Material Equipment Checklist

-

Upload

noteasytobeboo -

Category

Documents

-

view

217 -

download

0

description

Transcript of Material Equipment Checklist

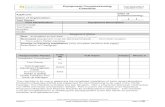

Material balance equipment Checklist:

1. Silo2. Oven drier3. Roll Crusher4. Mixing tank5. Wet ball mill6. Digester7. Double pipe heat exchanger8. Holding tank for sodium aluminate liquor (with high impurities)9. Indirect flash cooler (2)10. Wet cyclone11. Settling chamber12. Filter press13. Holding tank for sodium aluminate liquor (with low impurities)14. Crystallizer15. Hydrate tank for aluminum trihydrate16. Washer (1st stage)17. Rotary vacuum filter (1st stage)18. Washer(2nd stage)19. Rotary vacuum filter (2nd stage)20. Rotary kiln

Energy balance equipment checklist:

1. Oven driera. Power requirement

2. Roll crushera. Power requirement

3. Ball milla. Power requirement

4. Double pipe heat exchangera. Heat requirementb. Mass of utility required

5. Digestera. Heat requirementb. Mass of utility required

6. Indirect flash cooler (1st stage)a. Coolant required to lower temperature

7. Indirect flash cooler (2nd stage)a. Coolant required to lower temperature

8. Crystallizera. Coolant required to lower temperature

9. Washer(1st stage)a. Heat of solution

10. Washer (2nd stage)a. Heat of solution

11. Rotary kilna. Heat requirementb. Mass of fuel required