March 26-27, 2003 International Aircraft Systems Fire Protection Working Group Phoenix, Az Inerting...

-

Upload

charlene-hillary-douglas -

Category

Documents

-

view

217 -

download

0

description

Transcript of March 26-27, 2003 International Aircraft Systems Fire Protection Working Group Phoenix, Az Inerting...

March 26-27, 2003International Aircraft Systems Fire

Protection Working GroupPhoenix, Az

Inerting of a Scale 747SP Center-Wing Fuel Tank During a Typical Commercial Flight Profile

William CavageAAR-440 Fire Safety Research

Federal Aviation Administration

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________

Outline• Background• Model / Instrumentation• Test Data

– Effect of Holds at 5K Feet– Running System on Ground– Effect of Deposit Schemes– Starting Descent Altitude– Blocking Vent System Dive Port

• Summary

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Background

• FAA is seeking to improve upon existing fuel tank safety in fleet in the wake of TWA800 air disaster

• Inerting of fuel tanks could provide significant fuel tank protection.

• Focus of the testing is to validate the ability of the FAA simplified fuel tank inerting system to inert the CWT of a 747SP during a typical commercial flight profile

• Use modeling results to validate modeling methods with full-scale data

• Study inert gas distribution during the commercial mission

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Description of Model

• Quarter-scale model of Boeing 747SP CWT was built from three-quarter inch plywood by scaling drawings from Shepherd report– 24% length scale (1.4% Volume)– Spars and spanwise beams simulated with quarter-inch plywood

installed in slats with scaled penetration holes– Vent system simulated with PVC tubing plumbed to an

aluminum vent channel – Removable lid to allow for model maintenance and modification

• Model in 6x6x7 altitude chamber

• Model inerted with manual NEA mixer

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Photo of Model

ISFPWG Meeting - 3/26/03

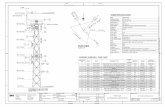

Scale Fuel Tank Testing___________________________________747 SP Bay Diagram with Volume Data

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Instrumentation

• Onboard oxygen analysis system (OBOAS) acquired bay oxygen concentration data– One sample port in each bay– Sample returned to tank through manifold

• Thermocouple in chamber gave temperature• Altitude measured by absolute pressure transducer• NEA Flow metered/measured with mass flow

controller and oxygen concentration determined with flow through type oxygen analyzer

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Onboard Oxygen Analysis System Block Diagram

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________

Altitude ChamberN

EA M

ixer

OxygenAnalyzer

Flow Controller

Scale Tank Testing Block Diagram

DAS

Nitr

ogen

CompressedAir

NEA Generator

Com

pute

r

T

OBOAS

PressureTransducer

Sample Return

Scale Tank Model

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Scope of Testing to Date

• All testing used same generic flight profile with different cruise times and different holds at 5K feet

• All testing uses same predicted system performance in terms of NEA flow and purity during above mentioned mission

• All tests had right side vent system blocked– Some tests had aft port on open vent side also blocked

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________OBIGG System Model

0

10

20

30

40

50

60

70

0 50 100 150 200 250 300 350

Time (min)

NEA

Flo

w (S

CFM

) / A

ltitu

de (k

ft)

0

2

4

6

8

10

12

14

Oxy

gen

Con

cent

ratio

n (%

O2)

NEA Flow Mission Profile NEA O2%

Climb

Cruise

Descent

System Model Data

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Effect of Hold at 5K Feet

• Baseline case (no hold) repeated with two different hold times– Hold at 5K feet– 5 and 10 minute holds

• Results indicate that holds using high flow mode have little effect on both tank average oxygen concentrations and worst bay oxygen concentrations– System is depositing NEA at approximate oxygen concentration as

tank– 5-10 minutes not that long to improve distribution for relatively

small spread

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

18

0 10 20 30 40 50 60

Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

Bay 1 Bay 2 Bay 3

Bay 4 Bay 5 Bay 6

Descent Inerting Data - 39K FeetStarting [O2] 2%, No Hold

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

0 10 20 30 40 50 60

Time (min)

Oxy

gen

Con

cent

ratio

n (%

vol

)

0

10

20

30

40

50

60

70

Altit

ude

(kft)

10 Minute Hold at 5K 5 Minute Hold at 5K No Hold Altitude - 10 Minute Hold Altitude - 5 Minute Hold Altitude - No Hold

Descent Inerting Data Comparison of Tank [O2]

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

0 10 20 30 40 50 60

Time (min)

Oxy

gen

Con

cent

ratio

n (%

vol

)

0

10

20

30

40

50

60

70

Altit

ude

(kft)

10 Minute Hold at 5K 5 Minute Hold at 5K No Hold Altitude - 10 Minute Hold Altitude - 5 Minute Hold Altitude - No Hold

Descent Inerting Data Comparison of Bay 1 [O2]

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Effect of Hold at 5K Feet (Cont’d)

• Ideally like to decrease tank average oxygen concentration before you use high flow mode to improve distribution– Use low flow mode during a hold at 5K feet (lower’s average tank

oxygen concentration)– Switch back to high flow for final descent (distributes)

• Results illustrate this flow methodology improves overall average tank oxygen concentration at touchdown but doesn’t increase in the worst bay oxygen concentration – Using high flow mode to distribute gas has diminishing returns

• Effect of sample system minimal when checked

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

18

0 10 20 30 40 50 60

Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

Bay 1 Bay 2 Bay 3

Bay 4 Bay 5 Bay 6

Descent Inerting Data - 39K FeetStarting [O2] 2%, 10 Min Hold at 5K

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

0 10 20 30 40 50 60 70Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

Bay 1 Bay 2 Bay 3 Bay 4 Bay 5 Bay 6

Descent Inerting Data - 39K FeetBaseline 10 Min Hold in Low Flow Mode

FinalDescent

Hold Pattern Touchdown

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

18

0 10 20 30 40 50 60

Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

) Bay 1 Bay 1 Bay 2 Bay 2 Bay 3 Bay 3 Bay 4 Bay 4 Bay 5 Bay 5 Bay 6 Bay 6

Descent Inerting Data - Check DataEffect of Sample System on Result

Continuous Intermittent

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Running System After Touchdown

• Repeated baseline case touchdown data with two tests that run system on ground after touchdown– 15 and 30 minutes system run times– one test only sampled beginning and end of ground sit time

• Running System in Low Flow Mode After Touchdown did little for worst bay oxygen concentration– Gave consistent benefit over time for tank average oxygen

• Running System in High Flow Mode After Touchdown did decrease bay oxygen concentration spread– Average oxygen concentration changed little– Again, diminishing returns on reducing spread

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

40 45 50 55 60 65 70 75 80

Time (min)

Oxy

gen

Con

cent

ratio

n (%

vol

)

0

10

20

30

40

50

60

70

NEA

Flo

w (C

FH)

15 Minutes 30 Minutes

NEA Purity NEA Purity

NEA Flow NEA Flow

Run System After LandingLow Flow Mode - Average Tank [O2]

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

40 45 50 55 60 65 70 75 80

Time (min)

Oxy

gen

Con

cent

ratio

n (%

vol

)

15 Minutes 30 Minutes

Run System After LandingLow Flow Mode - Bay 1 [O2]

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

0 10 20 30 40 50 60Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

Bay 1 Bay 2 Bay 3

Bay 4 Bay 5 Bay 6

Descent Inerting Data - 39K FeetRun System 10 Mins After Touchdown

Touchdown

System Off

(High Flow Mode)

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Deposit Scheme Comparison

• Compared running system after touchdown with two different deposit scenarios– Duel deposit method deposits low flow mode in bay 6 and high flow

mode in bays 1 and 3– Multi-deposit method deposits all flow into bay 6 and bay 2

(approximate equal split)– Baseline used low flow mode during 10 minute hold pattern

• Fancy deposit schemes did little to improve touchdown average or worst bay oxygen concentration– More work needed

• Repeatability check gave excellent results

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

0 10 20 30 40 50 60 70Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

High Flow Only During Hold Run for 10 Mins After TD Dual Deposit Method Multi-Deposit Method

Descent Inerting Data - From 39K Feet10 Min Hold @ 5K - System Low Flow

FinalDescent

Touchdown

Hold Pattern

Average Tank Oxygen Concentration

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

0 10 20 30 40 50 60 70Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

High Flow Only During Hold (Bay 1)

Run for 10 Mins After TD (Bay 1)

Dual Deposit Method (Bay 3)

Multi-Deposit Method (Bay 3)

Descent Inerting Data - From 39K Feet10 Min Hold @ 5K - System Low Flow Mode

FinalDescent Touchdown

Hold Pattern

Worst Bay Oxygen Concentration

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

0 10 20 30 40 50 60Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

Bay 1 Bay 1 Bay 2 Bay 2 Bay 3 Bay 3 Bay 4 Bay 4 Bay 5 Bay 5 Bay 6 Bay 6

Descent Inerting Data - 39K Feet10 Minute Hold with Switch to Low Flow

FinalDescent

Hold Pattern

Original Test Repeat Test

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Starting Altitude Comparison

• Compared original baseline descent case (from 39K feet) with two additional starting altitudes (32K and 25K)– Used same altitude profile with different starting point (same descent

rates) with no hold– Approximated system performance best possible

• Results were as expected– Starting altitude will have dramatic effect on resulting average oxygen

concentration provided the tank is consistently inert for all cases

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

0 5 10 15 20 25 30 35 40 45 50

Time (min)

Oxy

gen

Con

cent

ratio

n (%

vol

)

Descent from 25K Descent from 32K Descent from 39K

Descent Inerting Data Comparison of Average Tank [O2]

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________Effect of Blocking Dive Port

• Existing venting scheme does not give optimal inerting efficiency– Illustrated in constant inerting tests– Would improve by blocking dive port (aft vent port) on open side

• Repeated baseline test data (no hold) with this venting configuration– No effect on average tank oxygen concentration– Had adverse effect on distribution with 2% higher spike in worst bay

and a full 3% greater resulting worst bay oxygen concentration

• Compared two deposit schemes with this venting config– Use 10 min hold for comparison case– Only small effect observed on bay 1 spike and on result

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

0 5 10 15 20 25 30 35 40 45 50

Time (min)

Oxy

gen

Con

cent

ratio

n (%

vol

)

Rear Vent on Open Side Blocked

Half Vent System Blocked

Descent Inerting Data - 39K FeetAverage Tank [O2] Data

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

18

20

0 5 10 15 20 25 30 35 40 45 50Time (mins)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

Bay 1 Bay 1 Bay 2 Bay 2 Bay 3 Bay 3 Bay 4 Bay 4 Bay 5 Bay 5 Bay 6 Bay 6

Descent Inerting Data - 39K FeetComparison of Venting Configurations

Touchdown

Normally Blocked Rear Blocked Also

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________747SP Scale Fuel Tank Inerting Data

0

2

4

6

8

10

12

14

16

18

0 10 20 30 40 50 60Time (min)

Oxy

gen

Con

cent

ratio

n (%

Vol

)

Bay 1 Bay 1 Bay 2 Bay 2 Bay 3 Bay 3 Bay 4 Bay 4 Bay 5 Bay 5 Bay 6 Bay 6

Descent Inerting Data - 39K FeetComparison of Venting Configurations

Touchdown

Duel Deposit Single Deposit

Hold PatternFinal

Descent

ISFPWG Meeting - 3/26/03

Scale Fuel Tank Testing___________________________________

• Scale model data shows FAA inerting methodology sound given the predicted system performance– System could be slightly undersized

• Using high flow mode only, decent hold buy you very little in terms of average of worst bay oxygen concentrations

• Running system on ground after touchdown in high flow mode will decrease oxygen concentration spread, but has diminishing returns (when average oxygen concentration is near 12%)

• More elaborate deposit schemes and system methodologies give relatively small performance benefit, but could improve inerting capability significantly of a marginal system

Summary