Mixed Salt Recovery for High Quality Pulp (MSRP) MSRP Feb14.pdf · Mixed Salt Recovery for High...

Transcript of Mixed Salt Recovery for High Quality Pulp (MSRP) MSRP Feb14.pdf · Mixed Salt Recovery for High...

Internal Use Only Do not distributeInternal Use Only Do not distribute

Mixed Salt Recovery for High Quality Pulp (MSRP)

Dr. Jirachote Phattaranawik and TeamCentral R&D, SCG Chemicals Waste to Value

Cost saving & Environment

Green Manufacturingfor Sustainable Business

Internal Use Only Do not distributeInternal Use Only Do not distribute

Topics

1. Project background and motivation

2. Project development

3. Mill-trial operation and benefits

4. Commercialization and extended works

Waste to ValueCost saving & Environment

Internal Use Only Do not distributeInternal Use Only Do not distribute

Objectives

1) Recycle /reutilization of spent caustic in other applications 2) Develop own technology to recover the spent caustic 3) Develop product from raw spent caustic for reuse4) Develop utilization/consumption method of treated spent caustic

Targets to achieve at ROC

1) Reduce operating cost/treatment cost of this spent caustic (mixed salt liquor) – Approximately 55% reduction or 20 MB/year

2) Reduce amount of water discharge from ROC- 33% reduction or 160,000 m3/year

3) Achieve product quality & price for pulp mill application and other reuses

1. Project background and Motivation

Waste to ValueCost saving & Environment

SCG’s policy1) Supporting green manufacturing2) Increase operation flexibility (High flexibility)

Internal Use Only Do not distributeInternal Use Only Do not distribute

Rationale :

Wastewater treatment Plant

• Recycle/reuse Spent caustic system by using own competitivetechnology

• Find the Benefit from salt extract from Spent caustic

Already implemented (RO unit)

Diversion Box 20-25 m3/hr

Treated Spent Caustic by wet air oxidation (WAO)

6 m3/hr

Dilution Steam B/D

20 m3/hr

Cooling B/D 40 m3/hr

High toxicityVery difficult to treat

High organic load

Dilatants for spent caustic

Low organic load

the worst trouble for waste water system

1. Project background and Motivation

Spen

t cau

stic

lin

e: 3

3% fl

ow

22% flow

45% flow

-High salt (TDS) in the discharge- Conflicted (potentially) with new regulation

Discharge

Alternative solution:

Cost for treatment-55% for spent caustic treatment (40 B/m3)- most expensive/ costly- Total cost is 72 B/m3

1) expensive treatment cost, 2) toxicity and 3) environmental concern

Internal Use Only Do not distribute

Applications & Potential for reuse1) Pulp and Paper Mill

2) Fabric dyeing process

3) Leather tanning

1. Max. benefit to both SCG chemicals and Paper2. Ease for investigation/development

1. External party2. Market size is large, but variety (difficult for QC)3. Need more study

P

1. Project background and Motivation Waste to ValueCost saving & Environment

Valuable salts: NaOH, Na2S, Na2CO3

Central R&DSCG Chem

ROCSCG Chem

Phoenix PPPSCG Paper

R&DSCG Paper

Cross business

units

Internal By-Product Synergy (i-BPS)

ProductKraft recovery process at Phoenix Pulp and Paper

Innovation/ Technology

WasteCaustic salt from ROC

Internal Use Only Do not distribute

Internal Use Only Do not distribute

1. Wet air oxidation(~20-30 mil. Baht/year)-High Pressure Steam Plant Air, TurbineSteam Condensate, Cost of electricity consumption2. Waste Water Treatment Plant(~2-4 mil. Baht/year)

-Chemicals for Treatment, Cost of electricity consumption

Benefit to ROC Benefit to Phoenix

1. Value of chemicals (Salt cake)(~2-5 mil. Baht/year)2. Energy saving at recovery boiler(~0.2 mil. Baht/year),

Rational- Very high treatment cost for MSL- High TDS (salt) discharged wastewater- Environmental problem (water & odor)

Rational- Low efficiency at recovery boiler to convert Na2SO4 to Na2S- Heavy metal contaminated

1. Project background and Motivation

Waste to ValueCost saving & Environment

At ROC, SCG Chemicals At Phoenix PPC-SCG Paper

Prelim: Mixed salt liquor is used to : 1) Replace directly a salt cake2) Easier utilization without incineration & energy saving

Internal Use Only Do not distribute

Internal Use Only Do not distribute

Workshop: R&D Chem and Phoenix for customer survey and requirement

- Quality of product MSL required by Pulp Mill- Comparative analysis

1) Get and analyze the Customer’s requirement

2. Project development

Quality Phoenix Pulp and PaperGreen liquor

ROCRaw spent caustic

1. Suspended solid (SS) Lower than 100 ppm 200-250 ppmÏ

2. Total oil and grease Lower than 60 ppm 200-300 ppmÏ3. Total heavy metal Lower than 50 ppm 35-45 ppmP

4. Total active alkaline 30 – 200 ppm 50 ppmP5. Reaction efficiency

with CaO 75 – 85% 80%P

Remove: SS and red oil from spent caustic

Internal Use Only Do not distribute

Technology & process development to recover the mixed salt liquor (MSL)

2. Project development

Criteria for selection: Experimental work & conceptual Design

1) Chemical and physical processes able to remove red oil and suspended solid from raw MSL at high pH

2) High efficiencies for red oil removal and suspended solid removal at reasonably low operating cost

3) Reasonable investment cost, risk assessment for operation, safety issue

4) Ease of integration and upgrading

2) Select and develop the technology based on customer requirements

Waste to ValueCost saving & Environment

Internal Use Only Do not distribute

Available technologies for raw MSL (spent caustic) Treatment (Shopping list)- Need own development?

Factor/ commercial process

Wet air oxidation Electrodialysis Liquid-liquid

extractionChemical

precipitationMembrane technology

Operating condition 40 Bars, 200 C

ED cell, high voltage

atm, 2 stages

Atm, room temp

6 bars, room temp.

Process complexity Easy Moderate Moderate Easy Easy

Removal efficiency1) Red oil 2)Suspended solid

1) High2) Low

1) High2) Low

1) High2) High

1) Low2) Low

1) Low2) High

Concern Secondarywaste generation

Safety, expensive maintenance

Need toxicorganic, safety issue

Low removal efficiencies

Short membrane lifetime

Investment 60 MB 100 MB 120 MB 50 MB 80 MB

Operating cost(per Kg dry product)

8000 BÏ 6000 BÏ 6000 BÏ 3000 BÏ 5000 BÏ

Problems: NOT a cost-effective process for SCG1) Infeasible due to high investments and high operating cost2) Large amount of toxic waste generation3) Not able to remove both items in the same time

Internal Use Only Do not distribute

Technology Performance & operating cost Investment

Ultrafiltration (UF) with treatment chemicals

1) Good for oil and solid removals2) 1200 B/kg salt

30 MB Ï

High-speed centrifuge 1) Good for oil and solid removal2) 1200 B/kg salt

70 MB Ï

New invention of MSRP process- Hybrid- Removals oil and suspended

solid

1) Good for oil removal (lower than 50 ppm)

2) Good for solid removal (lower than 100 ppm

3) 900- 1200 B/kg salt

6 MB Pselected

2. Project development Waste to ValueCost saving & Environment

Development of own technology: 1) Single process (Remove both) or integrated (hybrid) process (Remove each, twice)2) Performance/cost: The hybrid process is much cost-effective.

Internal Use Only Do not distribute

2. Project development

Waste to ValueCost saving & Environment

MSRP process

MSRP process

Red oil

Product

solid removal

3) Product development

Product on spec.-Red oil lower than 50 ppm- Suspended solid lower than 100 ppm

Internal Use Only Do not distribute

Internal Use Only Do not distribute

5) Project evaluations from customer

- Great potential for chemical saving P- Mill-trial operation is in demands P- No impact hand sheet quality and process/unit operations P

6) Mill-trial scale operation to prove benefits on both ROC and Phoenix Pulp and

2. Project development

by Phoenix Pulp and Paper, SCG Paper team

Internal Use Only Do not distribute

MSRP benefit calculated from plant trial

MSRP processMixed salt liquor (MSL) (Spent caustic) from ROC

Phoenix Kraft’s recovery line 1

Mixed Salt cake = 18 tonsMSL = 370 tons

Loading MSL for 10 days-7.6 days in TK-3202- Stop WAO for 2.4 days

At ROC saving cost0.11 MB in 2.4 days

At Phoenix PPC, 0.34 MB for 10 days or 5 MB/year (batch operation)

1. WAO: 15.6 MB/year 1. Reduce salt cake: 64 tons , 10% better than expectation

2. WWTP: 0.55 MB/year 2. 20% reduction in bleaching agent: over expectation

Total: Cost Saving 16.1 MB/year

3. 3% Better pulp quality (strength and whiteness): over expectation

Better than expectation

High performance by-product 1) Cost saving and 2) production improvement

Internal Use Only Do not distribute

1. Successful own development technology 2. Produce acceptable product quality for both lab and pilot-scale

plants and cost-saving value for ROC is practically obtained.3. Proposal for full-scale plant at ROC was endorsed for 70 MB:

Commercialization and full-scale plant operation

4. Commercialization and extended works

Current works/activities to support the full-scale plant1) Preventive/counter measurements to plant variation2) Legal issues: EIA, official permission, insurance, waste to

product.3) Internal business model within SCG

Internal Use Only Do not distribute

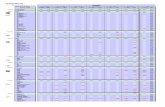

Tota

l Ben

efit

(MB)

to a

ll SC

G

Year

Extended plan for innovation development

2011 2013 2015 2017 2019 2021Start

30

60

90

ROC

Thailand RegionalAEC

Worldwide

MOC

PTT, IRPC, refinery plant

120

150Within SCG

Licensing/technology package/know-how transferring-exchanging

2023

Indonesia, Vietnam

USA, Canada, Brazil, South Africa , China,

Cost-saving, environmental benefit, CSR, Zero discharge

Technology value: 80 MB/year

Internal Use Only Do not distribute

Cross-BU collaboration

Internal By-Product Synergy (i-BPS)

Waste to ValueCost saving & Environment

Project Conclusion: Sustainability & Synergy & Collaboration