Frameries, BelgiumTel : +32-65-61-3230 Fax : +32-65-67-7338

Doosan Infracore America Corporation

2905 Shawnee Industrial Way, Suwanee, Georgia 30024, U. S. ATel : +1-770-831-2200 Fax : +1-770-831-0480

Doosan Infracore China Co., Ltd.

#28, Wuzhishan Road, Eco. & Tech, Development Zone, Yantai, Shandong, ChinaTel : +86-535-638-2000 Fax : +86-535-638-2004

Doosan Infracore Seoul Office

Doosan Tower 27th FL.18-12, Euljiro-6 Ga,

Jung-Gu, Seoul, Korea 100-730Tel : +82-2-3398-8049

Fax : +82-2-3398-8117

www.doosaninfracore.comwww.doosanmoxy.com

ILD MOXY000 0810

Doosan Infracore Middle East Center (Dubai)

P.O.Box 183127, Al-Serkal Building, Air Port Road,Dubai, U.A.ETel : +971-4-295-2781~2Fax :+971-4-295-2783

Doosan Infracore do Brasil ServiCos de Suporte Comercial Ltda.

Alameda Santos 2222Cj52CEP 01418.200Sao Paulo, SP, BrasilTel : +55-11-3061-3227Fax : +55-11-3061-2731

Doosan Infracore India Pvt.Ltd

Plot No. 34, Door No. 1/61-19, Palwels street, Ravi Colony,St. Thomas Mount, Chennai-600 016Tel : +91-44-4222-3900Fax : +91-44-4222-3905

Doosan Infracore U.K., Ltd.

Doosan House, Unit 6, 3Heol Y Gamlas, Parc Nantgarw, Nantgarw,Cardiff. CF15 7QU, U.K.

Tel :+44-1443-84-2273

Fax : +44-1443-84-1933

Doosan Infracore France

ZAC de La Clef Saint Pierre - Buroplus 2 1A Avenue Jean dAlembert78990Elancourt, FranceTel : +33-(0)1-30-16-21-41Fax : +33-(0)1-30-16-21-44

Doosan Infracore Europe S.A. Germay

Heinrich-von- Stephan str. 240764Langenfeld, GermanyTel : +49-2173-2035-210Fax : +49-2173-2035-219

Doosan Infracore Russia

123242, Moscow, Kapranova Lane, bld.3, office 402, 4-th floorBusiness Centre Premier Plaza

Tel: +7 (495)663 82 38

/(499) 923 12 55

Fax: +7 (495) 663 82 39

Doosan Infracore Europe S.A.

1A, Rue Achille Degrace, 7080Frameries, BelgiumTel : +32-65-61-3230Fax : +32-65-67-7338

Doosan Infracore Seoul Office

Doosan Tower 27th FL.18-12, Euljiro-6 Ga, Jung-Gu, Seoul, Korea 100-730Tel : +82-2-3398-8049 Fax : +82-2-3398-8117

Doosan Infracore China Co., Ltd.

#28, Wuzhishan Road, Eco. & Tech, Development Zone, Yantai, Shandong, ChinaTel : +86-535-638-2000Fax : +86-535-638-2004

Doosan Infracore America Corporation

2905 Shawnee Industrial Way

Suwanee, Georgia 30024, U. S. A.Tel : +1-770-831-2200

Fax : +1-770-831-0480

www.doosaninfracore.comwww.doosanmoxy.com

ILD MOXY000 0810