MBS MINERACLS COMPANY PROFILE Matora Work @ Heart

description

Transcript of MBS MINERACLS COMPANY PROFILE Matora Work @ Heart

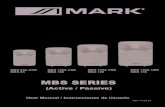

MBS MINERALS LTD Generating ground for high graded minerals Tel: +256 772 553975 /Fax: +256 414 09109 Mob: +256 782049109 Email: [email protected] Kampala Uganda East Africa Matora Phiri: It arent over till its over.The Evolution of King Phiri

5 July, 2012No, I will not begin with the trademark stutter. Nor will I coyly look down and grin a dimpled grin, or flick my head in mock dismissal. I will burst into a song of mining, with arms wide open in a green and gold Swiss pasture. I will not strum a mandolin in a blooming mining ground. I will restrain a mining move, and will do without the financial back up as I introduce Ugandas biggest mining Consultant Company. I have long since moved on as I realizes those days are almost over and dusk settles on my long, mining career as I thought to turn my career into business.The Million Faced Gold of Silver Screen

The Changing Face of Matora Phiri to MBS Minerals LtdIt has been good so far. But as my time draws near and no longer will hair colour hide my channel O beard, As I prepare to moult again. Take on a new that does not blotch my record, and ensures my cup of love for mining runneth over as always. As I began to move from the teeny bopper dreams to a suave adult fantasy. Am impeccably groomed; as I get up as acquired more gentile genre I have been very picky about the roles I am choosing now. As I age, I will do it with finesse; I will not even notice the transition. It is difficult for one to see me just as a professional miner... I want to put my best foot, nay, and nipple forward, it as I pray to GOD!!! .

I have been exploring the plethora of mining business opportunities I can garner while still at the crest of my success different. How Am I going to sell my mining technically services and as, one ponders. What other business am I going to venture into as a special effects mining. A clever move, as a Malawian, Zimbabwean/ Ugandan has established itself the outsourcing capital of the world, much to the indignation of those who accuse me of taking away their jobs. Iam not going to spread my eggs in one baskets, which makes sense. If youre a goose that lays golden eggs, youre better off laying them in different baskets, at least you have some baskets to fall back on when the cruel world comes stealing your glory.

Matora Means Blessing I know only too well that stardom is momentary in the whirligig of mining. You might remember Dreams Unlimited, and Matora. When my hopes came a crashing with my former bosses, I thought Id give it up. I even gloated when I reported a tiff between Busitema Mining Company ,Mimosa Mining Company ,Krone (U), H &H and Metallica Inc Guyana. When I managed to transform mining from a historical work of art into regular business, with exquisite mining technically experience, I thought Id let my own persona go to my head. Though I claimed I only tried to offer mining services. It failed with Shaft sinkers (U) ltd When I failed to make it to my expectations but thats another story. With a biggie like Lagaan that year, I bowed out graciously and vacated the limelight for the worthy. Yet, I did not give up. .

In 2010, I expand my horizons further as a Business miner by establishing MBS Minerals Ltd. Hence mining training courses to be conducted Therefore 2012 I Compiled Hard rock Miners Handbook. to enable mining to be conducted Smoothly and efficienttly .. So far, I have managed to keep it spiced up with Red Chill (mining experience) The success of Ugandan first trip was a good fortune. Then usuccess happened. Yet again, moving away from Zimbabwe. IMC PLUS LTD came along, this time, my good friends Business partners as they added value and comfort zone of the incorporated company(MBS MINERALS lTD), As IMC PLUS LTD/YORK ALLIANCE, MAJEST COM (U) LTD AND KRONE (U) LTD chose to administer the mining operation set in jungles of Uganda East Africa Shaft sinkers and all mining companies I worked for was okay, but it added in my faces this time as a Business miner A title that should appropriately belong to every Mining consultant, if you know what I mean.

I have been exploring the plethora of mining business opportunities I can garner while still at the crest of my success different. How Am I going to sell my mining technically services and as, one ponders. What other business am I going to venture into as a special effects mining. A clever move, as Malawian/Zimbabwean/ Ugandan has established itself the outsourcing capital of the world, much to the indignation of those who accuse me of taking away their jobs. Iam not going to spread my eggs in one basket, which makes sense. If youre a goose that lays golden eggs, youre better off laying them in different baskets, at least you have some baskets to fall back on when the cruel world comes stealing your glory.On the Road to EternityFrom all this, it becomes apparent that my retirement plans are worthy of applause. I had my stint as the megastar, the King of mines. I want to gently ease out, so that people always remember me not as just a professional miner but as a Business miner youthful bundle of chortling charisma. When my fellow Phiri and colleagues are sporting baggy eyes and love handles, still caught mining heroines half their age, I silently mould my persona to suit my age. It wont be a surprise if I faze myself out completely as a professional miner in front of the mining field to focus on areas where I can rightfully contribute after being in the industry for so long. It is pragmatic business sense to preserve the immortality of what people know me as the effervescent dream weaver. MBS MINERALS LTD MINING HARD ROCK HAND BOOK: is a comprehensive and coverage of Mining Training For easier and quicker understanding of mining the author has used simple words and sentence structures Technical terms and other words with other words with trainees or students may be unfamiliar are printed in bold letters and are explained fully.The main of author writing this book is to present the basic facts of mining in such a way as to help students/ mining cadets, artisanal miners small scale miners , Hard rock Oververseer miners, Shift bosses , Mine captains and Mine managers to realize the simplicity of the subject .

MBS MINERALS LTD East Africa Kampala Uganda

MBS MINERALS Hard Rock Miners Handbook

By Matora Phiri

H A R D R O C K M I N E R S H A N D B O O K

F O R W A R D

PUBLISHER EDITIONS MBS MINERALS LTD

Mbs minerals ltd Intosh Engineering

MBS MINERALS LTD

ForwardEdition 4By Matora Phiri

H A R D R O C K M I N E R S H A N D B O O K

F O R W A R D

Mbs minerals ltd Intosh Engineering

MBS MINERALS LTD

MBS MINERALS LTD 's Hard Rock Miners Handbook: is my passionate zeal and work of the heart by Matora Phiri

Originally published in 2013 and personally conceived as a compilation of Matora Phiri continuing 23++ year mining industry career, I personally knew the lifetime of effort that I put into the effect.

The Hard Rock Miners Handbook was personally conceived and written by Matora Phiri whose continuing23+ year mining industry career spans engineering, construction, and operation of mining projects Mr. MatoraWorldwide. The Handbook has been compiled to assist the training of Artisanal miners and small scale miners and engineers., in the difficult world of hard rock mining and is Matoras gift to the industry that continues to provide him with employment, challenges, and fascination. Although the accent of the Handbook is on metal mining as indicated by the title, it is our hope and intention that much of the information may alo be valuable to our friends mining soft, and other not-so-soft industrial mineral and energy resources. The main of author writing this book is to present the basic facts of mining in such a way as to help students/ mining cadets, artisanal miners small scale miners , Hard rock Oververseer miners, Shift bosses , Mine captains and Mine managers to realize the simplicity of the subject .

Mining industry response to the book is incredible. Thanks @ large part to the efforts by Matora Phiris research and website and many others; the

MBS MINERALS LTD Hard Rock Miners Handbook will be distributed over countries Worldwide Daily website hits and downloads continue as students and professors, miners, engineers and mining executives embrace the Hard Rock Miners Handbook as an invaluable source of practical mining information.

Thank you to everyone who contributed to the success of the original publication and this update. Thanks to Mbs minerals ltd most of all, but thanks also to the many persons who submitted new rules of thumb and tricks of the trade as well as those who helped with the chapter updates and reviews. A worthy cause `will be appreciated by many Worldwide.

MBS MINERALS LTD

The Handbook has been compiled to assist the training of Artisanal miners and small scale miners and engineers , mine captathe difficult world of hard rock mining and is Matoras gift to the industry that continues to provide him with employment, challenges, and fascination. Although the accent of the Handbook is on metal mining as indicated by the title, it is our hope and intention that much of the information may alo be valuable to our friends mining soft, and other not-so-soft industrial mineral and energy resources. The Handbook is a is publication intended to be of service and value to the mining companies we serve and the entire mining community, including students, teachers, consultants, contractors, manufacturers, salespersons, media representatives, financial institutions, mining associations, and government officials. It is our intention to of charge to any person involved in the mining industry. In addition to a limited number of hard copies, we are publishing CD version of the Handbook and the full text will be available from our website (www.mbsminerals.com). MBS MINERALS LTD compiled this hand book with the knowledge that to begin solving a problem, an immediate approximate answer is frequently both necessary and useful. Rules of Thumb and comparable data are often sufficient to provide immediate answers and to begin the problem solving process. As a result, excerpts of the Hard Rock Miners Handbook consisting of an abridged version of the Rules of Thumb were previously published and delivered at mining conventions in the USA and Canada. The strong response from mining people provided many new rules and encouraged us to pursue this endeavor as a separate project.

Rules of Thumb New Contributions

Mbs minerals ltd would s to expand the Rules of Thumb list. We are also seeking input and corrections to existing rules. (One unpublished Rule of Thumb is that 80% of all Rules of Thumb are wrong.) Not fearing controversy, we have plowed ahead with the Rules of Thumb project with the knowledge that, applied correctly, all of the Rules of Thumb are based on significant experience in the industry and add value to the decision-making process.New Rules of Thumb received will be gratefully acknowledged and carefully examined for addition to the list. We are sponsoring the development of the Rules of Thumb listing with the intention of making it the seed of a compilation that will include Rules of Thumb used throughout the worldwide mining industry. Visit our website noted above to view or download a copy of the Rules of Thumb, to comment on an existing rule, or to add a new rule to the list.

Matora gratefully acknowledges all of the persons who contributed to the development of the Hard Rock Miners Handbook. Many contributors are listed in the text of the Handbook as contributors of specific Rules of Thumb or Tricks of the Trade. In addition, we are grateful to all persons who advised Matora on a personal basis through his years of compiling the text. I am also personally grateful to the many Mining Companies and others outside of our company who contributed time to the section-by-section internal review process. Thank you AcknowledgmentsThe Art (Experience) of the Mining Industry

Certain contents of the Hard Rock Miners Handbook are controversial. One of the attractions of the mining industry is the fact that while our business is generally based on sound scientific principal, there is still significant art to the work we do. The art is the exciting part of our business. We dont truly know what the ground will be like until it is mined. And by then, if the art has not been prudently applied, it is too late for the application of scientific principal. Because of the unknowns, we rely on the experience of others and good Rules of Thumb to guide us in many instances. Herein lies the value of the Rules of Thumb and Tricks of the Trade sections of this Handbook. Use the Art (experience) contained in this Handbook use it wisely.Disclaimer

Because Rules of Thumb and other similar information can be misused (and on the advice of our Lawyer whose Rule of Thumb is to have a lawyer help you solve all of your problems), this Hard Rock Miners Handbook is published with the following disclaimer.

The primary usage of this Handbook should be in the development of conceptual designs, feasibility studies, and due diligence, or when a quick decision is required for the solution of an operating problem. Use of this handbook is not intended as a substitute for the application of sound engineering practice and design procedures. Although we firmly believe that this publication provides great value to our industry, MBS minerals ltd (and any of the individual referenced sources) does not guarantee the validity of its contents. Neither do we accept responsibility for application of any of the contents by others.

Where practical, direct quotes are provided for individual references; however, some were translated from a foreign language and others are recalled from memory or received by word of mouth. It is possible that some referenced sources were misinterpreted in the statements for which they are assigned credit. Although we have endeavored to accurately quote all individual references contained in the text, we apologize in advance for any misquotes that may be attributed to individual sources.

In closing, I would like to express my sincere appreciation to ALL the Mining Companies I have worked for his dedication to this project. I have known and worked with Dr Glendon Archer years and have thoroughly enjoyed the opportunity to participate with him in publishing this Handbook. To all of our mining industry friends, please feel free to use this Handbook wisely and share it with others. I hope that by publishing this Handbook, we have somehow made your jobs easier or helped you in some way to be competitive in a tough, but fun and interesting industry. Your future comments will always be welcome.

MBS MINERALS LTD HARD ROCK HANDBOOK

Rules of Thumb Tricks of the Trade Case Histories Example Problems

Royal Commission on mineral resources in Ontario, Canada stated that we had been mining by rules of thumb for long enough. The Royal Commission probably never imagined that over 100 years later we not only continue to employ these tools, but we lend more value to them than ever before.Exploration Geology and Ore Reserves

Rock Mechanics Mining Methods Mine LayoutEnvironmental Engineering Feasibility Studies Mineral Economics Cost EstimatingShaft Design

Shaft SinkingLateral Development and Ramps

Collars and Portals

Drum Hoists

Koepe / Friction Hoists

Wire Ropes, Sheaves, and Conveyances

Head frames and Bins Conveyors and Feeders Ventilation and Air Conditioning Compressed AirMine Dewatering

Backfill Explosives and Drilling ElectricalPasses, Bins, and Chutes Crushers and Rockbreakers Mineral ProcessingInfrastructure and TransportationMine Maintenance

Table of Contents

1.0 EXPLORATION GEOLOGY AND ORE RESERVES

1.1 INTRODUCTION .1.2 RULES OF THUMB 1.3 TRICKS OF THE TRADE 1.4 DIAMOND DRILLING1.5 ORE RESERVES1.6 EVALUATING EXPLORATION PROPERTIES 1.7 ESTIMATING ORE RESERVES.1.8 UNDERGROUND EXPLORATION ENTRIES 1.9 MINE ENTRY COMPARISONS1.10 TABLES 2.0 ROCK MECHANICS

2.1 INTRODUCTION 2.2 RULES OF THUMB 2.3 TRICKS OF THE TRADE 2.4 THE ROLE OF ROCK MECHANICS2.5 ROCK STRESS 2.5.1 Virgin (in situ) Ground Stress 2.5.2 Induced Ground Stress 2.6 GROUND CONTROL2.7 STABILITY OF EXCAVATIONS2.8 ROCKBURSTS 2.8.1 Causes of Rockbursts 2.8.2 Combating Rockbursts 2.8.3 Simple Truths about Rockbursts 2.8.4 Anecdotes of Rockburst Experiences 2.9 DEDICATION & ACKNOWLEDGEMENT

3.0 MINING METHODS...

3.1 INTRODUCTION 3.2 RULES OF THUMB 3.3 TRICKS OF THE TRADE 3.4 MINING METHOD SELECTION 3.5 DILUTION3.6 MINE PLANNING.3.7 MINING METHODS FOR LARGE CAPACITY UNDERGROUND MINES.....

4.0 MINE LAYOUT

4.1 INTRODUCTION 4.2 RULES OF THUMB 4.3 TRICKS OF THE TRADE .4.4 STRATEGY FOR UNDERGROUND MINES .

5.0 ENVIRONMENTAL ENGINEERING

5.1 INTRODUCTION 5.2 RULES OF THUMB 5.3 TRICKS OF THE TRADE 5.4 PROCEDURES

Mbs minerals ltdvi

xivxivMBS MINERALS LTD

5.5 ENVIRONMENTAL IMPACT STATEMENT .5.6 SCHEDULE 5.7 ACID ROCK DETERMINATION ......5.8 DRAINAGE DITCHES AND CULVERTS .....5.9 WATER DEMAND.5.10 CHLORINATION OF POTABLE WATER....5.11 RECYCLING MINE WATER5.12 SMELTER EMISSIONS ..5.13 CYANIDE ..

6.0 FEASIBILITY STUDIES

6.1 INTRODUCTION 6.2 RULES OF THUMB 6.3 TRICKS OF THE TRADE 6.4 ORDER-OF-MAGNITUDE FEASIBILITY ESTIMATE 6.5 PRELIMINARY FEASIBILITY STUDY .6.6 DETAILED FEASIBILITY STUDY

7.0 MINERAL ECONOMICS

7.1 INTRODUCTION 7.1.1 Accounting Practice 7.1.2 Commodity Market 7.1.3 Financing 7.1.4 Economic Evaluation 7.2 RULES OF THUMB 7.3 TRICKS OF THE TRADE 7.4 ECONOMIC EVALUATION 7.4.1 Cash Flow 7.4.2 Rate of Return on Investment 7.4.3 Payback 7.4.4 Competitive Cost 7.5 OPERATING MINE ECONOMICS 7.6 APPENDIX .

8.0 COST ESTIMATING .

8.1 INTRODUCTION 8.2 RULES OF THUMB 8.3 KEY DEFINITIONS AND ABBREVIATIONS 8.4 PROCEDURE.8.5 TOOLS OF THE TRADE 8.6 TRICKS OF THE TRADE 8.7 CATEGORIES AND CONFIDENCE LEVELS OF ESTIMATES 8.8 VALUE ENGINEERING 8.9 CALCULATION OF INTEREST COSTS 8.10 THE SIX-TENTHS RULE8.11 JACKS FACTORS 8.12 LANG FACTORS 8.13 CALCULATION OF EPCM COSTS ..8.14 OPERATING COST BREAKDOWN 8.15 CALCULATION OF PRODUCTIVITY TYPICAL VALUES 8.16 CALCULATION OF CONSUMPTION TYPICAL VALUES.

9.0 SHAFT DESIGN

9.1 INTRODUCTION 9.2 RULES OF THUMB .9.3 TRICKS OF THE TRADE9.4 FUNCTION OF CONCRETE LINING IN A CIRCULAR SHAFT .

9.4.1 Curb Rings 9.4.2 Continuous Lining 9.4.3 Role of Lining 9.4.4 Concrete Lining Advantages 9.5 STIFFNESS OF CONCRETE.9.6 STIFFNESS OF ROCK9.7 CONCRETE LINER DESIGN9.8 STEEL LINER DESIGN.. 9.8.1 Sandwich Liner . 9.8.2 Leaky Liners . 9.8.3 Hydrostatic Liner.9.9 SHAFT DESIGN TOLERANCES

10.0 SHAFT SINKING.

10.1 INTRODUCTION 10.2 RULES OF THUMB 10.3 TRICKS OF THE TRADE 10.4 TYPES OF SHAFTS 10.5 PLANNING AND PREPARATIONS RECIPE FOR SUCCESS 10.6 HOIST SELECTION FOR SHAFT SINKING10.7 SHAFT CONCRETE 10.7.1 Coriolus Effect 10.8 SOLVED PROBLEMS 10.8.1 Coriolus Effect 10.8.2 Over break Measurement.

11.0 LATERAL DEVELOPMENT AND RAMPS

11.1 INTRODUCTION 11.2 RULES OF THUMB11.3 TRICKS OF THE TRADE 11.4 TRACK VERSUS TRACKLESS 11.5 DESIGN AND FUNCTION OF LATERAL HEADINGS 11.6 LASER CONTROLS

12.0 COLLARS & PORTALS

12.1 INTRODUCTION 12.2 RULES OF THUMB 12.3 TRICKS OF THE TRADE 12.4 WELL POINTS AND WELL PUMP DEWATERING 12.5 BIG HOLE DRILLING

13.0 DRUM HOISTS

13.1 INTRODUCTION 13.2 RULES OF THUMB 13.3 TRICKS OF THE TRADE 13.4 HOIST CYCLE TIME T 13.4.1 Stops 13.4.2 Creep Times 13.5 MAXIMUM LINE SPEEDS FOR DRUM HOISTS 13.5.1 Case Histories 13.6 PRODUCTION AVAILABILITY

14.0 KOEPE / FRICTION HOISTS

14.1 INTRODUCTION 14.2 RULES OF THUMB 14.3 TRICKS OF THE TRADE 14.4 FRICTION HOIST DESIGN 14.5 TENSION RATIO 14.6 PRODUCTION AVAILABILITY 14.7 COMPARISONS

15.0 WIRE ROPES, SHEAVES, AND CONVEYANCES

15.1 INTRODUCTION 15.2 RULES OF THUMB 15.3 TRICKS OF THE TRADE 15.4 CHARACTERISTICS OF WIRE ROPES15.5 DIAMETER OF WIRE ROPES15.6 SAFETY FACTORS FOR WIRE ROPES 15.7 SELECTION OF WIRE ROPES .15.8 SELECTING ROPE ATTACHMENTS 15.9 MINIMUM DRUM AND SHEAVE DIAMETERS15.10 TYPICAL SKIP FACTORS FOR MINE HOIST15.11 CLEARANCES AND RUB ROPE REQUIREMENTS FOR ROPE GUIDED HOISTING SHAFTS15.12 ROPE STRETCH FOR SKIP HOIST ROPES

16.0 HEADFRAMES AND BINS

16.1 INTRODUCTION .16.2 RULES OF THUMB 16.3 TRICKS OF THE TRADE16.4 STEEL HEADFRAME VERSUS CONCRETE HEADFRAME16.5 WEIGHT OF A STEEL HEADFRAME16.6 HEIGHT OF A STEEL HEADFRAME.

17.0 CONVEYORS AND FEEDERS

17.1 INTRODUCTION 17.2 RULES OF THUMB 17.3 TRICKS OF THE TRADE 17.4 BELT CONVEYOR DESIGN 17.5 CONVEYOR BELT WIDTH17.6 CASE HISTORIES 17.7 POWER REQUIREMENTS 17.8 COMPUTER PROGRAM 17.9 PRODUCTION CAPACITY 17.10 FRICTION AROUND A CIRCULAR DRIVE17.11 FEEDER SELECTION AND DESIGN

18.0 VENTILATION AND AIR CONDITIONING

18.1 INTRODUCTION .18.2 RULES OF THUMB 18.3 TRICKS OF THE TRADE 18.4 CONVERSION FACTORS 18.5 CONSTANTS AND TYPICAL VALUES 18.6 DESIGN OF THE PRIMARY VENTILATION CIRCUIT18.7 NATURAL VENTILATION 18.8 DESIGN OF VENTILATION SHAFTS AND RAISES 18.9 FRICTION FACTOR FOR AN EQUIPPED MINESHAFT 18.10 VENTILATION DUCT DESIGN 18.11 SELECTION OF ELECTRIC POWERED VENTILATION FANS

18.12 AIR FANS 18.13 TESTING VENTILATION FAN PERFORMANCE .18.14 THRESHOLD LIMIT VALUE DIESEL PARTICULATE MATTER 18.16 HEAT GENERATED BY THE AUTO-COMPRESSION OF AIR 18.17 VENTILATION MANAGEMENT IN THE OPERATING MINE18.18 THE REQUIRED CAPACITY OF A MINE AIR HEATER . 18 HEAT LOAD 18.20 COOLING18.21 MECHANICAL REFRIGERATION

19.0 COMPRESSED AIR

19.1 INTRODUCTION 19.2 RULES OF THUMB 19.3 TRICKS OF THE TRADE 19.4 AIR LINE DIAMETER 19.5 AIR LINES LEAKS 19.6 AIR RECEIVER 19.7 COOLING WATER 19.8 EQUIPMENT AIR REQUIREMENTS 19.9 COMPRESSED AIR PLANT CAPACITY 19.10 ALTITUDE AND DEPTH

20.0 MINE DEWATERING

20.1 INTRODUCTION 20.2 RULES OF THUMB 20.3 TRICKS OF THE TRADE 20.4 SOURCE OF SLIMES .20.5 THE WATER BALANCE20.6 ESTIMATING AND MEASURING WATER FLOWS20.7 CLEAR WATER PUMPING....20.8 DIRTY WATER PUMPING.....20.9 DRAINAGE TUNNELS 20.10 CENTRIFUGAL PUMP SELECTION 20.11 FRICTION HEAD LOSS IN STEEL PIPE 20.12 MINIMUM WALL THICKNESS OF PIPING 20.13 SETTLING VELOCITY 20.14 UNDERGROUND DAM DESIGN

21.0 BACKFILL

21.1 INTRODUCTION .21.2 RULES OF THUMB 21.3 TRICKS OF THE TRADE 21.4 TYPES OF BACKFILL 21.5 PROPERTIES 21.6 CASE HISTORIES 21.7 COOLING FROM PASTE FILL

22.0 EXPLOSIVES AND DRILLING

22.1 INTRODUCTION 22.2 RULES OF THUMB 22.3 TRICKS OF THE TRADE 22.4 EXPLOSIVE SELECTION AND TYPES 22.5 CRATER BLASTING

22.6 SULFUR BLASTS 22.7 DRILLING BLASTHOLES 22.8 DRILL PATTERNS

23.0 ELECTRICAL

23.1 INTRODUCTION 23.2 RULES OF THUMB 23.3 TRICKS OF THE TRADE 23.4 NOMENCLATURE23.5 LAWS AND FORMULAE23.6 POWER FACTOR .23.7 ELECTRICAL DEMAND .23.8 POWER CONSUMPTION AND COST ESTIMATE23.9 STANDARD ELECTRICAL MOTOR SIZES 23.10 FULL LOAD CURRENT FOR AC AND DC MOTORS 23.11 TRANSMISSION LINE DATA 23.12 GROUNDING AND BONDING 23.13 RATINGS OF MOTOR CIRCUIT FUSES AND BREAKERS 23.14 FUSE RATINGS REQUIRED FOR MOTOR APPLICATIONS 23.15 WORLDWIDE POWER GRID SUPPLY SYSTEM FREQUENCIES23.16 WORLDWIDE POWER GRID SUPPLY SYSTEM VOLTAGES24.0 PASSES, BINS, AND CHUTES

24.1 INTRODUCTION 24.2 RULES OF THUMB 24.3 TRICKS OF THE TRADE 24.4 ORE PASS INCLINATION 24.5 ORE PASS SIZE 24.6 ORE PASS LININGS 24.7 ORE PASS STABILITY 24.8 DAMAGE CONTROL 24.9 THE PERFECT ORE PASS 24.10 GLORY HOLE ORE PASSES 24.11 FILL RAISES 24.12 BINS 24.13 CHUTES

25.0 CRUSHERS AND ROCKBREAKERS

25.1 INTRODUCTION .25.2 RULES OF THUMB .25.3 TRICKS OF THE TRADE .25.4 JAW CRUSHERS 25.5 GYRATORY CRUSHERS 25.6 CONE CRUSHERS 25.7 JAW CRUSHER VERSUS GYRATORY CRUSHER 25.8 LOCATING A PRIMARY CRUSHER UNDERGROUND25.9 DUST COLLECTION 25.10 CRUSHING WASTE ROCK 25.11 ROCKBREAKERS .

26.0 MINERAL PROCESSING

26.1 INTRODUCTION 26.2 RULES OF THUMB ...26.3 TRICKS OF THE TRADE 26.4 GRINDING26.5 BENEFICIATION

MBS MINERALS LTDviiiviii

ixixMBS MINERALS LTD MMMINERALSEngineering

27.0 INFRASTRUCTURE AND TRANSPORTATION

27.1 INTRODUCTION 27.2 RULES OF THUMB 27.3 TRICKS OF THE TRADE 27.4 HAUL ROADS27.5 RAILWAYS 27.6 LAND DRAINAGE AND CULVERTS 27.7 AIRCRAFT PAYLOAD CAPACITIES

28.0 MINE MAINTENANCE

28.1 INTRODUCTION 28.2 RULES OF THUMB 28.3 TRICKS OF THE TRADE 28.4 MANAGEMENT AND ADMINISTRATION 28.5 HUMAN RESOURCES MANAGEMENT28.6 WORK PRACTICE 28.7 OPERATING ENVIRONMENT 28.8 MAINTENANCE FOR SMALL MINES.28.9 APPENDIX 28.9.1 Logs and Certificates 28.9.2 Sample Work Standard 28.9.3 Work Standards Abbreviations 28.9.4 Mine Hoist Lubricants 28.9.5 Mine Hoist Tools, Equipment, and Supplies .

29.0 PROJECT,MINING MANAGEMENT AND SAFETY REGULATIONS

29.1 INTRODUCTION 29.2 STRATEGIC PLANNING 29.3 SYSTEMS AND PROCEDURES...29.4 EXECUTION29. 5 Mining Management and Safety regulations

APPENDIX I PROPERTIES OF MISCELLANEOUS MATERIALS

I.1 FUELS 291I.2 MODULUS OF ELASTICITY, E I.3 MINE TIMBERS AND POSTS I.4 PROPERTIES AND MEASUREMENT OF GOLD

APPENDIX II STATISTICAL TOOLS

II.1 STANDARD CHARTS

APPENDIX III DIRECTORY OF WEB SITES

APPENDIX IV CONVERSION FACTORS AND CONSTANTS

APPENDIX V BASIC TECHNICAL LIBRARY

INDEX

List of Tables

TABLE 1-1 CORE AND DRILL HOLE DIAMETERS . TABLE 1-2 CATEGORIES OF CERTAINTY TABLE 1-3 GEOLOGIC TIME TABLE 1-4 MOHS SCALE FOR MINERAL HARDNESS .. TABLE 1-5 MOHS' SCALE FOR ROCK HARDNESS TABLE 2-1 RESISTANCE VALUE COMPARISON TABLE 2-2 TABLE OF OBSERVATIONS (FACTS) TABLE 2-3 COMPRESSIVE STRENGTH TABLE 2-4 RECORD OF ROCKBURSTS FROM A LARGE CANADIAN MINE (EIGHT-YEAR PERIOD)

TABLE 3-1 MINING METHODS FOR SOME OF THE WORLDS LARGEST CAPACITY UNDERGROUND MINES

TABLE 4-1 ORE TRANSPORT METHODS EMPLOYED AT UNDERGROUND MINES . TABLE 5-1 ENVIRONMENTAL IMPACT STATEMENT CASE STUDY TABLE 5-2 PRECIPITATION OF COMMON METAL IONS. TABLE 5-3 FLOW CAPACITY TABLE 5-4 CULVERT ENTRANCE CAPACITY TABLE 5-5 WATER DEMAND TABLE 5-6 CHLORINATION QUANTITIES .

TABLE 6-1 METAL REDUCTION FACTORS

TABLE 8-1 ENGINEERING, PROCUREMENT, AND CONSTRUCTION MANAGEMENT VALUES TABLE 8-2 APPROXIMATE MINING COST BREAKDOWN TABLE 8-3 CALCULATION OF PRODUCTIVITY TYPICAL VALUES2

TABLE 8-4 CALCULATION OF CONSUMPTION

TYPICAL VALUES

TABLE 9-1 STIFFNESS OF COMMON ROCKS IN GPA

TABLE 10-1 SELECTION (DIAMETER) OF DOUBLE-DRUM HOIST FOR SHAFT SINKING

TABLE 12-1 APPROXIMATE UNCONFINED COMPRESSIVE STRENGTHS OF FROZEN GROUND TABLE 12-2 FREEZE PIPE SPACING (1)TABLE 12-3 FREEZE PIPE SPACING (2).TABLE 12-4 VISCOSITY COMPARED TO TEMPERATURE

TABLE 13-1 HOISTING SPEEDS ON WOOD GUIDES EXCEEDING 10M/S (2,000 FPM) TABLE 13-2 HOISTING SPEEDS ON FIXED GUIDES (STEEL), EXCEEDING 15M/S (3,000 FPM) TABLE 13-3 HOIST PLANT AVAILABILITY DOUBLE-DRUM HOIST (SEVEN DAYS PER WEEK OPERATION)

TABLE 14-1 HOIST PLANT AVAILABILITY

TABLE 15-1 HOISTING SPEEDS LESS THAN 1M/S TABLE 15-2 SKIP FACTORS

TABLE 16-1 HEIGHT OF STEEL HEADFRAME FOR A 10-FOOT (3M) DOUBLE DRUM PRODUCTION HOIST

TABLE 17-1 BELT CONVEYORS AT CANADIAN MINES TABLE 17-2 EQUIVALENT LIFT FOR BELT CONVEYOR LENGTHS

TABLE 18-1 CONVERSION FACTORS TABLE 18-2 CONSTANTS AND VALUES

TABLE 18-3 DIAMETERS FOR CIRCULAR SHAFTS AND RAISES 166TABLE 18-4 CASE HISTORIES TABLE 18-5 VENTILATION TABLE 18-6 AIR FAN AIRFLOW TABLE 18-7 TYPICAL TLVS FOR CONTAMINANTS AND RESPIRABLE DUSTS TABLE 18-8 HEAT BALANCE TABLE 18-9 MINE VENTILATION CAPACITY TABLE 18-10 CASE HISTORIES OF DEEP HOT MINING OPERATIONS

TABLE 19-1 TYPICAL COMPRESSED AIR REQUIREMENTS TABLE 19-2 EQUIPMENT AIR CONSUMPTION TABLE 19-3 STANDARD ATMOSPHERE AT ALTITUDES/DEPTHS AND AIR COMPRESSED TO 100PSIG (689 KPA) AT SEALEVEL

TABLE 20-1 UNDERGROUND MINE WATER BALANCE TABLE 20-2 FLOW RATES (USGPM) TABLE 20-3 FLOW RATE FROM A 1.38-INCH DIAMETER HOLE.TABLE 20-4 FLOW RATES FOR AN 8-INCH WIDE WEIR BOX TABLE 20-5 STANDARD DRAINAGE TUNNEL CAPACITY.TABLE 20-6 TRUE AREA OF OUTLET TABLE 20-7 STANDARD ELECTRIC MOTORS TABLE 20-8 FRICTION HEAD LOSS (FEET) PER 100 FEET OF SCHEDULE 40 STEEL PIPE (MINE SERVICE)TABLE 20-9 DIMENSIONS OF COMMERCIAL STEEL PIPE TABLE 20-10 OVERFLOW DAM DESIGN .TABLE 20-11 OVERFLOW DAM DESIGN (IMPERIALSTABLE 21-1 TYPICAL PROPERTIES OF STRUCTURAL BACKFILLS TABLE 21-2 TYPICAL PROPERTIES OF HYDRAULIC, CEMENTED BACKFILLS (CHF)TABLE 21-3 PASTE FILL CASE HISTORIES TABLE 21-4 CEMENTED ROCK FILL CASE HISTORIES

TABLE 23-1 ELECTRICAL NOMENCLATURE TABLE 23-2 TABULATION OF ESTIMATED POWER CONSUMPTION AND COST FOR A 2,500 TPD MINE .TABLE 23-3 KILOWATT-HOUR PER TONNE PROCESSED (TYPICAL VALUES) TABLE 23-4 STANDARD ELECTRIC MOTOR SIZES TABLE 23-5 FULL LOAD CURRENT DATA TABLE 23-6 TRANSMISSION LINE DATA TABLE 23-7 FUSE AND BREAKER RATINGS (CAN) TABLE 23-8 FUSE AND BREAKER RATINGS (USA) TABLE 23-9 REQUIRED FUSE RATINGS TABLE 23-10 WORLDWIDE POWER GRID SUPPLY SYSTEM FREQUENCIES .TABLE 23-11 WORLDWIDE POWER SUPPLY SYSTEM VOLTAGES

TABLE 26-1 BOND WORK INDEX FOR ROCKS AND MINERALSTABLE 26-2 FEED AND PRODUCT SIZES IN MICRONS ()

TABLE 27-1 DEGREE AND RADIUS OF CURVATURETABLE 27-2 AIRCRAFT PAYLOAD CAPACITIES

TABLE 28-1 ENGINE OIL CHANGE INTERVALSTABLE 28-2 MEASUREMENTS AND TESTS FOR MOBILE EQUIPMENT PREVENTIVE MAINTENANCETABLE 28-3 MAINTENANCE FUNCTIONS OF MAIN UNDERGROUND SHOPSTABLE 28-4 COMPONENT AREAS MAIN UNDERGROUND SHOP TABLE 28-5 STATIONARY AND PORTABLE EQUIPMENT TABLE 28-6 STOCK ITEMS .TABLE 28-7 FURNISHINGS AND SUNDRY ITEMS FOR UNDERGROUND SHOPS.

MBS MINERALS LTDx

xiiMBS MINERALS LTD

TABLE 28-8 HAND TOOLS TABLE 28-9 WORK PERFORMANCE STANDARDS ABBREVIATIONSTABLE 28-10 MINE HOIST LUBRICANTS

TABLE 29-1 COMMISSIONING TROUBLE SHOOTING MATRIX

TABLE I-1 PROPERTIES OF COMMON FUELSTABLE I-2 MODULUS OF ELASTICITY, E .TABLE I-3 PROPERTIES OF MINE TIMBERS AND POSTS TABLE I-4 GOLD PROPERTIES TABLE I-5 GOLD MEASUREMENT TABLE I-6 MEASUREMENT CONVERSION TABLE I-7 GRADE CONVERSIONS

List of Figures

FIGURE 2-1 INDUCED STRESSES AROUND SHAFTS FIGURE 2-2 OREBODY SHAPES . FIGURE 2-3 NUMBER OF EVENTS LARGER PER ANNUM VS. EVENT MAGNITUDE FIGURE 2-4 MAGNITUDE/HAZARD/TIME PLOT FOR SEISMIC EVENTS AT A TYPICAL LARGE MINE FIGURE 2-5 FALLS OF GROUND COMPARED TO ROCKBURSTS. FIGURE 3-1 FISHBONE CHART . FIGURE 4-1 MOVING ORE TO SURFACE FIGURE 18-1 DRAG COEFFICIENTS FIGURE 20-1 PORTABLE WEIR BOX IN DITCH FIGURE 20-2 RANGE OF EFFICIENCIES FIGURE 20-3 UNDERGROUND DAM DESIGN FIGURE 25-1 JAW CRUSHER TYPES FIGURE 27-1 MELTING POWER OF ROAD SALTS

MBS MINERALS LTDdsssltdcIntosh Engineeringxiixiixii

xiiiMbs minerals ltd cIntosh Engineering

Introduction

I N T R O D U C T I O N

The grand aim of all science is to cover the greatest number of empirical facts by logical deduction from the smallest number of hypotheses or axioms. Most of the fundamental ideas of science are essentially simple, and may, as a rule, be expressed in a language comprehensible to everyone.

Handbooks have long been used in our industry as the principal source of information for the solution of day-to-day problems. The goal of these texts is to present a digest of as much theory and practice as possible. Customarily, the books have been a collation of entries solicited from recognized experts in each of the many separate mining disciplines.

A few mining handbooks were written by individuals. Agricola wrote the first handbook for the mining industry, De Re Metalica, in the 16th century. In 1909, Principles of Mining was written by Herbert Hoover, a mining engineer who later became president of the United States. In 1949, Jack Spalding, an English mining engineer, left his job in South Africa toenlist in the army and serve in World War II. He wrote the first draft of his valuable handbook entitled Deep Mining during the six years that the Japanese held him as a prisoner of war. The camp commander burned his manuscript the day before his release. After the war, a mining company (John Taylor and Sons) sponsored him for one year to allow him to rewrite and publish the book.

When I began the journey of Compililing of this Hand book , I expected that others would write many of the chapters, but soon realized this was not going to happen. I did the best I could and my efforts were greatly improved by the constructive criticism and final reviews of employees and friends of.

Edition 3 was written to remedy some of the shortcomings found in the original text, add over 100 new rules of thumb, and generally update the handbook. A new chapter (Project Management) was added to explore managing, controlling, coordinating, and scheduling major mining projects.

The chapters on hoisting, rock mechanics, ventilation, and mineral processing are enhanced by the efforts of four individual experts: Sigurd Grimestad, Richard Brummer, Pierre Mousset-Jones, and Robert Shoemaker. These expertsfriends voluntarily critiqued and/or edited the original text and provided valuable the material.

I am indebted to Krone Uganda Ltd and Geological survey and mines of Uganda who once again directed the progress of the work,

MBS MINERALS LTD Hard Rock Miners Handbook Compilation

1.0 Exploration Geology and Ore Reserves

Mineral Exploration ActivitiesMineral exploration activities are undertaken to determine the presence of geological formations which may contain deposits such as precious metals, base metals, gemstones, coal or other minerals, as well as to determine the extent, geometry and grade of such deposits. Drilling, pitting, trenching and surface stripping are common activities undertaken during mineral exploration. Temporary work camps and docks are often established to support mineral exploration activities. This Operational Statement addresses activities that may occur in or near water and may impact fish and fish habitat if appropriate measures are not implemented.Mineral exploration activities may involve site reconnaissance, line cutting, temporary work camp operations, small diameter/low density drilling, high density drilling and/or bulk sampling (extraction of large samples of mineralized material) through large diameter drilling, pitting, trenching and surface stripping.This Operational Statement applies to all of the above mineral exploration activities when conducted on land, and to small diameter/low density drilling (see definition below) when carried out on ice. These activities are considered to be of low risk to fish and fish habitat when carried out in accordance with this Operational Statement.Other activities with the potential to affect fish or fish habitat such as providing access to the site, camp waste management, and seismic operations are not covered by this Operational Statement. For purposes of access, please see the Operational Statements forIce Bridges and Snow Fills,Clear Span Bridges, andTemporary Stream Crossing.Impacts to fish and fish habitat can occur during mineral exploration activities through loss of riparian habitat during site clearing, erosion and sedimentation, release of drilling fluids and cuttings into aquatic environments, disturbance to fish and fish habitat during sensitive life stages, and water withdrawals, particularly during low water periods, associated with drilling, surface stripping and camp operations. Direct fish mortality can occur as a result of the use of explosives in or near water and during pumping activities either through dewatering or entrainment/impingement.The purpose of the following sections is to describe the conditions under which this Operational Statement is applicable to your project and the measures to incorporate into your project in order to avoid negative impacts to fish and fish habitat. You may proceed with your mineral exploration activities without a DFO review if the following conditions apply to your activities: your project involves only small diameter/low density drilling (see definition below) when carried out on ice, no drill set-up (unless carried out on-ice), pitting, trenching or stripping operations are proposed below the Ordinary High Water Mark (HWM) (see definition below) of any water body, no on-ice drilling in known fish spawning habitat, and no large diameter on-ice drilling (>100 mm), will occur, no drilling with saltwater in permafrost conditions will occur, no explosives will be used in or near any water body, all drill cuttings will be contained and prevented from entering any water body, pits or trenches will be dug by hand or mechanical means other than hydraulic (water) trenching, this Operational Statement is posted at the work site and is readily available for reference by workers, and you incorporate theMeasures to Protect Fish and Fish Habitat during Mineral Exploration Activitieslisted below in this Operational Statement.

If you cannot meet all of the conditions listed above and cannot incorporate all of the measures listed below then your project may result in the violation of exploration activities. You are required to respect all local, municipal, territorial legislation that applies to the work being carried out in relation to this Operational Statement. office. This information is requested in order to evaluate the effectiveness of the work carried out in relation to this Operational Statement.

Measures to Protect Fish and Fish Habitat during Mineral Exploration ActivitiesSite Access and Preparation1. Use existing trails, roads, or cut lines wherever possible to avoid disturbance to the riparian vegetation. For winter access and stream crossings, please refer to theIce Bridges and Snow FillsandTemporary Stream CrossingOperational Statements.2. While this Operational Statement does not apply to the clearing of riparian vegetation, the removal of select plants within the exploration site may be required to meet operational and/or safety concerns. Vegetation removal is to be minimal and when practicable, prune or top the vegetation instead of uprooting. Temporary Work Camps/Docks

3. Utilize previously cleared areas or natural openings for temporary work camps or otherwise limit the amount of vegetation that is disturbed.4. Locate work camps, including storage areas, fuel caches, and helicopter landing pads, on dry stable ground, above the HWM, and employ measures to prevent the release of sediment or deleterious substances into any water body.5. Ensure that any temporary dock remains secure and in good repair, and is fully removed from below the HWM immediately following exploration activities at the site.

Exploratory Drilling

6. Contain all drill cuttings, fluids or sludge in closed systems for reuse, off-site disposal, or otherwise contain and stabilize them to prevent their entry into any water body. 6.1. Where sumps are utilized they are located above the HWM of any water body and are able to contain all drilling waste.7. Use only non-toxic drilling additives and muds.8. Plug and permanently seal any artesian flow that is encountered and any holes drilled in wet areas (e.g., lake or wetland) upon completion of the project.9. Small diameter/low density on-ice drilling (see definition below) may be undertaken, except in known fish spawning habitat (in which case the Operational Statement does not apply). Avoid drilling in gravel or rock rubble substrates in water depths less than four (4) metres within water bodies where fall-spawning fish species (e.g., trout, whitefish) are likely to be present. 9.1. Remove all project materials from the ice prior to spring break-up.Pitting, Trenching and Surface Stripping

10. Undertake pitting, trenching and surface stripping in a manner that ensures sediment-laden run-off does not enter any water body by using appropriate set-backs from the HWM and other effective sediment and erosion control measures (e.g., direct run-off to vegetated areas away from a water body or to an appropriately located sump, and stabilize any stockpiled material to prevent sediment from entering any water body).Water Withdrawal

11. In order to avoid negative impacts to fish and fish habitat caused by flow alterations, reduction in water levels, or entrainment/impingement at water pump intakes, the following measures are to be incorporated for any water-taking activities: 11.1 Whenever feasible, withdraw water from non-fish bearing water bodies only. 11.1.1. If fish-bearing water bodies cannot be avoided, use only larger streams or lakes and avoid small water bodies. 11.2. Ensure water withdrawal volumes do not impact fish or fish habitat. Withdrawals from fish-bearing waters should not result in any noticeable change in water level or downstream flows, particularly during sensitive life stages (e.g., by dewatering spawning or egg incubation areas). 11.3. For any multiple or simultaneous water withdrawals, consider the cumulative impact of the total withdrawal volume on fish habitat by all water users. 11.4. Ensure water pump intakes are designed and operated in a manner that prevents streambed disturbance and fish mortality.

General Measures12. Maintain an undisturbed natural buffer zone between areas of on-land exploration (e.g., pitting, trenching, or surface stripping) and the HWM of any water body to assist in sediment and erosion control and retention of riparian vegetation.13. Time any in-water mineral exploration activities to prevent disruption to sensitive fish life stages by adhering to appropriate fisheries timing windows (see theNunavut In-Water Construction Timing Windows), with the exception of on-ice drilling (see Measure 9), or any water withdrawal activities (see Measure 11).14. Operate machinery in a manner that minimizes disturbance to the water body bed and banks and prevents entry of deleterious substances into any water body. 14.1. Machinery is to arrive on site in a clean condition and is to be maintained free of fluid leaks. 14.2. Wash, refuel and service machinery and store fuel and other materials for the machinery away from the water, except for projects involving on-ice drilling where appropriate precautions are taken to prevent spills. 14.3. Keep an emergency spill kit on site in case of fluid leaks or spills from machinery.15. Apply appropriate measures, including an emergency contingency plan for inadvertent spills, to ensure that deleterious substances such as drill cuttings, acidic or metal leaching water, petroleum products, sediment, and debris do not enter any water body.16. Install effective sediment and erosion control measures, where appropriate, before starting work to prevent entry of sediment into any water body. Inspect them regularly during the course of the work and make all necessary repairs if any damage or malfunction occurs. 16.1. Ensure that the discharge of any water into or near a water body is done in a manner that prevents sedimentation or erosion (e.g., by stabilizing the discharge site).17. Stabilize and reclaim all disturbed areas upon completion of work. Immediately remove all debris or waste produced or associated with the work.18. Stabilize any waste materials removed from the work site to prevent them from entering any water body. This could include covering spoil piles with biodegradable mats or tarps or planting them with, preferably native, grass or shrubs.19. Vegetate any disturbed areas by planting and seeding preferably with native trees, shrubs or grasses and cover such areas with mulch to prevent erosion and to help seeds germinate. If there is insufficient time remaining in the growing season, the site should be stabilized (e.g., cover exposed areas with biodegradable erosion control blankets to keep the soil in place and prevent erosion) until naturally re-vegetated the following spring. If re-vegetation is not possible due to climatic extremes and/or lack of appropriate seed or stock, the site should be stabilized using effective sediment and erosion control measures. In areas with permafrost, care should be exercised to ensure these measures do not cause thawing or frost heave. 19.1. Maintain effective sediment and erosion control measures until re-vegetation of disturbed areas is achieved or until such areas have been permanently stabilized by other effective sediment and erosion control measures, in the event that re-vegetation is not possible.

Definitions:Small Diameter/Low Density Drilling (for on-ice drilling) small diameter boreholes (8% at Napak. Marbles, usually high in magnesia occur extensively in Moroto and Moyo districts. The marble has a range of shades from pure white, gray to a pink marble.

The major limestone deposits at Hima and Tororo have provided the major raw material for Uganda's Portland cement industry. The old plant at Tororo set up in 1953 has been rehabilitated and expanded by Tororo Cement Industries Ltd to produce 1,000 tons of cement per day. The company has adopted the international standard ISO 9002. The limestone at Tororo has high phosphorous content and hence cement is is manufactured after intensive selective mining. Production of cement is also based on clinker being imported from Japan and India. The company is mining marble in Moroto district, with encouraging results at Katikekile,. Hima's current production is 900 tons per day.

Uses: Limestone is used for making cement and lime both of which are important inputs in the construction industry. Lime is also used as soil conditioner in agriculture (to reduce soil acidity). The main use of marble is as a raw material for marble tiles, but if low in magnesia is also used in making Portland cement, and the white varieties are used to make calcium carbonate powder used in paint and detergents.

Phosphates: Apatite is the main commercial ore of phosphate known in Uganda. The most important occurrences are associated with carbonatites, the two largest being at Sukulu and Bukusu. Weathering of the carbonatites has resulted in the residual concentration of apatite, magnetite, vermiculite, pyrochlore, barite, and zircon and rare earth elements.

The total resource in three valleys at Sukulu is estimated at over 230 million tons, with still further large resources under the laterite mantle. The apatite content is variable, averaging 13.1% P2O5 and can be beneficiated to yield a product containing 40-42% P2O5. The deposit was mined by the Tororo Industrial Chemicals and Fertilizers Ltd. (TICAF). with a 25,000 tons/year single super-phosphate fertilizer plant at Tororo from 1964 to 1978.

Busumbu Ridge though a smaller deposit contains the richest concentration of phosphates in Bukusu. The bulk of the deposit consists of soft apatite-bearing soil, varying from 3 - 25% P2O5. A resource of 8.5 million tons averaging 13% P2O5 has been established. Busumbu Mining Company commenced mining the deposit in 1944, with the concentrate exported to Kenya for conversion to a low priced fertilizer soda phosphate with high citric solubility. It was not suitable to convert the resource to super-phosphate owing to its high alumina and iron contents and production ceased in 1963 when TICAF established their operation to manufacture commercial fertilizers from the soils of Sukulu.

Nilefos Limited, a local company, has acquired an Retention Licence for the Sukulu deposit. The company is seeking for joint venture partners to develop the mines and manufacture phosphate fertilizers and other by-products.

Uses: The major use of apatite is in making of fertilizers. Other uses include making of detergents and chemicals.

Salt: Salt includes salt for human and animal consumption as well as various salts for industrial uses. Salt has been extracted on a small-scale from hot springs at Kibiro in Hoima district and on a larger scale from the floor of crater lakes at Katwe (22 millions of mixed salt) and Kasenyi in Kasese district for many centuries. The salt is a mixture of sodium and potassium chlorides with lesser amounts of sulphate and carbonates. The current method of production is based on solar evaporation in ponds and the product is crude due to mixing of the salts during fractionation and crystallization as well as with mud at the lake bottom.Trona (sodium carbonate) occurs in the three areas, but on a larger scale at Katwe and Kasenyi. It is associated with mixed salts (sodium and potassium chlorides) and gypsum (calcium sulphate). At Katwe there is a resource of approximately 10 million tons of trona with mixed salts.Uses: Sodium chloride is for making of common salt for human consumption, and industrial chemicals; potassium chloride is used making of potassium-based fertilizers; trona is used in glass manufacturing.Vermiculite: Vermiculite is known to occur at Sukulu in Tororo district and Bukusu carbonatite Complex in Mbale district. The main occurrence at Bukusu is on a 10 km long semi-circular ridge (Namekhara, Nakhupa, Surumbusa, Kabatola and Sikusi), where vermiculite flakes occur in residual concentrations (from the leaching of phlogopite in carbonatite) below a surface cover of 3-5 m magnetite rubble. Apart from Namekhara, it is only Kabatola that contains appreciable quantities of vermiculite for exfoliation.

Recent exploration at Namekhara has delineated a resource of approximately 4 million tons of high quality vermiculite, which is probably one of the best known at present in the world. Gulf Resources (U) Ltd is currently mining and processing vermiculite with a planned output of 40,000 tons/year. Previous mining and processing activities were carried out by NPK Resources Ltd, Carmin resources Ltd. of Canada and Rio Tinto of South Africa.

Uses: Vermiculite is used as an insulator, in making fireproof boards, as a replacement of asbestos in brake linings, packaging materials, and lightweight concrete in construction. The poorer grades of vermiculite are used in horticulture (flowers), tea nurseries and golf courses, due to its ability to retain water over long period.

Platinum Group Minerals: Potential exists for platinum group metals (platinum, palladium and rhodium) in layered intrusives in the Archaean greenstone belts and areas with ultrabasic rocks. The high platinum assays of the Nakiloro chromite are indicative of this potential. Values as high as 3.0 - 7.5 grams per ton have been obtained on samples. The geology of the area is similar to the layered intrusives in South Africa, which have large deposits of platinum-group-metals (PGM).

Nickel (?Co, Cu): Potential exists for both primary volcanogenic massive Ni-Cu sulphide and secondary nickeliferous laterite deposits in/over ultramafics within Precambrian greenstone belts, and Lower-Middle Proterozoic sediments, but this has not been fully investigated.

An airborne geophysical survey carried out in 1980 over southern Uganda, and later followed by another similar survey of lower altitude and ground surveys identified magnetic bodies that are favourable for hosting nickel and cobalt in Kafunjo, Ntungamo district and Rugaga in Mbarara district, close to the border with Tanzania. Similar bodies in the same geological environment in Kabanga, Tanzania have been found to contain nickel mineralization.

Diamond: Potential for diamond exists in a number of areas in Uganda. Discovery of the diamonds in gravels occurred during prospecting for gold in Buhweju and a few small diamonds were found at Kibale in 1938 and Butale in 1956. Consequently, exploration for diamonds in the country was carried out in the period 1965-1974. Although no economic deposits were discovered, small diamonds and indicator minerals were discovered in many areas like southern Karamoja region, and Katakwi district. Cresta Mining Co. Ltd carried out exploration for diamonds in the basic volcanics of Kabale and Kisoro districts. Indicator minerals were identified and a follow-up work is recommended. Similarly, the basic volcanics in Bushenyi district are expected to have diamonds.

Rare Earth Elements: Good potential exists for small, irregular deposits of limited tonnage in pegmatites, but this has not been quantified. Potential exists for major deposits - the Sukulu carbonatite contains some rare earth elements, but this has not been fully investigated.2.3. Other Mineral OpportunitiesUranium: IBI Corporations prospective uranium land portfolio is comprised of approximately 2,882 square kilometres, primarily in Uganda. Geophysical interpretation of data from the recent Uganda Aerial Minerals Survey of the country identified uranium mineralization on the Companys uranium lands, with more than 30 uranium anomalies being identified within the area of the Companys approximately 2,047 Km2 Mubende area exploration licenses. With rising values of uranium, it is expected that anticipated demand for uranium for nuclear power generation will exceed projected supply for decades. Investors with technical and financial capability can work with IBI.

Kilembe Mines LtdKilembe Mines Limited (KML) is still under care and maintenance. Government strategy to resume mining has since been divestiture of majority shareholding to private partner who will manage the Company. KML acquired two exploration licenses, surrounding the mining lease to explore and add unto the proven reserves in readying for the resumption of mining. The divestiture of the Company is following set procedures in the divestiture of entities owned by Government of Uganda. As of current, the Transaction Advisor (J.T. Boyyd and PASS Ltd) are at the last stage of enterprise preparation so that implementation of the KML divestiture can begin so that potential companies can bid to acquire majority stake in the company.3. Mineral Sector Outlook3.1. Annual production volume/valueThe Government of Uganda put in place a Mineral Policy in 2001, whose goal is to develop the mineral sector to enable it contribute to sustainable economic and social growth by creating gainful employment and income, particularly to the rural population.

The goals and objectives of MBS MIERALS LTD are to: stimulate investment in the mineral sector by promoting private participation; ensure that mineral wealth supports national economic and social development; regularize and improve artisanal and small scale mining; stimulate and mitigate the adverse social and environmental impacts of mineral exploitation; remove restrictive practices on women participation in the mineral sector and protect children against mining hazards; develop and strengthen local capacity for mineral development; and add value to mineral ores and increase mineral trade.

Uganda currently produces a number of minerals valued at almost Ushs.100 billion. In terms of output value the most produced minerals as of end of 2010 were: limestone, cobalt, Wolfram, Tin, Kaolin and pozzolana. Table 2 lists the types of minerals by output and value.

Table 2: Mineral Production for January to December 2010 compared with 2009 figures

Table 2................................... continued

Source:Department of Geological Survey and Mines

**Average price of gold on LME and average URA monthly fixed exchange rates were used to compute the average value of gold (and other minerals) over the year. **Cobalt prices have been on the low for a long time subsequently resulting in a slump in processing activity at KCCL. However, the figures improved significantly in 2010 compared to 2009 figures.

The Non Tax Revenue generated increased to UGX 3.96 billion in 2010 from UGX 2.75 billion in 2009. In terms of revenue accruing from mineral operations, government earned UGX 2.436 billion, as non tax revenue (NTR) accruing from royalties and mineral license fees. Royalties alone contributed UGX 3.1 billion and UGX 1.701 billion of the total revenue generated shared at a rate of 80% for Central Government, 17% for Local Governments of mining districts and 3% to the lawful landowner. It is worthwhile noting that the major contributors to the revenue earned in 2009 were Tororo Cement Ltd, Hima Cement Ltd and Kasese Cobalt Company Ltd.

Figure 1 shows the revenue Uganda earned from royalties between year 2006 to 2010 which ranged between Ushs.1.8 billion in 2007 and Ushs.3.1billion in 2010. With improvements in the prices for cobalt and gold, the NTR resulting from royalties is expected to rise.3.2. Employment trend in the SectorThe mineral sector is increasingly becoming very important in responding to the labour needs of the country. If one considers artisanal mining, there are currently over 180 artisanal and small scale miners in Uganda providing employment to over 20,000 miners with indirect & induced labour numbering over 54,000. This sector has a multiplier effect of US$28.3/year according to recent studies by artisanal and small scale miners.3.3. Mineral Sector contribution to GDPMining and quarrying activities were estimated to have grown by 12.8 percent in fiscal year (FY) 2009/10 compared to a 4.3 percent increase during the FY2008/09. The growth in the mining and quarrying activities was due to increased demand for limestone, clay and quarry products. The sectors contribution to total GDP, at current prices, has been the lowest since FY2005/06 with a share of only 0.3 percent. Figure 2 compares the GDP growth rates with those of the mining sector over a 5-year period beginning FY2005/06. In the FY2009/10, the mining sector grew above that of the Gross Domestic Product. With a number of companies acquiring mining licences it is expected that the sectors prominence will be felt in the economy in the coming years. Further, the Government of Uganda (GoU) has identified the development of the countrys mineral resources as a major economic priority and has put in place an extensive plan to bring this to fruition. Agencies such as the World Bank, the African Development Fund and the Nordic Development Fund, have provided over US$47 million in funding to GoU to help further these mineral development strategies and initiatives.

4. Key strengths (competitive factors) or unique selling propositions4.1 Strategic location Uganda occupies a strategic position in East Africa, which gives it the advantage for the eventual development of exports of mineral products of Sudan, the Democratic Republic of Congo, Rwanda, Burundi, Kenya and Tanzania and the COMESA region as a whole.4.2 General investment incentivesUnder the Income Tax Act, Cap.340 the mining companies are given special consideration through a Variable Rate Income Tax (VRIT). The rationale for this arrangement is to capture a competitive share of net cash flows for the government at different mine profitability levels while at the same time providing suitable tax relief for projects. A minimum of 25% and a maximum 45% VRIT have been put in place depending on the level of profitability. Also under other tax provisions (like the East African Community Customs Management Act and Value Added Tax Act, Cap.349), there is the duty free importation of mining plant and equipment with VAT deferment facilities.4.3. Other incentives are: Investment protection under the Multilateral Investment Guarantee Agency (MIGA) Mineral exploration expenditures are expensed 100% Import taxes such as customs duty for all mining equipment is zero-rated There is externalisation of dividends and profits Generous depreciation allowance at 30% for all depreciable mining assets.

4.4 Availability of skillsThe Department of Geological Survey and Mines is being funded to undertake surveys aimed at providing the needed database to encourage investment in the sector, as well as the training of relevant personnel. The Department also has a cross section of professional staff that may be seconded on request, to companies wishing to commence new exploration programmes. Makerere University in Kampala offers degree courses in geology and various disciplines of engineering while a number of technicians are trained locally at Kyambogo University and other Technical Institutes spread throughout the country.4.5. Sustainable Management of Mineral Resources Project (SMMRP)The country has 648,400 line kms of magnetic and radiometric, and 22,709 line kms of electromagnetic [EM] data covering the entire country except for the Karamoja region. The data was generated as a result of an airborne geophysical survey undertaken by M/s Fugro Airborne Survey with the latest technology and supervised by Patterson Grant and Watson (PGW) that emphasized provision of very high quality data and outputs. This data is being integrated using GIS, with ground geophysical data, enhanced satellite imagery, geological mapping and geochemical surveys to delineate areas of high mineral resource potential. The information is available to potential investors wishing to have detailed exploration and development of mines. 5. Regulatory Framework/Licenses required for operation in the sector5.1. LicencingThe Mining Act 2003 repealed and replaced the Mining Act 1964, Cap. 248, with a new legislation on mining and mineral development, which conforms, and otherwise gives effect, to the relevant provisions of the Constitution; to vest the ownership and control of all minerals in Uganda in the Government. The Act also provides for the acquisition of mineral rights; and other related matters. Subject to the provisions of this Act, a person may acquire the right to search for, retain, mine and dispose of any mineral in Uganda by acquiring such right under and in accordance with the provisions of this Act.

Licensing for exploration and mining activities follows same procedures. It involves filling of forms available at the office of the Commissioner of the Department of Geological Survey and Mines (DGSM) and submitting them for assessment, paying assessment fees to the bank, getting a Uganda Revenue Authority (URA) receipt invoice, and then submitting it to the Commissioner for granting the license. 5.2. Types of Licenses and Mineral RightsIn order to operationalize the Mineral Policy, a new legislation, Mining Act, 2003 was enacted and appropriate regulations (The Mining Regulations 2004) were gazetted thereby replacing the Act of 1964 which was out-dated in many respects. The provisions in the new Act conform to the contemporary industry conditions and practices. They include: Prospecting Licence - the licence is granted to the holder to prospect for minerals around the country and the licence is non-exclusive. It is granted for one year and is not renewable. Exploration Licence - the licence area is to a maximum of 500 sq. km and duration of 3 years, renewable for two terms of 2 years each. On each renewal, half the area is relinquished. Retention Licence - the licence is a new feature in the law. It is granted to the holder of an exploration licence in cases when the identified mineral deposit cannot be exploited due to economic reasons. Its duration is 3 years, renewable once for 2 years. Mining Lease - the licence is for mining operations and is granted for 21 years and is renewable for 15 years. Location Licence the licence is for mining operations of a smaller investment where expenditure to achieve production will not exceed 500 currency points (a currency point is worth 20,000 Uganda shillings). It is granted to citizens of Uganda or in case of corporate, only where citizens of Uganda hold at least 51% of ownership. Its duration is 2 years, renewable for other terms of 2 years each.

5.3. Aspects/conditions to observe while acquiring licences/mineral rights Royalties - All minerals obtained from any mineral right are subjected to royalty payment for example: precious stones - 5% of the gross value, precious metals - 3% of the gross value, base metals and ores - 3% of the gross value, and industrial minerals vary from 500 to 3000 Uganda shillings per tonne. Adequate Compensation - the law provides for fair compensation upon disturbance of surface rights of landowner or lawful occupier. Mineral Agreements the law provides that the investor and government sign agreements relating to operations in order to stabilize legal, social and economic obligations of either party. Environment - the law has provisions on environment protection peculiar to mining operations.

5.4. Role of the Geological Survey and Mines Department (GSMD)The GSMD is the technical arm of MEMD and directly responsible for the implementation of the mineral policy. The duties include inter alia carrying out administration, supervising, regulating, monitoring, enforcing, training, providing extension services (collect, collate, process, analyse, archive and disseminate geoscience data) and promoting other sectoral activities.5.5. Mineral Regulations, 2004 (www.mining.co.ug )These regulations operationalise the Mining Act. They contain procedures/application forms for acquiring the various licences like: prospecting, exploration, retention, location, mining lease, export/movement permits, mineral dealers license, Goldsmiths license, certificate of amalgamation of location/mining lease, certificate of cessation/suspension/curtailment of working obligations, among others. Applications for these licenses are made to the Commissioner, GSMD and in many instances through the Office of Chief Administrative Officer at the district level.5.6. Other Laws:Other important laws enacted by the Government of Uganda that affect mining and exploration, besides the Mining Act 2003 and Mining Regulations 2004, include: The National Environment Act 2003 The Land Act 1998 (currently under revision) The Land Regulations Act 2004 Registration of Titles Act 2000 Contracts Act 2000 The Arbitration and Conciliation Act 20006. Mineral Exports/ImportsUnder section 117 of the Act, the Commissioner may grant to any person an import permit to import minerals into Uganda on conditions prescribed by law and any such person shall make a declaration before a customs officer regarding the type and quantity of minerals imported, after which the customs officer shall certify the import permit.

An import permit is issued only on payment of the prescribed fee and before any minerals are re-exported from Uganda, the relevant import permit is then surrendered to a customs officer who submits it to the Ministry of Energy and Mineral Development. Similarly, under section 116 of the Act, the Commissioner may also grant to any person an export/movement permit for exporting minerals outside Uganda.

The importation of minerals for re-export explains why in most cases the amount produced in tonnes is much less than that of the exports for some commodities e.g. gold on the one side and on the flip side the amount exported is less than that produced for some commodities such as cobalt due to stockpiling as global commodity prices plunge. The decline in production coupled with fluctuating market rates for minerals consequentially affected the mineral exports, showing a decline in export value since 2006.

Figure 3 shows the trend of mineral export for gold and cobalt between 2005 and 2009. The year 2006 witnessed the highest value of exports mainly attributed to gold re-exports. Currently, gold and cobalt account for over 95% of all minerals exports from Uganda. The escalating values of gold, along with the accompanying investor interest, have grown in the recent past and, in all likelihood, will continue. As noted by Barrick Gold, the supply of gold continues to lag demand, making the exploration and development of new gold resource sources imperative and Uganda will reap big from these developments.For cobalt, refined global production was around 54,000 tonnes in 2009, with consumption at about 52,000 tonnes. Many reports estimated that 2009 saw a global surplus of some 2,460 tonnes, compared with a deficit of about 2,410 tonnes in 2008. In 2010, worldwide production was between 55,000-60,000 tonnes, yet demand peaked only 50,000 tonnes. In terms of prices, the best Russian cobalt, 99.3 currently trades above US$20 a lb which is still way off peaks of over US$48 a lb hit in March 2008 before the global economic slump was felt. All these reasons explain the cobalt stockpile in Uganda.

In terms of major exports destinations, in 2010 the following minerals were exported as follows: Cobalt (Netherlands, China and

Belgium); Semi manufactured gold and articles of zinc (United Arab Emirates); Copper (U.K., UAE, Kenya, India, U.K., South Africa, Tanzania,); Articles of tantalum (U.K.); and articles of goldsmith (Germany).Generally, investment in mineral exploration is projected to increase from the current US$3 million to over US$50 million annually over the next five years. Fiscal revenues are expected to increase from US$ 1 million to US$ 35 million over the next five years. It is

also projected that the value of mineral exports will increase from the current level of under US$40 million to over US$ 350 million by 2015.

The importation of minerals for re-export explains why in most cases the amount produced in tonnes is much less than that of the exports for some commodities e.g. gold on the one side and on the flip side the amount exported is less than that produced for some commodities such as cobalt due to stockpiling as the global commodity prices plunge. The importation of minerals for re-export explains why in most cases the amount produced in tonnes is much less than that of the exports for some commodities e.g. gold on the one side and on the flip side the amount exported is less than that produced for some commodities such as cobalt due to stockpiling as the global commodity prices plunge.

Mineral imports have been steadily rising from about US$11 million in 2005 to US$25 million by end of 2009. Figure 4 shows the trend of import from 2005-2009. Gold is the major import. Uganda also imports some rough diamond to the tune of US$150,000 annually.7. Key Investors in the sector, ExamplesA number of exploration and mining concessions were granted, renewed or expired. By the end of 2010, there were 611 mining licenses issued to companies. Below are examples of some of the big companies holding mining licenses: Hima Cement Ltd for mining limestone and purchasing of pozzolanic materials in Kasese and Kabarole districts. The company holds mineral dealers license in base metals as well as in non-metallic (industrial/ building) minerals, with UGX 803,858,662/-earned as NTR in 2009. Tororo Cement Ltd for mining and exploration of limestone and pozzolanic materials in Tororo, Moroto, Mbale and Kapchorwa districts, with UGX 803,213,035/- earned as NTR in 2009. Kasese Cobalt Company Ltd continued with production of cobalt and the running of a sub-lease for limestone quarrying at Hima, with UGX 428,373,155/- earned as NTR in 2009. African Mineral Fields Limited for exploration for gold, platinum group of metals (PGM), and base metals in Ntungamo, Mukono, Kamwenge, Bushenyi, and Mbarara districts. Vangold Resources Limited, acquired seven non producing artisan beryllium mines and secured nine joint ventures with exploration licenses holders including Rwenzori Copper and Nickel, Beryllium Exploration Limited, Dome Mines Limited adjacent to the Kilembe copper Cobalt. AUC Mining Company which is developing a gold mine at Kamalenge in Mubende District. In early 2006, IBI Corporation, (IBI TSX-V) made a decision to change its strategy from being a single industrial minerals company successfully mining and globally marketing vermiculite, to become a high-value minerals exploration and development company, focused on Uganda. Subsequently, IBI sold its Namekara Uganda Vermiculite Mine to mining giant Rio Tinto for US $5 million in March 2007, with final closing in March of 2008. The Companys strategic mission in Uganda is now twofold: exploration for and development of potential uranium resources and investing in promising gold opportunities.8. Investment trends in the mining sector 8.1. Licenses IssuedThe Government of Uganda has identified the development of the countrys mineral resources as a major economic priority and has in place an extensive plan to bring this to fruition. Investment in mineral exploration is projected to increase from the current US$3 million to over US$50 million annually over the next five years.

At the beginning of 2010, a total of 517 licenses issued. Of these 99 Prospecting License (PL), 66 Exploration License (EL), 32 Location License (LL), 33 Mineral Dealers

License (MDL), 2 Blasters Certificate (BL) and 2 Goldsmiths License (GL) were granted, while 15 Exploration (ELs), and 5 Location Licenses (LLs) were renewed. Figure 3 shows the trend of licenses issued between 1999 and 2010 where the numbers grew from 66 licenses in 1999 to 517 in 2010, an impressive growth.8.2. Airborne Geophysical DataThe rise in the number of licenses issued is attributed to the proper dissemination of geophysical data. As of end of 2009, a number of companies had accessed this data as depicted in Table 3. Appendix2 also gives a list of other companies that are active in the mineral sector in Uganda.Table 3: List of Companies that acquired Airborne Geophysical Data in 2009

Source: MEMD, Annual report 2009/10

Appendix 2: Companies with significant mining operations in Uganda

Source: Department of Geological Surveys and Mines

Appendix 3: Map Showing Mineral Occurrences in Uganda

Source: Department Geological Survey and Mines

Appendix 4: Mineral Royalties by Contributing Mining Companies, 2010

Source: Department of Geological Survey and Mines

2.0 Rock Mechanics

2.1 Introduction

Chapter 2 is primarily concerned with underground mining. The application of rock mechanics to open pits (slope stability) is not pursued.Mining is defined as the art of working mines and a mine is defined as an excavation out of which minerals are dug. The latter definition is not complete. Implicit in the word mine is the need to insure that the mine excavation (or excavation cavity) is safe to work in.

The miner wants to plan development and mining so that the adverse effects of rock failure will be minimized. This is the place for rock mechanics, the science that studies the strength and failure characteristics of rocks.

The early approach to rock mechanics was to treat rock as an elastic body, not unlike the way civil engineers treat concrete. The elementary concept is that a unit of rock underground is stressed by the weight of rock above it and constrained by other rock around it, thus inducing a horizontal stress, which is a function of Poissons ratio.

The subsequent study of rock masses and the effects of geology has produced more realistic concepts to which the irregular geometry of an orebody gives challenge.Alex Ignatieff 1970Routine rock mechanics may be used to design temporary and permanent ground support designs in elastic or quasi-elastic ground (i.e. hard rock). Nevertheless, such systems fail as the condition of the rock mass approaches the Yield State in which condition plastic or viscous response components become dominant and any design based on or extrapolated from elastic behavior is void.

John D. Morton 1990

That rock is elastic can be demonstrated by bending a long length of drill core it will bend and (provided you dont break it) will spring back to its original position. Because of this elastic behavior, we can (as a first approximation) determine the stresses and strains around a mining excavation using the theory of elasticity; however, the properties of hard rocks are greatly altered by the inevitable presence of joints, laminations, geological contacts and other discontinuities. Although the individual solid blocks of rock can have considerable strength, the presence of the discontinuities reduces the strength of the overall rockmass. This reduction of strength and elastic properties must be accounted for in carrying out numerical modeling of a real mining geometry.

The situation is often further complicated by the fact that the integrity of a typical underground hard rock mine and the facility to safely mine within it, may rely on a structural (cemented) backfill which may not always behave elastically. Dynamic behavior is also possible, since deep hard rock mines (and even some that are shallow) can experience rockbursts caused by elastic instability. In spite of all these complications, three-dimensional numerical modeling has advanced to the stage where the elastic and post-failure inelastic behavior of the rock and ore in a typical deep hard rock mine can be modeled with a reasonable degree of confidence.

2.2 Rules of Thumb

Ground Stress

The vertical stress may be calculated on the basis of depth of overburden with an accuracy of 20%. This is sufficient for engineering purposes. Source: Z.T. Bieniawski

Discs occur in the core of diamond drill holes when the radial ground stresses are in excess of half the compressive rock strength. Source: Obert and Stephenson

The width of the zone of relaxed stress around a circular shaft that is sunk by a drill and blast method is approximately equal to one-third the radius of the shaft excavation. Source: J. F. Abel

Ground Control

The length of a rock bolt should be one-half to one-third the heading width. Mont Blanc Tunnel Rule (c.1965)

In hard rock mining, the ratio of bolt length to pattern spacing is normally 1:1. In fractured rock, it should be at least 2:1. (In civil tunnels and coalmines, it is typically 2:1.) Source: Lang and Bischoff (1982)

H A R D R O C K M I N E R S H A N D B O O K

Ground Control (continued)

In mining, the bolt length/bolt spacing ratio is acceptable between 1.2:1 and 1.5:1. Source: Z.T. Bieniawski(1992)

In good ground, the length of a roof bolt can be one-third of the span. The length of a wall bolt can be one-fifth of the wall height. The pattern spacing may be obtained by dividing the rock bolt length by one and one-half. Source: Mike Gray (1999)

The tension developed in a mechanical rock bolt is increased by approximately 40 Lbs. for each one foot-Lb. increment of torque applied to it. Source: Lewis and Clarke

A mechanical rock bolt installed at 30 degrees off the perpendicular may provide only 25% of the tension produced by a bolt equally torqued that is perpendicular to the rock face, unless a spherical washer is employed. Source: MAPAO

For each foot of friction bolt (split-set) installed, there is 1 ton of anchorage. Source: MAPAO

The shear strength (dowel strength) of a rock bolt may be assumed equal to one-half its tensile strength.Source: P. M. Dight

The thickness of the beam (zone of uniform compression) in the back of a bolted heading is approximately equal to the rock bolt length minus the spacing between them. Source: T.A. Lang

Holes drilled for resin bolts should be inch larger in diameter than the bolt. If it is increased to 3/8 inch, the pull out load is not affected but the stiffness of the bolt/resin assembly is lowered by more than 80%, besides wasting money on unnecessary resin. Source: Dr. Pierre Choquette

Holes drilled for cement-grouted bolts should be to 1 inch larger in diameter than the bolt. The larger gap is especially desired in weak ground to increase the bonding area. Source: Dr. Pierre Choquette