Michigan Milk Messenger: August 2015

-

Upload

michigan-milk-producers-association -

Category

Documents

-

view

218 -

download

1

description

Transcript of Michigan Milk Messenger: August 2015

MESSENGERMichigan Milk T H E O F F I C I A L P U B L I C AT I O N O F M I C H I G A N M I L K P R O D U C E R S A S S O C I AT I O N

Inside this issue:

Milkfor theHungryMMPA Donates Milk to MichiganFood Banks

VOL. 98 | ISSUE 2 | AUGUST 2015

MESSENGER | AUGUST 20152

Managing Editor ............................................... Sheila Burkhardt

Editors ..............................Alex Schnabelrauch, Allison Stuby

Advertising Manager .....................................Nancy Muszynski

Circulation .....................................................................................2,972

An Equal Opportunity Employer – F/M/V/D

Michigan Milk Messenger (USPS 345-320) is the official

publication of Michigan Milk Producers Association,

published monthly since June 1919. Subscriptions:

MMPA members, 50¢ per year; non-members, $5 per year.

41310 Bridge Street p: 248-474-6672

P.O. Box 8002 f: 248-474-0924

Novi, MI 48376-8002 w: www.mimilk.com

Periodical postage paid at Novi, MI and at additional offices.

POSTMASTER:

Send address changes to Michigan Milk Messenger,

PO Box 8002, Novi, MI 48376-8002.

(ISSN 0026-2315)

MESSENGER

16

20

Columns4 MMPA Matters Helping Our Neighbors in Need

6 Quality Watch The Forgotten Months:

Managing Cow Dry Off

8 News & Views

10 Legislative Watch Enrollment for 2016 MPP Open

August Features

12 MMPA Secures Level 3 SQF Certification

16 MMPA Donates 22,700 Gallons of Milk to Michigan Food Banks

18 Meet MMPA District 3 Director Dave Pyle

Michigan Milk

AUGUST 2015 | MESSENGER 3

22

Board of Directors

Officers

Ken Nobis, President

Mark Halbert, Vice President

Eric Frahm, Treasurer

Joe Diglio, General Manager/ Secretary

Josep Barenys, Assistant Treasurer

Todd Hoppe, General Counsel

Michigan Milk Producers Association (MMPA)Michigan Milk Producers Association, established in 1916, is a member owned and operated dairy

cooperative serving approximately 2,000 dairy farmers in Michigan, Indiana, Wisconsin and Ohio.

Departments24 Merchandise

25 Quality Premiums

26 Freeliners

28 Classifieds

29 Policies

30 Market Report

3 1 Staff

MESSENGER

Directors-At-LargeKen Nobis, St. Johns ................................ 989-224-6170 or 248-474-6672, ext. 201

Rodney Daniels, Whittemore .............................................................. 989-756-4935

Dan Javor, Hastings ........................................................................... 269-948-8345

Mark Halbert, Battle Creek ............................................................... 269-964-0511

James Reid, Jeddo ............................................................................ 810-327-6830

District Directors1. Hank Choate, Cement City ............................................................. 517-529-9032

2. Tim Hood, Paw Paw ....................................................................... 269-657-5771

3. David Pyle, Zeeland ....................................................................... 616-772-1512

4. Corby Werth, Alpena ...................................................................... 989-464-5436

5. Brent Wilson, Carson City .............................................................. 989-584-3481

6. Tony Jandernoa, Fowler ................................................................. 989-593-2224

7. Eric Frahm, Frankenmuth ............................................................... 989-652-3552

8. Leonard Brown, Sandusky ............................................................. 810-648-4505

20 Meet MMPA District 4 Director Corby Werth

22 MSUE Energy Efficiency Field Days

25 Clip and Send Antel-Bio Testing Form

MMPA recently donated

22,700 gallons of milk

to Michigan families in

need. Read more about

the donation and how to

get involved on pages 4

and 16.

Cover Story

helping Our Neighbors in needBy Ken noBis, President, Michigan MilK Producers association

As many of you are aware, MMPA donated 22,700 gallons of 2 percent milk to the Food Bank Council of Michigan (FBCM) in late June. If you saw the coverage of this event in various media channels, it appeared to be relatively effortless. Yet, as is often true, the action was more complicated than it might seem on the surface.

It is not easy to give milk away because, of course, the same regulatory compliance requirements that are in place when we sell milk are also there when we give it away. It took longer to bring this plan together than we originally anticipated, but maybe that was a good thing. As it played out, the milk was made available when school was out for the summer. It may be surprising 727,000 Michigan kids are faced with food insecurity in their daily lives, and this is exacerbated during summer break when no school meals are available.

The gift of the milk completed in the last week of June began in February when MMPA foresaw we would very likely have more milk available than we could find processing capacity to manage in the coming months. When MMPA staff members approached the board of directors with the idea of giving some milk to a feeding program, the board agreed and gave them the green light to explore the possibility. MMPA approached one processor about the prospect of putting 200,000 pounds of milk through its system, but that business was not able to fit it into their production process.

Then in early May we learned that the Food Bank Council of Northern Illinois had teamed up with Prairie Farms and was providing milk in its system for food bank recipients. Prairie Farms is based in Illinois and also operates in Michigan and, like MMPA, is a farmer-owned cooperative. Our staff contacted the FBCM to gauge its interest in a similar project and learned that “very, very interested” was the reply. We also learned milk is the most requested food by food bank system consumers.

Next we contacted Prairie Farms to ask if they could process the 200,000 pounds of MMPA milk. They replied they could and would do it at cost. The FBCM was able to come up with funds to cover the processing, so the effort came together. In the end, 22,700 gallons of milk were made available to local food banks throughout all 83 Michigan counties.

A question frequently asked by MMPA members about this donation was, “Why don’t we use checkoff funds to do this?” There is a clear reason why this is not possible. The checkoff program is a federal government mandated program which specifically prohibits the use of checkoff funds to pay for the gifting of milk.

With a large population of children who do not have reliable access to

a sufficient quantity of affordable, nutritious food, 22,700 gallons of

milk falls short of the need. Nevertheless, it is more than has ever been

contributed to the system before. It is a start and maybe it will help bring

to light the unmet need for all kids to have access to milk, encouraging

more people to contribute money and food to local food banks.

The food bank system not only provides food assistance to the working poor and others who meet eligibility guidelines, but also provides nutrition education. They try to make use of all donations, but point out to their clientele the value of nutrient-dense products like milk.

Our MMPA member-owners were proud to have been involved in this cooperative effort to provide support to members of our community in need. Maybe we should consider donating milk on a regular basis so these consumers will continue to drink milk once they are back on their feet and shopping in the dairy aisle.

MMpa MaTTers

Messenger | augusT 20154

“…727,000 Michigan kids

are faced with food

insecurity in their

daily lives, and this is

exacerbated during

summer break when

no school meals

are available.”

» for More inforMaTion

abouT The Milk donaTion,

see The sTory on page 16.

THE FORGOTTEN MONTHS: Managing Cow Dry OffBy Jared lyzenga, MMPa Msu Food systeMs FellowshiP intern

With the busy daily lives of dairy farmers, it may be easy to overlook the dry cow pen and focus on other aspects of the dairy. This can be problematic as the dry period is a very important time in a cow’s lifecycle. Proper care of cattle through their dry periods is crucial to ensure their mammary glands have

time to remodel and regenerate after the previous lactation, allowing them to have healthy and productive subsequent lactations.

While the dry period can serve as a time in which existing intramammary infections are cured, it is also a time where the animal can acquire new infections. Cattle are the most vulnerable to acquiring new infections during the time immediately following dry off and also immediately before and after freshening. With a successful dry cow program, managing cattle through these times is a priority.

Evaluating your Dry Cow ProgramTo help get an understanding of how well a dry cow program is working and if cattle are curing or acquiring new infections during the dry period, a California Mastitis Test (CMT) can be a useful tool. CMT your cattle at the time of dry off to see whether or not they are entering the dry period with infections and compare it with after freshening to see what infections are present when they are coming out of the dry period. When checking your fresh cattle with the CMT, ensure they are free of colostrum which may make it hard to interpret the CMT results.

If your herd is DHI tested, comparing individual cow somatic cell count values of the first test of the current lactation with the last test of the previous lactation can help determine if your cattle are acquiring new infections over the dry period. If there are a significant number of cows freshening with new infections, your dry cow management may need some changes.

Lowering Dry Cow New Infection RatesFirst, analyze the actual process of drying the cattle off. Dry cow treatment can be a very useful tool to help prevent new infections during the beginning of the dry period. However, the dry treatment only works if it is administered properly and the cattle have a clean, dry housing environment. Administering dry treatment through dirty teat ends can introduce bacteria into the udder and actually cause more harm than administering no treatment at all.

Here is a dry cow treatment protocol following milking:

• dip teats in germicidal teat dip (leave on for 30-45 seconds)

• dry with individual clean paper towel or cloth

• clean teat ends with provided alcohol wipes (baby wipes soaked in alcohol can be an

alternative to improve employee compliance and teat end cleanliness)

• administer dry treatment while only passing the tip of the cannula through the teat end

• immediately re-apply a germicidal teat dip

Poor dry cow housing conditions may also lead to increased incidences of new infections. It is important to ensure your dry cows have access to clean, dry bedding at all times. If your farm has separate maternity/fresh cow pens, make sure they are kept clean and the cows have access to dry bedding in those pens as the cattle are more vulnerable to acquiring mastitis during this transition period. Hospital cows should also be kept out of your maternity/fresh cow pens as they can act as an additional source of bacteria.

When managing mastitis in dry cows, remember being proactive and preventing new infections is much better than dealing with new infections after they occur.

QualiTy WaTch

Messenger | augusT 20156

“While the dry period

can serve as a time

in which existing

intramammary

infections are cured,

it is also a time where

the animal can acquire

new infections. ”

news & viewsneWs & VieWs

Messenger | august 20158

Upcoming Events

August8 hood farms family dairy

breakfast on the farm,

paw paw

13-14 MMpa oydc

conference, novi

29 pleasant View dairy

breakfast on the farm,

Jonesville

September22 advisory committee

Meeting, lansing

29-

oct. 3 World dairy expo,

Madison, Wisconsin

2015 OYDC Picnic

The annual Outstanding Young

Dairy Cooperator reunion was

held this summer at the home

of 2010 MMPA OYDC Burke and Lisa

Larsen in Scottville. Each summer the

past OYDCs gather for a picnic and

the chance to visit with friends.

Attendees at this year’s picnic

included: Front (left to right)

alice schwass, diane horning,

gloria crandall, Patti Jandernoa,

summer werth, dianne cook,

susan dick, louisa westendorp,

Jennifer lewis, lynda horning,

lisa larsen and Betty Kran.

Back (left to right) James schwass,

aaron gasper, earl horning, Pete

Bontekoe, tony Jandernoa, Jeremy

werth, tom cook, gordon dick,

al nichol, Mary nichol, doug

westendorp, Bruce lewis, Ken and

liz nobis, Jeff horning, Burke larsen,

ann and dave Pyle and Bob Kran.

August Farm Tour will Feature Manure Processing and Conservation Practices

The registration fee, which covers the tour, lunch and all materials, is $25 per person or $40 per farm up to four individuals. Please be sure to pre-register early for this event.“What’s New with Poo” promises to be an informative event. The tour will provide the opportunity to see practices being implemented on Michigan farms, time to network with fellow producers and learn from university and company researchers.

June Class III Price UpUSDA announced the Federal Order

Class III price rose $0.53 per cwt.

from May to June’s price of $16.72.

Class IV prices were little changed,

down a penny from May to $13.90

per cwt.

Producers Scoring 95 percent or more on Grade A Surveys and Federal Check Ratings Bloniarz Farms Sherwin Wilson Pleasant View Dairy Farm LLC *Wieciech Farms Brad Pellegrini *Robert Paidl *Milton PatzSteenblik Dairy IncDutch Meadows Dairy LLC *Thelen Dairy IncBerlyn Acres II LLCGlen Mast Maynard/Laura LehmanJerry Lehman Leland Lehman* Vernon Miller Dennis Yoder Jacob Weaver David Miller Norman Beech *100 percent

on August 18, 2015 Michigan State University (MSU) Extension and the

Clinton County Conservation District will be hosting a farm tour for livestock farmers and cash crop farmers who utilize manure in their crop nutrient program. This event will feature manure processing technologiesand conservation practices that help retain manure nutrients in the root zone for crop utilization.

The “What’s New with Poo” bus tour will originate from Providence

Agriculture’s Carson City location at 9650 Roosevelt Road at 8:15 a.m. Space

is limited and pre-registration is required. You may register online or by calling

the Clinton County Conservation District at 989-224-3720 or the Gratiot County

MSU Extension Office at 989-875-5233.

august 2015 | Messenger 9

The processes and four farms featured on the ‘‘What’s new with Poo” tour include:

• Manure handling and processing at Double Eagle Dairy. This innovative manure handling system processes manure into three or more components, each with a different nutrient composition. This system is designed to reduce the cost associated with manure application, improve manure nutrient utilization and reduce environmental risk.

• TheharvestablebuffersplantedbyNobisDairy. Harvestable buffers protect water quality without taking land out of production. Buffers are planted to a grass mixture of orchard grass, timothy, perennial ryegrass and brome grass and annually provide three cuttings of dry hay.

• ThecovercroprotationusedbyDutchMeadowsDairy. A unique cover crop rotation of triticale and sudan grass, which are also harvested as feed, increases the opportunity for manure application, reduces runoff and increases available feed.

• ManureseparationatVanderploegHolsteins.Separation improves manure nutrient management and reduces application costs. This visit will include a discussion on cow management and health when bedding with manure solids.

Amber Radatz, co-directorof the Wisconsin Discovery Farms, will be the event’s lunch time keynote speaker.

Discovery Farms is a cooperative effort

of Wisconsin farmers, University of

Wisconsin Extension and University

of Wisconsin, Madison. The farmer-

led program gathers and disseminates

creditable and unbiased water quality

information for the agriculture

community, consumers, researchers

and policy makers. Amber focuses on

assisting farmers with manure related

issues, water quality and nitrogen

efficiency.

» for More inforMaTion, VisiT

WWW.Msue.Msu.edu.

Messenger | augusT 201510

legislaTiVe WaTch

2016 Dairy Margin Protection Program enrollment open until september 30

A griculture Deputy Secretary Krysta Harden announced in June that starting July 1, 2015, dairy

farmers can enroll in the U.S. Department of Agriculture’s (USDA) Margin Protection Program (MPP) for coverage in 2016. The voluntary program, established by the 2014 Farm Bill, provides financial assistance to participating dairy operations when the margin – the difference between the price of milk and feed costs – falls below the coverage level selected by the farmer.

“More than half of our nation’s dairy producers enrolled in the 2015 program, which exceeded our expectations for the first year of the program,” Harden said. “We are confident that dairy farmers across the country will again take advantage of this safety net program for 2016.”

The Margin Protection Program gives participating dairy producers the flexibility to select coverage levels best suited for their operation. Enrollment began July 1 and ends on Sept. 30, 2015, for coverage in 2016. Participating farmers will remain in the program through 2018 and pay a $100 administrative fee each year. Producers also have

the option of selecting a different coverage level during open enrollment each year. Margin Protection Program payments are based on an operation’s historical production. An operation’s historical production will increase by 2.61 percent in 2016 if the operation participated in 2015.

USDA also has an online resource available to help dairy

producers decide which level of coverage will provide them

with the strongest safety net under a variety of conditions.

The enhanced Web tool, available at www.fsa.usda.gov/

mpptool, allows dairy farmers to quickly and easily combine

their unique operation data and other key variables to

calculate their coverage needs based on price projections.

Producers can also review historical data or estimate future

coverage based on data projections.

» To learn More abouT The Margin proTecTion prograM:

•VISITFSAonlIneATwww.FSA.uSdA.goV/dAIry

•STopbyAlocAlFSAoFFIce

•VISITFuTureFordAIry

» To find a local fsa office, VisiT offices.usda.goV

Dairy Groups Commend Senate and House for passing Tpa legislation

MMPA, the National Milk Producers Federation and the U.S. Dairy Export Council praised leaders in the

House and Senate for passing and sending to the White House new Trade Promotion Authority (TPA) legislation.

“America’s dairy producers are supplying an even greater share of dairy products exported around the world, and Michigan has ramped up our infrastructure to meet growing world demand,” MMPA President Ken Nobis said. “We applaud the passage of Trade Promotion Authority and welcome all efforts to reach new trade deals with other nations.”

NMPF and USDEC said Trade Promotion Authority is crucial to negotiating a better deal for dairy farmers in the pending Trans-Pacific Partnership, as well as in future free trade agreements.

“The U.S. dairy industry has been a strong advocate for TPA,” NMPF President and CEO Jim Mulhern said. “In turn, we have seen a broad level of support for TPA from many

members of Congress in dairy districts and states. TPA now must be used by our negotiators to conclude a positive outcome for U.S. dairy producers in the Trans-Pacific Partnership (TPP) so we are able to realize the net trade benefits that a strong agreement could offer to the industry.”

USDEC President Tom Suber added, “To remain competitive globally, our sector needs trade agreements that maximize our export opportunities across the wide range of dairy products produced in the United States. We are confident TPA will help the United States effectively pursue that path and expect our trade negotiators to insist on nothing less than balanced agreements with positive results for our industry.”

TPA, which expired in 2007, is important to the U.S. dairy industry because the United States now exports the equivalent of one-seventh of its milk production.

MMPA Advisory Committee

District 1Art Riske, Hanover ............................................... 517-524-6015Clark Emmons, Fayette, OH ................................ 419-452-6764Jeff Alexander, Hanover ...................................... 517-740-9981Perry Cisco, Hudson ........................................... 517-404-7997Carlton Evans, Litchfield ...................................... 517-398-0629

District 2Richard Thomas, Middlebury, IN ......................... 574-825-5198Donald Bever, Delton ........................................... 269-660-0498Heather Wing, Bellevue ....................................... 517-543-5577Michael Oesch, Middlebury, IN ........................... 574-825-2454Danny Ransler, Gobles ........................................ 269-628-4218

District 3Burke Larsen, Scottville ....................................... 231-757-2090Bill Stakenas, Freesoil .......................................... 231-757-9340Gary Nelsen, Grant ............................................. 231-834-7610Tim Butler, Sand Lake .......................................... 616-636-8567Nico Eadie, Conklin ............................................. 616-550-4041

District 4Dave Folkersma, Rudyard ................................... 906-478-3023Steve Brock, Daggett .......................................... 906-753-6439Ron Lucas, Posen ................................................ 989-379-4694Marvin Rubingh, Ellsworth................................... 231-588-6084Jeremy Werth, Herron ......................................... 989-464-4022

District 5Tom Jeppesen, Stanton ....................................... 989-762-5399Bruce Benthem, McBain ..................................... 231-825-8182Amy Martin, Leroy ............................................... 231-388-0496Mike Rasmussen, Edmore ................................... 989-762-5380Bill Jernstadt, Big Rapids .................................... 231-796-4650

District 6Kris Wardin, St. Johns ......................................... 989-640-9420Aaron Gasper, Lowell .......................................... 616-897-2747Steve Thelen, Fowler ............................................ 989-640-1075David Reed, Owosso ........................................... 989-723-2023Jamie Meyer, Ionia .............................................. 989-640-3372

District 7Eric Bergdolt, Vassar ........................................... 989-652-6500Steve Foley, Millington ......................................... 989-871-4028Rod Fowler, Chesaning ........................................ 989-845-6131John Bennett, Prescott ........................................ 989-345-4264Scott Kleinhardt, Clare ........................................ 989-386-8037

District 8Mike Bender, Croswell ......................................... 810-679-4782Scott Lamb, Jeddo .............................................. 810-404-8003Mike Noll, Croswell .............................................. 810-404-4071Jeremy Sharrard, Peck ........................................ 810-404-5076Dale Phillips, Marlette .......................................... 989-635-7917

At-LargeMark Crandall, Battle Creek ................................ 269-660-2229Tom Wing, Bellevue ............................................. 269-660-0498Bill Blumerich, Berlin ........................................... 810-395-2926Chuck White, Fowlerville...................................... 517-521-3564

augusT 2015 | Messenger 11

MESSENGER | AUGUST 201512

8OOFood safety documents,

twOProcessing Plants,

OnEcommitment to Quality Products

MMpa secures LEVEL 3Y SQF Certification Z

By eMily helsen, MMPa John dilland FellowshiP intern

EVERYONE GETS HUNGRY. Hungry for

a grilled CHEESE sandwich on a Sunday

afternoon, hungry for a late night bowl of

ICE CREAM you don’t need but eat anyway.

But most of all, today’s consumers are also

hungry for kNOWLEDGE about where

their food comes from.

As consumers are seeking to become aware of where and how their food is getting to them, the entire food supply chain must be more transparent, reliable and trustworthy when producing food grade items. MMPA is not immune to this trend. Reliability and trust between the food industry and consumers can be formed through the use of a food safety program such as Safe Quality Food (SQF). After obtaining Level 2 certification last year, MMPA reached the highest possible level of SQF—Level 3 Certification—in July 2015.

As a cooperative, MMPA strives to gain the utmost trust from our customers, hence our commitment to reaching SQF Level 3 Certification. This certification increases the marketability of MMPA milk and will allow the co-op to pursue and gain customers that weren’t an option before.

The continuing goal of SQF—the gold standard for food processing certification—is to help processors assess risk in food processing facilities while limiting food safety incidents. The program streamlines plant inspections, developing consistent food safety standards across the industry. Starting in 2012, MMPA customers were setting deadlines compelling the cooperative to achieve SQF certification to demonstrate the co-op’s commitment to food safety.

Becoming SQF certified is no walk in the park, but MMPA took on the challenge and achieved that goal in just a few short years. In July 2014, MMPA’s Constantine and Ovid plants achieved Level 2 SQF certification with “excellent” ratings. And by July 2015, the co-op earned Level 3 SQF certification after a rigorous auditing process. While MMPA plants have always produced high quality products using food safety protocols, SQF is a widely recognized certification, trusted and accepted by domestic and international buyers.

ABOVE: level 3 sQF certiFication deMonstrates the

Quality oF MMPa Products, such as Butter.

OPPOSITE PAGE: MMPa MeMBers’ MilK is unloaded daily in the

receiving area at the ovid Plant. thanKs to level 3 sQF

certiFication, MeMBer MilK Processed in Both ovid and

constantine will BeneFit FroM increased MarKetaBility.

AUGUST 2015 | MESSENGER 13

Each plant went through a series of steps to prepare for the official audit:

StEp OnE: Identified every production phase procedure from receiving to clean up. Those procedures were evaluated, documented and then cross-referenced with Good Manufacturing Practices (GMP) to make sure all procedures were on track with GMP requirements.

StEp twO: Created five HACCP plans for each plant, in which each plan identified and described prevention protocols for possible contaminants through each product’s complete life cycle.

StEp thrEE: Retrained employees on the new protocols and procedures that coincided with the SQF requirements.

StEp fOUr: Ensured all employees were informed about food safety, SQF and were ready for the audit. An exam was given to employees and a passing grade was required.

“to be able to supply any of our

products to our customers, we have

to be sQF certified and now many of

those customers are requiring a level

3 certification,” Amandeep Dhillon,

MMPA director of quality, said. “level

2 certification was mainly focused on

developing our hazard analysis critical

control Point (haccP) plans and Food

safety plans. now we have reached that

milestone, MMPa is able to focus on

strengthening our quality management

through level 3 certification.”

augusT 2015 | Messenger 13

In addition to the demands of Level 2 Certification,

Level 3 adds a quality management factor to the

equation.Toearnthiscertificationbothplants

had to follow these steps:

STEP ONE: Conducted risk assessments based on customer

complaints and internal quality history and identified key

quality factors that require special attention to maintain

high quality.

STEP TWO: Drafted food quality plans for each product

from completed assessments.

STEP THREE: Trained all employees on Level 3

Certification requirements, with emphasis on the difference

between safety and quality. This includes explaining the

food quality plans for each product.

STEP FOUR: Administered competency awareness quizzes

to all employees to ensure all understood the requirements

of the certification.

With all Level 3 requirements in place, the quality of MMPA products is certified, increasing the product’s marketability. With properly trained employees, less waste will be produced and both plants are becoming more efficient. “It’s beneficial to take the time and train all employees on SQF. It makes everyone more aware of what is required from them. SQF gives our employees more tools to use on the job and allows them to produce a high quality product,” affirmed Ovid SQF Practitioner Ron Steinhorst.

In mid-July, the Ovid and Constantine plants underwent SQF audits. Both were conducted by a licensed certification body and started with a desk audit which consisted of reviewing the more than 800 food safety documents that have been continuously prepared over the last few years. From there, the audit moved on to a plant inspection to gauge whether work instructions and the correct manufacturing procedures are being followed. While on the plant inspection, employees were randomly selected to answer questions about the plant’s commitment to SQF and the food safety plans that are in place.

Messenger | augusT 201514

LEVEL 3 SQF CERTIFICATION - CONTINUED

lead producTion superVisor ed lloyd on The Job aT The consTanTine planT. in July, boTh The consTanTine and oVid faciliTies underWenT a planT inspecTion as parT of The process To obTain leVel 3 sQf cerTificaTion.

AUGUST 2015 | MESSENGER 15

“Preparing the plants for the audit was a huge team

effort. without cooperation from the operators and

encouragement from the supervisors, it would’ve

been a difficult task to achieve,” said constantine

sQF Practitioner Jesse Mahoney. “the preparation

process became a little easier when everyone

understood the importance of this certification and

how it will impact MMPa’s future by making member

milk more marketable.”

Looking ahead, each plant will be SQF audited annually to maintain certifications to sustain high expectations. All new hires and contractors will need to pass food safety training before being allowed on the processing floor.

After two years preparing for Level 3 Certification, the benefits are obvious. First is the increased marketability of MMPA milk and the many doors certification opens for the co-op.

“Receiving this certification shows that we are committed to food safety and quality and Level 3 Certification distinctly sets MMPA apart from competitors” Dhillon said. “It will give us the ability to draw in more customers and be able to provide them and existing customers with an even higher quality product than we were already delivering.”

SQF CertificationLevel Requirements

LEVEL 2 LEVEL 3

food safety fundamentals

haccp food safety plan

haccp food Quality plan

MESSENGER | AUGUST 201516

MILk for THE HUNGRY:

MMPA Donates

22,700 Gallonsof Milk

to Michigan Food Banks

Every year, more than 1.7 million Michiganders –including 20 percent

of Michigan children – rely on food banks. Milk is one of the most requested food items. But on average, food banks are only able to provide the equivalent of less than one gallon of milk per person per year. Hungry children and families in Michigan communities are missing out on the essential nutrients supplied by milk because it’s not typically donated to food banks – even though it’s in high demand.

Messenger | augusT 201516

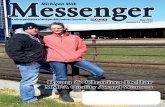

PICTURED: Prairie FarMs account Manager Joe risdon, MMPa vice President

MarK halBert, MMPa President Ken noBis, Food BanK council oF Michigan executive

director PhiliP Knight, Food BanK oF south central Michigan executive director

Keith williaMson and MMPa MeMBer heather wing gathered at halBert dairy

FarM on June 24 For the announceMent oF the MilK donation.

AUGUST 2015 | MESSENGER 17

Continuing its support for local communities and Michigan families, in June MMPA donated over 22,700 gallons of milk to the Food Bank Council of Michigan (FBCM), a statewide organization which stocks Michigan’s food banks. The donated milk will be distributed across Michigan to support families from all corners of the state.

“our dairy farmer owners are

happy to make this donation

to the children, seniors and

families struggling with hunger

in our local communities,”

MMPa President and dairy

farmer Ken nobis said. “we’ve

been a Michigan company

for nearly 100 years, and

we’re proud to continue our

cooperative’s tradition of

giving back. what better way

to serve those struggling

with hunger than the healthy,

natural, nutrient powerhouse

that is milk?”

The donation was announced at the farm of MMPA dairy farmers Mark and Fred Halbert in Battle Creek on June 24. The milk will be divided by the FBCM among the state’s regional food banks which serve all 83 Michigan counties. The donation will help

improve nutrition for food-insecure children who struggle to have enough food to grow healthy minds and bodies.

“This donation comes at a time of great need,” said Dr. Phillip Knight, executive director of Food Bank Council of Michigan. “During summer vacation, thousands of Michigan students are no longer able to rely on the meal they received at school. Thanks to MMPA and Prairie Farms Dairy, food banks throughout the state will be able to provide milk to children and families in need.”

In total, MMPA donated 200,000 pounds of milk which was processed at cost by Prairie Farms Dairy. The resulting 22,700 gallons of 2 percent white milk will offer nine essential nutrients, including 8 grams of high-quality protein per serving and three of the nutrients most likely to be missing in the American diet – calcium, vitamin D and potassium—to Michiganders in need.

“MMPA members are grateful to have the opportunity tomake milk available to people whose incomes are stretched by various factors,” Nobis said. “In Michigan, our cow’s average production is third highest in the nation, and we are currently experiencing unprecedented growth in our industry. As a result, the MMPA board decided it would be appropriate to share some of the highly nutritious product we produce with Michigan families who could use a little help.”

Milk is naturally nutrient-rich. It has

9 essential nutrients, including:

On average, food banks

can provide

gallon of milk

per person

per year

Michigan children may not know where their next meal will come from when school is not in session.

MILKis one of the most

requested foodbank items.

grams of

high-quality

protein

per serving.8

727,000School is out for summer!Unfortunately...

<1

MESSENGER | AUGUST 201518

Dave Pyle never thought he’d trade

in time in the milkhouse for the

board room. Yet thanks to support

from District 3 delegates, he can’t

wait to help guide the co-op into

the next century. Dave was recently

elected as the District 3 Director

and joined Corby Werth to be the

newest members on the MMPA

board of directors.

Dave is a fifth generation dairy farmer, farming the same land in Zeeland his family has cultivated since 1848. Today, Pyle Dairy Farm is a corporation with Dave and his sons, milking 130 registered Holsteins on 270 acres of corn, hay, wheat and soybeans.

“I grew up on this farm and I have always enjoyed it. Though I worked in Holland at a couple boat factories when I was young, but farm life kept calling me back,” Dave said. “In 1972, I started fulltime on the farm and never looked back.”

In the words of his wife Ann, he’s a man who knows what he wants and doesn’t waste time. In April of 1978, Dave met Ann and, by December, the two were husband and wife. They have three children, nine grandchildren and are happy their family remains so involved on the farm.

“Our children have always loved working at the dairy. When they were growing up, we didn’t force them to help on the farm,” Ann admitted. “This method paid off, because they grew to love dairy farming in their own right.”

MEET MMPA

District 3DIRECTOR

DavePyle

by allison sTuby

TOP: dave and ann Pyle

BOTTOM: district 3 director dave Pyle tends to calves on his 167-year-old FaMily FarM in zeeland, Michigan.

AUGUST 2015 | MESSENGER 19MBA114 - Forage Fertility Program • MIchigan Milk Messenger • 4.75”x10” • 4c • 7.8.15

Boost Yields with Midwestern BioAg’s Forage Fertility Program

Premium Dry Fertilizer BlendsOptimize plant growth and forage quality by providing balanced nutrition for your soil.

Bio-Cal® and OrganiCalDeliver multiple sources of fast-acting and slow-release calcium for improved plant health.

Liquid, Carbon-Based Fertilizers Ramp up forage yield and quality with foliar application after cutting. Made from a molasses base, this product line helps stimulate soil life.

Contact us today to learn more.MidwesternBioAg.com | 844.554.6677

Serving over 29 states with core facilities in WI, MN, IA, MI, OH & IL

“My family and their support is

the reason I am able to take time

to serve on the MMPA board. I am

very thankful for their assistance.

Family is what makes the experience

worthwhile,” Dave added.

The Pyle family enjoys hosting tours to educate others about dairy and agriculture. Hudsonville Ice Cream recently brought food bloggers to the farm and often hosts tours for potential customers. Ann, a teacher of 35 years, enjoys taking her students on tours of the dairy as well.

Openness is a trait Dave is proud to see in MMPA. “MMPA is a super co-op,” he said. “We are very transparent and not afraid to share information with members. When times are tough, it’s important members’ questions get answers.”

While Dave is new to the MMPA board room, he’s no stranger to leadership and brings with him valuable experience. In the past, Dave served on the MMPA Advisory and Nominating Committees and was treasurer of the West Michigan Local. In the 1990s, Dave and Ann were named Outstanding Young Dairy Cooperators of the West Michigan Local. He is also involved in his community and is serving on the Ottawa County Conservation District board. In addition, Dave has served on the Borculo Christian School board, the Zeeland Farmers Co-op board, Farm Service Agency board and Dairy Herd Improvement Association board.

Dave will work with the other 12 MMPA dairy farmer members on the board to set strategic goals for the co-op and oversee progress toward these goals.

“Thisisacriticaltimeinourindustry

and in our country. We need to be

strategic in deciding how we’re going

to face the issues in our industry,”

Dave said. “I am glad to see our

current board has a good mix of

farmers. Everyone comes from a

different background and brings a

uniqueperspectivetoMMPA.Thisis

beneficial to the success of our co-op

as it continues into the future.”

MESSENGER | AUGUST 201520

For Corby Werth, dairy farming is everything. Born and raised on his

family farm in Alpena, the dairy life is all he knows.

But Corby can see beyond his own driveway and strives to be a guiding

force in the industry. As the newly elected District 4 director, he hopes to

support MMPA and prepare for the future of dairy. Corby and Dave Pyle

are the two newest dairy farmer members of the MMPA board of directors.

Corby shares ownership of Werth Dairy with his father, mother, and brother. They milk 280 cows and farm 1,000 acres of corn and alfalfa. Corby works as the farm manager and herdsman, but taking care of the farm is truly a family effort that involves multiple generations. Even Corby’s teenage children, daughter, Annalee, and son, Carson, work on the farm. Annalee recently began milking cows, and Carson helps with calf care.

Corby is grooming Carson to become the fifth generation Werth to nurture their land and cattle since 1917.

“I love the challenge of dairy farming; it makes you stronger. And being raised on a farm, it’s just something in your blood,” Corby said. “My son is following in my footsteps and it’s great that he gets to grow up here and be involved with our operation before he gets ready to take over.”

MEET MMPA

District 4DIRECTOR

CorbyWerth

by allison sTuby

BELOW: carson, annalee, Melissa and corBy werth.

AUGUST 2015 | MESSENGER 21

34% minimum protein13% maximum crude fiber

4% minimum fat

Valero Meal

16% maximum fiber6% minimum protein

2.1% maximum calcium2% minimum fat

Citrus PulpLow Fat Hominy7% minimum protein7% maximum fiber4% minimum fat

Improve bottom-line $$. Lower feed costs. Maximize production.Ingredients from your trusted source.

Soybean meal, soybean hulls, cereal feed, cottonseed, distillers, gluten, canola meal, beet pulp, wet feeds, and more!

Traditional ZFS® Menu

Zeeland Farm Services, Inc.® MI: 866.888.7082 Fax: 616.772.7067 www.zfsinc.com

Corby and his wife, Melissa, were high school sweethearts and will celebrate their 20th wedding anniversary later this year. “Melissa was raised in town and now works at a hospital, but she followed me back to the farm and has somehow acclimated to farm life quite well. We live right next to the dairy and she enjoys the environment and helping out,” Corby said.

Though family and farming are of utmost importance to Corby, he sees value in taking the time to be involved in MMPA. His family’s knowledge and experience can provide insight to help the co-op move forward.

“We’re a fourth generation farm

and, through time, we’ve learned

how to tackle the challenges and

changes that go along with dairy

farming,” Corby explains. “MMPA

has always been here for our

dairy and good to my family. It’s

important for me to stay involved

and help shape the direction and

future success of our co-op.”

Prior to joining the board, Corby was vice chair of the Advisory Committee and local and district president. Outside of MMPA, Corby has served on the United Dairy Industry of Michigan board and the Michigan Dairy Market Committee. His experience will help guide decision making to make the best choices possible for MMPA members.

Alongside the other 12 MMPA member dairy farmers on the board, Corby will formulate strategic goals for the co-op and oversee progress toward these goals.

“We are at the cusp of our 100th

year as a co-op. As we begin

our next century, I want to see

MMPA continue to grow, maintain

a stable market and uphold

MMPA’s reputation,” he affirmed.

“It’s important the other board

members and I are responsible and

make decisions in the best interests

of the members.”

Gov. Snyder Signs Bill Extending MAEAP Through 2021

a legislative bill reauthorizing the Michigan Agriculture Environmental Assurance Program (MAEAP) was signed into law by Governor Snyder on July 15. The bill, sponsored by Rep. Dan Lauwers

(R-Brockway Township), extends MAEAP through 2021 and broadens the certifications for MAEAP from three years to five years. Existing MAEAP farms will be extended to five years from their original verification date.

The legislation also provides for expanding the MAEAP funding base by taxing all fertilizers and extending the sunset of those fees to 2021.

One of the key components of the new legislation is the creation of a tiered recognition program to highlight a farmer’s efforts as they implement environmental practices, but have not yet achieved MAEAP verification.

“We appreciate the efforts of Rep. Lauwers and Senator Mike Green and their work on the MAEAP bill,” MMPA President Ken Nobis stated. “The creation of a tiered recognition system is something we had requested through the bill development process. The tiered system will help with MMPA’s sustainability efforts by recognizing the work of dairy producers in implementing environmental practices before they become MAEAP verified.”

MSUE Energy Efficiency Field Days

T wo MMPA members are opening up their barn doors in

late August and early September to showcase innovative

technologies and how to improve energy efficiency on their

operations. Organized by Michigan State University extension and

funded by the U.S. Department of Energy’s State Energy Program

through the Michigan Energy Office, Michigan Agency for Energy,

these tours are set up in a hands-on, question and answer format.

Register today and learn more about applications for these sustainable technologies on your farm!

Wing Acres Dairy Long Day Lighting System Tour Michigan dairy farmers have been unsuccessful in attaining the full benefits of long day lighting (LDL) due to technical difficulties in measuring and maintaining light intensity and appropriately controlling the lighting system.

In cooperation with MMPA and funded by a grant from the Michigan Energy Office, a LDL project was initiated by Biosystems and Agricultural Engineering Department researchers at MSU to address technical difficulties preventing LDL from being adopted on Michigan dairy farms. Wing Acres Dairy’s LDL system successfully resolved technical difficulties encountered in the past and has been fully operational since January 2014.

The complete LDL system will be showcased at a twilight meeting at Wing Acres Dairy. Topics will include the LDL design and control system, the impact of LDL on milk production and herd health, the role of energy audits in securing dollars to implement a LDL system and sources of funding available to implement components of a LDL system.

Date: thursday, august 27, 2015

Time: 8:00 - 10:00 PM

Location: wing acres dairy, 15335 wing road,

Bellevue, Mi 49021

Register: there is no registration fee, but you are asked

to register in advance. to register go to

events.anr.msu.edu/2015ldlFieldday.

Biomass Heating and Milking Parlor Energy Efficiencies Field DayWeiss Centennial Farm’s biomass heating system and milking parlor energy conservation equipment will be showcased during this field day. The biomass heating system uses radiant heat from a gasifier to heat farm buildings and provide hot water for sanitary purposes in the milking parlor.

Topics will include robotic milkers, biomass heating design and control system, obtaining milking parlor energy efficiencies and sources of funding available to implement energy conservation practices.

Weiss Centennial Farm is a 60-cow dairy in Michigan’s Thumb area. For more information about the dairy go to www.weisscentennialfarm.com. For more information about Heiss Heaters go to www.heissheaters.com.

Date: thursday, september 3, 2015

Time: 9:30 a.m. – 1 p.m. (lunch is included, families

may participate in the farm’s corn maze

following lunch free of charge)

Location: weiss centennial Farm, 5450 weiss road,

Frankenmuth, Mi 48734

Register: there is no registration fee, but you are asked

to register in advance to aid in determining

food counts. to register go to events.anr.msu.

edu/2015dairyBiomassheating.

Questions about the Wing acres dairy long day lighting system Tour or Weiss centennial farm biomass heating and

Milking parlor energy efficiencies field day can be directed to al go, [email protected] or 517-214-6128, or charles

gould, [email protected] or 616-994-4547. accommodations for persons with disabilities may be requested by contacting

charles gould by august 13 to make arrangements. requests received after this date will be fulfilled when possible.

Messenger | augusT 201522

AUGUST 2015 | MESSENGER 23

Do you host farm tours, or plan to in the future?Whether your family is just starting to host farm tours, or you’re a seasoned farm tour pro, a new farm tour toolkit is available. It provides:

• Samplemessagesto help share your dairy experience with visitors

• Tipsforinvitingschools to your farm

• Asamplefarmtourplan, including messages to share at various areas of the farm

• Tipsforcustomizingeachtourto fit the audience’s needs

• Activitiestoengagevisitingchildren

Contact Jolene Griffin at 800-241-6455 or [email protected] for more information, and to share your farm tour experiences with us.

Dairy Promotion Grows Cheese SalesThe United Dairy Industry of Michigan continued their strong relationship with Michigan-based Domino’s® pizza brand through a March promotion that offered consumers 50 percent off online orders, resulting in an additional 150 orders per store. With consumer coupon purchases trending towards more cheese-heavy specialty pizzas, Domino’s® estimates Michigan stores sold 13,000 + incremental pounds of cheese as a result of this partnership.

augusT 2015 | Messenger 23

The New Recipe Booklets Are In! New recipe booklets are available. These dairy recipes were created by influential bloggers across the state. Contact us to learn more and to place your order. 1-800-241-MILK (6455)

New Bulk Tank BrushThe merchandise warehouse is now carrying a new style of bulk tank brush in addition to the round version. The new style is a 4 ½” x 8 ½” oval brush which will accept a standard threaded handle. It consists of a plastic block and features type 6.6 nylon bristles that soften when exposed to water for excellent soft scrubbing, safe for stainless steel.

The warehouse is also stocking a 48” threaded fiberglass handle for use with this brush. These handles are lightweight and durable. They will not warp, crack or chip from moisture. Stock numbers and prices are listed below.

Stock # Description Member Price

4246 oval Bulk tank Brush $23.63

4703 48” Fiberglass handle $14.45

Out of StockAs reported last month, much of the A&L product line is being discontinued. We will try to keep you informed when products have been depleted from our stock. Listed below are the items that have recently been exhausted.

OuTOfsTOck RePlAceMeNT

Stock # Description Stock # Description

350 acid hd 15 gal. 6992 envirocid plus 15 gal.

3506 al-chlor-10 15 gal. 6999 equipment san. 15 gal.

3510 aloe dip 15 gal. 6994 teat glo 15 gal.

3505 aloe dip 5 gal. 6118 teat glo 5 gal.

3511 aloe dip 55 gal. 6097 teat glo 55 gal.

3501 chlorkleen 15 gal. 6987 Principal 15 gal.

3521 Kleen 100 15 gal. 6093 conquest 15 gal.

3545 Proclean ii 15 gal. 6972 liquid hd 325 15 gal.

Messenger | augusT 201524

Three Ways to Order your MMPA Merchandise

1. Place order through your milk hauler

2. Call in your order:

duane farmer, supervisor ................................... 989-317-8370

Toll free ...................................................................877-367-6455

orders (novi) ................................... 800-572-5824 then dial 2

3. Fax in your order:

MMpa Merchandise fax..........................................989-317-8372

Chemical, Sanitizer

and Teat Dip

Contact Information

these are service personnel only.

order your Member Merchandise

supplies through your hauler.

ECOLAB

24 -Hour Medical

Emergency Hotline:

1-800-328-0026

For service, call the

ecolab service Message center

1-800-392-3392

or

Stan Palmer

5303 e. swan drive #3

Port clinton, oh 43452

419-797-2101

Ben Johnson

4461 cambridge dr.

Port huron, Mi 48060

810-824-0636

Jasonkoerth

7509 aborcrest dr.

Portage, Mi 49024

269-207-3773

Pat Mitchell

7273 n. rollin hwy.

addison, Mi 49220

517-403-0928

A & L Laboratories

24 -Hour Medical

Emergency Hotline:

1-800-424-9300

JeffTimm

nw 8665 c.r. M

shawano, wi 54166

612-840-0555

MerchandiseMerchandise

AUGUST 2015 | MESSENGER 25

MMPA Quality Premium Program MMPA Member Testing FeesPayment for testing will be made through an automatic milk

check deduction. all costs are listed per individual sample.

cowTests: $1

Cow samples may be tested for:

culture for streptococcus agalactiae, strep non ag, staphylococcus

aureus, coagulase negative staph, gram negative and/or scc.

Additional testing can be coordinated through your

MMPA member representative to include:

raw bacteria count and components.All herd tests must be scheduled with the laboratory through your MMPA member representative.

AdditionalTestsAvailable:

All costs are listed per individual sample.

• MycoplasmaCultures ..........................................................................$12

• BacteriologyCultures ..........................................................................$13

– Includes identification of bacteria and drug susceptibility.

• BovineViralDiarrhea

- Pcr ........................................................................................................$40

- elisa .......................................................................................................$6

• Johne’sMilkTest

- Pcr ........................................................................................................$40

- elisa – cows ........................................................................................$6

- elisa – tank ........................................................................................ $10

• BovineLeukosisTest

- elisa – cows ........................................................................................$6

- elisa – tank ........................................................................................ $10

• MilkPregnancyELISA ................................................................... $4.50

Lab test results by mail: $2/month

All tests must be scheduled through your MMPA member

representative or the laboratory for proper sample

submission protocol.

MerchandisepreMiuMs

201,000-225,000 .......... +20¢/cwt.

226,000-250,000 ...........+15¢/cwt.

251,000-300,000 ..........+00¢/cwt.

301,000-400,000 .........- 30¢/cwt.

401,000-500,000 ....... -$1.00/cwt.

501,000-600,000 ........-$1.50/cwt.

601,000 and greater . -$2.00/cwt.

somatic cell count premiums and deductions (in addition to

Federal order scc adjustments computed in the producer pay

price) will be paid at the following levels:

50,000 or below ........... +55¢/cwt.

51,000-75,000 ...............+50¢/cwt.

76,000-100,000 ............+45¢/cwt.

101,000-125,000 ............+40¢/cwt.

126,000-150,000........... +35¢/cwt.

151,000-175,000 ............+30¢/cwt.

176,000-200,000 ......... +25¢/cwt.

A payment of 5¢/cwt. will be added for each of the following, if the count is equal to or below:• 10,000 Raw Bacteria Count

• 20,000 Pre-Incubated (PI) Count

Therewillbeadeductionof10¢/cwt.for:• Greater than 100,000 Raw Bacteria Count

A high raw count deduction will be waived if the producer has

received the quality premium the previous three months for raw

bacteria count.

ToqualifyforRawandPIBacteriacountpremiumstheremustnot be any of the following during the month:• Positive drug residue

• Abnormal freeze points

• High load count shipment or rejected load shipment

• #3 or #4 sediment

• Raw Bacteria count over 100,000

The count levels for raw and PI will be determined on one test run

per month.

ToqualifyforMMPAsccpremiumstheremustbe:• No abnormal freeze points during the month

ToqualifyforMMPAvolumepremiumstheremustbe:• No abnormal freeze points during the month

• An average somatic cell count of 750,000 or less

ANTel-BIOTesTINg

loc/Hlr/producer# ________________________________ sample date _____________________________

Member name ______________________________________________________________________________

sample id _________________________________________________________________________________

blV elisa _________ Johne’s elisa ___________ Johne’s pcr ___________ pregnancy ____________

refer to above for current pricing. The cost of testing is the responsibility of the producer.

This card MusT be filled out completely when sending in samples to be tested by antel-bio

to avoid potential service charges.

Messenger | augusT 201526

Toplaceyourfreelineradpleasecall1-800-572-5824,ext.202,or

fax 248-426-3412, or email your ad to: [email protected].

freeliners

BullsRegistered Holstein Bulls: we now

have a nice selection of service

age bulls, sired by top ai sires.

green Meadow Farms, elsie, Mi.

989-862-4291 or see our website

at www.greenmeadowfarms.com.

Service age Holstein bulls. call steve

alexander, 810-622-8548 evenings or

810-404-8548.

Service age Reg. Holstein bulls,

deep pedigrees, some red carriers.

Jenesis genetics, 231-924-6163 or

231-225-8615.

Registered Holstein breeding bulls, all ai sired from top bulls, b&w, red,

red carrier and some polled, high

production, low scc herd. Bulls are

priced to sell. ver hage holsteins,

269-673-4886 or 269-217-6076, ask

for tim. www.verhageholsteins.com.

Registered year old Jersey bull. Fertility tested. grand Prix x

verify x Maximus. this guy should

improve looks, butterfat, and protein.

dam and granddam excellent.

517-238-5684.

Cows & HeifersSmall registered Holstein herd

sired by popular select sire bulls and

bred the same. call 574-370-8606 or

574-370-2667.

EquipmentJohn Deere grain drill model FB, 15

hole with seeder, hydraulic lift, $300.

616-837-8982.

18-ft. belt elevator, $350. 20-ft.

x-fold Brillion cultipacker. two 1,500

gal. septic tanks, $350 for 1, $600 for

the pair. 810-724-8825.

Gehl 1160 Merger, good condition,

$2,000 or best offer. 989-268-5789

leave message if no answer.

Bale grapler holds 15 small squares,

$3,000. weighted bags. 50 free

stalls, $25 each. Blower type for

harvestore silo. 810-404-2738.

New Holland 716 forage wagon,

16 ft. with 12 ton Kilbros running

gear, 12.5 x 15 tires, good condition.

$2,500 obo. 989-574-7229.

Dairy Equipment1500 gal. Surge bulk tank, good

condition. John deere 6420 MFwd

with 640 loader. 12-row anhydrous

tool bar. 1747 r Moline. 616-218-9350.

Better Built 6,600 gallon tank spreader, good condition, $12,500.

20-ft. grain box with steel sides

with heavy duty cylinder, grain door,

needs some work. $1,250. grain bins

8 and 14 ton $600 for the pair.

616-869-1459 or 616-292-8948.

Misc.Part time milker needed on

300 cow dairy in Fremont area.

call 231-218-4134.

Corn silage and snaplage for sale.

delivery available. call 231-250-8592.

Dairy FarmCheboygan, Mich. 367.11 acres,

includes double 16 parallel parlor,

4 years old. 2,000 gal. bulk tank,

400 free-stall barn, calf barn,

commodity barn, hay barn, maternity

barn, and pole barn. 45 ac. pasture

by main farm. 7 bedroom brick

home. can send or email packet with

pictures. equipment list and appraisal

available. crops for 2015 are in.

this can be a turn-key operation, or

raise heifers etc. Purchase price is

$990,000, this is for the farm only.

cows and equipment are separate.

we rent 600 +ac. with $40 being the

highest price paid per acre. contact

231-625-2036 or 517-202-9421.

we’re ready to make a deal!!

WantedRegistered Holsteins. call Brent

at 989-551-0681.

Concrete H bunks. call ray yoder

574-825-5858.

Freeliner Policy

the Freeliners column is open

to current MMPa members

who wish to advertise—at no

charge—goods or services

relating directly to their dairy

farm operations.

• Anitemsubmittedwill

be published for no more

than two consecutive

months (one month, unless

otherwise requested). after

that, it will be withdrawn.

• Itwillbepublishedagain

for no more than two

consecutive months only if

the member resubmits the

item by writing or calling

the novi office.

• Referencetoanameofa

firm or other commercial

enterprise with which a

member is involved will be

deleted, with permission of

the member.

• Ifthememberdoesnotwish

such deletion, he/she may

choose to have the item

published as a classified

ad at the regular per-line

classified ad rate.

• Freelinersmustbereceived

by the 10th of the month

preceding the desired

month of publication.

Example: To be included in

the September issue, the

freeliner must be at the

MMPA offic by August 10.

www.mimilk.com

AUGUST 2015 | MESSENGER 27

MESSENGER | AUGUST 201528

PTO and AutomaticStart Generators

1-800-248-8070M-40 South

Hamilton, MI 49419www.hamiltondist.com

REGISTERED HOLSTEIN BULLS

A special herd sire or a truck loadof breeder bulls.

Ready to go to work on your farm!

GREEN MEADOW FARMS6400 Hollister Road, Elsie, MI 48831

Phone: 989-862-4291

www.greenmeadowfarms.com

Over 100 service age bulls fOr yOur selectiOn! • Sired by the top sires from the

U.S. and Canada• From our top production cows

cost for classifieds is $20 per ad, up to six lines. all ads must be received by the 10th of the month before the

month of desired publication. send check or money order for $20 for up to 6 lines with your order. MMPa nei-

ther sponsors nor endorses products or services advertised in the Messenger. you may submit your ads by:

MAIL: classified ads | Michigan Milk Messenger

P.o. Box 8002, novi, Mi 48376-8002

EMAIL: [email protected] FAx: 248-426-3412

Concrete Groovingand Texturing

call: Jeff Brisky - Owner

toll free: 1-800-294-1202

cell: 1-716-353-1137

ALFALFA HAYLAGE (excellent

and fair grades) and corn silage.

989-723-1886 or 989-277-1414.

BARNWHITeWAsHINgAND

cleANINgWITHHIgHPRessuRe

AIR: serving all Michigan and indiana.

Miller spray service, inc. 574-825-9776.

DRY HAY & STRAW (large & small

bales) and barley for feed.

989-723-1886 or 989-277-1414.

MICHIGAN CERTIFIED WHEAT

SEED RED & WHITE, fall barley seed.

989723-1886 or 989-277-1414.

OPPeRMANgROOVINg: we can

fix your scabbled floors. diamond

sawed grooves, no hammering

or cracking of concrete. no hoof

damage. call opperman grooving

inc., Portland. 517-647-7381.

DAVIDsONceMeNTgROOVINg,

INC: no water needed. wider,

rougher grooves for better traction.

we also offer texturing for your

previously grooved floors. three

operators will travel Michigan and

other states. no interest payment

terms. established since 1987.

call 1-800-365-3361.

cONcReTegROOVINgBYTRI-

sTATescABBlINg, home of the

2” wide groove. Best traction,

lowest prices. (800) 554-2288.

www.tristatescabbling.com

AsuReWAYTOkeePYOuR

cOWsuPRIgHT!concrete

grooving/texturing provides

high quality traction in new & old

concrete, fast service. call for your

below pricing 989-635-1494. BLUE

RIBBONHOOfTRIMMINg,llc.

FOR SALE: 5000-4000-3000-

2500-2000-1500 OH MUELLER

lATeMODelBulkTANkMIlk

TANks, complete, will trade.

1-800-558-0112.

WANTeDTOBuY:useDBulk

MIlkTANks, 200 gallons & larger,

sunset & Mueller, 1-800-558-0112.

classified ads

AUGUST 2015 | MESSENGER 29

MMPA Policy on Drug Residue in Milk

MMPA Milk Quality Policy

MILk ON FARM – DRUG RESIDUE SUSPECTEDif a member suspects milk in the farm bulk tank contains

drug residue:

1. call a MMPa member representative to have the milk in the

tank tested. a “hold” must be placed on the tank contents

until the test results are known.

OR

2. the member can test the milk on the farm. if dumped, the

member must be sure to take the stick reading, record the

number of pounds of milk and report the information to their

member representative.

• Ifthetanktestsnegative(nodrugspresent),themilkmaybe

released and shipped.

• Ifthetanktestspositive(drugspresent),themember

representativewillauthorizethemembertodumpthetank

ofmilk.Thememberwillbepaid75%ofthevalueofthe

tankofmilkinvolved.*

• IfforanyreasonMMPApersonnelmustpickupsamplesat

the farm for testing three or more times within 12 consecutive

months,thememberinvolvedwillbecharged$25pertrip.

MILk SHIPPED — POSITIVE DRUGS CONFIRMEDif a member ships milk from the farm and testing by approved laboratory methods show that the milk contained drug residue, the member will be assessed the penalties imposed by the state regulatory agency and be disqualified for raw and Pi bacteria count premiums.

if a loss is incurred by MMPa due to the disposal and/or non-marketability of a load of milk or milk products containing drug residue, then the member responsible will be provided an invoice for the entire value of the loss plus transportation and disposal costs as required by the Pasteurized Milk ordinance. this invoice may be submitted to the member’s insurance carrier. MMPa must receive settlement on the invoice within 90 days of issuance. if settlement is not made within 90 days, the full amount of the invoice will be deducted from the next milk check unless other settlement arrangements are made.

Milk from that member’s farm tank must be tested and found clear of drugs before the next tank of milk can be picked up.

a hauler whose entire load sample shows the presence of drugs will be charged the amount of an average shipment on that load if the individual member samples all show negative.

ALL POSITIVE DRUG RESIDUE SHIPMENTS MUST BE REPORTED TO THE ENFORCEMENT AGENCY.

QUALITY QUESTIONABLEwhen a member suspects that the milk in the farm bulk tank is of poor quality they should call a MMPa member representative who will authorize milk in the tank to be dumped. if the member dumps the milk on their own, they must be sure to take the stick reading and record the number of pounds of milk, and report the information to the member representative.

if the milk is dumped, the member will be paid 75% of the value of the tank of milk involved.*

in order to receive payment for an added water voluntary dump, the member must install a swingline safety switch. the swingline safety switch can be ordered from the Mt. Pleasant warehouse. the MMPa member representative will verify the switch has been installed. reimbursement for the swingline safety switch and the voluntary dump will then be made to the member.

the member assumes all liability for losses incurred as a result of shipping poor quality or contaminated milk.

MILk SHIPPED – HIGH BACTERIA COUNT

If…1. a load of milk is received (unloaded) at a dairy processing plant and,

2. a sample from the load has a bacteria count of 300,000 or more and,

3. testing of the individual member samples on that load identifies the member or members having a bacteria count of 300,000 or more, then the member or members involved will be charged the value of one-half of one day’s production** and will be disqualified for raw and Pi bacteria count premiums.

*Thememberwillonlybepaidfortwo(2)voluntarydumpsinarolling 12 month period.

**Formembersusingmorethanonebulktank,theassessmentwillbe basedonthevalueofmilkinthetankortanksinviolationofthe MMPA quality policy.

REJECTED LOAD SHIPMENT

If…1. a load of milk is rejected (not unloaded) at a dairy processing

plant and,

2. the milk cannot be sold through normal grade a channels for reasons of quality which results in the load being sold or disposed of at a loss to MMPa, and,

3. testing of the individual member samples on that load identifies the member or members that caused the contamination or rejection of the load, then, the member or members responsible will be charged the full value of the loss to MMPa plus transportation and disposal costs, and be disqualified for raw and Pi bacteria count premiums except for loads rejected for temperature.

4. MMPa will provide an invoice to the member for the amount of the loss, to be submitted to the member’s insurance carrier. MMPa must receive settlement on the invoice within 90 days of issuance. if settlement is not made within 90 days, the full amount of the invoice will be deducted from the next milk check unless other settlement arrangements are made.

if a member has three or more occurances within 12 consecutive months, that member must appear before the MMPa board of directors to review steps taken on the farm to correct the quality problem which will enable MMPa to continue to market the milk for this member.

HAULERa hauler whose entire load sample exceeds 300,000 cells per ml bacteria count will be charged the amount of an average ship-ment on that load if the individual member samples all are less than 100,000. a hauler will be responsible for all costs incurred by MMPa for loads rejected for temperature.

charges and assessments made under this program will be with-held from milk checks of members or haulers involved.

Merchandisepolicies

MESSENGER | AUGUST 201530

Market Statistics - Mideast Federal Order #33 (pounds)

% This Month Year Ago Change

Total Class 1 Sales 484,648,540 467,110,497 +3.75

Total Class 2 Sales 349,567,402 162,691,318 +114.87

Total Class 3 Sales 331,184,579 539,323,620 -38.59

Total Class 4 Sales 268,964,800 219,962,536 +22.28

Total Production 1,434,365,321 1,389,087,971 +3.26

Class 1 Utilization 33.8% 33.6%

Mideast Federal Order #33Total Producers......................................................................................................................... 5,741

Avg. Daily Production per farm ........................................................................................... 8,328

Avg. Protein Test ......................................................................................................................3.00%

Avg. Butterfat Test ..................................................................................................................3.59%

Avg. Oth Solids Test ...............................................................................................................5.76%

Avg. SCC - MMPA ................................................................................................................ 171,000

Component Pricing Information -Mideast Federal Order #33Protein Price /lb ....................................................................................................................$2.6915

Butterfat Price /lb .................................................................................................................$2.1011

Other Solids Price /lb ..........................................................................................................$0.2322

Class III Price @ 3.5% ............................................................................................................. $16.72

Prod. Price Diff /cwt. - Mich Mkt ....................................................................................... ($0.66)

Uniform Price @ 3.5% ........................................................................................................... $16.06

SCC Adjustment /cwt /1000 .......................................................................................... $0.00086

AMS Survey PricesProduct Monthly Avg

Cheese /lb................................................................................................................................. 1.7222

Butter /lb................................................................................................................................... 1.9065

Nonfat Dry Milk /lb................................................................................................................ 0.9283

Dry Whey /lb ............................................................................................................................ 0.4245

MARKET REPORT

Statistical Summary | FOR MILK MARKETED IN JUNE 2015

National Trends(million pounds)

2015 2014 % Change

Production

California 3,396 3,549 -4.3

Wisconsin 2,403 2,324 +3.4

Idaho 1,204 1,192 +1.0

New York 1,193 1,159 +2.9

Pennsylvania 909 882 +3.1

Michigan 865 807 +7.2

Texas 848 866 -2.1

Minnesota 789 757 +4.2

New Mexico 657 688 -4.5

Washington 560 562 -0.4

Ohio 455 458 -0.7

Indiana 337 328 +2.7

*Total U.S. 16,354 16,241 +0.7

*U.S Y-T-D 98,764 97,287 +1.5

* For 23 States

Market Statistics - Mideast Federal Order #33 (pounds)

% This Month Year Ago Change

Total Class 1 Sales 484,648,540 467,110,497 +3.75

Total Class 2 Sales 349,567,402 162,691,318 +114.87

Total Class 3 Sales 331,184,579 539,323,620 -38.59

Total Class 4 Sales 268,964,800 219,962,536 +22.28

Total Production 1,434,365,321 1,389,087,971 +3.26

Class 1 Utilization 33.8% 33.6%

AUGUST 2015 | MESSENGER 31

*If you are unable to reach your assigned member representative, please contact the repre-sentatives listed in your area.

MMPa Field staff*Northwest Area Ben Chapin, Supervisor, Blanchard ......................................... 989-289-0731

Frank Brazeau, Energy Auditor, Oconto, WI .................... 906-250-0337

Lyndsay Earl, Ludington .................................................................. 231-519-2455

Sarah Michalek, Portland ..............................................................248-305-0537

Deb Navarre, Leroy .........................................................................248-520-3580

Dirk Okkema, Blanchard ............................................................. 248-756-2062

Northeast AreaChristy Dinsmoore, Supervisor

& Mastitis Management Specialist, Fairgrove .....................248-513-7920

Lindsay Green, Energy Auditor, East Lansing ...................989-488-8159

Ashley Herriman, Alpena ............................................................. 269-245-6632

Angie Kirsch, Harbor Beach ..........................................................231-414-4539

Drew Rupprecht, Clio ..................................................................... 269-986-6793

South AreaEd Zuchnik, Supervisor

& Energy Auditor, Three Rivers .................................................. 269-967-7351

Krista Beeker, Topeka, IN .............................................................. 269-986-6792

Dave Brady, Grass Lake .......................517-522-5965 or (c) 517-937-9061

Elyse Martin, Charlotte ....................................................................810-701-6460

Joe Packard, Kalamazoo ............................................................... 248-520-3481

Emily Smith, Bronson ..................................................................... 269-535-0822

Other Services

BulkTankcalibration

Gary Best, Lapeer ..............................810-664-4984 or (c) 586-484-9279

Merchandise Coordinator, Energy Auditor

Katie Pierson, Coleman .................................................................989-289-9686

Mastitis Management Specialist

Steve Lehman, Ithaca .........................989-875-3441 or (c) 989-330-1638

MMPA Labs

Novi (Monday-Friday, 8 a.m.-4:30 p.m.)

In Michigan .................................................................................... 800-572-5824

Toll Free........................................................................................... 800-233-2405

Ovid (Daily, 6 a.m.-10 p.m.) ....................................................989-834-2515

Constantine (Daily, 7 a.m.-10 p.m.) .....................................800-391-7560

Merchandise - Mt. PleasantDuane Farmer, Supervisor