Metal Detector Homemade

description

Transcript of Metal Detector Homemade

Geotech Page 1

Sil

icon

Chi

p, J

une

2002

— C

opyr

ight

Sil

icon

Chi

p P

ubli

cati

ons

Pty

Ltd

, rep

rodu

ce f

or p

erso

nal u

se o

nly

An induction balance (IB) metal loca-tor has a good depth of penetration anddistinguishes well between ferrous andnon-ferrous metals. It is also capable, toa large extent, of rejecting iron and alsotin foil This is a boon for anyone who issearching for coins or noble metals.

My aim with this design was to cre-ate a ‘minimalist’ device — one thatwould work well but without all thebells and whistles of the expensive,commercial designs. I found that it waspossible, with just a handful of compo-nents, to design a high-quality metallocator.

For instance, on comparison with thefirst-class EE-Magenta Buccaneer, thisdesign delivers 95% of the perfor-mance in the category where it reallymatters — a clear indication of the pres-ence of metal.

Simple, but it works An IB metal locator is usually far

more complex than the design shownhere — the EE-Magenta Buccaneer, forexample, uses more than 70 compo-nents. This one uses less than 20.

The reason for the simplicity is that Ihave dispensed with analog circuitry,and instead used a digital transmitterand receiver.

As the search coils pass over metal,

only digital signals of a certain ampli-tude break through to a peak detector(IC1b). Since these are in the audiorange, they are immediately transferredto the piezo sounder or headphones.

On testing the sensitivity of thisdesign in air, with optimal tuning andusing a 25mm-diameter brass coin, itgave a clear signal at 150mm, and a‘screaming’ signal at 110mm. It wasalso able to detect a pin at 30mm.

‘Matchless’Metal

LocatorWant to find a fortune? Buried treasure, perhaps? Lostcoins on the beach? Or perhaps you fancy earning somepocket money finding other people’s valuables. Either way,this project should really interest you. It’s an el-cheapoinduction balance (IB) metal locator that delivers surpris-ingly good performance.

by Thomas Scarborough

Geotech Page 2

Sil

icon

Chi

p, J

une

2002

— C

opyr

ight

Sil

icon

Chi

p P

ubli

cati

ons

Pty

Ltd

, rep

rodu

ce f

or p

erso

nal u

se o

nly

Note that these figuresmay not apply in tbe ground, wheredepth of penetration will depend largelyon the mineralisation present.

In contrast, the locator is far morereluctant to pick up tin foil. A tin foildisk of the same size as the brass coinwas only detected at half the distance in

air. Thisrejection of tin foil is due in

part to the metal locator’s low fre-quency, which avoids what is calledskin effect.

Besides this, if the two coils are posi-tioned as described, ferrous metals(iron) are, to a very large extent,rejected — to such an extent, in fact,that a 25mm diameter brass coin weigh-ing seven grams looks the same to themetal locator as a lump of iron weigh-

Geotech Page 3

Sil

icon

Chi

p, J

une

2002

— C

opyr

ight

Sil

icon

Chi

p P

ubli

cati

ons

Pty

Ltd

, rep

rodu

ce f

or p

erso

nal u

se o

nly

ing 20 times as much. Large nonferrousohjects are detected at half a metre dis-tance and more.

The locator’s power consumption isconveniently low. It draws around10mA, which means that it may bepowered off a small 9V battery. If analkaline battery is used, this will pro-vide about 48 hours’ continuous use. Inmy experience, the number of coins thatare found on a beach in an hour or twoshould easily make up for the cost ofbatteries!

Finally, while the stability of the loca-tor is not the best, it’s by no means theworst either. Re-tuning is necessaryfrom time to time, especially in the firstfew minutes of use. One soon becomesaccustomed to giving the Fine Tuneknob an occasional tweak — perhapswith every 40 or 50 sweeps of thesearch head.

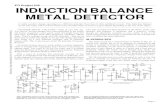

Circuit description The search head of a typical IB metal

locator contains two coils: a transmitter(Tx) coil and receiver (Rx) coil.

In this case, the Tx coil is driven by asquare wave oscillator, which sets up analternating magnetic field in the coil.The Rx coil is then positioned in such away that it partly overlaps the Tx coil.By adjusting the amount of overlap, apoint can be found where the voltagesin the Rx coil ‘null’ or cancel out, sothat little or no electrical output is pro-duced. A metal object which enters thefield then causes an imbalance, result-ing in a signal.

The transmitter (IC1a) is a standard555 oscillator configuration, using onehalf of the ICM7556IPD dual lowpower CMOS version of this IC.

Do NOT use the veteran NE556N IC,by the way.

IC1a oscillates at about 700Hz, deter-mined by R/C components around pins1, 2 and 6. The 680Ω resistor limits thecurrent passing through the Tx coil.

Geotech Page 4

Sil

icon

Chi

p, J

une

2002

— C

opyr

ight

Sil

icon

Chi

p P

ubli

cati

ons

Pty

Ltd

, rep

rodu

ce f

or p

erso

nal u

se o

nly

The receiver section (IC1b) is pre-ceded by a simple yet sensitivepreamplifier stage, based on Q1, whichamplifies the signal received from theRx coil. This is fed directly to IC1b,which is used here as a high-perfor-mance sine-square convertor. Its input

at pins 8 and 12 is biased by the dividerformed by the 10kΩ resistor and potsVR1-VR3, so that only pulses of a cer-tain amplitude break through to outputpin 9.

There is a point at which, with care-ful adjustment, the signal is just

breaking through in the form of a crack-ling sound. When the locator’s output isadjusted to a fast crackle, the presenceof metal turns this into a ‘scream’. Thisis heard from the piezo sounder orthrough standard headphones. The 7556IC allows up to 100mA of output cur-rent, therefore no further amplificationis required.

Winding the coils The one drawback to any IB metal

locator design is its need for two coils,which must be very carefully and rig-idly positioned in relation to oneanother. Sometimes there’s no roomeven for a fraction-of-a-millimetre errorin positioning these coils. While thisparticular design makes things easierthan usual, the placement of the coilswill still require some patience. On theother hand, the winding of the coils isrelatively easy. Each coil also includes aelectrostatic (Faraday) shield, whichhelps to minimise ground effect.

The winding of the (identical) coils isnot critical and a little give and take ispermissible.

I used 30SWG (0.315mm) enamelledcopper wire, winding 70 turns on a cir-cular former, 120mm in diameter.

I created the former with a sheet ofstiff cardboard with 12 pins stuckthrough it at a suitable angle (the headsfacing slightly outwards). The coil waswound clockwise around the pins, thentemporarily held together with stubs ofinsulating tape passed under the coiland pressed together over the top. Thecoil may be jumble-wound (that is, youdon’t have to wind the turns on side-by-side in neat layers).

Once this has been done, the pins areremoved, and a second coil is wound in

Geotech Page 5

Sil

icon

Chi

p, J

une

2002

— C

opyr

ight

Sil

icon

Chi

p P

ubli

cati

ons

Pty

Ltd

, rep

rodu

ce f

or p

erso

nal u

se o

nly

the same way. In each case, mark thebeginning and end wires. Each coil isthen tightly bound by winding insulat-ing tape around its entire circumference.

Now we add a Faraday shield to eachcoil. This is accomplished with somelong, thin strips of aluminium foil. Firstscrape the enamel off each coil’s endwire. Solder a 100mm length of barewire to the winding wire, and twist thisaround the coil, over the insulating tape.This provides electrical contact for theFaraday shield.

Beginning at the base of this lead, thefoil is wound around the circumferenceof the coil, so that no insulating tape isstill visible under the foil but the foilshould not complete a full 360°. Leavea small gap (say 10mm) so that the endof the foil does not meet the start afterhaving gone most of the way around.Do this with both coils. Each coil isnow again tightly bound with insulat-ing tape around its entire circumference.

Attach each of the coils to its ownlength of quality single-core screenedaudio cable, with the Faraday shield ineach case being soldered to the screen.Do not use stereo or twin-core micro-phone wire to run both leads together;this may cause interference between thecoils.

Gently bend the completed coils untileach one is reasonably flat and circular,with each end wire facing away fromyou, and to the right of the beginningwire. Now bend them further until theyform lopsided ovals like capital Ds (seeFig.2). The backs of the Ds overlapeach other slightly in the centre of thesearch head. This is the critical part ofthe operation, which we shall completeafter having constructed the circuit.

Last of all, wind strips of absorbentcloth around each coil (I used strips ofthin dishwashing cloth such as Chux),using a little all-purpose glue to keepthem in place. Later, when epoxy resinis poured over the coils, this cloth

Geotech Page 6

Sil

icon

Chi

p, J

une

2002

— C

opyr

ight

Sil

icon

Chi

p P

ubli

cati

ons

Pty

Ltd

, rep

rodu

ce f

or p

erso

nal u

se o

nly

meshes the coils into the resin.

Construction The PC board of the Matchless Metal

Locator measures 48mm x 42mm, andis coded 04106021. There are not manycomponents, so it should be easy toassemble the board using the PC boardoverlay diagram in Fig.3.

With the exception of the CMOS IC,component values and types are notcritical. The one critical component isthe ICM7556IPD CMOS IC. I also triedthe TS556CN IC in this position — itworked, but not as well.

Begin board assembly by solderingthe nine terminal pins, the 14-pin dual-in-line socket for IC1 and the resistors.Continue with the capacitors, diodesand Q1.

Once soldering is complete, carefullycheck the board for any solder bridges,then use some short lengths of qualityscreened microphone wire to attach thepiezo sounder, VR2 and VR3, with thescreen (or braid) always being wired to0V. If you wish, add a socket for head-phones in parallel with or in place of thepiezo sounder. Use insulated hookupwire to attach the battery and switch S1,keeping the leads short. Finally, attachthe screened cables from the coils, withthe screen again going to 0V, and insertIC1 in the DIL socket. Note that IC1 isstatic sensitive, and requires carefulhandling (discharge your body to earthbefore handling).

Fig.5 shows the suggested hardware

construc-tion, using PVC piping and joints. Bendthe base of the metal locator’s shaftunder very hot water to obtain the angleshown. Alternatively, a swivel jointmay be made.

The entire electronics (apart from thesearch coils) is mounted in a metal case,ensuring that no part of the underside ofthe PC board is touching the case. Theadjustment slot for VR1 should beaccessible via a small hole in the case.Mount VR2 and VR3 where quick andeasy adjustment is possible.

A metal case is essential, otherwisethe circuit is affected by electrostaticcoupling (or capacitive effects). Themetal case is connected to 0V, throughthe tab on the copper side of the PCboard.

I was unable to obtain a purpose-made metal case in my city (Cape

Town) but found thatgood quality metal sweet tins

were readily available, so I used one ofthese. They are also considerablycheaper than similarly sized electronicsenclosures and of course you get thesweets as well!

Setting the coils A completed PC board is needed

before we can ’pot’ the coils. These arepotted with epoxy resin in a hard plas-tic dinner plate, the sort you’d find in apicnic set. Any plastic plate of suitablesize will do, on condition that it is rigid.

(A tip: don’t pinch them from thefamily picnic set ....)

First place the coils on top of oneanother — ensuring that they are cor-rectly orientated, with each end wirefacing away from you, and to the rightof the beginning wire. Adjust both VR2and VR3 to their midpoint. Adjust VR1

to about 90kΩ. Then attach a 9Vbattery and switch on. The circuitwill most likely be screaming; thatis, beeping loudly and continuously.

Now slowly move the coils apart.When they are somewhere past thehalfway point, the headphones willfall silent. This is where the volt-ages in the Rx coil ‘null’. Continueto move the coils apart. At a precisepoint just before the coils no longeroverlap at all — the headphones willbegin to scream again (there may ormay not be a low-level beep justbefore this).

It is at this precise point, and not afraction of a millimetre either way,that the coils need to be set.

Take an indelible marker pen andmark out holes in the lower platearound both coils. These holes areused to pass cable ties through, tohold the coils tightly to the plate.Also use a cable tie to hold the audiocables to the plate. Use some Blu-tak

http:/detectordemetais.r30.com.br - http://www.perus.com - http://www.eletronica.com - http://www.novaeletronica.com.br

Sil

icon

Chi

p, J

une

2002

— C

opyr

ight

Sil

icon

Chi

p P

ublic

atio

ns P

ty L

td, r

epro

duce

for

per

sona

l use

onl

y(or Presstik) to tightly seal the holesunderneath the plate before pouring inthe resin — epoxy resin can be very‘runny’ and sticks faster than manyglues.

Also at this point carefully bend thecoils at the centre of the plate until youreach the exact balance at which there isneither silence nor screaming in thepiezo sounder/headphones, but just acrackle. A little drift should not matterat this point.

Now you are ready to mix and pourthe resin. Use a modest amount of cata-lyst, so that there will be not too muchheat and shrinkage in the resin. Pour theresin over the cloth which surrounds thecoils, so as to soak it, and keep on pour-ing at least until the entire bottom of theplate is covered with resin.

The circuit may no longer functioncorrectly at this point until the resin has

hardened, so make no more adjust-ments at this stage, but switch thecircuit off and leave it for 24 hours orso.

I potted two sets of coils (that is, twocomplete search heads). The firstworked perfectly, precisely as I had setit in the plate. The second contractedslightly as the resin set, so that no set-tings of VR2 or VR3 would produce atone in the headphones. However, thisis where the design of the MatchlessMetal Locator shows its flexibility. Byturning VR1 clockwise, the circuit wasagain functioning normally when VR2and VR3 were set to their midpoint.

How to use it Keep the search head away from all

metal — and “noisy” computer equip-ment — and switch on. Adjustpotentiometers VR2 (Tune) and VR3

(Fine Tune) to their mid-points. Thenadjust VR1 with a screwdriver or plas-tic alignment tool until the metal locatoris just at the point where a crackle isheard, between silence and a scream (orbetween a low-level hum and a scream).Use the tune and fine-tune knobs forany further tuning.

A fast crackling sound produces thebest results. Move a coin over thesearch head and the piezo soundershould scream.

In actual use, the adjustment of themetal locator will be affected by themineralisation of the ground you aresearching, as well as temperature andvoltage variations. So as mentioned ear-lier, readjustments to VR3 and VR2 areinevitable from time to time.

That’s really all there is to it. In caseof any problems, though, the authormay be contacted at [email protected].