Mechanical Engg. courses

description

Transcript of Mechanical Engg. courses

COMBUSTION ENGINES EMISSIONS

DELHI TECHNOLOGICALUNIVERSITY SCHEME OF EXAMINATION

AND

COURSE OF READING

FORPROPOSED SYLLABUS

B.Tech. (MECHANICAL ENGINEERING)Semester I Examination November, 2010Semester II Examination May, 2011Semester III Examination November, 2011Semester IV Examination May, 2012Semester V Examination November, 2012Semester VI Examination May, 2013Semester VII Examination November, 2013Semester VIII Examination May, 2014 Syllabus applicable to the students seeking admission to the B.Tech. (Mechanical Engineering) Course in the academic year 2010.

DELHI TECHNOLOGICAL UNIVERSITYNEW SCHEME OF EXAMINATION

1.There shall be the following four year Degree courses under the Faculty of Technology.

i. Bachelor of Technology (Electronics & Communication)

ii. Bachelor of Technology (Computer)

iii. Bachelor of Technology (Electrical)

iv. Bachelor of Technology (Mechanical)

v. Bachelor of Technology (Production & Industrial)

vi. Bachelor of Technology (Civil)

vii. Bachelor of Technology (Environmental)

viii. Bachelor of Technology (Polymer Science & Chemical Technology)

ix. Bachelor ofTechnology (Information Technology)

x. Bachelor of Technology (Bio Technology)

xi. Bachelor of Technology (Software Engineering)

xii. Bachelor of Technology (Electrical& Electronics)

xiii. Bachelor of Technology (Automobile Engg)

xiv. Bachelor of Technology (Engineering Physics)

2.In addition to the conditions laid down in Ordinance I, a candidate seeking admission to any of the above Courses of study for the Bachelors Degree should satisfy the following conditions.

(a)Educational Qualifications:

A candidate passing any one of the following examinations and securing 60 percent or more marks in the aggregate of Physics, chemistry And Mathematics shall be eligible for admission to the first Semester of Bachelor of Technology Course provided he/she has passed in each subject separately ;

i. Senior Schools Certificate Examination (12 year course) of the Central Board of Secondary Education (C.B.S.E.), New Delhi.

ii. Indian School Certificate Examination (12 Year course) of the Council for Indian School Certificate Examination, New Delhi.

iii. B.Sc. (Gen.) Group A final Examination of the University of Delhi or equivalent examination.

iv. B.Sc. (Hons.) Examination in Physics, chemistry and Mathematics of the University of Delhi with combination of Physics, Chemistry, Mathematics and equal weightage to the subsidiary subjects or equivalent examination.

v. Any other examination recognized as equivalent to the Senior School Certificate Examination of the C.B.S.E by the University of Delhi.

A candidate must additionally have passed English as a subject of study at the 12th class level (core or elective)

NOTE : There shall be no direct admission to any level of the Courses above the Ist Semester.

3.Under each B.Tech. Degree course certain subjects are offered which can be classified as Theory/ Practical/ Drawing/ Design/ Project/ Practical Training. Further classification is based on the relationship of the subjects with the degree courses admitted to, namely Humanities and Social Science/ Basic Sciences/ Allied engineering, Departmental, core, etc.

In addition to the above, a subject could be classified as a compulsory one or as one of the pre-requisite for another subject. The Committee of courses and Studies of the concerned Department shall do this classification.

4.A student who joins the first semester will be automatically, deemed to have registered for the subjects which are listed under the first Semester of the SUGGESTED SCHEME OF LEARNING. Every student is required to register for the subjects to be taught in the second and subsequent semesters. This process of registration shall start just before the start of next semester. The student will also indicate during registration of subject/ subjects of earlier Semester(s) in which he/ she desire to appear, if otherwise eligible. Such a student will be allowed to appear in the End Semester Examination and his/ her marks of mid terms activities will remain unaltered since attendance is compulsory, a student will be permitted to register for course/ courses which he can attend. The number of theory subjects permitted will not be more than six. The total duration of contact period should not ordinarily exceed thirty two hours per week.

5.B.Tech Degree shall be awarded if a student has earned a minimum of 228 credits as specified in each degree program subject to break up and compulsory credit as mentioned there in. However, a student may register in subjects leading to a maximum of 240 credits in the entire course.

A student should keep a watch on his progress and register in those papers in which he must earn the credit to satisfy the above requirement of the particular degree.

If a student earns more than a specified minimum credit for degree the best marks in the minimum credits (satisfying the above conditions) will be considered for the purposes of classification of result.

6.Evaluation and Review

The committee of Courses & Studies in each Department shall specify the following for the degree course:-

(a)Suggested Scheme of Learning.

(b)Minimum credits needed for the degree course and break up in terms of classification of courses i.e.

a. Humanities and Social Sciences

b. Basic Sciences

c. Allied Engineering

d. Departmental Core

e. Practical Training

f. Unspecified/ Elective and

g. Project.

The committee of courses & Studies in each Department shall appoint one or more Evaluation-cum-Review Committees each dealing with group of subjects. This E.R.C consist of the teachers who are likely to teach subjects in the group.

The E.R.C. has the following functions:

i. To recommend appointment of paper setters/ examiners of various examinations at the start of each Semester.

ii. To get prepared quizzes, assignments, test papers etc. for the mid-term and the end semester examination and to get them evaluated. Normally each concerned teacher, who is also a member of E.R.C., will do this job for his class. However, in exceptional circumstances any part the work will be entrusted to some other member of E.R. C.

iii. The mode of evaluation of the mid-term activities whose weightage shall be 30% and the end of term examination whose weightages shall be 70% (The mid-term activities will be one mid term test or 20% weightage which will be supplemented by assignments, quizzes etc. for a theory course with weightage of 10%). For a practical course, 30% weightage be given for internal evaluation and 70% for End Semester Examination. At the end of the Semester, the E.R.C. Chairman will send to the University the consolidated marks for the mid-term activities and the End Semester in separate column for tabulation and for declaration of results.

iv. To consider the individual representation of students about evaluation and take the remedial action if needed. After scrutinizing the E.R.C may alter the marks awarded upward/ downward. The decision of the ERC shall be final. The candidate shall apply for the same on a prescribed Proforma along with the evaluation fee prescribed the University from time to time only for the end Semester Examination within seven days from the date of declaration of result.

v. To moderate the quiz/ assignment test papers given by each concerned teacher in class with a view to maintain uniformity of standards and course coverage amongst various classes and to attain stipulated level of learning.

vi. To review and moderate the mid term and end of term results of each class with a view to maintain uniformity of standards and course coverage amongst various classes and to attain stipulated level of learning.

vii. To lay guidelines for teaching a subject.

7.Classification of Result:

A student has to secure 40% or more marks in a subject evaluation to earn the credits assigned to the subject. A student after having secured the minimum credit as needed for the degree course will be eligible for the award of degree. The final result will be evaluated as below:

Each subject will carry 100 marks.

(See clause 5 for best grades in the minimum credits)

The final result will be classified based on the average marks as follows.

First Class with Distinction 75% or more

First Class 60% or more but less than 75%

Second Class 50% or more but less than 60%

Pass Class 40% or more but less than 50%

8.A student has to put in a minimum of 75% attendance separately in each subject for which he has registered. A relaxation up to a maximum of 25% may be given on the production of satisfactory evidence that:

(a)The student was busy in authorized activities.

(b)The student was ill.

Note:-(i)A student should submit the evidence to the above fact within three working days of resuming the studies. Certificates submitted later will not be considered.

(ii)No relaxation in attendance beyond 25% is permitted in any case.

(iii)The registration of a student stands cancelled if his attendance requirements are not satisfied in the subject.

9.The duration of the course is not less than 8 Semesters and the span is not more than 14 semesters.

A student who earn 15 credits or less at the end of the first semester will receive a warning for his/her poor performance, if he fails to earn at least 25 credits at the end of the second semester, he has to leave the course and institution.

In case a student has not earned a minimum of 100 credits at the end of eight semester, his admission to the course and the institution stands cancelled. The admission stands cancelled at the end of 14 semester in any case.

10.The Institution /University may cancel the registration of all the subjects in a given semester if:

1.The student has not cleared the dues to the institution /hostel.

2.A punishment is awarded leading to the cancellation.

At discretion of the institution the result may be withheld even if the registration of the student stands.

11.There shall be a Central Advisory Committee consisting of the following:

(a)Dean, Faculty of Technology, (Chairman of the Committee)

(b)Heads, of the Institutions.

(c)Heads of the Departments in the Faculty of Technology.

This Committee shall have the following functions:

(i)Lay guidelines for the process of registration.

(ii)Give an interpretation of the rules in case of difference of opinion which shall be binding on all.

12.Under very exceptional conditions minor relaxations in rules may be allowed and implemented by the Central Advisory Committee. However, same relaxation in rules can not be granted in a subsequent semester. In case the conditions warrant such a relaxation again, the rules shall have to amended.

General Notes:

1.For all Theory Papers (Code:TH) there is one min-semester test of 30 marks (20+10 Assignments) and an end-semester exam. of 3 hours duration for 70 marks. The total marks for the Theory Papers is thus 100.

2.For all Practical Papers (Code: PR) there is semester assessment of 30 marks and an end semester exam of 3 hours or 4 hours duration for 70 marks. The total marks for the Practical paper is thus 100.

3.For all valuation of Sessional (Code ; VS) there is semester assessment of 100 marks. There is no end-semester exam for these courses. Credit of VS are not included in the total credits of semester. However, it is mandatory to pass the VS course.

4.At VII and VIII semester levels there is assessment of Practical Training Reports by a duly constituted Board. The report is to be submitted by summer /winter breaks. The total marks associated with each Practical Training Report is 100 marks of which 30 marks are awarded by the department on the basis of supervision of Industrial Training.

5.At VIII semester level there is assessment of Project Report by a duly constituted Board. The report is to be submitted by the student of the project work performed at the VII and VIII semester levels. The total marks associated with the project report is 100 marks of which 30 marks are awarded by the department on the basis of guidance of Project Work.

6.The total credits in all scheme of examination to B.Tech. Courses upto VIII semester will be 240 and the denominator for calculation of average marks for final result will be 228.

7.The project and the Practical Training after V & VI Semester are mandatory.

8.Candidates securing 236 to 240 credits are declared to have passed B.Tech. Final examination.

9.Candidates securing 229 to 235 credits are declared to have passed B.Tech. Final examination provided they skip/ fail in not more than 4 credits in CORE.

10.Candidates securing exactly 228 credits are declared to have passed B.Tech. Final examination, provided they skip/ fail in not more than 4 credits in core, not more than 4 credits in Applied Engineering, and not more than 4 credits in Applied Sciences & Humanities.

MECHANICAL ENGINEERING DEPARTMENT

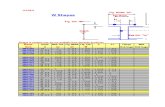

Summary of Revised Scheme of Examination

Total Credits for B.Tech. degree: 240Semester wise: I-30, II-30, III-30, IV-30, V-30, VI-30, VII-30, VIII-30Distribution of credits :SubjectsHACTOTAL CREDITSM

I19110030

II14070930

III08101230

IV00092130

V00062430

VI00042630

VII00082230

VIII00111930

Total Credits 2404166133240

Percentage Contents of H, A, C17.08%27.50%55.41%100%

HHumanities, Social Studies and Basic Sciences

AAllied Engineering

CCore (include major project and practical training also)

MMandatory Core

Industrial training of 12 weeks duration during summer vacations after 6th semester and 4 weeks after 5th semester.

VS (Evaluation of sessional courses have been converted in the form of regular theory or practical course with End Semester Examination)SUGGESTED SCHEME FOR BTech.FIRSTSEMESTER(MECHANICAL ENGINEERING)(common to all branches)S.No.Course No.SubjectLTPEvaluationTotal MarksCredit Type

TH1MA 101Mathematics-1310Sessional End

30

701004H

TH2HU 102Communication skills 21030

701003H

TH3PH 103Applied Physics31030

701004H

TH4CH 104Applied Chemistry31030

701004H

TH5EE

105Electrical sciences 31030

701004A

TH6IT

106Fundamentals of Information Technology21030

701003A

PR1PH 107Applied Physics Lab00230

701002H

PR2CH 108Applied Chemistry Lab00230

701002H

PR3EE

109Electrical Sciences Lab00230

701002A

PR4IT

110Information Technology Lab00230

701002A

TOTALPractice30 hrs100030

SUGGESTED SCHEME FOR BTech. SECOND SEMESTER (MECHANICAL ENGINEERING)

(Comman to all branches)S.No.Course No.SubjectLTPEvaluationTotal MarksCredit Type

TH1MA 111Mathematics-II310Sessional End

30

701004H

TH2EN 112 Environmental Science20030

701002A

TH3AS 113Applied Physics-II40030

701004H

TH4AS 114Engineering Materials40030

701004H

TH5ME 115Basic Mechanical Engineering31030

701004C

TH6COE 116Programming Fundamentals20030

701002A

PR1ME 117Engineering Graphics00330

701003A

PR2COE 118Programming Lab00230

701002C

PR3PH 119Applied Physics Lab00230

701002A

PR4PE 120Workshop Practice00330

701003C

TOTALPractice30 hrs100030

SUGGESTED SCHEME FOR B.Tech. THIRD SEMESTER (MECHANICAL ENGINEERING)

S.No.Course No.SubjectLTPEvaluation Sessional End

Total MarksCredit Type

TH1ME 201THERMAL ENGINEERING - I31030 701004C

TH2ME 202ENGINEERING MATERIALS AND METALLURGY30030 701003A

TH3ME 203NUMERICAL TECHNIQUES31030 701004H

TH4ME 204QUANTITATIVE TECHNIQUE(*Probability & Statistical Methods)31030 701004A

TH5ME 205ENGINEERING MECHANICS 31030 701004C

TH6ME 206ENGINEERING ECONOMICS AND ACCOUNTANCY40030 701004H

PR1ME 207THERMAL ENGINEERING - I / ENGINEERING MECHANICSLAB00230 701002C

PR2ME 208MACHINE DRAWING00230 701002C

PR3ME 209ENGINEERING MATERIALS AND METALLURGY LAB00230 701002A

VS1ME 210SELF STUDY00130 70

1001C

TOTAL30hrs100030

SUGGESTED SCHEME FOR B.Tech. FOURTH SEMESTER (MECHANICAL ENGINEERING)

S.No.Course No.SubjectLTPEvaluation Sessional EndTotal MarksCredit Type

TH1ME 211THERMAL ENGINEERING - II31030 701004C

TH2ME 212FLUID MECHANICS31030 701004C

TH3ME 213INSTRUMENTATION AND CONTROL ENGINEERING31030 701004C

TH4ME 214KINEMATICS OF MACHINES31030 701004C

TH5ME 215 PRINCIPLE OF MANUFACTURING SYSTEMS31030 701004A

TH6ME 216PRODUCTION AND OPERATIONS MANAGEMENT I30030 701003A

PR1ME 217THERMAL ENGINEERING - II / FLUID MECHANICS LAB00230 701002C

PR2ME 218INSTRUMENTATION AND CONTROL ENGG. / KINEMATICS OF MACHINES LAB00230 701002C

PR3ME 219MACHINE SHOP LAB 00230 701002A

VS2ME 220SELF STUDY00130 701001C

TOTAL30hrs100030

SUGGESTED SCHEME FOR B.Tech. FIFTH SEMESTER (MECHANICAL ENGINEERING)

S.No.Course No.SubjectLTPEvaluation Total MarksCredit Type

SessionalEnd

TH1ME 301I C ENGINES31030 701004C

TH2ME 302FLUID SYSTEMS31030

701004C

TH3ME 303DYNAMICS OF MACHINES31030

701004C

TH4ME 304MECHANICS OF SOLIDS

31030

701004C

TH5ME 305MANUFACTURING TECHNIQUES I31030

701004A

PR1ME 306I C ENGINES / FLUID SYSTEMS LAB 00230

701002C

PR2ME 307DYNAMICS OF MACHINES00230

701002C

PR3 ME 308MECHANICS OF SOLIDS LAB00230 701002C

PR4ME 309MANUFACTURING TECHNIQUES I LAB00230

701002C

PR5ME 310MINOR PROJECT-I00230

701002C

Industrial Training (Durations 4 weeks in winter vacation at the end of Vth semester)

TOTAL30hrs100030

SUGGESTED SCHEME FOR B.Tech. SIXTH SEMESTER (MECHANICAL ENGINEERING)

S.No.Course No.SubjectLTPEvaluation Sessional End

Total MarksCredit Type

TH1ME 311TRANSPORT PHENOMENON31030

701004C

TH2ME 312REFRIGERATION AND AIR CONDITIONING31030

701004C

TH3ME 313MACHINE DESIGN I30030

701003C

TH4ME 314POWER PLANT ENGINEERING31030

701004C

TH5ME 315PRODUCTION AND OPERATION MANAGEMENT II31030

701004A

PR1ME 316TRANSPORT PHENOMENON / REFRIGERATION AND AIR CONDITIONING LAB00230

701002C

PR2ME 317MACHINE DESIGN - I LAB00330

701003C

PR3ME 318POWER PLANT ENGINEERING LAB00230 701002C

PR4ME 319MINOR PROJECT-II (FABRICATION )00230

702002C

PR5ME 320VIVA VOCE EXAM OF V SEMESTER INDUSTRIAL TRAINING 00230

701002C

Industrial Training (Durations SIX-EIGHT weeks in Summer vacation at the end of VIth semester)

TOTAL30hrs 100030

SUGGESTED SCHEME FOR B.Tech. SEVENTH SEMESTER (MECHANICAL ENGINEERING)

S.No.Course No.SubjectLTPEvaluation Sessional EndTotal MarksCredit Type

TH1ME 401MECHATRONICS31030 701004A

TH2ME 402CAD-CAM31030 701004C

TH3ME 403MACHINE DESIGN II30030 701003C

TH4*ME47XELECTIVE I31030 701004C

TH5ME 405OPEN ELECTIVE I31030 701004A

PR1ME406MECHATRONICS LAB/CAD-CAM LAB00230 701002C

PR2ME 407MACHINE DESIGN - II LAB00330 701003C

PR3ME 408ELECTIVE I LAB00230 701002C

PR4ME 409MAJOR PROJECT (PART-I) 00230 701002C

PR5ME 410VIVA VOICE EXAM OF VI SEMESTER INDUSTRIAL TRAINING00230 701002C

TOTAL30hrs100030

*X - 1 TO 5 , T,P, DSUGGESTED SCHEME FOR B.Tech. EIGHTH SEMESTER (MECHANICALENGINEERING)

S.No.Course No.Subject LTPEvaluation Sessional EndTotal MarksCredit Type

TH1ME 411MANUFACTURING TECHNIQUES II31030

701004A

TH2ME*48XELECTIVE- II 31030

701004C

TH3ME 413OPEN ELECTIVE II31030

701004A

PR1ME 414MANUFACTURING TECHNIQUES - II LAB00330

701003A

PR2ME 415ELECTIVE- II LAB00330

701003C

PR3ME 416SEMINAR / REPORT00230

701002C

PR4ME 417MAJOR PROJECT (PART-II)001030

7040010C

TOTAL30 hrs100030

*X - 1 TO 5 , T,P, D

GRAND TOTALMARKS = 8000 CREDITS = 240

ELECTIVE SUBJECTSTHERMAL GROUPELECTIVE-1ELECTIVE-2

471T-NON-CONVENTIONAL

ENERGY RESOURES481T-COMBUSTION GENERATED POLUTION

472T -NUCLEAR ENERGY482T-COMPUTATIONAL FLUID DYNAMICS

473T-AUTOMOBILE ENGINEERING

483T-FUEL CELL TECHNOLOGY

474T-SELECTED TOPICS484T-HYBRID TECHNOLOGY

485T-SELECTED TOPICS

DESIGN GROUPELECTIVE-1ELECTIVE-2

471D -MECHANICAL VIBRATIONS481D -FRACTURE MECHANICS

472D-FINITE ELEMENT METHOD482D-ELASTIC & PLASTIC BEHAVIOUR OF ENGG.MATERIALS

473D TRIBOLOGY483D-ANALYSIS AND SYNTHESIS OF LINKAGES

474D -EXPERMENTAL STRESS ANALYSIS484D-ROBOTICS AND AUTOMATION

475D-SELECTED TOPICS485D-SELECTED TOPICS

PRODUCTION GROUPELECTIVE-1ELECTIVE-2

471P -DIMENSIONAL QUALITY ENGINEERING481P- QUALITY MANAGEMENT SYSTEMS

472P-ADVANCEDMACHINING PROCESSES482P -MATERIALS MANAGEMENT

473P-AUTOMATION IN MANUFACTURING 483P -SUPLLY CHAIN MANAGEMENT

474P -COMPUTER INTEGRATED MANUFACTURING484P -FINANCIAL MANAGEMENT

475 P- RELIABILITY ENGINEERING485P- PACKAGING TECHNOLOGY

476P-SELECTED TOPICS486P-SELECTED TOPICS

ME- 201 THERMAL ENGINEERING I

L TPCredits

3 104C

UNIT I

Fundamentals:

Properties of pure substance in solid, liquid and vapour phase, PVT behavior of simple compressible system, T-S and H-S diagram, steam tables, determination of quality of steam, throttling calorimeter, combined separating & throttling calorimeter, maxwell and other thermodynamics relations,mixture of non reactive ideal gases, real gases, compressibility chart, law of corresponding state, air water vapor mixture, calculation of properties of air water vapour mixture

UNIT II

Rankine Cycle and Analysis:

Rankine cycle and its representation on T-S and H-S diagrams; effect of low back pressure and high entry pressure and temperature and its limitations; necessity of re-heating, ideal and actual regenerative feed water heating cycle and its limitations, typical feed water heating arrangements for various capacity power plants.

UNIT III

Introduction to Boilers:

Classification of boilers, boiler mountings and accessories; draft systems, circulation system; combustion and its calculations, and boiler performance.

UNIT IV

Steam Nozzles:

Types of nozzles, flow of steam through nozzles; condition for maximum discharge through nozzle; nozzle efficiency,effect of friction and supersaturated flow through nozzle.

UNIT V

Steam Turbines:Working principle and types of steam turbines; velocity diagrams for impulse and reaction turbines, compounding of impulse turbines; optimum velocity ratio and maximum efficiency,blade twisting, comparison of impulse and reaction turbines,condition line and reheat-factor, losses in steam turbines; governing of steam turbines, UNIT VI

Steam Condensers:

Types and working of condensers, types and performance of cooling towers

Suggested Readings:

1. Engineering Thermodynamics by P.K.Nag, Tata Mcgraw Hill Publishing Company Limited.2. Engineering Thermodynamics byRogers, Pearson Education.

3. Thermodynamics by Kenneth Wark, Mcgraw-hill Book Company.4. Engineering Thermodynamics by Gordon Rogers and Yon Mayhew, Pearson publisher.

5. Fundamentals of Classical Thermodynamics by Van Wylen and Sonntag, John Wiley & Sons Inc.

6. Fundamentals of Engineering Thermodynamics by Moran and Shaprio, John Wiley & Sons, Inc.7. Thermodynamics: An Engineering Approach by Cengel and Boles, The McGraw-Hill Companies.

8. Applied Thermodynamics for Engineering TechnologistsbyT.D. Eastop, Longman publisher.9. Treatise on Heat Engineering by V. P.Vasandani and D.S. Kumar, Metropolitan Book Co. (p) Ltd.ME-202ENGINEERING MATERIALS AND METULLURGY L T P Credits

3 1 0 4AUNIT I

Structure of metal: Crystal structure, miller indices, lattices, imperfections, elementary treatment of point and line defects and their relation to mechanical properties.

Deformation: Slip, twinning, effect of cold and hot working on mechanical properties, principles of recovery, re-crystallization and grain growth.

UNIT II

Fracture: Fracture of metals and alloys, brittle and ductile, fracture, fatigue failure, effect of alloying elements, design consideration.

Creep:Basic consideration in the selection of material for high and low temperature service, creep curve, effect of material variables on creep properties, brittle failure at low temperature.

UNIT III

Solidification: Phases in metal system, lever rule, solidification of metal and alloys, solid solution, eutectic, eutectoid and inter-metallic compounds, Iron carbon equilibrium diagram, TTT-diagram.

Heat Treatment: Principles and purpose of heat treatment of plain carbon steels, annealing, normalizing, hardening, tempering, isothermal treatment, case hardening carburizing, nitriding etc, precipitating hardening of aluminum alloys.

UNIT IV

Materials: Plain Carbon steels, effect of alloying elements, properties and uses, heat treatment of tool steels, stainless, spring and wear resisting steels. Production, composition, properties, and use of non-ferrous alloys e.g., brasses, bronzes, duralumin, die-casting and bearing alloys. IS standards codes for steels.Corrosion: Types of corrosion, Galvanic cell, rusting of Iron, Methods of protection from corrosion.

UNIT V

Fiber Reinforced Composites: General characteristics, Applications, Introduction to Fibers glass, carbon, Kevlar 49 fibers. Matrix Polymeric, Metallic, Ceramic Matrix, Coupling agents and fillers.Introduction to the practice and discipline of Nano- Science, Nano scale dimension, Nano science and engineering principles, Nano materials, carbon nano-tube technology and industrial applications.UNIT VI. Extraction of metals from sulphide ores and concentrates using bio-hydro metallurgical processes. The biological and chemical principles of bioleaching/bio-oxidation processes. Bacteria used in these processes and their characteristics, bacterial leaching mechanism, the parameters affecting bioleaching/bio-oxidation processes and process design.Suggested Books:

Text Books:1. Material Science & Engineering,V.Raghavan Prentice Hall India Ltd., 2001.2. Material Science and Engineering an Introduction, William D. Callister Jr, John wiley & Sons.3. Materials & Processes in Manufacture, Degarmo E. Paul et.al, Prentice Hall India,

Reference Books:

1. Engineering Metallurgy Part 1,Raymond A Higgim., Prentice Hall India, New Delhi, 1998. 2.Principles of Engineering Metallurgy, L. Krishna Reddy, New Age Publication, New Delhi. 3.Engineering Materials & Properties,.Buduisky et al, Prentice Hall India, New Delhi,

4. Mechanical Metallurgy, Dieter, Mc Graw hill ME-203 NUMERICAL TECHNIQUES L T P Credits

3 1 0 4HUNIT I(Solution of Algebraic and Transcendental Equations)Bisection method, RegulaFalsi method, Secant methods, Newton-Raphson method, Rate of convergence, Fixed-point method.

UNIT II

(System of Linear Algebraic Equations)Gauss elimination method, Crouts method, Gauss-Seidel method.

UNIT III

(Interpolation)Finite and various difference operators, Interpolation formulae (Newtons forward and backward, Stirling, Bessels and Everetts).,UNIT IV

(Interpolation and Curve fitting and Numerical Differentiation )

Lagranges interpolation formula. Interpolation with a cubic spline, Curve fitting by Least square method,Numerical differentiation.

UNIT V

(Numerical Integration) Newton-Cotes integration formula, Trapezoidal rule, Simpsons 1/3rd rule and error estimation, Rombergs Integration.UNIT VI

(Numerical Solution of Ordinary Differential Equations) Picards method, Taylor series method, Euler and Modified Euler method, Runge-Kutta Fourth order methods, Milnes method, Adams-Moulton method.

Suggested readings:

1. Applied Numerical Analysis: Curtis F. Gerald and Patrick G. Wheatley- Pearson, Education Ltd.

2. Numerical Method: E. Balagurusamy T.M.H.

3. Numerical Methods for Scientific and Engg. Computations: M.K.Jain, S.R.K. Iyenger and R.K. Jain- Wiley Eastern Ltd.

4. Introductory Methods of Numerical Analysis: S.S.Sastry, P.H.I.

5. Advance Engineering Mathematics, Vol 2, H.C. Taneja , I.K. International

ME-204 QUANTITATIVE TECHNIQUES

L T P Credits

3 1 0 3

Unit I: Introduction to statistics

Nature and role of statistics in management, Measures of central tendency and dispersion, Kurtosis.

Unit II: Introduction to probability theory

Probability theory, jointly distributed random variables, distributions - continuous and discrete; Sampling distributions.

Unit III: Hypothesis Testing

Estimation and hypothesis testing; Parametric tests; t-test; ANOVA; Non-parametric tests; Chi-square test, Correlation and regression analysis, logistic regression analysis, Applications of statistical packages.

Unit IV: Linear Programming

Problem- formulation and applications, solution through graphical method and Simplex methods, introduction to non-linear programming.

Unit V:Transportation Models

Transportation and transshipment problems, assignment and sequences models.Unit VI: Decision Theory

Decision Tree, Game Theory-Minimax and Maximin, Dominance Principle and use of OR software packages.

Suggested Readings:

1. Quantitative Methods by J K Sharma, MacMillan Publishers.

2. Quantitative Methods for Business by Anderson, Cengage Learning

3. Business statistics by Bajpai, Pearson India

ME-205 ENGINEERING MECHANICS L T P Credits

3 1 0 4CStatics

UNIT IIntroduction. Important Vector quantities of Mechanics, Force: Equivalent System of Forces. Moment of a force: Varignons Theorem. Couple: Equivalent Couples, Equilibrium of Rigid Bodies: Free Body Diagram, Conditions of Rigid Bodies.

(Solution of the problems by Vector method also.)First Moment (centre of gravity) & Second Moment (moment of inertia)of Curvilinear, Plane and Solid Bodies. UNIT IITruss: Types, Solution of Simple plane trusses by analytical and graphical methods. Shear Forces and Bending Moments in Different Beams.

UNIT IIIFriction: Laws of dry friction, Friction Cone, Angle of Repose, Engineering Applications of friction e.g. Wedge, Belt & Pulley and Screw Jack etc.

Lifting machines: Mechanical Advantage, Velocity ratio, Efficiency and law of machines, self locking or reversibility of machines.Dynamics:UNIT IV:

Kinematics of a particle, velocity and acceleration of a particle in path coordinates, rectangular, cylindrical and spherical coordinates, Vector derivatives in rotating systems.

UNIT V:

Dynamics of of a particle, Linear momentum, Angular momentum, Energy methods, Dynamics of system of particles, orbital motion, kinematics of a rigid body, Chasles theorem,

UNIT VI: Inertia tensor, Principal axes, Dynamics of a rigid body, Eulers equations, DAlemberts principle, Principle of virtual work and stability,

Suggested Readings:

1. Mechanics for Engineers: Statics, Ferdinand P. Beer and E Russel Johnson.

Tata Mcgraw hill Publishing Company Limited.

2.Engineering Mechanics: Statics; Meriam and Kraige, John Willey & Sons.

3.Engineeering Mechanics: Statics &Dynamics;IrwingH.Shames; Prentice Hall of India.

4.S.Timoshenko and D.H.Young; Engineering Mechanics, McGrawHill.

5.Engineering Mechanics by S.S.Bhavikatti ,New age International puplications

ME-206 ENGINEERING ECONOMICS AND ACCOUNTANCY L T P Credits

4 0 0 4HUnit I:Introduction to Engineering Economics

Concept of engineering economics Engineering efficiency; Demand Analysis, Law of Demand, Determinants of demand, Elasticity of demand-Price, Income and cross elasticity. Uses of concepts of elasticity of demand in managerial decision, introduction to micro and macro-economics.

Unit II:Demand Forecasting and Cost Estimation

Meaning, significance and methods of demand forecasting, production function, Laws of returns to scale & Law of Diminishing returns scale. An overview of Short and Long run cost curves fixed cost, variable cost, average cost, marginal cost, Opportunity cost, Break-Even-Analysis.

Unit III:Time Value of Money

Present worth, annual worth, Future worth, internal rate of return, External rate of return.

Unit IV: Comparison among alternatives

Present worth method (Revenue dominated cash flow diagram), Future worth method (Revenue dominated cash flow diagram, cost dominated cash flow diagram), Annual equivalent method (Revenue dominated cash flow diagram, cost dominated cash flow diagram), rate of return method, Examples in all the methods.

Unit V:Depreciation and Taxes

Depreciation- Introduction, Classical Methods: Straight line method of depreciation, declining balance method of depreciation-Sum of the years digits method of depreciation, sinking fund method of depreciation/ Annuity method of depreciation, Modified accelerated cost recovery system, Tax concepts and after tax economic comparison.

Unit VI: Book Keeping

Principles of double entry system: bank reconciliation statement, single entry system: joint venture and consignment account.

Suggested Readings:

1. Engineering Economy, Sullivan, Wicks, and Koelling, Pearson International

2. Macroeconomics: Understanding the Wealth of Nations by David Miles and Andrew Scott, Wiley

PRACTICALSME-207THERMALENGINEERING -1/ENGINEERING MECHANICS PRACTICAL

L T P Credits

0 0 2 2C-Experiments based on the theory syllabus of the subject ME201/ME205.

-Case analysis: System identification, Analyzing it with the principles of Mechanics (with content of the syllabus).

-Case Study: of the Simple Mechanical systems, based on the principle of Mechanics (with content of the syllabus)

ME- 208 MACHINE DRAWING PRACTICAL L T P Credits

0 0 2 2CEngineering Drawing as per IS-696:SP- 46

Free- hand sketching & Scale drawing,

Free- hand exercises for drawing three views from various models:

Drawing of Two/Three views of:

Cotter Joint, Knuckle Joint, Rivets & Riveted joints, Types of Screw threads and their representation, Screws/Bolts and nuts, rigid coupling, Flexible coupling, simple bush Bearing, Plummer Block, ball & Roller bearing, Steam Engine parts, I.C engine parts i.e Connecting rod, Piston.

Introduction to AUTO CAD, Practice of assembly drawing using AUTO- CAD.

Suggested readings:

1. IS-696 Code Of Practice Of Engineering DrawingPublisher BIS2. SP -46 Engineering Drawing for School And Colleges

Publisher BIS

3. Machine Drawing by P.S. Gill ME- 209 ENGINEERING MATERIALS AND METALLURGY LAB

PRATICAL L T P Credits

0 0 2 2AExperiments based on the theory syllabus of the subject ME202ME-210 SELF STUDY L T P Credits(VS1)

0 0 1 1CSuggested Reading:As suggested by the Teacher

ME-211 THERMAL ENGINEERING II

LTPCredits

3104C

UNIT I

Reciprocating Air Compressor:

Steady flow analysis, isothermal, adiabatic and polytropic compression; single and multi-stage compression, ideal intermediate pressure; compressor clearance, volumetric and isothermal efficiency; minimum work requirement of a compressor.UNIT II

Centrifugal compressor:

Velocity diagrams, efficiency of compressor stage, choice of reaction, stage pressure rise, surging, multi-stage compressor, compressor performance, vaccum pump.

UNIT III

Gas Power CyclesAir standard cycle Otto, diesel and dual cycles, P-V and T-s diagrams of these cycles, efficiency, mean effective pressure. comparison of otto, diesel, dual cycles for same compression ratio and heat input, stirling cycles, ericsson cycle, atkinson cycle, basic gas turbine (Brayton) cycle (for open and closed systems), efficiency of gas turbine cycle

UNIT IV

Gas Turbines:

Simple open and close cycle gas turbine, efficiency and specific output of simple cycle, effects of regeneration, re-heating and inter-cooling on efficiency and work output, effect of operating variables on thermal efficiency, air rate, work ratio; water injection, Advantages and disadvantages of gas turbine, gas turbine components, performance and application of gas turbine

UNIT V

Gas Dynamics: Fundamentals of gas dynamics, energy equation, stagnation properties, isentropic flow through nozzle and diffusers, Introduction to shock waves, UNIT VI Jet Propulsion:introduction to jet propulsion, advantages and disadvantages of jet propulsion turbojet engine with and without after burner, turboprop, ram jet, pulse jet, rocket engines operation, sold and liquid propellants.

Suggested Readings:

1. Engineering Thermodynamics by Gordon Rogers and Yon Mayhew, Pearson publisher.

2. Thermal Engineering by S. Domkundwar, DhanpatRai& Co (p) Ltd3. Applied Thermodynamics by Onkar Singh, New Age International (p) Limited 4. Gas Turbines by Cohen & Rogers, Pearson Prentice Hall5. Fundamentals of Gas Dynamics By Robert D. Zucker and Oscar Biblarz, John Wiley & Sons, Inc.6. Fundamentals of Gas Dynamics by Robert P. Benedict, John Wiley & Sons, Inc. ME- 212 FLUID MECHANICS L T P Credits

3 1 0 4CUNIT IIntroduction: Fluid and flow definition and types, continuum, fluid properties.

Fluid Statics: Pressure variation in a static fluid; hydrostatic manometry; forces on planes and curved surfaces, stability of submerged and floating bodies.

UNIT IIFluid kinematics: General description of fluid motion, steady flow, uniform flow; stream, streak and path lines; Lagrangian and Eulerian approach; Continuity equation, particle acceleration; rotational and irrotational flow; stream function; velocity potential function, flow nets; circulation; simple flows; source, sink, vortex, doublet, free and forced vortex.

UNIT IIIFluid Dynamics: Concept of system and control volume; Reynolds transport theorem, Euler;s equation, Bernouliis equation, Navier stokes equation; Flow measurement- Venturimeter, Orfice meter, Pitot- tube, flow meters, notches.

Dimensional analysis: Buckinghams - Theorem. Non-dimensional parameters, similarity and its application to fluid problems.

UNIT IVViscous flow: Laminar flow between parallel surfaces and through circular pipes, Momentum and Kinetic energy correction factors; power absorbed in viscous resistance, film lubrication.

UNIT V

Turbulent flow: Transition from laminar to turbulent flow, turbulence and turbulence intensity, turbulence modeling, Prandil mixing length hypothesis; flow losses in pipes- major and minor losses, pipes in series and parallel, hydraulically smooth and smooth and rough pipes, friction factor charts.

UNIT VILaminar and Turbulent Boundary Layer flows: Boundary layer concept, boundary layer thickness, displacement, momentum and energy thickness. Momentum integral equation; drag on flat plate. Boundary separation. Flow around immersed bodies- drag and lift.

Suggested Readings:

1. Introduction to Fluid Mechanics and Fluid Machines,Som.S.K&Biswas.G Tata McGraw-Hills Publishing Company Limited (2003)

2. Fluid Mechanics, Cengel&Cimbala, , Tata McGraw-Hills Publishing Company Limited (2006)3. Fluid Mechanics, White.F.M, Tata McGraw-Hill Publishing Company Limited(2008)

4. Fluid Mechanics & Machinery Agarwal.S.K, Tata McGraw-Hill Publishing Company Limited.5.Fluid Mechanics & Fluid Power Engineering, Dr.D.S.Kumar, , S.K.Kataria&Sons(2008).

6. A Text Book of Fluid Mechanics & Hydraulic Machines, Bansal.Dr.R.K, ,Laxmi Publications(P) Ltd., New Delhi.

ME213 :INSTRUMENTATION AND CONTROL ENGINEERING

L T P Credits

3 1 0 4CUNIT I

Physical quantities and their measurements, Different grades of measurability, scales and scale-invariant properties, Errors, precision(resolution), accuracy and calibration standards; Transducers of different types and their usage. Basic characteristics and Response of measuring instruments under static and dynamic conditions;UNIT II

Intermediate or signal conditioning devices like amplifiers, integrating and differentiating circuits; Display devices like voltmeters, CRO, VTVM and recorders.

UNIT III

Measurement of displacements, strains, velocity, acceleration, temperature, pressure and fluid flow.

High pressure measurement, strain-gage pressure cells, Bourdon tubes with nearly circular cross-section.

Low-pressure(vacuum) measurement, diaphragm gages, Mcleod gage,

Knudsen gage, Momentum-transfer gage, Thermal-conductivity gage, Ionisation gage.

Temperature measurement, use of bimaterials, Resistance thermometers, thermocouples, semi-conductor -junction temperature sensors, linear-quartz thermometer, optical pyrometry, infrared pyrometry and thermography.

Miscellaneous instruments: Telesurf, stroboscope, extensometers.

UNIT IV

Dynamic and static systems, Feedback control, Open and closed loop control systems.

Transfer functions, Frequency response, Bode and Nyquist diagrams.

Stability of dynamic systems, Root locus technique, Routhstablitytest.Automatic control system design, continuous-time single-loop feedback control

UNIT V

Design using root locus method and Routh criterion, Design for given frequency/bandwidthand resonance peak.

Multi-loop and other control configurations.

Nonlinear control systems, design and stability. Discretizing continuous-time models, difference equations, forward differentiation,backward differentiation, discretizing a simulator of dynamic system, stability of discrete-time model, discretizing a signal filter.UNIT VI

Discrete-time control systems, single-loop digital controllers, PI and PID control.

Micro-computer control systems, DA/AD converters. Computer data acquisition and control, Pulse measurements and command, Pulse outputs and stepper motor, Micro-computer realization of a liquid level/flow control system.

.

SUGGESTED READINGS:

1.Mechanical Measurements- Beckwith, Marangoni, Lienhard, Pearson Education

2. Measurement systems Application and Design Doebelin, Tata McGraw Hill

3.Book System dynamics & control EroniniUmez-Eronini, Thomson Press. ME- 214 KINEMATICS OF MACHINES L T P Credits

3 1 0 4C UNIT IVelocity and Acceleration: Introduction to simple mechanisms, displacement, velocity and acceleration curves, velocities of different points. In mechanisms, relative velocity method, instantaneous centre method, three centre in line theorem, graphical methods of finding acceleration of different points in mechanisms, acceleration in slider crank mechanism, Coriolis component of acceleration.

UNIT IIMechanism with lower pairs: Description of Straight line mechanisms like Peaucelliers mechanism and Hart mechanism, Engine indicator mechanism, Steering mechanism of vehicles, Hooks joint etc.

UNIT IIIFriction: Pivot and Collar friction, clutches and belt rope drives axis, boundary friction, film lubrication, rolling friction.UNIT IVCams: Classification, uniform acceleration SHM type construction of Cam profile. High speed Cams. Cams with specified contours. Analysis of a rigid Eccentric CamUNIT VToothed Gearing: Geometry of tooth profiles, cycloidal and involute profile, minimum number of teeth on pinion, interference, arc of contact, terminology of helical gears.

Gear trains: Simple compound and epicyclic gear trains.

UNIT VI

Introduction to synthesis of linkages, use of software for motion and interference analysis.

Suggested Readings:

1. The Theory of Machines, Thomas Beven, CBS publishers and distributers

2. Theory of Machines, Rattan.S.S,McGraw-Hills Ltd.

3. Kinematics and Dynamics of Machinery, R.L.Norton,Tata McGraw-Hill

4. Theory of Machines and Mechanisms, John.J.UickerJr, Gordon R.Pencock,JosephE.Shigley, Oxford University press.ME- 215 PRINCIPLE OF MANUFACTURING SYSTEMS

L T P Credits

3 1 0 4AUNIT I

Introduction to Machine Tools:Classification, similarities; various cutting tools and cutting fluids: speed of cutting, feed rate, machining rate and machining time.

UNIT II

Lathe: Construction, important mechanisms viz ., apron, tail stock, head- stock, feed box; specification, operations e.g., taper turning, eccentric turning, screw cutting.

UNIT II

Drilling machine: Construction, feed mechanism: Specification, geometry and nomenclature of twist drill, operations e.g reaming, boring, tapping.

UNIT III

Milling machine: Construction, types specifications; cutters, dividing head, simple compound and differential indexing; various operations: Slab milling, angle cutting, slot milling, fly milling, slit gear milling, spur and bevel, T- slot milling, nature of operations, up and down milling.

UNIT IV

Shaper, Slotter, Planer; Construction, automatic feed mechanism, quick return mechanisms: operations e.g., horizontal, vertical and inclined machining, spline cutting, keyway cutting, contour machining.

UNIT V

Grinding Machines: M, n types and construction features, Operations e.g Plane, cylindrical, internal and centreless grinding, tool and cutter grinding, grinding wheels- specifications, shapes, setting, dressing, truing.

Suggested Readings:1. Fundamentals of Metal Cutting & Machine Tools by B.L.Juneja, G.S.Sekhon&Nitin Seth, New Age International Publications.

2. Manufacturing Technology: Metal Cutting & Machine Tools by P.N.Rao, Tata McGraw Hill Publications.3. Introduction to Machining Science by G.K.Lal, New Age International Publications.

4. Workshop Technology Vol.2, by B.S.Raghuwanshi, DhanpatRai& Sons, Publications.

5. Elements of Workshop Technology Vol.2, by HazraChandhari, Media Promoters

ME- 216 PRODUCTION AND OPERATION MANAGEMENT -I

L T P Credits

3 0 0 3AUNIT I:Introduction to POMIntroduction to POM, Operations strategy, strategy design process, corporate and operations strategies, Operations competitive dimensions, Process of decision making under- certainty, uncertainty and risk. UNIT II:Product and Process Design

Product design and development processes, product life cycle, Process flow chart, Types of processes, Process performance, Learning curve.

UNIT III:Facility location and Layout

Factors affecting the location decisions, methods of facility location- factor rating systems, centroid method, and profit volume analysis; Types of layout, Block diagram and Assembly Line Balancing.

UNIT IV:Demand Forecasting

Qualitative and quantitative forecasting, Time series and regression models, Measures of forecasting errors.

UNIT V: Inventory model

Importance of inventory, understocking and overstocking, Fixed order quantity models and fixed time period models (EOQ models), Selective inventory management- ABC, VED, and FSN analysis, JIT manufacturing system, Toyota production systems- KANBAN model, and elimination of waste.

UNIT VI: Project Management

Defining and organizing projects, feasibility study of projects, project planning, project scheduling- work breakdown structure, PERT & CPM, analyzing cost-time trade off, monitoring and controlling of projects.

Text Books:1. Operations Management, Jay Heizer, Barry Render; Pearson learning

2. Operations management for competitive advantage; Chase, Jacob, and Aquilano; TMH3. Modern Production/Operations Management, Buffa and Serin, John Weily India. Reference Books:1. Operation Management, Krajewski and Ritzwan, Pearson Education.

2. Production and Operations Management, Adam, Jr. Elbert, PHI

PRACTICAL

ME-217 THERMAL ENGINEERING I I LAB /FLUID MECHANICS LAB

L T P Credits

0 0 2 2C Based on Course work corresponding Thermal Engineering- II ME- 211/Fluid mechanics ME-212.

ME-218 INSTRUMENTATION AND SIGNAL PROCESSINGLAB/ THEORY OF MACHINES LAB

PRACTICAL

L T P Credits 0 0 2 2CBased on Course work corresponding to INSTRUMENTATION AND SIGNAL PROCESSINGME -213/Theory of machines -ME214 ME- 219 MACHINE SHOP LAB PRACTICAL

L T P Credits

0 0 2 2ABased on Course work corresponding to Principle of manufacturing systems ME 215

ME-220SELF STUDYL T P Credits(VS2)

0 0 1 1CBased on Course Work Suggested by the Teacher ME 210 ME-301 I.C. ENGINES

L TPCredits

3 104C

UNIT I

Introduction to I.C Engines:

Classification; two and four stroke, SI and CI engines parts, working principle and valve and port timing diagram

UNIT II

Combustion Phenomenon in SI engines:Principles of combustion in SI engine,effect of engines and operating variables on ignition delay & flame propagation, combustion chamber for SI engines, cycle to cycle variation, pre-ignition, abnormal combustion, theory of detonation, effect of engine and operating variables on detonation, surface ignition, adiabatic flame temperature, ignition systems

UNIT III

Combustion phenomenon in CI engines:

Principles of combustion in CI engine, delay period, variables affecting delay period, diesel knock, methods of controlling diesel knock, combustion process & combustion chambers for CI engines

UNIT IV

Fuel system and Mixture requirement in SI and CI Engine:

Carburetion- working principles, chemically correct air-fuel ratio and load variation, compensating devices, venture and jet dimension calculation, modern fuel induction system, multi point fuel injection system, fuel injection: common rail direct injection

UNIT V

Engine Testing, Supercharging, Lubrication and Engine Cooling:

Engine performance and testing , measurement of power,supercharging limits of SI &CI engines methods of supercharging, superchargers, turbo charging, lubrication principles, function of lubricating system, properties of lubricating oil, additives, cooling system, air cooling, water cooling

UNIT VI

Introduction to Automotive Fuels:

Petroleum based fuels and their properties, knock rating of engine fuels, necessity of alternative fuels, LPG, CNG, producer gas, biogas, H2, biodiesel and alcohols

Suggested Readings:

1. I.C Engines and Air Pollution by E.F.Obert, Intext Educational Publishers.2. I.C Engines by Ferguson, John Wiley & Sons.

3. Fundamentals of I.C Engines by J.B Heywood, Tata McGraw-Hill Companies.

4. I.C Engines by Mathur& Sharma, DhanpatRai and Sons.5. The Internal Combustion Engine - Theory and Practice Vols. I & II by C.F.Taylor, MIT Press. ME- 302 FLUID SYSTEMS

L T P Credits

3 1 0 4CUNIT IINTRODUCTION: Euler's equation of turbo machines; impulses and reaction forces due to fluid systems on stationary and moving systems of vanes; jet propulsion.

UNIT IIWATER TURBINES: Classification; Pelton, Francis, propeller and Kaplan turbines; Velocity triangles, efficiency, draft tubes, governing.

UNIT IIIPumps: Centrifugal pumps; velocity triangles, efficiency, turbine pumps, axial and mixed flow pumps, positive displacement pumps; reciprocating, gear and wave pumps.

Performance of Fluid Machines: Similarity laws applied to roto-dynamic machines, specific speed, unit quantities, characteristic curves, use of models, cavitation and attendant problems in turbo machines, selection of turbines, hydroelectric plants.

UNIT IVHydraulic power transmission: Transmission of hydraulic power through pipe lines; water hammer; precaution against water hammer in turbines and pump installations, hydraulic ram.

UNIT VMiscellaneous Hydraulic Machines: Accumulators, intensifiers, presses, cranes, fluid coupling, torque converter. Hydraulic and Pneumatic Power: Simple Hydraulic circuits, hydraulic control valves, Pneumatic power.

UNIT VI

Introduction to Computational Fluid Dynamicsand its Application for simple CFD solutions for incompressible, compressible,laminar, turbulent flows, flows with heat transfer and flow with free surface.

Suggested Readings:1.Introduction to Fluid Mechanics and Fluid Machines,Som.S.K&Biswas.G Tata McGraw-Hills Publishing Company Limited (2003)

2., Fluid Mechanics ,Yunus A. Cengel and John M Cimbala, Second Edition, McGraw-Hill 3., Fluid Mechanics,Dr.D.S.Kumar&Agarwal.S.K Fluid Power Engineering, S.K.Kataria& Sons (2008).

4. A Text Book of Fluid Mechanics & Hydraulic Machines",.Dr.R.K,BansalLaxmi Publications(P) Ltd., New Delhi.

5.Fluid Flow Machines", GovindaRao.N.S, Tata McGraw-Hills Publishing CompanyLimitedME- 303 DYNAMICS OF MACHINES L T P Credits

3 1 0 4CUNIT IFlywheels: Turning moment diagrams forI.C engines; steam engine and power presses, speed and energy fluctuations.

UNIT II

Governors: Function of a governor, types of governors, weight loaded, spring loaded, efforts and power of a governor, controlling diagrams.UNIT IIIGyroscopes: Principles of Gyroscope, gyroscopic couple and its effect on two wheel and four wheel vehicles and ships.

UNIT IVBalancing: Balancing of rotating parts and primary balancing of reciprocating parts, primary and secondary balancing of in-line engines, partial balancing of locomotive engines and its effect, balancing machines.

UNIT V

Vibrations: Free vibration of a body single degree of freedom; transverse vibration of beams with uniform and concentrated loads by Rayleigh method; torsional free vibration of two rotor system, three rotor system and geared systems; damped free vibrations with viscous damping; logarithmic decrement; response of damped spring mass system to harmonic forces; whirling of shafts, vibration isolation and vibration of mass supported on foundations subject to vibrations; vibration simulation.

UNIT VIIntroduction to Tribology: Theory of friction wear and lubrication.

Suggested Readings:Text Books:1.The Theory of Machines, Thomas Beven, CBS publishers and distributers 2.Theory of Machines, Rattan.S.S,McGraw-Hills Ltd.

3.Kinematics and Dynamics of Machinery, R.L.Norton,Tata McGraw-Hill

Reference Books: 1.Theory of Machines and Mechanisms, John.J.UickerJr, Gordon R.Pencock,JosephE.Shigley, Oxford University press.

2.Fundamentals of Vibrations by Leonard Meirovitch McGraw-Hill company

3.Fundamentals of Vibrations by Graham Kelley, McGraw-Hill company

ME- 304 MECHANICS OF SOLIDS

L T P Credits

3 1 0 4CUNIT I Simple stresses and strains: Concept of stress and strain; stress and strain diagram, Hooke's law, Young's modulus, Poison ratio, stress at a point, stress and strains in bars subjected to axial loading. Modulus of elasticity, stress produced in compound bars subject to axial loading. Temperature stress and strain calculations due to applications of axial loads and variation of temperature in single and compound walls. Strain Energy: Strain Energy under due to axial loads, stresses due to sudden and impact loads

UNIT II Compound stress and strains: The two dimensional system; stress at a point on a plane, principal stresses and principal planes; Mohr's circle of stresses.

Bending: bending theory, derivation of bending formula: its application to beam of rectangular, circular and channel sections.

UNIT III:

3D Stress, Theory of failure ,Strain energy, Impact load : Concept of three dimensional stress and strain, Stress tensor, three stress invariants, St. Vernants principle ,Generalized hooks law, Theory of failures, Strain energy in torsion and bending, Castigliano Theorem.UNIT IV Torsion: Derivation of torsion equation and its assumptions. Applications of the equation of the hollow and solid circular shafts torsional rigidity. principal stresses and maximum shear stresses under combined loading of bending and torsion.

Springs: - Deflection of springs, Close-coiled helical springs subjected to axial load and axial twist, spiral and leaf springs under torque and Moment.

UNIT VSlope and deflection: Relationship between moment, slope and deflection, Mohr's theorem; Moment area method; method of integration; Macaulay's method: Use of all these methods to calculate slope and deflection for the following :

a)Cantilevers

b)Simply supported beams with and without overhang.

c)Under concentrated loads, uniformly distributed loads or combination of concentrated and uniformly distributed loads.

Columns and struts: Columns of different end conditions and failure of columns, Euler's formulas; Rankine-Gordon's formula, Johnson's empirical formula for axially loaded columns and their applications.

UNIT VI Cylinders and spheres: Thin Cylinders and spheres; Derivation of formulae and calculation of hoop stress, longitudinal stress in a thin cylinder and sphere subjected to internal pressure.

Thick cylinders: Hoop , radial and longitudinal stresses in thick cylinders due to internal and external pressure, Compound cylinders ,Stresses in shrink fits.

Rotating disc of uniform thickness, disc of variable thickness , Rotating shaft and cylinders.

Suggested Readings:

1. "Engg. Mechanics of solids", Popov Eger P., Prentice Hall, New Delhi, 1998

2. "Strength of Materials",SriNath L.S. et.al., McMillan, New Delhi,2001

3. "Strength of Materials",Sadhu Singh, Khanna Publishers, New Delhi, 2000.

4. "Elements of Strength of Materials",Timoshenko S.P., East-West affiliated,

New Delhi, 2000.

5.., "Mechanics of Materials", Hibbler R.C Prentice Hall, New Delhi, 1994.

7., "Mechanics of Solids", Fenner, Roger.T U.K. B.C. Publication, New Delhi, 1990.

8.Mechanics of materials by James M. Gere.

ME-305 MANUFACTURING TECHNOLOGY-I

L T P Credits

3 1 0 4AUNIT ICasting: Properties of moulding sand, Sand testing, Gating and risering system, Principle, process and applications of Die casting, Centrifugal casting, Investment casting, and Continuous casting, Melting of metal for casting, Casting defects their causes and remedies, Cleaning and Inspection of castings, Foundry mechanization and lay out.

UNIT IIWelding: Principle, equipment, and applications of Submerged Arc Welding (SAW), Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), Plasma Arc Welding, UNIT III

Ultrasonic Welding, Electron Beam Welding (EBW) and Laser Beam Welding (LBW).Gas cutting and arc cutting of metals, Welding defects their causes and remedies.UNIT IVMetal Forming: Mechanical behaviour of metals in elastic and plastic deformation, stress-strain relationships, Yield criteria, Concept of flow stress by true stress-strain curves

UNIT V

Hot Forming and Cold Forming, Analysis of important metal forming processes like Forging, Rolling, Extrusion, Wire Drawing by slab method, Sheet metal forming processes. Introduction to High Energy rate forming processes.

UNIT VIPowder Metallurgy: Powder metallurgy process and operations, Advantages, Applications and Limitations of powder metallurgy.

Suggested Readings:

1. Manufacturing Technology by P.N.Rao, Tata McGraw Hill Publications

2. Manufacturing Processes and Automation by R.S.Parmar, Khanna Publications

3. Workshop Technology Vol.1, by B.S.Raghuwanshi, DhanpatRai Publications

4. Processes & Materials of Manufacture by R.A.Lindberg, Prentice Hall Publication5. Principle of Metal Casting by Heine & Rosenthal, Tata McGraw Hills Publication6. Welding Processes and Technology by R.S.Parmar, Khanna Publications

7. Welding & Welding Technology by Richard L Little, Tata McGraw Hill Publications

8. Metal Forming Processes by G.R.Nagpal, Khanna Publications.

ME-306 I C ENGINES LAB/FLUID SYSTEMSLABPRACTICAL

L T P Credits

0 0 2 2CBased on the Course work corresponding to I C ENGINES ME 301/Fluid systems ME302ME-307DYNAMICS OF MACHINES LAB PRACTICAL

L T P Credits

0 0 2 2CBased on the Course work corresponding to Dynamics of Machines ME 303 ME 308 MECHANICS OF SOLIDS LAB PRACTICAL

L T P Credits

0 0 2 2CBased on the Course work corresponding to Mechanics of Solids ME 304

ME- 309 MANUFACTURING TECHNOLOGY-1 LAB PRACTICAL

L T P Credits

0 0 2 2CBased on the Course work corresponding to Manufacturing Technology -1 ME 305ME-319 MINOR PROJECT L T P Credits

0 0 2 2CIndustrial Training (Duration four weeks in winter vacationat the end of Vthsemester)ME- 311 TRANSPORT PHENOMENON

LTPCredits

3104C

UNIT I

Introduction and Conduction:

Various modes of heat transfer, Fourier's, Newton's and Stefan Boltzman's Law, combined modes of heat transfer, thermal diffusivity, and overall heat transfer coefficient, thermal conductivity of solids, liquids and gases, factors influencing conductivity, measurement, general differential equation of conduction, one dimensional steady state conduction, linear heat flow through a plane and composite wall, tube and sphere, critical thickness of insulation, effect of variable thermal conductivity, conduction with heat sources, heat transfer from extended surfaces, fin performances, concept of corrected fin length/ error in temperature measurement by thermometer well, transient heat conduction- lumped system analysis, transient temperature charts (Heisler and Grober charts), transient heat conduction in multidimensional systems.

UNIT II

Convection (Forced)

Introduction, laminar boundary layer equations for internal and external flows; laminar forced convention on a flat plate and in a tube, Reynolds-Colburn analogy/Dimensional analysis and physical significance of the dimensionless parameters

UNIT III

Convection (Natural)

Dimensional analysis of natural convection; empirical relationship for natural convection, convection with phase change, description of condensing flow, theoretical model of condensing flow, introduction to heat pipe, regimes of boiling heat transfer, empirical relationships for convection with phase change.

UNIT IVThermal Radiation:

Introduction, absorption and reflection of radiant energy, emission, radiosity and irradiation, black and non black bodies, kirchchoff's law; intensity of radiation, radiation exchange between black surface, geometric configuration factor, grey body radiation exchange between surfaces of unit configuration factors, radiation shields, electrical analogy to simple problems, non-luminous gas radiation, errors in temperature measurement due to radiation.

UNIT V

Heat Exchangers

Different types of heat exchangers; design of heat exchangers, LMTD and NTU methods, fouling factor and correction factor, Introduction to compact and plate heat exchangers.

UNIT VIMass Transfer

Mass and mole concentrations, molecular diffusion, Fick's law; eddy diffusion, molecular diffusion from an evaporating fluid surfaces, introduction to mass transfer in laminar and turbulent convection, dimensional less parameters in convective mass transfer, combined heat and mass transfer

Suggested Readings:

1. Fundamentals of Engineering Heat and Mass Transfer by R.C.Sachdeva, New Age International Publishers.

2. Fundamentals of Heat and Mass Transfer by P Frank. Incropera and David P. DeWitt, John Wiley and Sons.

3. Heat Transfer by A. Bejan, John Wiley and Sons.

4. Heat Transfer by M.N. Ozisik, McGraw Hill Book Co.

5. Heat Transfer A Practical Approach by A.CenegelYunus, Tata McGraw Hill.

6. Engineering Heat and Mass Transfer by Mahesh M. Rathore, Laxmi Publications.

7. Heat and Mass Transfer by J.P Holman, Tata McGraw Hill.

8. Fundamentals of Momentum, Heat and Mass Transfer by James R.Welty; John Wiley & Sons (Pvt). Ltd.ME -312 REFRIGERATION AND AIR CONDITIONING

LTPCredits

3104C

UNIT I

Introduction to Refrigeration:

Necessity and applications, unit of refrigeration and C.O.P., types of Ideal cycles of refrigeration, air-refrigeration, bell coleman cycle, open and dense air systems, actual air-refrigeration system problems, refrigeration needs of aircrafts, actual refrigeration system

UNIT II

Vapour Compression Refrigeration:

Working principle and essential components of the plant, simple vapour compression refrigeration cycle - COP, Representation of cycle on T-S and p-h charts - effects of sub cooling and super heating - cycle analysis - Actual cycle, Influence of various parameters on system performance necessity of multistaging, multistage compression system, and their analysis, necessity and working of cascading system

UNIT III

Refrigerants and Absorption Refrigeration:Desirable properties of refrigerations , classification of refrigerants used, nomenclature, ozone depletion, global warming, vapor absorption system, calculation of max COP, description and working of NH3 - water system and Li Br water, three fluid absorption system and its salient features, steam jet refrigeration system - working principle, basic components and analysis, principle and operation of vortex tube or hilsch tube.

UNIT IV

Air Conditioning:

Psychometric properties & processes, comfort air-conditioning, summer and winter air-conditioning, cooling & dehumidification systems, load calculation and applied psychrometry

UNIT V

Human Comfort:

Requirements of human comfort and concept of effective temperature, comfort chart, comfort air-conditioning, requirements of industrial air-conditioning, air-conditioning load calculations.

UNIT - VI

Control:Refrigeration and air-conditioning control, air handling, air distribution and duct design

Suggested Readings:

1. Refrigeration and Air Conditioning by C. P. Arora, Tata McGraw Hill

2. Refrigeration and Air Conditioning by A. R .Trott and T. C. Welch, Butterworth- Heinemann

3. Refrigeration and Air ConditioningTechnology by Whitman, Jhonson and Tomczyk, Thomson Delmer Learning

4. Refrigeration and Air Conditioning by Abdul Ameen, Prentice Hall of India Ltd.

5. Basic Refrigeration and Air Conditioning by P. N. Ananthanarayan, Tata McGraw Hill

6. Refrigeration and Air Conditioning by Wilbert F. Stoecker and Jerold W. Jones, Tata McGraw Hill

7. Refrigeration and Air Conditioning by Richard Charles Jordan, Gayle B. Priester, Prentice hall of India Ltd.

8. ASHRAE Handbook Refrigeration 2010 ME- 313 MACHINE DESIGN I

L T P Credits

3 0 0 3CUNIT I:

Introduction to design, comprising of Mechanical engineering design, design process, Interaction between design process elements, Design-economics, Uncertainty, Stress and strength, Codes and Standards, Factors of safety, Reliability, Probabilistic approach to Design.

UNIT II:

Selection of materials- the basics, selection strategy, families of engineering materials- ferrous and non- ferrous metals, heat treatment of metals, Designation of steels as per IS: 1570-1978, ASTM standards., Attribute limits and material indices, computer aided selection.

Manufacturing considerations in design, interchangeability, Limits, Fits, and Tolerances as per Indian Std. System, Surface roughness.

UNIT III:

Failures resulting from static loading, static strength, and stress concentration.

Failures resulting from variable loading, introduction to fatigue to metals, Strain life relationship, stress life relationship. Endurance limit modifying factors, stress concentration and notch sensitivity, Cumulative fatigue damage. The design factors in fatigue.

UNIT IV:

Design of mechanical elements, including solid modeling, and finite element analysis of machine components using available software in CAD Laboratory.

UNIT V

Design of screws, power screws. Design of riveted joints- under direct and eccentric loads, Design of Pipes and pipe joints.

UNIT VIKeys and couplings, Design of Mechanical springs for static and fatigue loading.

Design of spur gears using Lewis equation and AGMA design equations.

Suggested Readings:

1.Mechanical Engineering Design,Shigley, J. E., Mischke, C. R. and Budynas, R. G., McGraw Hill, 7th Edition, 2004. International.

2.Fundamental of Machine Component Design, "Juvinall, R. C., and Marshek, K. M., John Wiley and Sons, 2000.

3.Fundamentals of Machine Elements Hamrock, B. J., Jacobson, B. Schmidt, S. R.,. McGraw Hill, 1999.4.An Integrated Approach,Norton, R. L., Machine Design: Pearson Education, Indian Reprint-2001.5. Machine Design Bhandari TMH

6. Machine Design D. K. Aggarwal and P. C. SharmaDhanpatRaiME- 314 POWER PLANT ENGINEERING

LTPCredits

3104C

UNIT I

Classification of power plants, base load and Peak load power stations, co-generated power plant, captive power plant, and their fields of application & selection criteria, Indian energy scenario, Indian coals: formation, properties, analysis, benefication and heating value calculation of coals; cocking and non-cocking coals, fuel handling systems; coal gasification

UNIT II

Steam Generators:High pressure utility boiler, natural and forced circulation, fuel handling, coking and non-coking coal, coal benefication, coal pulverization, pulverized fuel firing system, combustion process, need of excess air, cyclone furnace, fluidized bed boiler, placement of evaporator, economizers, super heaters, re-heaters, air pre-heater in the boiler, de-aeration, boiler blow- down, ash collection by bag house, gravity separation, electrostatic precipitators and wet scrubbers, boiler efficiency calculations, water treatment: external and internal treatment

UNIT III

Combined Cycle Power Plants:Binary vapour cycles, coupled cycles, gas turbine- steam turbine power plant, gas pipe line control, MHD- Steam power plant, thermionic steam power plant, integrated coal combined cycle (IGCC) power plant

UNIT IVOther power plants Nuclear power plants - working and types of nuclear reactors, boiling water reactor, pressurized water reactor, fast breeder reactor, controls in nuclear power plants, hydro power plant -classification and working of hydroelectric power plants, diesel and tidal power plants.

UNIT V

Instrumentation and Controls in power plants:Important instruments used for temperature, flow, pressure, water/steam conductivity measurement; flue gas analysis, drum level control, combustion control, super heater and re-heater temperature control, furnace safeguard and supervisory system (FSSS), auto turbine run-up system(ATRS), interlocks and protection of boiler turbines

UNIT VIEnvironment Pollution and Energy conservation:Economics of power generation: load duration curves, power plant economics, pollution from power plants, disposal/management of nuclear power plant waste. concept of energy conservation and energy auditing

Suggested Readings:Text Books:

1. Power Plant Engineering by M.M. Elwakil, Tata McGraw Hill.

2. Power Plant Engineering by P.K Nag, Tata McGraw Hill.

3. Steam and Gas turbines by A Kostyuk and V Frolov, MIR Publishers.

Reference Books1. Modern Power Plant Engineering by J Wiesman and R Eckart, Prentice hall India Ltd.

2. Planning Fundamentals of thermal Power Plants by F.S Aschner, John Wiley.

3. Applied Thermodynamics by T.D Eastop and McConkey, Longman Scientific and Technical.4. CEGB volumes on power plant.5. NTPC/NPTI publications on Power plants.ME-315 PRODUCTION AND OPERATION MANAGEMENT-IIL T P Credits

3 1 0 4CUnit I :Productivity Production systems and their classifications; Productivity variables and measurement Productivity-Total and partial productivity, Reasons and remedy for poor productivity.

Unit II: Work Study Work System Design: Taylors scientific management, Gilbreths contributions; method study, micro-motion study, principles of motion economy; work measurement - stop watch time study, micro motion and memo motion, work sampling, standard data, PMTS; job evaluation, merit rating, incentive schemes, and wage administration; business process reengineering, introduction to ergonomics and its applications.

Unit III: Production Planning and Control

Types and characteristics of production systems Objective and functions of Production, Planning & Control, Routing, Scheduling and Operations scheduling, production scheduling, job shop scheduling problems, sequencing problems, scheduling tools and techniques, Loading, Dispatching and its sheets & Gantt charts.Unit IV: Quality Management Concepts of quality, total quality management, cost of quality; statistical quality control, Concept of specification limits, statistical control limits, process capability, Process control and control charts for both attributes and variable data. Acceptance Sampling- Single and double sampling, six sigma, ISO 9000 & ISO 14000.Unit V: Resource Planning

Enterprise resource planning (ERP), material required planning (MRP), manufacturing resource planning (MRP II), aggregate planning.

Unit VI: Reliability and Maintenance

Reliability, availability and maintainability; distribution of failure and repair times; determination of MTBF and MTTR, reliability models; system reliability determination; Maintenance management and its objectives, Various types of Maintenance Planning, House Keeping, 5S concepts.TEXT BOOK1. Introduction to work Study; Oxford and IBH publishing Co. Pvt. Ltd, New Delhi

2. Industrial Engineering and Management; B. Kumar, Khanna Publication.Reference Book1. Operation Management, Krajewski and Ritzwan, Pearson Education.

2. Work study and ergonomics, S.K. Sharma & Savita Sharma, Katson, Delhi.

3. Industrial Engineering & Management, Ravi Shanker, Galgotia Publication, Delhi

ME 316 HEAT AND MASS TRANFER/REFRIGERATION AND AIR CONDITIONING LAB PRACTICAL

L T P Credits

0 0 2 4CBased on the Course work corresponding to HEAT AND MASS TRANSFER LAB ME- 311/ REFRIGERATION AND AIR CONDITIONING LAB ME-312ME 317 MACHINE DESIGN -I LAB

PRACTICAL

L T P Credits

0 0 3 3CBased on the Course work corresponding to Machine Design-I ME 313ME 318 POWER PLANT ENGINEERING LAB

PRACTICAL

L T P Credits

0 0 2 2CME- 319 MINOR PROUECT-II(FABRICATION)

PRACTICALL T P Credits

0 0 4 4CME-320 VIVA- VOICE EXAM OF Vth SEMESTER INDUSTRIAL TRANING

PRACTICAL

L T P Credits

0 0 2 2C

Industrial training (Duration SIX-EIGHT weeks in summer vacation at the end of VIth semester) ME-401 MECHATRONICS

L T P Credits

3 1 0 4AUNIT IIntroduction to mechatronic systems and components; Sensors and transducers; UNIT II

Actuators- electrical, electromechanical, electromagnetic, hydraulic, pneumatic,

smart material actuators, micro actuators, nano actuators. Active actuators- piezoelectric, shape memory alloys(SMA), electro active polymers(EAP), magneto restrictive, magneto rheological fluid(MR). Stepper and servo motors, Encoders and resolvers.

UNIT IIIModeling, analysis and simulation of dynamic systems; use of MATLAB; Bode, Nyquist and root-locus plot;

UNIT IVFeedback systems: Open and closed loop control systems; Stability and sensitivity; PID, phase lag and phase lead compensation,UNIT V Sampled data systems and Digital controllers; DA/AD converters, microprocessors, interfacing with computers,

UNIT VIDigital logic: Analysis and synthesis of mechatronic systems with application to robotics, CNC systems and others.

Suggested Readings :1. Introduction to Mechatronics and Measurement systems,( special Indian edition), Alciatore ,David Tata-McGraw Hill India Ltd.

2. Mechatronics: Principles, Concepts and applications,Mahalik.N, Tata-McGraw Hill India Ltd.

3. Mechatronics: Principles and applications, Onwubolu,Elsevier India Pvt Ltd.

4. Mechatronics by Hindustan Machine Tools Ltd.,McGraw- Hill Ltd.

5. Mechatronics: Electronic Control systems in Mechanical and Electrical Engineering. 3/e, Pearson Education. 6.Dan Necsulescu, "Mechatronics",Pearson Education Asia,2002(Indian reprint)7.Mechatronics W. Bolton , Pearson Education

ME 402 CAD/CAM

L T P Credits

3 1 0 4CUNIT I

Introduction:

Introduction to CAD. Elements and essential requirements of CAD.hardware

Concepts of integrated CAD/CAM, Necessity & its importance, Engineering Applications.

Computer Graphics

CAD/CAM systems, Graphics Input devices-cursor control Devices, Digitizers, Keyboard terminals, Image scanner, Speech control devices and Touch, panels, Graphics displaydevices-Cathode Ray Tube, Random & Raster scan display, Colour CRT monitors,Direct View Storage Tubes, Flat Panel display, Hard copy printers and plotters

UNIT II

Geometric Modeling: Fundamentals of Geometric Modeling. Its application in analysis and manufacturing. Two Dimensional and Three dimensional line, surface and volume models; Constructive Solid Geometry (CSG); basics of boundary presentation- spline, Bezier, B-spline, and NURBS; sculpture surfaces, classification, basics of coons, Bezier, B-spline and ruled surfaces; tweaking, constraint based parametric modeling; wire-frame modeling, definition of point, line and circle; polynomial curve fitting. Introduction to rapid prototyping. UNIT III

Finite Element Method:

Introduction, Principles of Finite elements modeling, Stiffness matrix/displacement matrix, Stiffness matrix for spring system, bar & beam elements, bar elements in 2D space (truss element)UNIT IVNumeric control and part programming: Principles of NC machines, CNC, DNC; NC modes of point to point, -line and 2D, 3D contouring; NC part programming; ISO standard for coding, preparatory functions(G)- motion, dwell, unit, preset, cutter compensation, coordinate and plane selection groups; miscellaneous (M) codes; CLDATA and tool path simulation; adaptive control, sequence control and PLC; simple part programming examples.

UNIT V Group Technology: Importance of batch and job shop production; merits of converting zigzag process layout flow to smooth flow in cellular layout, Production Flow Analysis (PFA) and clustering methods; concept of part families and coding; hierarchical, attribute and hybrid coding; OPITZ, MICLASS and DCLASS coding; FMS; material handling; robots, AGV and their programming; agile mfg; Introduction to Computer Aided Process Planning (CAPP).UNIT VIRobotics:Introduction to robots. Types and generations of Robots, Classification of Robots. Structure and operation of Robot, Robot applications in manufacturing industries. Robot languages and programming methods. Introduction to Artificial Intelligence for Intelligent manufacturing.

Suggested Readings:

Text Books:

1. Principles of Computer Aided Design and Manufacturing ; Farid Amirouche ; Pearson.