Measurement of Conductive Magneto-Dielectric … of Conductive Magneto-Dielectric Material...

-

Upload

nguyenhuong -

Category

Documents

-

view

221 -

download

5

Transcript of Measurement of Conductive Magneto-Dielectric … of Conductive Magneto-Dielectric Material...

Measurement of Conductive Magneto-Dielectric Material Parameters in High Noise Environment

Aleksey Solovey #1, Mark Wasson#2, Raj Mittra *3 #L-3Communications ESSCO

90 Nemco Way, Ayer, MA 01432, USA [email protected], [email protected]

*Electromagnetic Communication Laboratory, The Pennsylvania State University University Park, PA 16802, USA

Abstract— An advanced post-processing technique for free space transmission loss measurement of homogenous conductive magneto-dielectric materials has been developed. This technique dramatically improves the tolerance of material parameters extracted based on very noisy raw measurement data.

I. INTRODUCTION Free space transmission loss only measurement [1] of

homogeneous conductive magneto-dielectric (HCMD) material specific conductivity σ, complex permittivity ε and permeability µ was considered in [2] primarily from the standpoint of uniqueness of extracted material parameters and its mutual tradeoffs. To reduce the influence of measurement errors, the “Rolling Window” (RW) [3] and “sandwich” [2] measurement approaches were also introduced.

This paper is dedicated to further improvement of RW and “sandwich” post-processing techniques for the case when the measured data contain very high level of random and systematic measurement errors.

The measured transmission loss (TL) and insertion phase delay (IPD) data were simulated by the superposition of unperturbed, “perfect’ measurement with the systematic and random error components at the 2GHz – 40GHz frequency band for two HCMD samples with material parameters shown in Table I. At this frequency band, the 11mil sample has virtually linear TL and IPD characteristics, while the 110mil sample TL curve has two maxima and minima.

TABLE I MATERIAL PARAMETERS OF HCMD USED IN SIMULATIONS

t, mil εr tanδε σ, Si/m µr tanδµ

11 or 110 4.2 0.014 0.05 2.5 0.010

II. IMPROVEMENT OF POST-PROCESSING ALGORITHM To reduce the impact of measurement errors, the CPU

intensive statistical post-processing algorithms [2] have to be employed, and thus, it is important to speed up the algorithm convergence and optimize the goal function calculations.

A. Decreasing Number of Local Minima of the Goal Function For the fastest convergence the goal function has to be a

weighted sum of variances between the theoretical and measured TL and IPD characteristics. However, for the

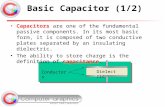

reliable extraction of “weak” material parameters such as loss tangents and conductivity, the TL curve must have at least two maxima/minima within the test frequency band [2]. In that case, the IPD curve might jump from -180º to +180º causing the ziggurat profile of goal function (Fig. 1). Elimination of this artificial phase shift makes the goal function profile smooth, possessing much fewer valleys with local minima.

0.1050.1075

0.110.1125

0.115

Thicknessinch 4

4.1

4.2

4.3

4.4

Permittivity

0

0.1

0.2

0.3

0.1050.1075

0.110.1125

0.115

Thicknessinch

Fig. 1 Ziggurat profile of goal function due to artificial 360º phase shift

B. Finding the Most Effective Minimization Algorithm Apart from multiple local minima [2], the goal function has

deep, temperate and twisted valleys that cause significant tradeoffs between thickness and permittivity/permeability as well as between the electric and magnetic loss tangents of extracted material parameters.

In the absence of any measurement errors, the consecutive application of the GA [4] and Quasi-Newton [5] algorithms causes fast and unconditional convergence to the exact set of material parameters. While the GA is the most effective in converging to the vicinity of the global minimum, the Quasi-Newton algorithm is the most effective in traveling along the multi-dimension valley toward its exact position.

III. ELIMINATION OF SYSTEMATIC ERROR OF RW ANALYSIS Although the traditional RW analysis [3] helps average out

the random measurement errors, it creates however, the systematic errors of the extracted material parameters for any nonlinear TL and IPD characteristics. The novel approach that totally eliminates this systematic error and improves RW analysis random errors averaging capability is introduced.

A. Systematic Error Induced by Width of Rolling Window Since the wideband TL curve is a quasi-periodic function of

frequency with the quasi-period P, the natural parameter that describes the width W of the RW is the W/P ratio. For the HCMD described in Table I, the systematic error of the traditional RW analysis in absence of any measurement errors is shown in Table II. As is seen, the excessive RW width first affects the material loss tangents, then the conductivity, then the permeability and finally, the permittivity and thickness.

TABLE III SYSTEMATIC ERROR OF TRADITIONAL RW ANALYSIS

W / P, %

Systematic Error of Material Parameters, % t εr tan δε σ µr tan δµ

1 0.0014 -.0059 -0.097 0.056 0.0038 0.14 2 -1.4 1.3 -0.19 1.7 1.5 0.60 3 -2.3 2.1 -0.57 2.8 2.4 1.3 5 -2.2 1.9 -2.2 3.7 2.4 3.7

10 -2.0 1.4 -9.8 7.9 2.6 14.3 15 -2.3 1.1 -21.5 15.5 3.5 30.9 20 -1.7 -0.3 -36.5 25.0 3.8 51.7 30 -2.3 -2.1 -71.8 54.0 7.2 101 50 -4.2 -7.6 -152 133 18.4 211

B. Eliminating the Systematic Error of the RW Analysis To eliminate the systematic error induced by the width of

the RW, the RW averaging should be applied to measured and theoretical TL and IPD characteristics simultaneously. In the absence of any measurements errors, it allows extraction of the exact values of the material parameters regardless of the width of RW until the W/P ratio starts approaching 100%, where the best-fitting procedure becomes ill-defined.

IV. EXTRACTION OF HCMD MATERIAL PARAMETERS IN A VERY HIGH NOISE ENVIRONMENT

Since the measurement errors do distort the measured TL and IPD characteristics, the material parameters found from the exact solution of the best-fitting problem become incorrect. This is especially true for “weak” material parameters such as loss tangents and conductivity that might become up to several times off its correct values or even negative.

Instead, in a high noise measurement environment, it is more efficient to gather an extensive statistics of approximate solutions of the best-fitting problem and then calculate the extracted material parameters as its mean values. When testing known materials, the single search in the vicinity of the nominal values of material parameters might be sufficient. For unknown materials, it’s better to make few searches within first, a very wide, and then more and more narrow area of the material parameters. By comparing the measured and best fitted characteristics, it’s easy to evaluate which way to move and resize this area for the next search.

A. Random Measurement Errors Only Case The case when measurement data contain only random

Gaussian errors with 0.8dB TL and 12º IPD standard deviations was investigated first. The maximum error of extracted material parameters is shown in Table IV for the

110mil thick HCMD and in Table V for the 11mil “sandwich” HCMD. Applied post-processing techniques are explained in Table III.

TABLE III DESCRIPTION OF POST-PROCESSING TECHNIQUES IN TABLES IV-VII

Mode Extracted material parameters were found as… 1 Exact solution. No RW averaging. 2 Mean of almost exact solutions. No RW averaging. 3 Mean of approximate solutions. No RW averaging. 4 Mean of approximate solutions. Only measured data

RW averaging. W/P = 10%. 5-9 Mean of approx. solutions. Theoretical and measured

data RW averaging. W/P = 10%, 20%, 30%, 50%, 80%.

TABLE IV MAXIMUM ERROR OF EXTRACTED MATERIAL PARAMETERS FOR 110MIL THICK MATERIAL SAMPLE AND RANDOM MEASUREMENT ERRORS ONLY

Post-Process Mode

Maximum Error of Extracted Parameters, % Standard Deviation of Random Gaussian Error 0.8dB and 12º

t εr tan δε σ µr tan δµ 1 49 61 1746 309 41 2264 2 19 14 59 38 20 12 3 4.4 4.0 15 5.5 5.3 17 4 1.5 2.3 8.4 2.3 2.1 1.1 5 1.5 2.2 7.6 2.0 1.9 1.0 6 1.4 2.2 7.6 2.1 1.9 0.9 7 1.4 2.2 7.6 1.9 1.8 0.7 8 0.7 1.7 5.8 1.6 1.8 0.7 9 0.9 1.3 4.8 1.6 1.7 0.5

5 10 15 20 25 30 35 40

Frequency , GHz

-4

-3

-2

-1

0

1

Transmission Loss , dB

5 10 15 20 25 30 35 40

Frequency , GHz

-150-100-50

050

100150

IPD , degs

Fig. 2 Example of 110mil Thick HCMD Characteristics Polluted by Random Gaussian Errors with Standard Deviation 0.8dB and 12º

For the 110mil thick sample, the exact best-fitting of the

theoretical curves to the measured data (row 1, Table IV) delivers only rough estimation of “strong” material parameters, while values of “weak” material parameters become irrelevant. At the same time, the calculation of material parameters based on mean values of almost exact or approximate solutions (rows 2 – 3, Table IV), dramatically improves its tolerances.

The application of the RW analysis only to the measured data along with the calculation of the material parameters based on a mean of approximate solutions (row 4, Table IV), makes its tolerances acceptable from virtually any practical standpoints. Further increase of the width of RW (rows 5 – 9, Table IV) steadily improves tolerances of extracted material parameter, since the modified RW analysis introduced in section III allows the use of any desirable width of the RW.

The example of measured (green), unperturbed (red) and best fitted (blue) characteristics for the error level of extracted material parameters corresponded with data in row 9, Table IV is shown in Fig. 2.

TABLE V MAXIMUM ERROR OF EXTRACTED MATERIAL PARAMETERS FOR 11MIL

THIN SANDWICH MATERIAL SAMPLE AND RANDOM MEASUREMENT ERRORS

Post-Process Mode

Maximum Error of Extracted Parameters, % Standard Deviation of Random Gaussian Error 0.8dB and 12º

t εr tan δε σ µr tan δµ 1 52 88 824 533 104 1570 2 74 35 191 48 30 62 3 4.8 4.2 34 9.7 8.0 10.7 4 2.2 2.6 21 4.5 6.6 4.5 5 2.1 2.6 20 5.1 6.4 5.2 6 2.1 2.7 22 4.9 6.8 5.5 7 2.0 2.7 22 4.8 7.0 5.1 8 1.5 2.2 20 6.0 6.5 5.0 9 1.0 1.6 17 6.9 5.6 4.0

5 10 15 20 25 30 35 40

Frequency , GHz

-4

-3

-2

-1

0

1

2

Transmission Loss , dB

5 10 15 20 25 30 35 40

Frequency , GHz

-100

-80

-60

-40

-20

0

20

IPD , degs

Fig. 3 Example of 11mil Thin Sandwich HCMD Characteristics Polluted by Random Gaussian Errors with Standard Deviation 0.8dB and 12º.

For 11mil thin material sample with virtually linear TL and

IPD characteristics within the 2GHz – 40GHz frequency band, it’s impossible to extract any meaningful “weak” material parameters based on the exact solution of the best-fitting problem even in a presence of small measurement noise [2]. The “sandwich” measurement scheme [2] helps to mitigate that problem but for the low measurement noise level only.

The progress that is reached by combining the “sandwich” measurement scheme for two 11mil thin material samples placed 0.75” apart with the post-processing techniques described in this paper is shown in Table V. The tolerances of extracted material parameters are somewhat worse than for the thick material sample but still look good. The example of measured, unperturbed and best fitted characteristics for the error level of extracted material parameters corresponded with row 9, Table V is shown in Fig. 3.

B. Systematic and Random Measurement Errors Case The systematic measurement errors were simulated by

smooth, quasi-periodic in frequency and quasi-random in magnitude TL and IPD curves with the quasi-period several times less than the investigated test frequency band.

TABLE VI MAXIMUM ERROR OF EXTRACTED MATERIAL PARAMETERS FOR RANDOM AND SYSTEMATIC MEASUREMENT ERRORS AND THICK MATERIAL SAMPLE

Post-Process Mode

Maximum Error of Extracted Parameters, % Sta. Deviation of Systematic and Random Errors 0.8dB and 12º

t εr tan δε σ µr tan δµ 1 61 124 2100 363 114 2695 2 22 27 55 77 17 29 3 7.0 7.8 34 12 7.3 4.6 4 4.1 2.8 23 4.4 5.5 1.5 5 4.1 2.8 24 4.5 5.3 1.5 6 3.5 3.0 24 4.7 4.7 1.5 7 3.8 3.1 24 5.8 4.0 1.5 8 2.1 3.0 23 7.2 5.9 1.1 9 2.5 2.8 22 8.2 6.2 1.0

5 10 15 20 25 30 35 40

Frequency , GHz

-4-3-2-1012

Transmission Loss , dB

5 10 15 20 25 30 35 40

Frequency , GHz

-150-100-50

050

100150

IPD , degs

Fig. 4 Example of 110mil Thick HCMD TL and IPD Characteristics Polluted by Systematic and Random Errors with Standard Deviation 0.8dB and 12º. The standard deviation of systematic errors for the TL and

IPD characteristics were chosen the same 0.8dB and 12º as for the random ones. Those systematic errors were combined with Gaussian random errors and unperturbed “measured” TL

and IPD characteristics. Results of the same investigation that was done for the random measurement error only case are shown in Tables VI � VII and Figs. 4 – 5 respectively.

TABLE VII MAXIMUM ERROR OF EXTRACTED MATERIAL PARAMETERS FOR RANDOM

AND SYSTEMATIC MEASUREMENT ERRORS AND THIN SANDWICH MATERIAL

Post-Process Mode

Maximum Error of Extracted Parameters, % Sta. Deviation of Systematic and Random Errors 0.8dB and 12º

t εr tan δε σ µr tan δµ 1 48 86 1437 1337 29 4516 2 54 54 257 26 28 95 3 3.9 3.6 35 5.8 7.8 13 4 4.5 4.2 36 8.8 5.7 14 5 4.5 4.2 36 9.0 5.6 13 6 5.0 3.8 36 9.0 7.7 14 7 5.4 4.3 34 9.0 8.0 13 8 4.2 4.5 20 11 8.0 8.7 9 1.8 4.5 22 12 8.0 4.6

5 10 15 20 25 30 35 40

Frequency , GHz

-4-3-2-1012

Transmission Loss , dB

5 10 15 20 25 30 35

Frequency , GHz

-100-80-60-40-20020

IPD , degs

Fig. 5 Example of 11mil Thin Sandwich HCMD Characteristics Polluted by Systematic and Random Errors with Standard Deviation 0.8dB and 12º. The presence of systematic errors increases the inaccuracy

in determination of material parameters. Nevertheless, in spite of the very high level of random and systematic errors illustrated in Figs. 2 – 5, the advanced post-processing technique described in section III – IV of the present paper allows the extraction of the HCMD material parameters with practically acceptable tolerances.

It should be underscored that the investigated systematic errors were simulated as quasi-random ones. That is why those errors still can be suppressed using considered post-processing technique and do not introduce the significant difference in the tolerance of the extracted material parameters.

It is also interesting to note that while the errors of the extracted material parameters for thin material sample are bigger than for the thick one, the best fitted TL and IPD

curves better match the unperturbed material TL and IPD characteristics for the thin samples. This reflects the fact that for the thin material samples the TL and IPD curves are less sensitive to the variations of the material parameters than those for the thick samples.

V. CONCLUSIONS 1. The advanced post-processing technique for the

wideband free space TL only measurement of the HCMD material parameters in high noise environment was developed.

2. This technique combines the statistical and the improved RW post-processing approaches and allows the reliable extraction of the HCMD material parameters even for the case when systematic and random measurement errors exceed the level of measured TL and IPD characteristics.

3. According to the statistical post-processing approach, the HCMD material parameters should be extracted not from the exact best-fitting of the theoretical and measured curves but instead, as a statistical mean of material parameters extracted from the numerous approximate best-fittings.

4. The traditional RW analysis technique was improved by application of the RW averaging not only to the measured, but also to the theoretical TL and IPD characteristics. That completely eliminates the systematic error induced by the traditional RW analysis and allows the use of much bigger width of the RW to achieve higher level of averaging of random errors.

5. For thin material samples with virtually linear TL and IPD characteristics, the combination of “sandwich” measurement approach [2] and the post-processing technique introduced in this paper allows the extraction of the HCMD material parameters with tolerances that are somewhat worse but still comparable with those for the thick material samples.

6. Although the simultaneous presence of quasi-random systematic and random measurement errors makes tolerances of extracted material parameters somewhat worse than for the random measurement error only case, those tolerances are still acceptable from virtually any practical standpoints.

Cleared by DoD/OSR for public release under 11-S-2281 on May 12, 2011.

REFERENCES [1] Zhonghai Guo, Guangwen (George) Pan, Steven Hall, and Christopher

Pan, “Broadband Characterization of Complex Permittivity for Low-Loss Dielectrics: Circular PC Board Disk Approach” IEEE Transactions on Antennas and Propagation, vol. 57, No. 10, pp. 3126–3135, October 2009.

[2] Aleksey Solovey, Mark Wasson, Raj Mittra, “Free Space Transmission Loss Measurements of Magneto-Dielectric Materials: Solution Uniqueness and Measurement Tolerance Tradeoffs”, in Proc. EuMW’2010, October 2010, Paris, France, pp. 1587-1590.

[3] Chan, T.F., Golub, G.H., and LeVeque, R.J., "Algorithms for Computing the Sample Variance: Analysis and Recommendations" American Statistician, vol. 37, pp. 242-247, 1983.

[4] R. L. Haupt and D. H. Werner, Genetic Algorithms in Electromagnetics, USA: A. Wiley – Interscience, 2007.

[5] Broyden C. G., “Quasi-Newton Methods and their Application to Function Minimization” Mathematics of Computation, vol. 21, No. 99, pp. 368–381, July 1967.