Mechanics Problems

-

Upload

anish-puthuraya -

Category

Documents

-

view

225 -

download

2

description

Transcript of Mechanics Problems

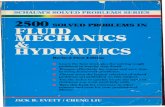

INDIAN INSTITUTE OF TECHNOLOGY, BOMBAYMECHANICAL ENGINEERING DEPARTMENT

SOLID MECHANICS (ME 201)

TUTORIAL SHEET (NO. 3) ON AXIALLY LOADED ELEMENTS

Q.1. In a particular machine an element consists of a 150mm dia brass cylinder with a 6.25mm wall thickness and a 250mm dia. aluminium cylinder with 6.25mm wall thickness. The aluminium cylinder is made 0.08mm shorter than the brass cylinder. When there is an external load P = 2000kN, determine stresses in aluminium and brass cylinders. Use E a = 70GPa and Eb = 100GPa.

Q.2.A stiff beam is hinged at one end and supported by two springs each of stiffness K. Where should a force P be applied so that the spring constant of the system (P divided by deflection at the point of application of P) is (20/9)K?

Q.3. The top and bottom edges of a rectangular bar of 2000mm length is subjected to stresses of uniform intensity . The decrease in height at section AB is 15 x 10-3mm.

P

Brass

Aluminium

0.08mm

250mm

C

K

a a

P

What is the total elongation of the bar in the x direction? Given E = 200GPa and Poisson’s ratio = 0.25.

Q.4. A composite cylinder consists of a brass cylinder of 300mm internal radius and 3mm thickness, and a steel cylinder of 303mm internal radius and 6mm thickness. Both cylinders are of length 60mm. If the brass cylinder is subjected to a radial pressure of 1.4MPa estimate the tangential stresses in the brass and steel cylinders. Assume that Eb = 0.5Es and the cylinders are initially assembled without any radial interference between them.

150mm

Brass

Steel

x

2000mm

A

B

400mm

y 10mm