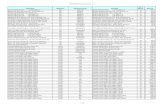

Manufacturer Part Numbers

-

Upload

shailendra-tiwari -

Category

Documents

-

view

12 -

download

0

description

Transcript of Manufacturer Part Numbers

APAC Procedure Business Process

Manufacturer Part Numbers Procedure Training Document

Local Group Companies

Submit Date, 21-Nov-04 <Confidential>

<Other Clause> Copyright @ 2003 Holcim Services (Asia) Ltd.

APBM

Document Control Document Name Manufacturer Part Numbers Procedure Training Document Author Ha Tran File Name & Path Created 21-Nov-04 Last Edited Printed on

Version Revision Date Revision Description Author Sign-off V 1.0 21-Nov-04 Ha Tran

Document Approval

Role Name Signature Date

Distribution List

Role Name Signature Date

Manufacturer Part Numbers Procedure Training Document 2/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Table of Contents POSSIBLE USES................................................................................................................................. 4

EXAMPLE: ........................................................................................................................................... 4 PREREQUISITES AND MASTER DATA ............................................................................................ 5

ACTIVATE MPN USAGE AND DEFINE MANUFACTURER PART PROFILE ...................................................... 5 CREATION OF MANUFACTURER MASTER RECORDS................................................................................. 5

Manufacturer and vendor are not identical....................................................................................................5 Manufacturer and vendor are identical..........................................................................................................6 Manufacturer has particular plants from which materials are required to be procured..................................6 Creation of MPN Material master records .....................................................................................................6

APPROVED MANUFACTURER PARTS LIST (AMPL) ...................................................................... 7 USE.................................................................................................................................................... 7 PREREQUISITES .................................................................................................................................. 8

BUSINESS PROCESS PROCEDURE................................................................................................. 9 1. ASSIGNMENT OF MANUFACTURER PART PROFILE TO THE MATERIAL MASTER RECORD....................... 9 2. CREATION OF MPN MATERIAL MASTER RECORDS.......................................................................... 14 3. CREATION OF APPROVED MANUFACTURER PARTS LIST................................................................... 17 4. CREATION OF PURCHASE REQUISITION FOR MPN MATERIAL ITEM ................................................... 20 5. CREATION OF PURCHASE ORDER THROUGH THE CONVERSION OF PURCHASE REQUISITION .............. 23 6. MANUFACTURER PART NUMBER PROFILE....................................................................................... 29

Manufacturer Part Numbers Procedure Training Document 3/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Possible Uses

The enterprise wishes to influence the source of supply or quality of materials that are not ordered directly from the manufacturer. To this end, it is possible to inform the vendor from whom a certain material (that is, a vendor who acts as a middleman, or dealer) of the desired manufacturer’s name and the part number used by the latter for the material is procured. It is also possible to let the pre-defined vendor know precisely which of the manufacturer’s plants the enterprise wishes to source the material from. The vendor is notified of the manufacturer’s part number, the external description used by the manufacturer, and – if applicable – the desired manufacturer plant in the purchasing document that is sent to him. To be more specific, the manufacturer’s part number (MPN) and description, as well as the specific manufacturing plant (if applicable), are included in the data sent to the vendor with the purchase order.

Example: The nominated vendor procures steel bolts from the manufacturers Snyder Co., and Miller Corp. for resale. Since the quality of Snyder bolts does not satisfy the enterprise’s technical requirements, it is required to have the Miller product. Then this nominated vendor was informed of this requirement by specifying the manufacturer and the manufacturer part number in the purchase order. It can be possible to use the manufacturer part number (MPN) in the procurement process along with the enterprise’s internal (that is, the company’s own) material number. Stocks are managed only under the pre-defined internal material number. Likewise, material requirements planning is only carried out with respect to this internal material number. Once the goods receipt into stock is posted, for the ordered MPN material, any additional MPN information on the material is lost. Material valuation, too, is based exclusively on the enterprise’s internal material number. It is possible to store the manufacturer name, manufacturer number, and specific material designations and text in MPN material master records. The enterprise will have the option of creating purchasing info records with special conditions and control data for MPN materials. The source determination process for MPN materials can be controlled with the aid of source lists and quota arrangements. If it is required to check whether a certain manufacturer part may be ordered and used, it is mandatory to use the approved manufacturer parts list (AMPL).

Manufacturer Part Numbers Procedure Training Document 4/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Prerequisites and Master Data

The following preconditions must be satisfied before the enterprise can be able to work with manufacturer part numbers:

1.

2.

3.

4.

5.

The general use of MPNs must be activated in Customizing.

At least one manufacturer part profile must be defined in Customizing.

Master records must be created for manufacturers (and, if necessary, manufacturer plants).

A master record must be created for the enterprise’s own material in each case.

If there is more than one MPN material, further MPN material master records must be created.

Individual prerequisites are discussed in more detail in the following:

Activate MPN usage and define manufacturer part profile Manufacturer part profiles needed in order to work with manufacturer parts are created in Customizing for purchasing. Manufacturer part profiles enable the enterprise to specify, for each of the enterprise’s own materials, the conditions under which the MPN material may be used in the procurement process. In the profile, the following (among other things) can be specified:

• Whether it is mandatory to enter an MPN material in the purchase order • Whether purchasing info records are created for the enterprise’s own material or for the

MPN materials • Whether the MPN material may be changed within the procurement process, and, if so,

whether the system then carries out a new price determination process. • Whether the system is to check the approved manufacturer parts list when an MPN

material is entered. • Whether the purchase order text for the enterprise’s own material or the MPN material is

used. The MPN profile can be entered in the purchasing view of the master record for the internal material.

Creation of manufacturer master records If it is expected to choose between several manufacturers of a certain material (or between several plants of a certain manufacturer of a certain material) during the procurement process, separate master records must be created for the manufacturers of MPN materials (and, if applicable, for individual plants of these manufacturers). The number of master records to be maintained for manufacturers, manufacturer plants, and vendors depends on whether or not the manufacturer and the vendor are identical and whether it is required to procure materials from certain plants of a manufacturer.

Manufacturer and vendor are not identical If the manufacturer is not the vendor, then it is possible to store details on the former in a manufacturer master record with minimal data entry effort. The account group MNFR is then assigned to this manufacturer master record. If the enterprise uses the internal number assignment for this account group, but wish to store an external designation for the manufacturer, enter this designation in the control data (External Manufacturer field). The external designation is then shown in the purchase order message.

Manufacturer Part Numbers Procedure Training Document 5/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Manufacturer and vendor are identical If the vendor is simultaneously the manufacturer, it is possible to work with vendor master records. If the enterprise expects to specify different manufacturer plants belonging to the vendor, it should be assured that a partner schema that takes into account the partner role HS is assigned to the account group of the vendor master record. The manufacturer plants must have the partner role HS in the vendor master record.

Manufacturer has particular plants from which materials are required to be procured If the manufacturer has several manufacturing plants, it is possible to create separate manufacturer master records for these plants with the account group MNFR. The manufacturing plants must have the partner role HS (manufacturer plant) in the master record of the manufacturer (or vendor). The following graphic shows which partner roles the enterprise has to maintain in the master records for the vendor, manufacturer, and manufacturer plant:

Creation of MPN Material master records When necessary settings were made in Customizing and all necessary manufacturer master records have been created, the material master records can be created. If the enterprise works with manufacturer part numbers, the number of manufacturers of a part corresponding to the enterprise’s internal number determines the number of MPN material master records.

• If there is just one manufacturer part number for one of internal materials, it is possible to enter it and the manufacturer directly in the material master record for such internal material. In this case, it is not necessary to create an MPN material.

• If there are several manufacturer part numbers for a certain internal material, it is mandatory to create MPN material master records with material type HERS. Enter the Manufacturer part number, the manufacturer (this can be either a vendor master record

Manufacturer Part Numbers Procedure Training Document 6/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

or a manufacturer master record), and the number of the enterprise’s own, inventory-managed material in the purchasing view of the MPN material master records.

Noted that it is possible to search for MPN materials by invoking the input help and then choosing the search help for manufacturer part numbers.

If it is required to define different prices for different MPN materials corresponding to one of the enterprise’s internal materials, purchasing info records should be maintained not for the enterprise’s own material but for the MPN materials. To do so, it is mandatory to stipulate in the MPN profile that purchasing info records can be created for MPN only. As a result, it is impossible to create an info record for this internal material. Noted if the enterprise is working with consignment info records, the info records must be created for the enterprise’s own material. This originated from the fact that in the case of goods issues involving consignment materials, the system searches for the info records for the enterprise’s own, inventory-managed materials and does not take MPN material into account. It can always be possible to create contracts for both the MPN material and internal inventory-managed material. If the MPN material is not specified in the contract itself, this can be done in subsequent contract release orders. When creating a purchase requisition, it is possible to enter either the internal material or the MPN material in the item overview. If the MPN material is entered, the system converts it into the internal material – that is, in the item overview, the number of the internal material and the MPN is always seen. The MPN material is displayed in the item details on the Source of Supply tab page. The automatic source determination process then takes place according to the same rules that apply to the source determination process without the use of MPN materials. If more than one source of supply per MPN material have been stored in the system, the source determination process can be controlled using a source list or quota arrangement. If an MPN requirement has been set in the relevant manufacturer part profile, it is mandatory to specify an MPN material instead of the enterprise’s own material in every purchase order and in every scheduling agreement. If no MPN requirement has been defined in the manufacturer part profile for the material to be procured, either the MPN material or the enterprise’s internal material number can be entered.

Approved Manufacturer Parts List (AMPL)

Use If the enterprise wishes to check and control which MPN materials may be procured, it is necessary to make use of the approved manufacturer parts list (AMPL). In this list, it can be specified for each MPN material

• Whether it can be procured for a certain plant only or for all the plants of the enterprise. • The period during which the MPN material may be procured • Whether it must belong to a certain revision level • Whether it may only be procured from a certain manufacturer plant • Whether it is blocked and, if so, why

Noted that it is possible to define reasons for blocking MPN materials in Customizing for Purchasing under Material Master.

Manufacturer Part Numbers Procedure Training Document 7/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Prerequisites

• A Manufacturer part profile should be defined under Material master in Customizing for Purchasing. Set the indicator for AMPL management so that the system checks the approved manufacturer parts list when the MPN material is entered.

• Enter the manufacturer part profile in the master record of the inventory-managed material (Purchasing view).

• In order that the system checks whether the manufacturer plant entered is allowed, it is mandatory to o Create master records with the account group MNFR for the manufacturer plants; o Enter the manufacturer plants with the partner role HS in the manufacturer or vendor

master record; o Specify a checking rule in the manufacturer part profile.

Manufacturer Part Numbers Procedure Training Document 8/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Business Process Procedure

1. Assignment of Manufacturer Part Profile to the Material Master Record

1.1 Access transaction by Via Menu Logistics Materials Management Material Master Material

Change Immediately Via Transaction Code MM02

Key T-Code: MM 02

Fig-01

Manufacturer Part Numbers Procedure Training Document 9/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

1.2. On “Change Material (Initial Screen)” screen, fill in the data as below:

Fig-02

Field Name Description R/O/C/D User Action and Values Material Alphanumeric key uniquely

identifying the material R Select a specific material number

which relevant fields are required to be maintained

Change number Number used to uniquely identify a change master record

O Enter the change number if you make a change with reference to a change number, or create a object with a change number

Click on icon or press “ENTER”. Then the pop up screen appears as shown.

Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 10/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

1.3. On the pop up screen, maintain information as specified in the table below:

Fig-03

Field Name Description R/O/C/D User Action and Values Select ‘Purchasing’ view and click

on icon. Then the pop up screen appears as shown.

Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 11/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

1.4. On the pop up screen, maintain information as specified in the table below:

Fig-04

Field Name Description R/O/C/D User Action and Values Plant Key uniquely identifying a

plant R Select the plant number

Click on icon Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 12/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

1.5. On “Change Material XXXXXXXXXXXX” screen, fill in the data as below:

Fig-05

Field Name Description R/O/C/D User Action and Values Mfr part profile Define how you can work

with MPN materials in the procurement process

R Enter the Mfr part profile

Click on icon to save the latest maintenance of this master record

Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 13/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

2. Creation of MPN Material Master Records

2.1. Access transaction by Via Menu Logistics Materials Management Material Master Material

Create (General) Immediately Via Transaction Code MM01

Key T-Code: MM01

Fig-06

Manufacturer Part Numbers Procedure Training Document 14/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

2.2. On “Create Material (Initial Screen)” screen, fill in the data as below:

Fig-07

Field Name Description R/O/C/D User Action and Values Material Alphanumeric key uniquely

identifying the material R Enter the material number

Industry Sector Key that specifies the branch of industry to which the material is assigned

R Enter the industry sector

Material Type Key that assigns the material to a group of materials such as raw materials, operating supplies or trading goods

R Enter the material type

Change number Number used to uniquely identify a change master record

O Enter the change number if you make a change with reference to a change number, or create a object with a change number

Click on icon to choose which views are to be maintained

Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 15/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

2.3. On “Create Material XXXXXXXXXXXX” screen, make the proper entry of related information into the related fields and then click on icon:

Fig-08

Manufacturer Part Numbers Procedure Training Document 16/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

3. Creation of Approved Manufacturer Parts List

3.1. Access transaction by Via Menu Logistics Materials Management Purchasing Master Data

Approved Manufacturer Parts Maintain Via Transaction Code MP01

Key T-Code: MP01

Fig-09

Manufacturer Part Numbers Procedure Training Document 17/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

3.2. On “Maintain Approved Manufacturer Parts Lost: Initial Screen” screen, fill in the data as below:

Fig-10

Field Name Description R/O/C/D User Action and Values Int. Material number

Key that uniquely identifies a material

R Enter the Int. Material Number

Press “ENTER” Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 18/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

3.3. On “Maintain Approved Manufacturer Parts Lost: Initial Screen” screen, click on icon to save and post this AMPL

Fig-11

Fig-12 Manufacturer Part Numbers Procedure Training Document 19/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

4. Creation of Purchase Requisition for MPN material item

4.1. Access transaction by Via Menu Logistics Materials Management Purchasing Purchase

Requisition Create Via Transaction Code ME51N

Key T-Code: ME51N

Fig-13

Manufacturer Part Numbers Procedure Training Document 20/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

4.2. On “Create Purchase Requisition” screen, fill in the data as below:

Fig-14

Field Name Description R/O/C/D User Action and Values A (Account assignment category)

Specifies whether accounting for an item is to be effected via an auxiliary account

O Enter the account assignment category

Item category Key defining how the procurement of material or service item is controlled

O Enter the item category

Material Uniquely identifies a material

R Enter the material

Quantity Specifies the quantity to be ordered, as stipulated in the purchase requisition

R Enter the PO quantity

Valuation price Shows the price of the requested material per price unit

R Enter the valuation price

Total value Total value of item R Enter the total value

Deliv. date Date on which the goods are to be delivered or the service is to be performed

R Enter the delivery date

The material number field in the PR line item can be used for both Internal material number or MPN material number; the source determination can also be made based upon the set-up of

Manufacturer Part Numbers Procedure Training Document 21/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Field Name Description R/O/C/D User Action and Values

purchasing info record for MPN material number.

Click on icon to check the correctness of all entries and then

click on icon to save the purchase requisition

Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 22/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

5. Creation of Purchase Order through the conversion of Purchase Requisition

5.1. Access transaction by Via Menu Logistics Materials Management Purchasing Purchase

Requisition Follow-on Functions Create Purchase Order Automatically via Purchase Requisitions

Via Transaction Code ME59

Key T-Code: ME59

Fig-15

Manufacturer Part Numbers Procedure Training Document 23/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

5.2. On “Automatic Creation of Purchase Orders from Requisitions” screen, fill in the data as below:

Fig-16

Field Name Description R/O/C/D User Action and Values Purchasing Group Key for a buyer or a group

of buyers, who is/are responsible for certain purchasing activities

R Enter the purchasing group number

Purchasing Organization

Denotes the purchasing organization

O Enter the purchasing organization number

Vendor Number of the vendor defined as the fixed source of supply for this purchase requisition

O Enter the vendor number

Contract Specifies the number of the outline agreement that this purchase order or purchase requisition refers to

O Enter the contract number

Plant Specifies the key for a production facility or branch office within the company

R Enter the plant number

Supplying plant Describes the plant from which the ordered material is supplied

O Enter the supplying plant number

Automatic generation of POs

R Select the indicator

Other indicators O Select the indicator

Manufacturer Part Numbers Procedure Training Document 24/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Field Name Description R/O/C/D User Action and Values

Material group Key that you use to group together several materials or services with the same attributes, and to assign them to a particular material group

O Enter the material group

Release date Specifies the date on which the purchase order should be initiated on the basis of the purchase requisition

O Enter the release date

Delivery date Date on which an item is to be delivered or the service provided

O Enter the delivery date

Materials planner / controller

Specifies the number of the MRP controller or group of MRP controllers responsible for material planning for the material

O Enter the materials planner / controller number

Purchase requisition

Alphanumeric key uniquely identifying a purchase requisition

O Enter the purchase requisition number

Click on icon, the next screen will pop up indicating that the testing of automatic creation of PO is successful

Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 25/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

5.3. On “Automatic Creation of Purchase Orders from Requisitions” screen, click on icon to go back to the previous screen:

Fig-17

Manufacturer Part Numbers Procedure Training Document 26/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

5.4. On “Automatic Creation of Purchase Orders from Requisitions” screen, fill in the data as below:

Fig-18

Field Name Description R/O/C/D User Action and Values Specifies that the automatic generation of purchase orders from requisitions is to be carried out as a test

R Uncheck the indicator so as to help generate the Purchase Order automatically from PR

Click on icon

Legend: R = Required, O = Optional, C = Conditional, D = Display

Manufacturer Part Numbers Procedure Training Document 27/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Fig-19

5.5. Go back to Transaction ME23N to check the status of this newly created purchasing document.

Manufacturer Part Numbers Procedure Training Document 28/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

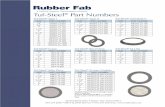

6. Manufacturer Part Number Profile There have been totally four MPN Profiles being maintained in the configuration and it is of criticality to have the better understanding of the implication of each and every such profile for appropriate selection during usage.

6.1. In regard to MPN Profile 1 – MPN0 The proper settings in configuration for this profile is enclosed –

Fig-20 Using this profile will provide the following features –

1. The Order Text (PO Text) will be copied from the MPN Material Master instead of from internal material master data;

2. The MPN Material Number must be maintained in either purchase order or scheduling agreement instead of the internal material number;

3. The MPN Material Number can be changed during procurement process (ie. When creating the purchase order by referencing to the purchase requisition, when working with the vendor confirmations and at the times of goods receipt).

4. The purchasing info record can only be created with MPN Material Number instead of the internal material number;

5. As soon as the MPN Material Number is entered, it will be validated against all possible entries being available in the Approved Manufacturer Part List (to determine, for example whether the material can only be for a certain plant);

6. The information structure from the Logistics Information System (LIS) will be updated with the MPN material.

Manufacturer Part Numbers Procedure Training Document 29/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

6.2. In regard to MPN Profile 2 – MPN1 The proper settings in configuration for this profile is enclosed –

Fig-21 Using this profile will provide the following features –

1. The Order Text (PO Text) will be copied from the MPN Material Master instead of from internal material master data;

2. The MPN Material Number can be changed during procurement process (ie. When

creating the purchase order by referencing to the purchase requisition, when working with the vendor confirmations and at the times of goods receipt).

3. As soon as the MPN Material Number is entered, it will be validated against all

possible entries being available in the Approved Manufacturer Part List (to determine, for example whether the material can only be for a certain plant);

4. The information structure from the Logistics Information System (LIS) will be

updated with the MPN material.

Manufacturer Part Numbers Procedure Training Document 30/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

6.3. In regard to MPN Profile 3 – MPN2 The proper settings in configuration for this profile is enclosed –

Fig-22 Using this profile will provide the following features –

1. The Order Text (PO Text) will be copied from the MPN Material Master instead of from internal material master data;

2. The MPN Material Number must be maintained in either purchase order or scheduling

agreement instead of the internal material number; 3. The purchasing info record can only be created with MPN Material Number instead of

the internal material number; 4. As soon as the MPN Material Number is entered, it will be validated against all possible

entries being available in the Approved Manufacturer Part List (to determine, for example whether the material can only be for a certain plant);

5. The information structure from the Logistics Information System (LIS) will be updated

with the MPN material.

Manufacturer Part Numbers Procedure Training Document 31/32

This document is for Super Users Training on 17 – 21 January, 04

APBM

Manufacturer Part Numbers Procedure Training Document 32/32

This document is for Super Users Training on 17 – 21 January, 04

6.4. In regard to MPN Profile 4 – MPN3 The proper settings in configuration for this profile is enclosed –

Fig-23 Using this profile will provide the following features –

1. The Order Text (PO Text) will be copied from the MPN Material Master instead of from internal material master data;

2. As soon as the MPN Material Number is entered, it will be validated against all possible

entries being available in the Approved Manufacturer Part List (to determine, for example whether the material can only be for a certain plant);

3. The information structure from the Logistics Information System (LIS) will be updated

with the MPN material.