Marlow 1.5 tech brief SUBBED NEW SH-March10 Table Final€¦ · Dyneema® SK78 and SK99 to Vectran...

Transcript of Marlow 1.5 tech brief SUBBED NEW SH-March10 Table Final€¦ · Dyneema® SK78 and SK99 to Vectran...

Brought to you in association with

36 SEAHORSE

has carved a niche for itself as the ultimate performancecore material.

• DM20 has slightly lower tenacity than SK78, but has onemajor advantage in that it exhibits virtually zero creep. Usedmainly for static load applications such as standing rigging.Another area of confusion can be heat-setting and pre-

stretching. Every Marlow D12 Dyneema® core is pre-stretchedto reduce ‘bedding-in’ elongation, limit the amount of elasticelongation and improve rope strength. Pre-stretching involvesthe application of heat during the process and is sometimesknown as heat-setting, although simply applying heat does nothave the same effect. Marlow have now been pre-stretchingDyneema® cores for over 25 years and that experience meanswe know exactly how to improve a rope’s performance withoutcompromising flexibility or damaging the fibre.

Marlow’s MAX Technology takes pre-stretching to a newlevel by using a precisely controlled process to takeDyneema® to the limits of heat and load during the Pre-Stretching process – it could be called ‘Super Pre-Stretching’.D12 MAX ropes were introduced to offer the ultimate instrength realisation from Dyneema® and to virtually eliminateelastic and ‘bedding-in’ elongation.

D12 MAX ropes are stronger size for size than standardD12 – the MAX process packs more Dyneema® into the samediameter, hence the extra strength. However, D12 MAX ropes are stiffer and harder than the standard pre-stretchedD12 ropes.

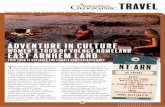

The graphs (opposite) show the relative elongation ofDyneema® SK78 and SK99 to Vectran and Zylon.

When elongation is measured as a % of break load (Fig. 2,middle), it is shown that while PBO offers the lowestelongation followed by Dyneema® in D12 MAX and then D12,there is no differential between SK78 and SK99.

However, when elongation is measured at a given load (for

example, 4,000kg), which is more relevant tospecifying rope for onboard applications (Fig. 1, top), the advantages of SK99 overSK78 in terms of elongation are clear. This isbecause the rope is working at a lowerpercentage of its break load.

Dyneema® exhibits creep, and it is important tounderstand how this affects a rope’s elongationcharacteristics. Creep can often have a negative effect on arope’s performance and strength, when ropes are subjected tohigh loads for extended periods. The extension over timegraph (Fig. 3, bottom) shows how Dyneema® ropes behaveover a period of time. • Initial loading will result in elastic extension. This is

immediate upon loading and is immediately recoverableupon release of the load (elastic contraction).

• After the elastic extension of the initial loading the rope willexperience what is known as viscoelastic extension. This isfurther extension over time and is fairly limited. Unlikeelastic stretch, viscoelastic stretch will only recover slowlyover time once the load is released.

• Finally there is creep, which is permanent, non-recoverableand time dependent. Creep occurs at the yarn molecularlevel when the rope is under constant load.

• Once the load is released and elastic and viscoelasticextension recovered the rope wil l ult imately haveexperienced an element of permanent extension. This is afactor of both creep and ‘bedding in’, which is whenindividual fibre components in the rope and/or splice settleinto their preferred position when under load.Marlow lead the market in performance yachting rope

technology. Our Grand Prix Series offers performance benefitsand a competitive edge… and is specified by winners!Jon Mitchell, Managing Director www.marlowropes.com q

SEAHORSE 37

The demands on high-performance running rigging arebecoming higher and Marlow’s Grand Prix Series offers coreoptions using Dyneema®, Vectran and Zylon (PBO). Each hasits own strengths and weaknesses, but Dyneema® hasbecome the ‘Gold Standard’ for performance running rigging.

Dyneema® is a HMPE (High Modulus Polyethylene), alsoknown as UHMWPE or Ultra High Molecular WeightPolyethylene and is available in a number of different grades.All grades of Dyneema® have excellent fatigue resistance(cyclic bending) and UV, chemical and abrasion resistance,but all have poor heat resistance due to a relatively lowmelting point (150°C).

Dyneema® offers the best strength-to-weight ratio of anymaterial used in rope manufacture, rivalled only by PBO, and isnow the material of choice for high-performance cores. Marlowoffer a range of Dyneema® cores to suit applicationpreferences as well as budget. However, with new grades ofDyneema® being introduced and different treatments available,the decision as to which core is best can often be confusing. • SK75 – for many years the strongest Dyneema® grade and

the standard material that everybody understands. Thanksto new and improved grades, SK75 is being used less andless and is now not offered by Marlow.

• SK78 – has become the standard grade used by Marlowand other reputable manufacturers. SK78 has the samestrength as SK75 but offers significantly improved creepcharacteristics than its predecessor.

• SK90 – launched in 2009 and offers approximately 10-15% strength improvement over SK75/8. However,SK90 only has the same elongation and creepcharacteristics as SK75. While still available, SK90 is nownot specified by Marlow ropes due to the introduction of…

• SK99 – the latest offering from DSM Dyneema® launchedin 2013. SK99 has 20% strength advantage over SK78and crucially retains the same elongation and creepcharacteristics as SK78 – outgunning SK90 on all levels!SK99 has an unmatched strength-to-weight ratio and

Technical

Brief

Holding onWhy the latest Dyneema® products are better than ever...

To be involved in the Technical Brief advertorial column please contact – [email protected]

0

10

20

30

40

50

60

70

80

90

100

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

Load

(% o

f AB

L)

Elongation (%)

Load/Extension (%/%)

D12 SK99

D12 MAX SK99

V12 (Vectran)

Z12 (HM PBO)

0

10

20

30

40

50

60

70

80

90

100

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

Load

(% o

f AB

L)

Elongation (%)

Load/Extension (%/%)

D12 SK99

D12 MAX SK99

V12 (Vectran)

Z12 (HM PBO)

0

2000

4000

6000

8000

10000

12000

14000

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

Load

(kg)

Elongation (%)

Load Extention of 9mm cores (%/kg)

D12 SK78

D12 SK99

D12 MAX SK78

D12 MAX SK99

V12 (Vectran)

Z12 (HM PBO)

0

2000

4000

6000

8000

10000

12000

14000

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

Load

(kg)

Elongation (%)

Load Extention of 9mm cores (%/kg)

D12 SK78

D12 SK99

D12 MAX SK78

D12 MAX SK99

V12 (Vectran)

Z12 (HM PBO)

Exte

nsio

n (%

)

Time

Extension over time

SK75 SK78 SK99

Viscoelastic Contraction

Permenent Extension

Elastic Contraction

Elastic Extension

Viscoelastic Extension

Extension due to Creep

Extension over time

Load/Extension (%/%)

Load Extension of 9mm cores (%/kg)

D12 99/78

D12 MAX 99/78

V12 (Vectran)

Z12 (HM PBO)

![Vectran | Engineering Data by · PDF fileENGINEERING DATA VECTRAN TECH.FNL[FINAL]-QXD 10/26/99 10:13 AM Page 2 Grasp The World OfOf Tomorrow Grasp The World Tomorrow ENGINEERING DATA](https://static.fdocuments.us/doc/165x107/5a9e5a7d7f8b9a0d7f8d946b/vectran-engineering-data-by-data-vectran-techfnlfinal-qxd-102699-1013-am.jpg)