MBE growth of a novel chalcopyrite-type ternary compound MnGeP 2

description

Transcript of MBE growth of a novel chalcopyrite-type ternary compound MnGeP 2

-

MBE growth of a novel chalcopyrite-type ternary compound MnGeP2K. Sato, T. Ishibashi, K. Minami, H. Yuasa. J. Jogo, T. Nagatsuka, A. Mizusawa, Y. Kangawa and A. Koukitu Tokyo University of Agriculture and Technology, View from City Park, Denver

ICTMC14, Denver, Oct. 1, 2004

-

Scope of this talkSummary of previous studies of chalcopyrite type magnetic semiconductorsResults of in-situ photoelectron spectroscopySuggested existence of chalcopyrite MnGeP2Thermodynamic analysisMOMBE growth of MnGeP2Magnetic and magneto-optical characterization

ICTMC14, Denver, Oct. 1, 2004

-

Brief summary of previous studies of chalcopyrite type magnetic semiconductorsWe have been working with Mn-substituted chalcopyrite type semiconductors CdGeP2 and ZnGeP2, in which we have confirmed ferromagnetic behavior up to 423 K and 350 K, respectively. Magneto-optical effect was also observed.These samples were obtained by deposition and subsequent diffusion of Mn to bulk single crystals of ternary compounds.Theoretical calculation suggests that CdGeP2 system with vacancies or non-stoichiometric composition will lead to ferromagnetism although ferromagnetism is not favored in stoichiometric (Cd, Mn)GeP2.

ICTMC14, Denver, Oct. 1, 2004

-

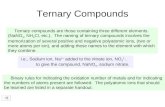

II-IV-V2 chalcopyrites

a()c()Tm(C)Eg(eV)no, nen, pZnSiP25.39910.43513702.96~3.1260, 11ZnSiAs25.60610.89010962.123.355, 3.39240, 170ZnGeP25.46510.77110252.343.248, 3.295- , 20ZnGeAs25.67211.1538501.15~3.38- , 23ZnSnP25.65111.3029301.66~3.21- , 55ZnSnAs25.85211.7057750.73~3.53- , 190CdSiP25.67810.43111202.45~2.95150, 90CdSiAs25.88410.8828501.55~3.22- , 500CdGeP25.74110.7757901.723.356, 3.3901500,80CdGeAs25.94311.2176700.573.565, 3.6784000,1500CdSnP25.90011.5185701.17~3.142000,150CdSnAs26.09411.9185960.26~3.4611000,190

ICTMC14, Denver, Oct. 1, 2004

-

Previous preparation methodMn was deposited on single crystals of CdGeP2 and ZnGeP2 at Tsub400C, by which Mn was diffused into the bulk to substitute group II and IV cations. During growth RHEED pattern of chalcopyrite structure seems sustainedMn-diffused crystals show ferromagnetism above room temperature.

ICTMC14, Denver, Oct. 1, 2004

-

Preparation of Mn-doped chalcopyritesHost crystal: CdGeP2, ZnGeP2Mn depositionTsub=RT to 380-400CMn diffusion@T=300-500C

ICTMC14, Denver, Oct. 1, 2004

-

RHEED patterns during Mn deositionTepmerature of Deposition is important to keep CH structure

ICTMC14, Denver, Oct. 1, 2004

-

XRD of ZnGeP2:Mn by RINT RAPIDRing: Unident ified phase (not MnP)Chalcopyrite spot

ICTMC14, Denver, Oct. 1, 2004

-

Magnetization Curves at RTHc~0.4kOe, Hs~2kOe for in-plane magnetizationMs=3.510-4emu, if all 30nm Mn atoms are incorporated V=3mm5mm0.03m=4.510-7cm3 0.95610-20 emu/atomgS=1.03 1.03B (S=1/2)

ICTMC14, Denver, Oct. 1, 2004

-

Temperature-dependence of magnetization at H=0Tc=320K

ICTMC14, Denver, Oct. 1, 2004

-

CdGeP2-MnMagnetization (VSM)77K287K423KK.Sato et al.: J.Phys.Chem.Solids64(2003)1461

ICTMC14, Denver, Oct. 1, 2004

-

ZnGeP2-MnMagnetization (SQUID)K.Sato, G.Medvedkin, T. Ishibashi: J.Cryst. Growth 236 (2002) 6095K150K350K

ICTMC14, Denver, Oct. 1, 2004

-

Origin of Ferromagnetism?It seems two ferromagnetic components are mixed, one with Tc~320K and the other with Tc higher than 400K.

ICTMC14, Denver, Oct. 1, 2004

-

Magneto-Optical Kerr EffectK. Sato et al.: J. Magn. Soc. Jpn. 25 (2001) 283.

ICTMC14, Denver, Oct. 1, 2004

-

ProblemsInhomogeneous depth profile of Mn obtained by the deposition-diffusion technique.Electrical properties of the surface shows a metallic behavior.Preparation of homogeneously Mn-doped layer is necessary. Effort to obtain CdGeP2:Mn thin films by MBE

ICTMC14, Denver, Oct. 1, 2004

-

Careful preparation necessarySynthesis of bulk or powder CdGeP2:Mn from constituent elements was tried. However, it was difficult to prevent formation of second phase compounds.In bulk ZnGeP2:Mn prepared at elevated temperature (T>550C), room-temperature ferromagnetism is suspected as due to MnP precipitated in the material. Careful preparation of films with homogeneous distribution of Mn is strongly required.

ICTMC14, Denver, Oct. 1, 2004

-

Magnetic properties of bulk ZnMnGeP2Preparation by solid state reaction of Zn+Ge+Mn+P at max 1130CAntiferromagnetism below 47KFerromagnetism between 47 and 312KMT curveMH curveMn3%MH curve Mn5.6%Cho et al. Phys. Rev. Lett. 88 (2002)257203

ICTMC14, Denver, Oct. 1, 2004

-

NMR studies in ZnMnGeP2Very small amount of MnP phase that cannot be found by XRD was detected by NMR in polycrystalline ZnMnGeP2 material prepared by the same method as did by Cho.Hwang et al.: Appl. Phys. Lett. 83 (2003) 1809ZnMnGeP2 Mn15%Mixture of ZnGeP2 and MnP

ICTMC14, Denver, Oct. 1, 2004

-

Inhomogeneous depth profile of Mn in CdGeP2:MnMedvedkin et al.:JJAP 39 (2000) L949

ICTMC14, Denver, Oct. 1, 2004

-

In-situ photoelectron spectroscopyPhotoelectron spectrometer with MBE systemWith Ar-ion etching deviceSynchrotron radiation: Photon Factory BL-18ASpecimen: ZnGeP2single crystal, polished and etchedDeposit Mn and interrupt to measure PESAfter deposition of 50nm Mn, sputter-etched by Ar-ion and at each stage PES was measuredIshida et al. Phys. Rev. Lett. 91 (2003) 107202

ICTMC14, Denver, Oct. 1, 2004

-

In-situ Photoemission Apparatus at Photon Factory BL-18A

ICTMC14, Denver, Oct. 1, 2004

-

PES during depositionstartendZnGeP2:MnMnGeP2Zn signalMn signal

ICTMC14, Denver, Oct. 1, 2004

-

Core signal intensity during deposition

ICTMC14, Denver, Oct. 1, 2004

-

PES during sputterT = 400 Cd = 250Binding energy (eV)Intensity (arbitrary units)Mg KaStart sputterEndsputter

ICTMC14, Denver, Oct. 1, 2004

-

Sputtering time dependence of Mn 3p - 3d resonance photoemission structure

ICTMC14, Denver, Oct. 1, 2004

-

Core signal intensity during sputteringMnGeZn

ICTMC14, Denver, Oct. 1, 2004

-

M-H and M-T curves of Mn-deposited ZnGeP2 crystal at 400M-H curves at T=10 and 330 K upper: before sputter-etching lower: after 200 min sputterM-T curves in the sputtering series

ICTMC14, Denver, Oct. 1, 2004

-

Suggested existence of chalcopyrite MnGeP2Photoemission The surface composition is MnGeP2 RHEED pattern of initial chalcopyrite structure remained during growthIs chalcopyrite-type MnGeP2 really exist?

ICTMC14, Denver, Oct. 1, 2004

-

Two approaches for obtaining II1-xMnxGeP2 thin filmFound very difficult

ICTMC14, Denver, Oct. 1, 2004

-

Thermodynamic analysis for MBE growth of MnGeP2To know whether MnGeP2 can be obtained as a stable compound using the MBE technique, thermodynamic analysis is performed.

ICTMC14, Denver, Oct. 1, 2004

-

Driving force for depositionIn the thermodynamic analysis, we used parameters of driving force for deposition P, Input partial pressure, P0, and equilibrium partial pressure at vapor-solid interface, P. Here, driving force for deposition P is the difference between input partial pressure and equilibrium partial pressure :P=P0-P; where P0 is input partial pressure, and P equilibrium partial pressureUsing these parameters, we can obtain Input mole ratio, RMn, and solid composition, x, as follows:

ICTMC14, Denver, Oct. 1, 2004

-

Driving force for deposition, PXP: Equilibrium partial pressureP0: Input partial pressureDriving force for deposition, P

ICTMC14, Denver, Oct. 1, 2004

-

MBEMn(g)+1/2 P2(g) = MnP(s)Ge(g)+1/2 P2(g) = GeP(s)Conservation constraintsPMn+Ge0-PMn+Ge= 2(PP20-PP2)Pi = PMn+PGe+PP2Equilibrium equation for reaction

Here, we assume P2 molecule as a group-V source, because more than 80% of TBP is cracked and changed to P2 rather than P4 at 813C. using these equations equilibrium partial pressure, which is unknoun parameter, is calculated.

ICTMC14, Denver, Oct. 1, 2004

-

Ab-initio calculation of enthalpy of mixing Enthalpy of mixingHm Hm=EMnGeP-{xEMnP+(1-x)EGeP}Interaction parameter = Hm/x(1-x)Solid composition x x= PMn/(PMn+ PGe) vs Input molar ratio of Mn RMn=P0Mn/(P0Mn+P0Ge)Ab initio calculations using DMOL3 code

ICTMC14, Denver, Oct. 1, 2004

-

Enthalpy of Mixing in (Mn,Ge)P as a Function of Solid CompositionThe function, Hm, is estimated from the ab initio total energy calculations for structure models. (ZB)(ZB)

ICTMC14, Denver, Oct. 1, 2004

-

Calculated Enthalpy of MixingIt is found, in the graph, that enthalpy of mixing has negative value.This is because the chalcopyrite structure with x=0.5 becomes stable compared with random alloy

ICTMC14, Denver, Oct. 1, 2004

-

Interaction parameter W=DHm/x(1-x)From the calculated enthalpy of mixing, Hm, we estimated interaction parameter, W, to be 3044x-33726 [cal/mol]. Using this function, we carried out the thermo-dynamic analyses and examined the relationships between input mole ratio and solid composition.

ICTMC14, Denver, Oct. 1, 2004

-

Vapor/solid distribution relationshipHere, the thermodynamic calculations were performed under the following conditions;PMn0+PGe0=1.0x10-7 torrPP20=2.0x10-7 torrIt is found, in the graph, that small input mole ratio is required to make MnGeP2 at higher temperatures. This is because that Mn-P bond is easily formed compared with Ge-P bond.

ICTMC14, Denver, Oct. 1, 2004

-

MOMBE growth of MnGeP2We applied MOMBE technique to obtain MnGeP2 films on GaAs substrate.Mn and Ge are supplied from solid state source using K-cellsAs P source, TBP (tertiary butyl phosphine) MO source is employed.TBP is cracked to form P2 using cracking cell at 813 C

ICTMC14, Denver, Oct. 1, 2004

-

MBE apparatusMn, Ge: solid source K-cellP: gas source cracking cell at 813C

ICTMC14, Denver, Oct. 1, 2004

-

Illustration of MBE apparatus

ICTMC14, Denver, Oct. 1, 2004

-

Cracking of TBPBeam et al.: J. Cryst. Growth 116 (92) 436

ICTMC14, Denver, Oct. 1, 2004

-

Growth condition on GaAs (001)

ICTMC14, Denver, Oct. 1, 2004

-

XRD in the Films grown on GaAs

ICTMC14, Denver, Oct. 1, 2004

-

Reciprocal lattice mappingMnGeP2/GaAssample#3Diffraction spots from theMnGeP2 deviates slightlyfrom that of substrate

ICTMC14, Denver, Oct. 1, 2004

-

Growth condition on InP (001)

ICTMC14, Denver, Oct. 1, 2004

-

XRD in the Films grown on InP

ICTMC14, Denver, Oct. 1, 2004

-

MnGeP2/InP(001)

ICTMC14, Denver, Oct. 1, 2004

-

Reciprocal lattice mappingInP 004InP 115MnGeP2 008MnGeP2 11 10MnGeP2 116InP 113MnGeP2/InPsample#8InP 004MnGeP2 008InP 115

ICTMC14, Denver, Oct. 1, 2004

-

Lattice constants of MnGeP2Zhao et al, Phys. Rev. B.63(2001) 201202(R)Cho et al., Sol. St. Commun. 129 2004 609

ICTMC14, Denver, Oct. 1, 2004

-

Lattice constants* Yu-Jun Zhao, et al. : Phys. Rev. B . 63 (2001), 201202(R)** Sunglae Cho, et al. : Solid State Commun . 1292004609-613

ICTMC14, Denver, Oct. 1, 2004

-

Magnetization of MnGeP2/InPMagnetic properties in MnGeP2/InP(001) (sample #6) , (a) M-H curves at 30 K, 295 K, 350 K, and (b) an M-T curve measured at remanence.Measured at Tohoku University

ICTMC14, Denver, Oct. 1, 2004

-

RHEED during growth of MnGeP2/InPInP[110]azimuthSEM observationThree dimensional island growth is obvious

ICTMC14, Denver, Oct. 1, 2004

-

Introduction of buffer layerIn order to achieve 2D growth of MnGeP2 film on GaAs(001),we have introduced a buffer layer and investigated its effect.

ICTMC14, Denver, Oct. 1, 2004

-

Why Ge is employed as a buffer?II-Ge-V2 chalcopyrites tend to form solid solution with Ge.Lattice matchEasy introduction

Borshchevskii, A.S., Goryunova, N.A., Kesamanly, F.P.,and Nasledov, D.N., Phys. Status Solidi 21, 9 (1967).

ICTMC14, Denver, Oct. 1, 2004

-

Growth conditions

ICTMC14, Denver, Oct. 1, 2004

-

RHEED patternGaAs Sub.MnGeP2~1 nmAzimuth GaAs[110]Ge bufferlayerMnGeP2~15 nmMnGeP2/GaAsMnGeP2/Ge/GaAs#1#2

ICTMC14, Denver, Oct. 1, 2004

-

Effect of Ge buffer

ICTMC14, Denver, Oct. 1, 2004

-

2- XRD curveInP 002InP 004GaAs 002GaAs 004MnGeP2CuKbCuKbMnGeP2/InP(001)#2ref.MnGeP2/Ge/GaAs

ICTMC14, Denver, Oct. 1, 2004

-

Magnetic and magneto-optical characterizationMagnetic measurement by SQUID magnetometerMagneto-optical Kerr spectra using PEM

ICTMC14, Denver, Oct. 1, 2004

-

Magnetization in MnGeP2/Ge/GaAs

Magnetic properties of MnGeP2 /Ge/GaAs (sample #10)film; (a) M-H, (b) M-T curves measured with H=100 Oe.Measured at Univ. Tokyo

ICTMC14, Denver, Oct. 1, 2004

-

Magneto-optical spectrometer

ICTMC14, Denver, Oct. 1, 2004

-

MO spectra in MnGeP2 and MnP

ICTMC14, Denver, Oct. 1, 2004

-

Conclusion (1)We have studied the growth of ternary MnGeP2 films on GaAs(001) and InP(001) substrates.It is found that in order to suppress secondary phases and to obtain a MnGeP2, following conditions were required; i) Low growth rate (~0.01nm/s). ii) Excess P2 flow late relative to the flux of metals. iii) Growth temperature ~435C.

ICTMC14, Denver, Oct. 1, 2004

-

Conclusion (2)Introduction of Ge-buffer drastically improves surface morphologyLattice constants were estimated a=5.693 , c=11.303, assuming chalcopyrite structure.Ferromagnetic properties appeared at room temperature, Tc being 320K. Magnetic moment is as small as 0.1B/Mn atomWell-defined magneto-optical effect is observed, the peak Kerr rotation being as small as 0.04 at room temperature.

ICTMC14, Denver, Oct. 1, 2004

-

Acknowledgment

This work has been carried out under the 21st Century COEprogram on Future Nano-Material of TUAT and supported in part by the Grant-in-Aid for Scientific Research(A) We are thankful to Sumitomo Electric Industries, Ltd. forsupplying GaAs substrates.

ICTMC14, Denver, Oct. 1, 2004

There are two approach to make (Cd, Mn)GeP2. One of them is add Mn to CdGeP2 matrix, and another is add Cd to MnGeP2 matrix. Here, we consider latter case, and carried out thermodynamic analyses to obtain MnGeP2 matrix.

In the thermodynamic analysis, we used these parameters of Driving force for deposition, DP, Input partial pressure, P0, and equilibrium partial pressure at vapor-solid interface, P. Here, driving force for deposition is the difference between input partial pressure and equilibrium partial pressure. Using these parameters, we can obtain Input mole ratio, RMn, and solid composition, x, as follows.

In the present study, we consider these reactions in MOMBE. Here, we assume P2 molecule as a group-V source, because more than 80% of TBP is cracked and changed to P2 at 813 C instead of P4. Followings are the conservation constraints and equilibrium equation for these reaction, and using these equation we calculate equilibrium partial pressure, which is unknoun parameter, and examine relationship between input mole ratio, RMn, and solid composition, x.

Here, aMnP and aGeP are the activity as a function of interaction parameter, omega. In the present study, we estimated enthalpy of mixing, DHm, for (Mn,Ge)P using ab initio calculation to obtain interaction parameter, omega. This view graph shows the solid composition as a function of input Mn mole ratio. Here, the thermodynamic calculations were performed under the following conditions; PMn0+PGe0=1E-7

It is found, in the graph, that small input mole ratio is required to make MnGeP2 at higher temperatures. This is because that Mn-P bond is easily formed compared with Ge-P bond. The results agree with the experimental results, qualitatively. (???)

Furthermore, the results imply that the thermodynamic analisis is a powefull method to get the informations to control the composition of the materials.

Now, we perform the thermodynamic analyses for CdGeP2 in order to make (Cd,Mn)GeP2.