Manual Instrucoes ALUP

-

Upload

francisco-paiva -

Category

Documents

-

view

5.085 -

download

515

Transcript of Manual Instrucoes ALUP

-

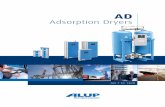

Operating manual

Screw compressor

ALLEGRO 16 - 38

-

2 2006

All rights belong to:

ALUP Kompressoren GmbH

Adolf-Ehmann-Strae 2

73257 Kngen

Tel.: 0049-180-5258700

Fax: 0049-180-5258701

No part of this manual may be duplicated by mechanical or electronic means without the express written permission from ALUP Compressors GmbH.

$OOSDUWLFXODUVLQWKLVPDQXDODUHVSHFLHGWRRXUEHVWNQRZOHGJHEXWZLWKRXWguarantee.

:HUHVHUYHWKHULJKWWRPDNHFKDQJHVWRLQIRUPDWLRQRQKDUGZDUHDQGUP-ware documentation at any time without previous announcement.

:HDUHWKDQNIXOIRUDQ\FULWLFLVPDQGVXJJHVWLRQV

-

3Table of contents

1. Safety instructions.........................................................4

1.1 Symbols in this manual.............................................41.2 Proper usage ............................................................5 4XDOLHGSHUVRQQHO...................................................51.4 General safety instructions .......................................6

2. Functional description ..................................................8

2. Functional description.................................................10

3. Storage and transport .................................................12

4. Installation ....................................................................14

4.1 Setting up ...............................................................144.2 Ventilation ...............................................................144.3 Forced ventilation(optional) ....................................154.4 Water cooling (optional)..........................................164.5 Heat recovery for heating water /

potable water (optional) ..........................................164.6 Connection to the compressed air net....................174.7 Electrical connections.............................................17

5. Displays and operating elements...............................18

5.1 Plant main switch....................................................185.2 Emergency OFF .....................................................185.3 Air Control 3 (option) ..............................................19

5.3.1 Basic display..................................................205.3.2 ON/OFF switching of compressed

air generation.................................................20)XQFWLRQNH\UHVHUYDWLRQLQWKHEDVLFGLVSOD\ 21

5.3.3.1 Capacity utilization ..........................225.3.3.2 Service ............................................225.3.3.3 LLC status .......................................235.3.3.4 Compressor pass ............................235.3.3.5 Diagram net pressure......................24 'LDJUDPQDOFRPSUHVVLRQ

temperature ....................................245.3.3.7 Diagram compressed

DLUDPRXQWGD\SUROH....................245.3.3.8 Diagram compressed

DLUDPRXQWVZHHNSUROH ...............245.3.3.9 Modify diagram settings ..................25

5.3.4 Menu system .................................................265.3.4.1 Sub-menu Limit values....................275.3.4.2 Sub-menu Operating parameters....285.3.4.3 Sub-menu Service intervals ............295.3.4.4 Sub-menu Timer..............................305.3.4.5 Sub-menu Fault log ........................325.3.4.6 Sub-menu Display parameters........32 6XEPHQX&RQJXUDWLRQ .................335.3.4.8 Sub-menu Lead lag control (LLC) ...345.3.4.9 Sub-menu Accessories....................345.3.4.10 Sub-menu Diagnosis .......................35

5.3.5 Warnings / maintenance................................365.3.6 Malfunctions ..................................................375.3.7 Adjustment of the display contrast.................38

5.4 Air Control 1............................................................395.4.1 Basic display..................................................405.4.2 ON/OFF switching of compressed

air generation.................................................415.4.3 Viewing additional operating data..................41

5.4.4 Menu system .................................................425.4.4.1 Unit parameterisation ......................425.4.4.2 Basic parameterisation....................435.4.4.3 Code 2: Operating mode.................445.4.4.4 Code 3: Automatic restart

after power failure............................45 &RGH/RFDOFRQWURO

UHPRWHFRQWURO//&2. ..................455.4.4.6 Code 11: Start and stop pressure ...455.4.4.7 Code 18: Lead leg control (LLC) ....465.4.4.8 Code 21: Maintenance

DFNQRZOHGJHPHQW ...........................46 &RGH2IIORDGRII

star/delta time..................................475.4.4.10 Code 65: Condensate valve ............475.4.4.11 Code 90: Unit for pressure

indication ........................................485.4.4.12 Code 95: Unit for temperature

indication .........................................485.4.4.13 Code 9999: Software version ..........48

:DUQLQJVPDLQWHQDQFHZRUN .......................495.4.6 Malfunctions ..................................................505.4.7 Adjustment of the display contrast.................51

6. Correcting malfunctions .............................................52

7. Initial commissioning ..................................................54

7.1 Preparatory activities ..............................................54 &KHFNFRROLQJXLGOHYHO ..........................................547.3 Start-up lubrication of the compressor stage..........547.4 Rotational direction control .....................................557.5 Basic settings .........................................................56

7.5.1 Controlling the unitby means of Air Control 3 567.5.2 Controlling the unitby means of Air Control 1 56

7.6 Switch on compressed air generation ....................577.7 Concluding activities...............................................57

8. Service ..........................................................................58

8.1 Overview Maintenance intervals.............................588.2 Preparatory activities ..............................................58 &KHFNFRROLQJXLGOHYHOUHOOFRROLQJXLG ...........59 &KHFNIRUOHDNDJH...................................................60 &KHFNWKHFRPSUHVVRUWHPSHUDWXUH .......................60 &KHFNWKHFRROHUIRUIRXOLQJ....................................60 &KHFNIRUFRQGHQVDWH.............................................61 &RROLQJXLGUHSODFHPHQW

UHSODFLQJFRROLQJXLGOWHU .....................................62 5HSODFLQJFRROLQJXLGVHSDUDWRU ...........................645HSODFLQJDLUOWHU...................................................65&KHFNVDIHW\YDOYH .................................................65&KHFNGULYH.............................................................668.13Relubrication of the electric motor ..........................668.14Concluding activities...............................................67

9. Technical Data..............................................................68

9.1 Dimensions for connections ...................................699.2 Data air-cooled compressors..................................699.3 Electrical data .........................................................69

10. Service manual ...........................................................70

-

41. Safety instructions

You are reading this manual in order to learn about the screw compressor. ,WFRQWDLQVLQIRUPDWLRQWKDWLVUHTXLUHGIRUVDIHPDOIXQFWLRQIUHHRSHUDWLRQRIWKHV\VWHP3OHDVHNHHSLQPLQGWKDWGDPDJHLQFXUUHGGXHWRLPSURSHUusage may not fall under the conditions of guarantee!

)RU WKLV UHDVRQSOHDVHNHHS WKLVPDQXDOZKHUHDOOXVHUVFDQKDYH IUHHaccess to it at any time.

7KHV\VWHPZDVGHYHORSHGPDQXIDFWXUHGWHVWHGDQGGRFXPHQWHGLQVWDWHof-the-art technology and considering all the current safety standards.

,QQRUPDOFLUFXPVWDQFHVQRGDQJHUIRUSHUVRQQHORUSURSHUW\FDQUHVXOWfrom the system if you comply with the stipulations of the service manual DQGLIWKHWUDQVSRUWDVVHPEO\VHUYLFHDQGWKHGHVFULEHGKDQGOLQJLVFDUULHGout according to the regulations.

1HYHUWKHOHVVFHUWDLQULVNVUHPDLQ

Safety instructions

This symbol is employed whenever personal damage can be incurred

by carelessness, or by ignoring the instructions.

1.1 Symbols in this manual

This symbol is employed when damage to property can occur through

carelessness, or by ignoring the instructions.

Italic text is employed when we would like to draw your attention to particular

information.

7H[WLQDIUDPHVLJQLHVWKHGHVFULSWLRQRIDQDFWLYLW\WREHFDUULHGRXWE\the user.

DANGER

NOTICE

-

5The system is exclusively designed for

the generation of compressed air and

for operation in an environment without explosion risk.

The units are designed for a minimum pressure of 5 bar (operating over-pressure)!

Any other utilization must be regarded as not in compliance with the design purpose!

The manufacturer/vendor is fundamentally not liable for damage incurred if the system is not used according to its design purpose!

1.2 Proper usage

The generated compressed air may not be used for human respiration. In

case the compressed air is used for pharmaceutical or sanitary purposes, it

must undergo further treatment. The same is true when the compressed air

is used in production plants and comes into direct contact with foodstuffs.

7KLVPDQXDO LVGLUHFWHG WR TXDOLHGSHUVRQQHOZKRDUHFRPPLVVLRQHGZLWKWKHWUDQVSRUW LQVWDOODWLRQRSHUDWLRQRUVHUYLFHRIWKHV\VWHP7KHVHindividuals must read the chapter relevant to their duties.

4XDOLHGSHUVRQQHODUHLQGLYLGXDOVZKR XSRQWKHEDVLVRIWKHLUSURIHVVLRQDOWUDLQLQJNQRZOHGJHDQGH[SHULHQFH

DVZHOODVWKHLUXQGHUVWDQGLQJRIWKHUHOHYDQWQRUPVFDQDVVHVVWKHZRUNWREHFDUULHGRXWZLWKUHJDUGWRDOOSRVVLEOHGDQJHUVRU

EDVHGRQPDQ\\HDUVRIDFWLYLW\LQDFRPSDUDEOHHOGKDYHWKHVDPHVWDWHRINQRZOHGJHDVVRPHRQHZLWKSURIHVVLRQDOWUDLQLQJ

Activities that are not described in this manual may only be carried out by our customer service department or by authorized technical personnel.

4XDOLHGSHUVRQQHO

8QTXDOLHGDFWLRQVRUGLVUHJDUGLQJWKHZDUQLQJV LQ WKLVPDQXDORU WKRVHDI[HG WR WKHSURGXFW FDQ OHDG WR VHULRXVSHUVRQDO LQMXU\ RU GDPDJH WRmaterial!

-

61. Safety instructions

1.4 General safety instructions

DANGER

DANGER

DANGER

DANGER

Damage to the sense organs!

Compressed air streams may not be directed towards persons. When

applying compressed air, dust particles can be raised by the air stream.

Therefore, when working with compressed air, protect your eyes with

safety glasses.

Loss or decrease of compressor safety !

5HWURWWLQJRUPRGLFDWLRQVRQ WKHV\VWHPFDQ UHGXFH LWV OHYHORIsafety! The results could be serious personal, material or environmen-

WDOGDPDJH3RVVLEOHUHWURWWLQJRUPRGLFDWLRQVRQWKHV\VWHPZLWKequipment components from third party manufacturers must therefore

UVWEHFOHDUHGE\XV

Loss of contact protection!

The side panelings of the system are part of the contact protection

system to protect personnel from fan impellers that start up automati-

cally, moving machine parts, hot surfaces and dangerous voltages!

Furthermore, they are required for sound insulation and cooling air

conduction. Therefore they must not be removed when the unit is in

operation.

For initial commissioning, it is required to remove the side paneling of

the system. Furthermore, in the process of the initial commissioning

of the plant, the mains switch must be turned on.

The initial commissioning, therefore, may only be carried out by quali-

HGWHFKQLFDOSHUVRQQHO

Injuries caused by fan impellers that start automatically, moving ma-

FKLQHSDUWVKRWVXUIDFHVRUHVFDSLQJFRROLQJXLGPLVWInstallation, service or repair work on the components of the system

must, if not otherwise described, be categorically carried out only on

DVZLWFKHGRIIVXIFLHQWO\FRROHGRIIDQGSUHVVXUHIUHHV\VWHP7KHsystem must be secured against an illicit or accidental switching-on.

The shut-off device for the compressed air net must be closed.

If measuring or testing work is required on the electrical components

while the system is in operation, they must be carried out by electri-

cians observing all the relevant safety regulations.

-

7Loss or decrease of compressor dependability!

Only original spare parts and lubrications may be employed!

We recommend that a set of service parts subject to wear be kept on

stock, in order to guarantee high compressor availability. Our customer

service would be glad to help you with your selection.

NOTICE

NOTICE

Carry out the activities in all of the following chapters in the order given.

Damage to the system may result in environmental damage!

Before initial commissioning, the system must have been correctly

installed according to Chapter 6!

For the operation of the compressor (equipment in the sense of Pres-

sure Equipment Directive 97/23/EC) please observe national regulations

and laws. In Germany, operating equipment must be operated in ac-

cordance with the regulations laid down in the ordinance on industrial

safety and health (BetrSichV)!

Dispose of all used or defective materials in a proper way!

This is especially true for components/materials containing cooling

liquid. Please note that the accumulated condensation containing

cooling liquid may not enter the sewage system!

:HRIIHUDQDSSURSULDWHFRROLQJXLGZDWHUVHSDUDWRUIRUFRQGHQVD-tion processing.

Compressed air receivers require regular technical inspections!

Please notify the commissioning of the system at the technical inspection

authority responsible for you. They will inspect the system and provide a

receiver test book.

Document all the activities carried out (e.g. in some table format).

-

82. Functional description

2.1 Drive

2.2 Air path

The frequency converter supplies the electric motor with electric power. )RUWKHRSHUDWLQJSULQFLSOHRIWKHIUHTXHQF\FRQYHUWHUSOHDVHUHIHUWRWKHinstructions in the control cabinet.

7KHHOHFWULFPRWRU GULYHV WKH FRPSUHVVRU VWDJH YLDD H[LEO\ VXSSRUWHGcoupling.

)UHVKDLUVXSSOLHGE\WKHLQWHJUDWHGFRROLQJDLUYHQWLODWRULVOWHUHGWKURXJKWKHDLUOWHUV7KHDLU LV WKHQGLUHFWHGYLD WKHVXFWLRQUHJXODWRU LQWR WKHFRPSUHVVRUVWDJHZKHUHLWLVFRPSUHVVHGWRWKHQDOFRPSUHVVLRQSUHVVXUHWRJHWKHUZLWKLQMHFWHGFRROLQJXLG,QWKHFRROLQJXLGUHVHUYRLUWKHFRPSUHVVHGDLULVVHSDUDWHGIURPWKHFRROLQJXLGDQGWKHGRZQVWUHDPFRROLQJXLGVHSDUDWRUUHPRYHVWKHUHPDLQLQJFRROLQJXLGIURPWKHFRPSUHVVHGDLU7KHDLUWKHQRZVYLDWKHminimum pressure non-return valve into the compressed air aftercooler and is cooled down to 10 - 15 C above the ambient temperature before it leaves the compressor through the compressed air connection.

The suction regulator opens shortly after the compressor has started up for generating compressed air. It closes when the compressor changes over to off-load operation and/or comes to a standstill and unloads the system via the relief valve.

-

9 &RROLQJXLGFLUFXODWLRQ

2.4 Cooling

7KHFRROLQJXLG LVVSUD\HG LQWR WKHDLUHQGDQGKDV WKH IROORZLQJ IXQF-tions:

heat removal of the temperature increase caused by the compression process

sealing lubrication of the rotors to each other and to the housing with a FRROLQJXLGOP

bearing lubrication

noise dampening

7KHFRROLQJXLGOHDYHVWKHDLUHQGWRJHWKHUZLWKWKHFRPSUHVVHGDLUDVDKRWFRROLQJXLGUHWXUQDLUPL[WXUH7KHFRROLQJXLGLVVHSDUDWHGIURPWKHFRPSUHVVHGDLULQWRWKHVHSHUDWRUWDQNE\WKHFRROLQJXLGVHSDUDWRUDQGZKHQVHSDUDWHGLWRZVWRWKHFRRO-LQJXLGKHDWH[FKDQJHU7KHFRROLQJXLGWHPSHUDWXUHUHJXODWRUPL[HVWKHFRROHGGRZQFRROLQJXLGZLWKWKHFRROLQJXLGKHDWH[FKDQJHUE\SDVVKRWFRROLQJXLGDVGHQHGE\WKHVHWSRLQWWHPSHUDWXUH)LQDOO\WKHFRROLQJXLGOWHUFOHDQVWKHFRROLQJXLGEHIRUHLWLVDJDLQLQMHFWHGLQWKHDLUHQG,I GHVLUHGE\ WKH FXVWRPHU DQDGGLWLRQDO KHDWHU FDQEH LQVWDOOHG LQ WKHVHSHUDWRUWDQNHLWKHURULJLQDOO\RUVXEVHTXHQWWRSXUFKDVH,WSUHYHQWVFRQ-GHQVDWLRQGDPDJHLQWKHFDVHRIFROGRUGDPSFRPSUHVVRUHQYLURQPHQWVfor example.

7KH FRPSUHVVHG DLU DIWHUFRROHU RI WKH FRROLQJ XLG KHDW H[FKDQJHU LVcooled either by

a built-in cooling air ventilator or

water cooling.

The electric motor is always cooled by its own ventilator fan.

,QWKHFDVHRIZDWHUFRROHGFRPSUHVVRUVDIUHVKDLUYHQWLODWRUDGGLWLRQDOO\HQVXUHVVXIFLHQWIUHVKLQWDNHDLUIRUWKHUHPRYDORIUDGLDWHGKHDW

-

10

2.5 Flow diagram

2. Functional description

-

11

20

19

10

01

09

02

05

1215

01

05

02

07

04

20

1219

01 Switching cabinet02 Electric motor03 Coupling$LUOWHU05 Suction regulator06 Compressor level &RROLQJXLGUHVHUYRLU08 Safety valve09 Drain,QOHWWWLQJ11 Additional heater (optional)&RROLQJXLGVHSDUDWRU13 Minimum pressure non-return

valve14 Relief valve15 Compressed air after-cooler

16 Compressed air connection&RROLQJXLGFRROHU&RROLQJXLGWHPSHUDWXUHUHJX-

lator&RROLQJXLGOWHU20 Cooling air ventilator21 Cooling water inlet22 Throttle valve compressed air

after-cooler23 Solenoid valve24 HCR water inlet25 HCR heat exchanger26 HCR thermostat 27 HCR water outlet28 HCR thermostat valve

2.6 Components

2.7 Legend

-

12

3. Storage and transport

Observe the local regulations and other requirements pertaining to the

professional use of tools, lifting and transport equipment, as well as

the valid standards and regulations for accident prevention.

3OHDVHVWRUHWKHV\VWHPRQO\LQDGU\IURVWIUHHURRP

8VHD IRUNOLIW WUXFN IRU WUDQVSRUW)RUVKRUW WUDQVSRUWDWLRQGLVWDQFHVDpalette lifting trolley may be used.

DANGER

For measurements and weights, see Chapter 9.

Always transport the system in its normal operating orientation in a pres-sure-free state. Tilting or laying the system down is not allowed.

-

13

-

14

4.2 Ventilation

4. Installation

4.1 Setting up Install the system in locations with the following environmental condi-tions:

max. height above sea level: 1000 m ambient temperature: +5 to +40 C ambient temperature for Version T: +5 to +45 C DPELHQWFRQGLWLRQV FRROGU\GXVWIUHH

DANGER

2SHQDPHRUUHDVZHOODVZHOGLQJZRUNLQWKHYLFLQLW\RIWKHV\VWHPare forbidden!

Space requirements and system weights are dependent on the compressor type purchased. Measurements and weights: see Chapter 9.

$OZD\VPDLQWDLQWKHPLQLPDOFOHDUDQFHVWRWKHZDOOVRURWKHUREMHFWVVRthat system service functions can be carried out without hindrance. For the HQWLUHVHULHVWKHPLQLPXPFOHDUDQFHLVPP

We recommend setting up the compressors in a separate compressor room.

NOTICE

7KHDLUHQWHULQJWKHLQWDNHRSHQLQJLVXVHGIRUWKHFRPSUHVVLRQDVZHOODVfor compressor cooling.

7KHYHQWLODWLRQPXVWIXOOODWOHDVWWKHIROORZLQJFULWHULD 6XSSO\ UHTXLUHGFRROLQJDLUDPRXQWVDVGHQHG LQ&KDSWHUGDQG

9.3

5HPRYHH[KDXVWDLUDVGHQHGLQ&KDSWHULQRUGHUWRSUHYHQWDKHDW-ing up of the compressor site

7KHFRROLQJDLUPXVWEHFRROGU\DQGGXVWIUHH The temperature of the aspired cooling air must be within the range of

+5C to +40C.

,QWKHFDVHRIDVSLUDWLRQIURPRXWVLGHSURYLGHDUHFLUFXODWLRQDS

0DNHFHUWDLQ WKDW WKHVXSSO\DLUFRQWDLQVQRGDQJHURXVH[SORVLYHJDVPL[WXUHVVWHDPGXVWRUDJJUHVVLYHSROOXWDQWV

0DNHFHUWDLQWKDWWKHSODFHRILQVWDOODWLRQLVGXVWIUHHDVZHOODVZLWKLQthe prescribed operating temperature limits and as cool as possible. If QHFHVVDU\HQVXUHWKHSURIHVVLRQDO LQVWDOODWLRQRIIRUFHGDLUYHQWLODWLRQOWHULQJURRPFRROLQJRUKHDWLQJ

Make certain that the place of installation is professionally ventila-

ted.

Make certain that no circulating air short-circuit (the intake of the

exhausted warm air) can occur.

-

15

4.3 Forced ventilation

(optional)

&RROLQJDLUYROXPHRZVVHH&KDSWHU

Forced ventilation must be dimensioned in such a way that the required IUHVKDQGH[KDXVWDLUFRQVLGHULQJ WKHDYDLODEOH UHVLGXDOSUHVVXUHRI WKHFRPSUHVVRUYHQWLODWRUFDQEHVXSSOLHGDQGH[SHOOHG

Nominal diameters of the channel connections and information on the re-sidual pressure : see Chapter 9.

,IYHQWLODWLRQGXFWVDUH WREHFRQQHFWHG WR WKHV\VWHP WKHQ WKHUHTXLUHGsupporting supplementary ventilators should be included when planning the ducts.

The exhaust air can also be utilized for the purpose of heat recovery.

-

16

4. Installation

4.4 Water cooling (optional)

4.5 Heat recovery for heating

water / potable water (op-

tional)

)RUFRROLQJZDWHUTXDQWLWLHVWHPSHUDWXUHVDQGFRQQHFWLRQVsee chapter 9.

7KHFRROLQJZDWHUPXVWIXOOOWKHIROORZLQJFULWHULD Inlet temperature less than + 35 C

Pre-pressure 4 bar to10 bar

3UHOWUDWLRQZLWKDPHVKZLGWKRIDWOHDVWPP Electrical conductivity: 10 - 500 S/cm

3+ 7RWDOKDUGQHVVP0ROOA solenoid valve (optional) should be installed before the cooling water inlet.

The cooling water current through the compressed air after-cooler should be set with the throttle valve belonging to it in such a way that the compressed DLURXWOHWWHPSHUDWXUHLV&KLJKHUWKDQWKHLQWDNHDLU7KHFRQQHFWLRQVWRWKHFRROLQJZDWHUVXSSO\PXVWEHH[LEOHDQGZDWHUresistant.

:DWHUDPRXQWVWHPSHUDWXUHVDQGSUHVVXUHVVHH&KDSWHUThe heat recovery is to be connected appropriately (see drawing in Chapter DVGHQHG7KHZDWHUIRUKHDWUHFRYHU\PXVWIXOOOWKHIROORZLQJFULWHULD pressure of up to 10 bar

SUHOWHULQJZLWKDPHVKZLGWKRIDWOHDVWPP

)RUZDWHUFRROHGSODQWVWKHWHPSHUDWXUHRIWKHFRPSUHVVHGDLUDIWHUFRROHURIWKHFRROLQJXLGKHDWH[FKDQJHULVORZHUHGZLWKH[WHUQDOFRROLQJZDWHU

Compressors can be supplied with the optional heat recovery system

for heating water or

IRUSRWDEOHZDWHUVDIHW\KHDWH[FKDQJHUZLWKEORFNLQJPHGLXP

-

17

4.7 Electrical connections

7HVWWKHFRUUHFWIXQFWLRQLQJRIDOOVDIHW\IDFLOLWLHVSURWHFWLYHJURXQGLQJprotective switch etc.).

&DUHIXOO\ORFNWKHFRQWUROFDELQHWDIWHUWKHFRQQHFWLRQZRUNLVFRPSOH-ted.

NOTICE

DANGER

4.6 Connection to the com-

pressed air net

Unpredictable movements of the compressed air hose!

During load switching in the compressed air net, the hose can move

suddenly and with great force. Therefore the hose must be adequately

DQFKRUHGRU[HGDANGER

:HDVVXPHWKHH[LVWHQFHRIDSURIHVVLRQDOO\GHVLJQHGLQVWDOOHGDQGVHU-viced compressed air net.

Install an additional shut-off valve at the input of the compressed air net.&RQQHFWWKHV\VWHPRQO\ZLWKDH[LEOHFRPSUHVVHGDLUKRVHWRWKHFRP-pressed air net. Length of the hose employed: max.1.5 m.

7KHXQLWLVSURYLGHGIRUFRQQHFWLRQWRDWKUHHSKDVHVXSSO\V\VWHPFORFN-wise). Properly dimensioned safety equipment (to protect personnel/the unit) must be installed in the power supply lines.

All the relevant data for the connections can be found

in Chapter 9

on the nameplate of the system.

Electrical voltage!

Only trained electricians may connect the system to the electrical

supply network.

%HIRUHPDNLQJWKHFRQQHFWLRQVDFFRUGLQJWRWKHFRPSUHVVRUQDPHSODWHGHWHUPLQHLIWKHDYDLODEOHVXSSO\QHWZRUNLVDGHTXDWH9ROWDJHGHYLDWLRQVJUHDWHUWKDQDUHQRWDOORZHG

/D\ WKHVXSSO\FDEOHVSURIHVVLRQDOO\0DNHFHUWDLQ WKDW WKH LQVWDOODWLRQFDQQRWHQGDQJHULQGLYLGXDOVRUSURSHUW\7DNHLQWRDFFRXQWWKHQHFHVVDU\FDEOHGLDPHWHUVVWUDLQUHOLHIDQGPD[DOORZHGFDEOHOHQJWKV

Connect the system according to the circuit diagram. The circuit diagram is provided in the control cabinet of the system.

Damage to the system is possible!

Before switching on the generation of compressed air, initial commis-

sioning according to Chapter 6 must be correctly carried out!

NOTICE

When using residual-current-operated circuit-breakers in conjunction

with a speed-controlled machine, install exclusively residual-current-

operated circuit-breakers that are suitable for this application!

-

18

5. Displays and operating elements

5.1 Plant main switch

DANGER

5.2 Emergency OFF The system may be stopped with EMERGENCY OFF in the case of a real

emergency!

7KHPDLQVZLWFKIXOOOVWKHIXQFWLRQRIWKHHPHUJHQF\VWRS6WRSWKHPRWRULQFDVHRIGDQJHUSUHVVNH\

The compressor main switch must be switched off for all service or

installation work and protected from illicit or accidental switching

RQHJDI[DZDUQLQJVLJQWRWKHPDLQVZLWFKIRUELGGLQJLWVEHLQJturned on)!

Enable system:

1. switch main switch off and on.

SUHVVNH\ WRDFNQRZOHGJHWKHPDOIXQFWLRQ SUHVVNH\ to switch the system on again.

The units main switch that is installed on the control cabinet connects or disconnects the unit to and from the power supply.

0DNHVXUHWKDWWKHVKXWGRZQV\VWHPLVVXIFLHQWO\SURWHFWHGDJDLQVWrecommissioning!

Enable the system only when the cause of danger has been profes-

sionally removed and a securely operating state is achieved.DANGER

-

19

5.3 Air Control 3 (option) 7KHRSHUDWLQJGLVSOD\GHVNRIWKH$LU&RQWURO displays the plant states / operating data

switches on and off compressed air generation

is used for plant parameterizing.

)XQFWLRQNH\V

0RGLFDWLRQRISDUDPHWHUYDOXHVSelection of sub-menus

&RQUPDWLRQRISDUDPHWHUFKDQJHVEditing modes in the sub-menus

Display additional operation data.

Switch on compressor.

Integrated green LED

%OLQNLQJ FRPSUHVVRULVQRWUXQQLQJFDQDWDQ\WLPHbe automatically started up.

Lighted: Compressor is running.

Compressor shut down.

Signals a current warning/malfunction with the inte-grated red LED.

-

20

Switching ON: press NH\ .The compressor is ready and can start up automatically at any time.

Switching OFF: press NH\ .)RUWKHGXUDWLRQRIWKHVWDQGVWLOOWLPHWKHFRPSUHVVRUVZLWFKHVWRWKHLGOLQJstate and afterwards off.

5. Displays and operating elements

5.3.1 Basic display

5.3.2 ON/OFF switching of com-

pressed air generation

$IWHUVZLWFKLQJRQWKHPDLQVZLWFKRUGXULQJQRUPDORSHUDWLRQ$LU&RQWURO3 will inform you about the plant condition.

Momentarily available net pressureat compressed air output

MomentaryFRPSUHVVLRQQDOtemperature

Service or malfunction messages with service telephone number

&XUUHQWUHVHUYDWLRQRIWKHIXQFWLRQNH\V

Supplementary information:

Supplymentary information

Switching times are programmed6\PERODVKHV Compressor was switched off by the timerSymbol ON: Compressor was switched on by the timer

5.3.4.4

Pressure times are programmed 5.3.4.4

$QWLIUHH]HDFWLYHFRPSUHVVRUGRHVQRWVWDUWXS 6

RESTART Automatic restart programmed 5.3.4.2

REMOTE Remote control mode programmed6\PERODVKHV Compressor OFFSymbol ON:,QUHPRWHPRGH&RPSUHVVRU21

5.3.4.7

LLC MODE On-load/off-load controlled by higher-level control 5.3.4.7

AUTOMATIC OPT.

Meaning: Display of programmed off-load running control

Motor running

Solenoid valve open

Additional heater switched on

-

21

5.3.3 Function key reservation

in the basic display

,QWKHEDVLFGLVSOD\WKHIROORZLQJLQIRUPDWLYHSLFWXUHVFDQEHDFFHVVHGZLWKWKHIXQFWLRQNH\V

:LWKWKHNH\ and WKHPRGHDQGWKHUHIRUHWKHUHVHUYDWLRQRIWKHIXQFWLRQNH\VLQWKHEDVLFGLVSOD\FDQEHFKDQJHG

Mode 1 = reservation 1

Plant pass

ServiceCapacity utilization

Lead lag control

%\SUHVVLQJWKHGHQHGIXQFWLRQNH\WKHUHVSHFWLYHLQIRUPDWLRQVFUHHQLVopened.

7KHNH\ returns to the basic display from all information screens.

Mode 2 = reservation 2

Diagramair amounts ZHHNO\SUROH

Diagramair amounts GDLO\SUROH

Diagramnet pressure

Diagram compression temperature

-

22

5.3.3.2 Service

(Mode 1 - F3)

The Service diagram shows the remaining time in hours until the respective service interval is due.

,IWKHUHPDLQLQJWLPHLVOHVVWKDQKRXUVXQWLOWKHQH[WVHUYLFHWKHUHVSHF-WLYHEDUEHJLQVWREOLQNDQGDGHQHGZDUQLQJDSSHDUVRQWKHGLVSOD\

Change of mode 5.3.3

5. Displays and operating elements

$LUOWHU

&RROLQJXLGOWHU

&RROLQJXLGVHSDUDWRU

Motor lubrication

Compressor

5.3.3.1 Capacity utilization

(Mode 1 - F1)

7KLVGLDJUDPUHSUHVHQWVWKHUXQQLQJRIIORDGRQORDGDQGVWDQGVWLOOKRXUVin the form of bar diagrams. The respective current hour count is also dis-played in the bars.

Example:

Change of mode 5.3.3

:LWKWKHH[FHSWLRQRIWKHRIIORDGKRXUVDOOEDUVDUHUHSUHVHQWHGIURPWKHleft and growing to the right. The sum of the on-load hours and the off-load hours yields the total service hours.

The scaling units of this diagram are according to the service hours. If the QXPEHURIWKHVWDQGVWLOOKRXUVLVJUHDWHUWKDQWKHVHUYLFHKRXUVWKHEDUVof the standstill hours will be cut off. In this case note the displayed hour count in the bars.

Total service hours

On-load oad hours

Off-load hours

Standstill hours

-

23

5.3.3.4 Compressor pass

(Mode 1 - F4)

The individual machine data stored in the compressor pass are required for our customer service.

Change of mode 5.3.3

5.3.3.3 LLC status

(mode 1 - F3)

This display shows the status of 4 additional compressors (K2 - K4) when RQHDGGLWLRQDO//&PRGXOHLVXVHGRUDGGLWLRQDOFRPSUHVVRUV..when two additional LLC modules are used.

Change of mode 5.3.3

Fault and Off-load are displayed for compressors K2 - K5 (or K2 - K9) RQO\LIWKHFRUUHVSRQGLQJIHHGEDFNIDXOWDQGPRWRUUXQQLQJLVZLUHGWRWKHadditional module.

On-load

Off-load

Ready for operation

Fault

This display is only available if Lead lag control was activated by select-ing YES in the Lead lag control menu (see Chapter 5.3.4.8).

-

24

5. Displays and operating elements

5.3.3.8 Diagram compressed air

DPRXQWVZHHNSUROH(Mode 2 - F4)

,QWKLVGLDJUDPWKHFXUUHQWSURFHVVRIWKHFRPSUHVVHGDLUTXDQWLW\IRUDZHHNLVGLVSOD\HG

5.3.3.7 Diagram compressed air

DPRXQWGD\SUROH(Mode 2 - F3)

,QWKLVGLDJUDPWKHFXUUHQWSURFHVVRIWKHFRPSUHVVHGTXDQWLW\IRUDGD\is displayed.

'LDJUDPQDOFRPSUHV-sion temperature

(Mode 2 - F2)

,QWKLVGLDJUDPWKHFXUUHQWSURFHVVRIWKHQDOFRPSUHVVLRQWHPSHUDWXUHis displayed.

5.3.3.5 Diagram net pressure

(Mode 2 - F1)

,QWKLVGLDJUDPWKHFXUUHQWSURFHVVRIWKHQHWSUHVVXUHVLVGLVSOD\HG

Change of mode 5.3.3

Change of mode 5.3.3

Change of mode 5.3.3

Change of mode 5.3.3

-

25

5.3.3.9 Modify diagram settings

7KHNH\ X/Y-Init is for resetting the scale division for the default values preset in X-AUTO.

7KH NH\ ldeletes the recorded measurement values of the currently displayed time diagram.

X-AUTO settings 5.3.4.6

The scale divisions of the axis can be changed by editing the axis values.

y-axis: - The values of the y-axis can be changed in every diagram. The data in the diagram are continually updated even after the edit function.

x-axis: ,Q WKH GLDJUDP DLU TW\ZN WKH [D[LV YDOXHV FDQQRW EHFKDQJHGFKDQJHVDUHSRVVLEOHLQDOORWKHUGLDJUDPV

$IWHUHGLWLQJWKH[D[LVYDOXHVWKHGLDJUDPLVQRORQJHUFRQ-tinually updated.

X-AUTO: 7KHNH\ activates or deactivates X-AUTO ,I;$87221WKHYDOXHVRIWKH[D[LVDUHDXWRPDWLFDOO\

XSGDWHG7KH;$872XVHVWKHSUHVHWGHIDXOWYDOXHVGHQHGin the menu Display parameter diagrams (see Chapter 5.3.4.6).The manual editing x-axis values are deleted.

6HOHFWLRQRIWKHD[LVYDOXHVWREHFKDQJHGZLWKWKHNH\V and

&RQUPDWLRQRIWKHVHOHFWLRQZLWKENTER

0RGLFDWLRQRIWKHEOLQNLQJYDOXHZLWK and .Moving the cursor with and .

&RQUPDWLRQRIWKHPRGLFDWLRQVZLWKENTER.

Axis value y-axis (Max)

Axis value y-axis (Min)

Axis value x-axis (time point 1) Axis value x-axis (time point 2)

Procedure for the scale division of the axis.

-

26

5. Displays and operating elements

5.3.4 Menu system All basic settings of the system can be viewed in the menu system. If the PRGLFDWLRQVKDYHQRLQXHQFHRQRSHUDWLRQDOVDIHW\WKH\PD\EHPRGLHGby means of a code entry.

After pressing the INFO NH\WKHPDLQPHQXDSSHDUVUHTXHVWLQJWKHFRGHentry.

Code 0000: View the basic settings

Code 0001: View and change basic settings

0RGLFDWLRQRIWKHEOLQNLQJYDOXHVZLWKWKHNH\V and .Moving the cursors with and .

&RQUPDWLRQRIWKHPRGLFDWLRQVZLWKENTER.

7KHUHDIWHUWKHPDLQPHQXDSSHDUVZLWKWKHIROORZLQJVXEPHQXV

7KHVXEPHQXFDQEHVHOHFWHGZLWKWKHNH\V and .The selection is FRQUPHGZLWKENTER.

,QHYHU\RSHUDWLQJOHYHO will lead you to the next higher operating le-vel.

Limit values 5.3.4.1Operating parameters 5.3.4.2Service intervals 5.3.4.3Timer 5.3.4.4Malfunction storage 5.3.4.5Display parameter 5.3.4.6&RQJXUDWLRQ Lead lag control 5.3.4.8Accessories 5.3.4.9Diagnose 5.3.4.10

-

27

5.3.4.1 Sub-menu Limit values This menu contains the pressure / temperature limit values:

If the Code 0001 LVHQWHUHG WKHSDUDPHWHUVRI WKHVXEPHQXVKRXOGEHchanged as follows:

7KHVHOHFWLRQRIWKHGHVLUHGPHQXSRVLWLRQLVFDUULHGRXWZLWKWKHNH\V and .

7KHVHOHFWLRQLVFRQUPHGZLWKENTER. 0RGLFDWLRQRIWKHEOLQNLQJYDOXHZLWKWKHNH\V and .

Moving the cursor with and .

&RQUPDWLRQRIWKHPRGLFDWLRQVZLWKENTER.

Start pressure Lower value for the pressure regulation Can be edited

Stop pressure Upper value for the pressure regulation Can be edited

Safety pressure Maximum permissible pressure formalfunction triggering (always 0.8 bargreater than stop pressure)

Display

Final compressiontemperature min

0LQLPXPSHUPLVVLEOHQDOFRPSUHVVLRQtemperature

Display

Final compressiontemperature max

0D[LPXPSHUPLVVLEOHQDOFRPSUHVVLRQtemperature

Display

Selection of the menu position 0RGLFDWLRQRIWKHEOLQNLQJvalues

ENTER &RQUPVHOHFWLRQPRGLFDWLRQ%DFNWRWKHQH[WKLJKHUOHYHO

-

28

5.3.4.2 Sub-menu

Operating parameters

7KLVPHQXFRQWDLQVSDUDPHWHUVZKLFKLQXHQFHWKHWHPSRUDOUHJXODWLRQRIthe compressor:

Operating mode Automatic

The text AUTOMATIC is displayed in the basic display. After reaching the VWRSSUHVVXUHWKHV\VWHPFKDQJHVRYHUWRWKHRIIORDGPRGHDIWHUUXQQLQJtime) for the duration of the run-on time and the basic display shows the text run-on time with the respective residual time. At the conclusion of WKHUXQRQWLPHWKHPRWRUVZLWFKHVRII7KHFRPSUHVVRUFDQEHVWDUWHGXSautomatically at any time after falling below the start pressure.

Operating mode On-/off-load

The text ON-/OFF-LOAD is displayed in the basic display. The compres-VRUVZLWFKHVEHWZHHQRQORDGDQGRIIORDGRSHUDWLRQZKLFKPHDQVWKDWLWVrun-on time is unlimited.

Operating mode Automatic Optional

The text AUTOMATIC OPT. is displayed in the basic display. After reaching WKHVWRSSUHVVXUHWKHV\VWHPJRHVLQWRWKHRIIORDGPRGHAfter 10 and after 40 seconds the net pressure is measured.

,IWKHSUHVVXUHGURSVDERYHWKHWKUHVKROG0D[SUHVVXUHGURSWKHQWKHsystem is in the idling state for the duration of the run-on time. In the basic GLVSOD\WKHWH[W5XQRQDSSHDUVZLWKWKHUHVLGXDOWLPHDVGHQHG,IWKHYDOXHOLHVEHORZWKHWKUHVKROG0D[SUHVVXUHGURSWKHQWKHV\VWHPswitches off after completing the OFF time.

Max. no. of motor starts

,IWKHQXPEHURIWKHPD[LPXPSRVVLEOHPRWRUVWDUWVSHUKRXULVH[FHHGHGthen the compressor temporarily switches to the operation mode on-/off-load.

5. Displays and operating elements

Selection of the menu position 0RGLFDWLRQRIWKHEOLQNLQJvalues

ENTER &RQUPVHOHFWLRQPRGLFDWLRQ%DFNWRWKHQH[WKLJKHUOHYHO

Run-on time Run-on time of the motors in automatic operation

Display

Off time Run-on time of the motor for manual swit-ching-off delay and for automatic restart

Display

Star/delta time Star/delta time Display

Automatic restart Start after voltage return Can be edited

Operating mode: Behavior on load switching Setting range:AUTOMATICON-/OFF-LOADAUTOMATIC OPT.

Can be edited

Max. pressure loss Maximum pressure loss Display

Max. no. of motor starts

Maximum switching cycles of the motor per hour

Display

-

29

5.3.4.3 Sub-menu

Service intervals

,Q WKLVPHQX DOO VHUYLFH LQWHUYDOV DUH GLVSOD\HG RU DFNQRZOHGJHGDIWHUFDUU\LQJRXWWKHVSHFLFVHUYLFHVHH&KDSWHU:LWKWKHDFNQRZOHGJHPHQWWKHGLVSOD\HGUHVLGXDOWLPHIRUWKHYDOXHRIWKHrespective service intervals (see Chapter 8.1) is reset.

Service interval ASF 6HUYLFHLQWHUYDODLUOWHU Display

Service interval OLF 6HUYLFHLQWHUYDOFRROLQJXLGOWHU Display

Service interval OLAB 6HUYLFHVLQWHUYDOFRROLQJXLGVHSDUDWRU Display

Service interval motor Service interval for motor lubrication Display

Service interval compr. Service interval compressor Display

Service hours Total operating hours (motor on) Display

Load hours Accumulated load hours Display

Standstill hours Accumulated standstill hours(system on motor off)

Display

6HUYLFHZRUNDFNQRZOHGJHG

-

30

5. Displays and operating elements

5.3.4.4 Sub-menu Timer 7KHDGMXVWPHQWRIWKHLQWHJUDWHGUHDOWLPHFORFNDVZHOODVDOOVZLWFKLQJprocesses dependant upon it are in this menu.

Switching times for compressor

,QWKLVPHQXWKHVZLWFKLQJRQRIIWLPHVRIWKHFRPSUHVVRUVDUHGHQHG

Date/time Setting the current date and timeAttention: The adjustment is entered to WKHUHDOWLPHFORFNZKHQWKHVHFRQGVDUHFRQUPHGZLWKENTER

Edit

Compressor switching times

Branch to the sub-menu Edit

Compressor pressure times

Branch to the sub-menu Edit

Switching times LLC Branch to the sub-menu Edit

Pressure times LLC Branch to the sub-menu Edit

)RUWKHDFWLYDWLRQRIWKHWLPHUWKHSDUDPHWHURIWKHWLPHUFKDQQHOVPXVWEHset to ON in the highest menu line.

If the timer channel is set to ON and

LIWKHWLPHUFORFNRXWSXWLVDFWLYDWHGDFORFNDSSHDUVLQWKHGLVSOD\ LIWKHWLPHURXWSXWLVQRWDFWLYDWHGDEOLQNLQJFORFNDSSHDUVLQWKHGLV-

play

Seven switching times with the channels K1 K7 can be programmed.

$FKDQQHOLVDFWLYHZKHQDWOHDVWRQHRIWKHZHHNGD\VLVPDUNHGEODFN,QRUGHUWRFRQWLQXRXVO\DFWLYDWHWKHWLPHURXWSXWIRURQHRUDQXPEHURIGD\Vthe switching time should be set to 00:00.

7LPHUFORFNRXWSXWDFWLYH

0R7KXQWLORFORFN)UXQWLORFORFN

Switching times as well as pressure times can be programmed with the timer independently of each other.

:KHQSURJUDPPLQJVZLWFKLQJWLPHVWKHFRPSUHVVRUQHHGVQRORQJHUEHmanually switched on and off. This is to prevent the possibility that the compressor might for instance start up automatically at night in order to compensate for loss in the compressed air net.

)RUDOLPLWHGWLPHYDOXHVGHYLDWLQJIURPWKHSUHVHWOLPLWYDOXHVVHH&KDS-ter 5.3.4.1) can be set for the start and stop pressure. In this way only the minimal required operating pressure is always generated so that energy is saved.

Selection of the menu position 0RGLFDWLRQRIWKHEOLQNLQJvalues

ENTER &RQUPVHOHFWLRQPRGLFDWLRQ%DFNWRWKHQH[WKLJKHUOHYHO

-

31

If the timer for switching times is activated, then the compressor only

works during the switching times entered!

$GMXVWVZLWFKLQJWLPHVZHHNGD\VPDUNHGEODFN

&KDQQHOVHOHFWLRQZLWKWKHNH\V and

&RQUPVHOHFWLRQZLWKENTER.

0RYHWKHFXUVRUWRWKHGHVLUHGZHHNGD\E\XVLQJNH\ and . (In RUGHUWRGHOHWHDQDOUHDG\VHOHFWHGZHHNGD\SUHVVNH\ .)

4. Set the cursor with and RQWRWKHFORFNWLPHDQGXVHNH\V and WRPRGLI\WKHEOLQNLQJYDOXH

6WRUHWKHVHWWLQJVZLWKWKHNH\ENTER.

Compressor pressure times

,QWKLVPHQXWKHSUHVVXUHWLPHVRIWKHFRPSUHVVRUVDUHGHQHGLQFUHDVLQJpressure / decreasing pressure).

,QRUGHUWRDFWLYDWHWKHWLPHUWKHXSSHUPRVWPHQXURZRIWKHSDUDPHWHUIRUthe timer channels must be set to ON.

$FKDQQHO LVDFWLYHZKHQDW OHDVWRQHRI WKHZHHNGD\V LVPDUNHGEODFN(For switching times adjustment: see paragraph Compressor switching times)

The channels are searched beginning with K1 to K7 to determine whether a FKDQQHOLVDFWLYDWHGIRUWKHFXUUHQWFORFNWLPH,IQRYDOLGFKDQQHOLVIRXQGthen the settings in the menu limit values are valid. In order to activate the WLPHURXWSXWIRURQHRUDQXPEHURIGD\VFRQWLQXRXVO\WKHVZLWFKLQJWLPHof 00:00 should be entered.

Switching times LLC /pressure times LLC

Switching times or pressure times can only be entered if the supplementary module for Lead lag control (LLC) is installed in the control system.

The settings are to be carried out as described in Compressor switching times or Compressor pressure times

NOTICE

7LPHUFORFNRXWSXWDFWLYH6D6RXQWLORFORFN

IURP6DRFORFNXQWLO6XRFORFN

-

32

Pressure dimension Selection of the unit for the display of the line pressure

Edit

Temperature dimension Selection of the unit for the display of WKHQDOFRPSUHVVLRQWHPSHUDWXUH

Edit

Language Selection of the display language Edit

Pressure offset Readjustment possibility for the net pressure sensor

Display

Diagrams Settings for diagrams Edit

Texts Texts for the compressor pass Display

5. Displays and operating elements

5.3.4.5 Sub-menu Fault log

5.3.4.6 Sub-menu

Display parameters

,QWKLVPHQXWKHSDUDPHWHUVIRUWKHRXWSXWWRWKHGLVSOD\DUHVWRUHG

Diagrams

,QWKLVPHQXWKHGLVSOD\SDUDPHWHUVGHIDXOWYDOXHV;$872VHH&KDSWHU5.3.3.8) for the diagrams can be set:

Saving interval 6DYLQJLQWHUYDOIRUWKHUHFRUGLQJRIWKHOLQHSUHVVXUHWKHQDOFRPSUHVVLRQWHPSHUDWXUHRIWKHPRPHQWDU\GHOLYHU\quanitiy. The control system always saves the most recent 8000 values. For a saving interval of 12s (basic setting) the-re is a logging duration of 12s x 8000 = 96000s = 26.7h

Number of points X-auto

Number of the recorded values for function X-Auto on the time axis at a saving interval of 12 s and up to 300 points for X-Auto a time axis scaling of 12s x 300 = 3600s =1h

Line pressure low

Lower scale value of the x-axis of the diagramline pressure (see 5.3.3.4)

Line pressure high

Upper scale value of the x-axis of the diagramline pressure (see 5.3.3.4)

Temperature low Lower scale value of the x-axis of the diagramFinal compression temperature (see 5.3.3.5)

Temperature high

Upper scale value of the x-axis of the diagramFinal compression temperature (see 5.3.3.5) (basic 120C)

Air quantity day low

Lower scale value of the x-axis of the diagram Compressed DLUTXDQWLW\GDLO\SUROHVHH

Air quantity day high

Upper scale value of the x-axis of the diagram&RPSUHVVHGDLUTXDQWLW\GDLO\SUROHVHH

Air quantity ZHHNORZ

Lower scale value of the x-axis of the diagram Compressed DLUTXDQWLW\ZHHNO\SUROHVHH

Air quantity ZHHNKLJK

Upper scale value of the x-axis of the diagram Compressed DLUTXDQWLW\ZHHNO\SUROHVHH

,QWKLVPHQX\RXFDQYLHZWKHODVWVHUYLFHVZDUQLQJVDQGIDXOWVZLWKindication of the date and time.

Selection of the menu position 0RGLFDWLRQRIWKHEOLQNLQJvalues

ENTER &RQUPVHOHFWLRQPRGLFDWLRQ%DFNWRWKHQH[WKLJKHUOHYHO

-

33

5.3.4.7 Sub-menu

&RQJXUDWLRQ

Remote mode

Determines how the compressor is switched on or off.

Local operation: The compressor can only be switched on or off at the ope-UDWLQJGLVSOD\GHVNRI$LU&RQWURO

Remote control: The compressor can be switched on or off with an electri-FDOVLJQDORUWKHNH\ ,QWKHEDVLFGLVSOD\DSSHDUVDVWKHEOLQNLQJWH[WREMOTE.

Machine type 6HOHFWLRQRIDSUHGHQHGPDFKLQHW\SH Display

Maximal pressure Maximum permissible machine pressure Display

0D[LPDODLURZ Delivered air quantity at maximum speed in on-load operation

Display

Remote mode Switching on/off of the system Edit

LLC operation Operation with external base load alternate switching

Edit

Power fail Stop Switching-off when low voltage is recognized Display

Frequency converter Settings of the frequency converter Display

Communication Settings for serial communication Display

Heating Settings of the additional heater Display

During active remote operation, the signal of the remote control must

be switched off after pressing the key .NOTICE

//&2.,VIRUWKHQRWLFDWLRQRIUHDGLQHVVIRURSHUDWLRQRIDVXSHULRUFRQWUROsystem to the compressor. (see also LLC Operation 5.3.4.9)

LLC mode

The compressors are controlled by a higher-level control system. The text LLC MODE (see also Remote Mode 5.3.4.9) appears in the basic display

Selection of the menu position 0RGLFDWLRQRIWKHEOLQNLQJvalues

ENTER &RQUPVHOHFWLRQPRGLFDWLRQ%DFNWRWKHQH[WKLJKHUOHYHO

-

34

5. Displays and operating elements

5.3.4.8 Sub-menu

Lead lag control (LLC)

5.3.4.9 Sub-menu Accessories

This menu contains the settings for the operation as the LLC Master.

)RUWKHXWLOL]DWLRQRIWKHIXQFWLRQ/HDGODJFRQWURO$LU&RQWUROPXVWEHWWHGZLWK a supplementary module for up to 4 additional compressors

two supplementary modules for up to 8 additional compressors.

Lead lag control Parameter for the activation of the LLC Master characteristics(basic setting: NO)

Display

Start pressure Lower pressure threshold for switching on a compressor

Edit

Stop pressure Upper pressure threshold for switching off a compressor

Edit

Cut out at 3HUFHQWDJHRIPDVWHUPDFKLQHSRZHUbelow which slave compressors are cut out

Edit

Cut in at 3HUFHQWDJHRIPDVWHUPDFKLQHSRZHUabove which slave compressors are cut out

Edit

Start delay Minimal time between the switching on of two compressors

Edit

Stop delay Minimal time between theswitching off of two compressors

Edit

Changeover interval Priority 1

Time between changeovers of LLC for compressors having priority 1

Edit

Changeover interval Priority 2

Time between changeovers of LLC for compressors having priority 2

Edit

Changeover interval Priority 3

Time between changeovers of LLC for compressors having priority 3

Edit

Priorities Assignment of sequencing priority Edit

(see also Chapter 5.3.4.7)

Accessories module Additional module for accessories availa-ble

Display

,QSXWFRQJXUDWLRQ Function of digital inputs Edit

2XWSXWFRQJXUDWLRQ Function of digital outputs Edit

Switching times output 1 6ZLWFKLQJWLPHVGHQHGIRUDFFHVVRULHV Edit

Switching times output 2 6ZLWFKLQJWLPHVGHQHGIRUDFFHVVRULHV Edit

Switching times output 3 6ZLWFKLQJWLPHVGHQHGIRUDFFHVVRULHV Edit

Switching times output 4 6ZLWFKLQJWLPHVGHQHGIRUDFFHVVRULHV Edit

This menu contains the settings for the connection of accessories.

7REHDEOHWRXWLOL]HWKLVIXQFWLRQ$LU&RQWUROPXVWEHWWHGZLWKDFFHVVR-ries modules.

The LLC master function may only be activated when the compressor

is actually used as master unit!

NOTICE

Selection of the menu position 0RGLFDWLRQRIWKHEOLQNLQJvalues

ENTER &RQUPVHOHFWLRQPRGLFDWLRQ%DFNWRWKHQH[WKLJKHUOHYHO

-

35

Switching times

7KHVZLWFKLQJRQRIIWLPHVRIDQDFFHVVRU\UHOD\RXWSXWDUHGHQHGLQWKLVmenu.

)RUWKHDFWLYDWLRQRIWKHWLPHUWKHXSSHUPRVWPHQXURZRIWKHSDUDPHWHUof the timer channels must be set to ON.

Seven switching times can be programmed with the channels K1 K7. One FKDQQHOLVDFWLYHZKHQDWOHDVWRQHRIWKHZHHNGD\VLVPDUNHGEODFN

)RUDGMXVWPHQWRIWKHVZLWFKLQJWLPHVVHHSDUDJUDSK&RPSUHVVRUVZLWFK-ing times Chapter 5.3.4.4.

,QRUGHUWRFRQWLQXDOO\DFWLYDWHWKHWLPHURXWSXWIRURQHRUDQXPEHURIGD\Vset the switching time to 00:00.

,QSXWFRQJXUDWLRQ

The inputs 1 to 8 can be used in order to switch the compressor to malfunc-tion or warning.

7LPHUFORFNRXWSXWDFWLYH

0R7KXQWLORFORFN)UXQWLORFORFN

5.3.4.10 Sub-menu Diagnosis This menu describes the current states of digital inputs and outputs.

-

36

$ZDUQLQJLVSUHVHQWZKHQWKHUHGOLJKWLVEOLQNLQJThe compressor is not switched off.

The display contains the additional information:

EOLQNLQJV\PEROZDUQLQJWULDQJOH type of warning

telephone number of the service hotline

5.3.5 Warnings / maintenance

NOTICE

Damage to the system is possible!

Necessary maintenance work appear as warnings.

$FNQRZOHGJHWKHVHZDUQLQJVRQO\ZKHQWKHGHQHGPDLQWHQDQFHZRUNhas actually been carried out!

Maintenance work not carried out degrades the service life and re-

liability of the system. Please note that damage because of improper

usage might invalidate the warranty!

Only original spare parts may be used.

Information on service: see Chapter 8.

6HUYLFHVZRUNDFNQRZOHGJHG $VGHVFULEHGLQ&KDSWHUFDOOXSWKHPDLQPHQXDQGWKHQWKHVXE

menu Maintenance schedule.

6HOHFWWKHPDLQWHQDQFHZRUNWREHFDUULHGRXWXVLQJNH\V and .

3UHVVNH\ WRDFNQRZOHGJHWKHVHUYLFH

%\GRXEOHFOLFNLQJNH\ you will return to the basic display.

:KDWWRGRIRUVSHFLFZDUQLQJVPDLQWHQDQFHZRUNLVGHVFULEHGLQChapter 8.

5. Displays and operating elements

-

37

5.3.6 Malfunctions A malfunction has occurred when the red light is permanently on.

The compressor is stopped automatically.

,QDGGLWLRQWKHGLVSOD\DOVRVKRZV EOLQNLQJV\PEROWRRONH\ type of malfunction

telephone number of the service hotline

0DOIXQFWLRQVFDQRQO\EHDFNQRZOHGJHGZKHQWKHFDXVHKDVEHHQSURIHV-sionally repaired. Troubleshooting and repair should be done exclusively E\TXDOLHGSHUVRQQHO

)DXOWPHVVDJHVDFNQRZOHGJHG SUHVVNH\ . SUHVVNH\ in order to restart the compressed air generation.

-

38

5. Displays and operating elements

The display contrast of the control was selected so that it ensures optimum readability under nearly all operating conditions. If it is nevertheless required to adjust the contrast under certain conditions (e.g. unfavourable lighting FRQGLWLRQVGLUHFWVXQOLJKWIROORZWKHVWHSVEHORZ

5.3.7 Adjustment of the display

contrast

2. Open the control cabinet/control box of the compressor.

3. At the rear of the control you can see a small opening at the top.

1. Make sure that the compressor is disconnected from the power

supply by actuating the master switch.

DANGER

Insert a small plain slot screwdriver through this opening to reach the ad-justment screw for correcting the contrast.

7RLQFUHDVHWKHFRQWUDVWVOLJKWO\WXUQFORFNZLVHE\WXUQLQJFRXQWHUFOR-FNZLVH\RXUHGXFHWKHFRQWUDVW

5. Close the control cabinet/control box before recommissioning.

-

39

5.4 Air Control 1 7KHRSHUDWLQJGLVSOD\GHVNRI$LU&RQWURO displays the compressor states / operating data

switches on and off compressed air generation

is used for compressor parameterizing.

0RGLFDWLRQRISDUDPHWHUYDOXHV

&RQUPDWLRQRISDUDPHWHUFKDQJHV

Display additional operating data.

Switch on compressor.

Integrated green LED

%OLQNLQJ FRPSUHVVRULVQRWUXQQLQJFDQDWDQ\WLPHbe automatically started up.

Lighted: Compressor is running.

Compressor shut down.

Signals a current warning/malfunction with the inte-grated red LED.

-

40

Instead of the current compressor temperature you can also have the cur-

UHQWFRROLQJXLGWHPSHUDWXUHGLVSOD\HG3UHVVNH\ . For viewing further RSHUDWLQJGDWDVHH&KDSWHU

5.4.1 Basic display $IWHUVZLWFKLQJRQWKHPDLQVZLWFKRUGXULQJQRUPDORSHUDWLRQ$LU&RQWURO1 will inform you about the compressor state.

Current pressure

Warning present (see Chapter 5.4.5)

Motor is running

Compressor compresses air

Fault is present (see Chapter 5.4.6)

RESTART Automatic restart after power supply is activated

AUTOMATIC Operating mode Automatic or Automatic optional

REMOTE - Flashing: Generation of compressed air ON/OFF by remote switch

- Continuous: Generation of compressed air con-trolled by higher-level control

Current compressor temperature

5. Displays and operating elements

-

41

5.4.2 ON/OFF switching of com-

pressed air generation

5.4.3 Viewing additional opera-

ting data

Switching ON: press NH\ .The compressor is ready and can start up automatically at any time.

Press the INFONH\UHSHDWHGO\WRYLHZWKHIROORZLQJRSHUDWLQJGDWDLQWKHorder below.

Switching OFF: press NH\ .)RU WKHGXUDWLRQRI WKHRII WLPH WKHFRPSUHVVRUVZLWFKHV WR WKHRIIORDGstate and afterwards off.

The compressor starts up only when

the current line pressure falls below the start pressure and

the compressor temperature is at least 1 C.

'XULQJWKHVZLWFKLQJRIISURFHVVWKHXQLWUVWFKDQJHVRYHUWRWKHRIIORDGPRGHPRWRUUXQQLQJEXWFRPSUHVVRUGRHVQRWFRPSUHVVDLUDDVKLQJpoint appears in the display) for the duration of the off time (45 s). Only then is the unit switched off (motor stops).

Operating data

1x Start pressure in bar. The compressor starts up as soon as the line pressure falls below this value.

2x Stop pressure in bar. The unit changes over to the off-load mode as soon as the line pressure increases above this value.

3x Safety pressure in bar (= stop pressure + 0.8 bar). When this safety SUHVVXUHLVUHDFKHGWKHFRPSUHVVRUVKXWVGRZQDQGDQHUURUPHV-sage is output.

4x min. permissible compressor temperature

5x max. permissible compressor temperature

6x Total running hours

7x On-load hours

[ 5HPDLQLQJVHUYLFHOLIHRIDLUOWHU [ 5HPDLQLQJVHUYLFHOLIHRIFRROLQJXLGDQGFRROLQJXLGOWHU[ 5HPDLQLQJVHUYLFHOLIHRIQHVHSDUDWRU11x Remaining service life of motor lubrication

12x Time remaining until compressor must be serviced

Display of faults/warnings is deactivated!

As long as the operating data above are viewed, no fault messages

or warning can be output. This screen should therefore be exited as

soon as possible.NOTICE

-

42

All basic settings of the system can be viewed in the menu system. If the PRGLFDWLRQVKDYHQRLQXHQFHRQRSHUDWLRQDOVDIHW\WKH\PD\EHPRGLHGby means of a code entry.

Unit parameterisation 5.4.4.1Basic parameterisation 5.4.4.2Available code numbers

5.4.4.3 bis 5.4.4.13

5.4.4.1 Unit parameterisation 7KHXQLWFDQRQO\EHSDUDPHWHULVHGZKHQWKHJHQHUDWLRQRIFRPSUHVVHGair is switched off. See Chapter 5.4.2.

3DUDPHWHUVDOORZWKHXQLWWREHDGMXVWHGWR\RXUVSHFLFUHTXLUHPHQWV7RWKLVHQG$LU&RQWUROPXVWEHVZLWFKHGWRWKHSDUDPHWHULVDWLRQPRGHThe individual parameters can be selected with a code and then changed. A description of available code numbers can be found in Chapters 5.4.4.3 to 5.4.4.13.

1RZVHOHFWWKHUHTXLUHGFRGHE\PHDQVRINH\V and .3. Press ENTERWRDFWLYDWHWKHFRGH$LU&RQWUROFKDQJHVWRWKHUVW

sub-level.

With some codes, several parameters can be entered one after the other.

In these cases, simply press key ENTER to select the subsequent param-

eter.

8VHNH\V and to change the current setting of the selected code according to your requirements.

3UHVVNH\ENTERWRWDNHRYHUWKHQHZVHWWLQJVRUSUHVVNH\ to leave the setting unchanged and return to the next higher level.

Paremeterisation procedure:

3UHVVNH\ until the message cod appears in the display. Air Control 1 is now at the main level of the parameterisation mode.

CodeDVKLQJ

5.4.4 Menu system

5. Displays and operating elements

-

43

5.4.4.2 Basic parameterisation 7KHXQLWFDQRQO\EHSDUDPHWHULVHGZKHQWKHJHQHUDWLRQRIFRPSUHVVHGair is switched off. See Chapter 5.4.2.

The basic parameterisation prepares the unit for operation.

3UHVVNH\ until the message cod appears in the display. 6HOHFWFRGHE\PHDQVRINH\V and DQGSUHVVNH\ENTER. 3UHVVNH\INFO.

Air Control 1 now shows the start pressure. The compressor compresses air as soon as the line pressure falls below this value. Possible adjust-ment range: 3.5 to maximum pressure of the unit.

$GMXVWWKHUHTXLUHGVWDUWSUHVVXUHXVLQJNH\V and FRQUPWKHVHWWLQJE\SUHVVLQJNH\ENTER.

3UHVVNH\INFO.

6WRSSUHVVXUHDVKLQJ

6WDUWSUHVVXUHDVKLQJ

&RGHDVKLQJ

Air Control 1 shows the stop pressure. The compressor changes over to off-load operation as soon as the line pressure exceeds this value. Possible adjustment range: 3.5 to maximum pressure of the unit.

The stop pressure must be higher than the start pressure!

6HOHFWWKHUHTXLUHGSDUDPHWHUYDOXHXVLQJNH\V and DQGFRQUPWKHVHWWLQJE\SUHVVLQJNH\ENTER.

3UHVVNH\ to complete the basic parameterisation.

-

44

5.4.4.3 Code 2: Operating mode Determines how the unit is to respond when the start or stop pressure is reached. Both limit values are set during basic parameterisation (see Chapter 5.4.4.2).

0: Automatic.

The symbol Automatic appears in the display.The motor starts up and the compressor compresses air (= on-load RSHUDWLRQDVVRRQDVWKHOLQHSUHVVXUHIDOOVEHORZWKHVWDUWSUHVVXUH7KHXQLW FKDQJHVRYHU WR RIIORDGRSHUDWLRQ PRWRU UXQQLQJ EXW WKHFRPSUHVVRUGRHVQRWFRPSUHVVDLUDVVRRQDVWKHOLQHSUHVVXUHH[-FHHGVWKHVWRSSUHVVXUH$VVRRQDVWKHRIIORDGSKDVHVWDUWVWKHRIIWLPHHODSVHVIRUWKHSDUDPHWHULVDWLRQVHH&RGH&KDSWHUThe motor stops after the off time.

1: On-/off-load

The symbol Automatic is not shown in the display. ,QFRQWUDVWWRWKHDXWRPDWLFRSHUDWLQJPRGHWKHPRWRUQHYHUVWRSVUXQ-

ning. The compressor compresses air as soon as the line pressure falls below the start pressure. The unit changes over to off-load operation PRWRULVUXQQLQJEXWWKHFRPSUHVVRUGRHVQRWFRPSUHVVDLUDVVRRQas the line pressure rises above the stop pressure.

2: Automatic optional

The symbol Automatic and an additional dot before the temperature are shown in the display.

6LPLODUWRWKHDXWRPDWLFPRGH+HUHWKHXVHUKDVDQLQXHQFHRQKRZRIWHQWKHPRWRUVWRSV7RWKLVHQGWKHSDUDPHWHUVPD[LPXPSUHVVXUHloss (adjustment range 0.0 to 9.9 bar) and max. number of motor starts (adjustment range 1 to 55 cycles/hour) are queried additionally.

Function Max. pressure loss: :KHQ WKH XQLW FKDQJHV RYHU IURPRQORDG WR RIIORDG RSHUDWLRQ$LU

Control 1 saves the current line pressure after 10 and after 40 seconds. If the pressure loss thus established is higher than the Max. pressure ORVVWKHPRWRUVKXWVGRZQDIWHUWKHRIIWLPHKDVHODSVHGSDUDPHWHUL-VDWLRQZLWKFRGHVHH&KDSWHURWKHUZLVHDIWHUWKHRIIWLPH(45 s).

Function Max. number of motor starts: 7KHPRWRU LV QRW VZLWFKHGRII DIWHU WKH RII WLPHHODSVHGZKHQ WKH

number of starting cycles of the compressor exceeds the Max. number of motor starts.

5. Displays and operating elements

-

45

5.4.4.4 Code 3: Automatic re-

start after power failure

Determines whether the generation of compressed air is to restart automati-cally after a mains power failure.

0: Automatic restart: OFF

The generation of pressure remains deactivated after a power failure. The fault message power fail is output.

1: Automatic restart: ON

:KHQ WKLV IXQFWLRQ LV DFWLYDWHG WKH GLVSOD\ VKRZV WKH V\PERO UH-start.If the generation of pressure was activated before the power failure RFFXUHGWKHXQLWUHVWDUWVDXWRPDWLFDOO\DIWHUWKHRIIWLPH,QWKLVFDVHthe fault message power fail is not output. If the generation of pressure ZDVGHDFWLYDWHGEHIRUHWKHSRZHUIDLOXUHLWUHPDLQVGHDFWLYDWHG

5.4.4.5 Code 8: Local control,

remote control, LLC-OK

'HWHUPLQHVKRZWKHJHQHUDWLRQRISUHVVXUHLVWREHVZLWFKHGRQDQGRII

0: Local control

The generation of compressed air can only be switched on or off from the control panel of Air Control 1.

1: Remote control

The generation of compressed air can be switched on only by way of a positive edge (24 VDC) at terminal 23 and switched off only by means of DORZOHYHO9DWWHUPLQDORUE\SUHVVLQJNH\ . This functionality LVVLJQDOOHGRQWKHGLVSOD\RI$LU&RQWUROE\DDVKLQJWH[W5HPRWHIf the NH\LVORFDOO\RSHUDWHGRQWKHXQLWWKHXQLWVZLWFKHVRIIDIWHUVHFRQGVDQGIRUVDIHW\UHDVRQVFDQRQO\EHUHVWDUWHGE\UHPRWHcontrol after the NH\ZDVRSHUDWHGORFDOO\DFNQRZOHGJHPHQW7KLValso applies to a start via PLANT CONTROL V/T.

2: LLC-OK

The input at terminal 23 is used to signal the readiness for operation of an external control. The external control can only be switch between on-load and off-load operation when a high level (24 VDC) is applied VHHFRGHYDOXH&KDSWHU:KHQDORZOHYHOLVDSSOLHGLLC operation is automatically switched off and the internal pressure sensor used.

5.4.4.6 Code 11: Start and stop

pressure

'HWHUPLQDWLRQRIWKHVWDUWDQGVWRSSUHVVXUHVIRUWKHSURFHGXUHVHH&KDS-ter 5.4.4.2

-

46

5.4.4.7 Code 18: Lead leg con-

trol (LLC)

Determines whether the changeover between on-load and off-load opera-tion is to be controlled by the internal pressure senor or by a higher-level control.

0: Changing over between on-load/off-load operation by internal pres-

sure sensor

1: Changing over between on-load/off-load operation by external

control (e.g. PLC)

On-load operation when a high level (24 VDC) is applied to terminal 22.Off-load operation when a low level (0 V) is applied to terminal 22. This functionality is signaled by the text remote that appears continuously in the display of Air Control 1.

5.4.4.8 Code 21: Maintenance

acknowledgement

,VXVHGIRUDFNQRZOHGJLQJDPDLQWHQDQFHZDUQLQJFXUUHQWO\SUHVHQW)RUWKHPHDQLQJRIPDLQWDLQHQFHQXPEHUVDQGDFNQRZOHGJHPHQWRIZDUQLQJVsee Chapter 5.4.5.

NOTICE

Possible damage to the unit!

Required maintenance work is signalled in the form of warnings.

Acknowledge these warning only, when the required maintenance has

actually been carried out!

If the unit is not serviced, its service life and reliability are reduced.

Please note that damage resulting from improper handling is not cov-

ered by the warranty!

Use only genuine spare parts.

More information about servicing can be found in Chapter 8.

5. Displays and operating elements

-

47

5.4.4.10 Code 65: Condensate

valve

,VXVHGIRUDGMXVWLQJWKHLPSXOVHDQGEUHDNWLPHVRIWKHFRQGHQVDWHYDO-ve.

0: Impulse time

Duty cycle of the condensate valve

1: Break time

Off time of the condensat valve

5.4.4.9 Code 51: Off-load, off,

star/delta time

0: Off-load time

Adjustment range: 10 - 1200 s. Operation in conjunction with Code 2 (operating mode). Is used in the operating modes Automatic and Automatic optional.

1: Off time

Adjustment range: 0 - 60 s. The factory setting of 45 s should be retained. 'XULQJWKHRIIWLPHWKHPRWRULVUXQQLQJLQWKHLGOHPRGHQRFRPSUHVVHGair is generated. The off time elapses

ZKHQNH\ is pressed for switching off- according to the Automatic optional mode

:KHQWKHIXQFWLRQ$XWRPDWLFUHVWDUWDIWHUSRZHUIDLOXUH LVVHOHFWHGthe start-up of the motor is delayed for the set time of standstill.

2: Star/delta time

Adjustment range: 3 - 30 s. Determines after which time changing over is WRWDNHSODFHIURPVWDUWRGHOWDFLUFXLWZKHQWKHPRWRULVVZLWFKHGRQ

The relevant times can be entered successively at operating levels 0 to 2.

-

48

5.4.4.11 Code 90: Unit for pres-

sure indication

Determines the unit for the pressure indication:

0: bar

1: MPa

2: psi

5.4.4.12 Code 95: Unit for tempe-

rature indication

Determines the unit for the temperature indication:

0: Degree Celsius (C)

1: Degree Fahrenheit (F)

2: Kelvin (K)

5.4.4.13 Code 9999: Software

version

Indicates the software version of Air Control 1.

5. Displays and operating elements

-

49

$FNQRZOHGJHPDLQWHQDQFHZRUN 3UHVVNH\ (ca. 3 sec.) until the message cod appears in the dis-

play.

6HOHFW&RGHXVLQJNH\V and .3. Press ENTERWKHQ .

$ZDUQLQJLVSUHVHQWZKHQWKHUHGOLJKWLVEOLQNLQJThe compressor is not switched off.

The following is displayed:

5.4.5 Warnings / maintenance

work

Meaning of maintenance numbers:

2 ([FHVVLYHQDOFRPSUHVVLRQWHPSHUDWXUH3 Excessive line pressure

11 5HPDLQLQJWLPHXQWLODLUOWHULVWREHVHUYLFHGK12 5HPDLQLQJWLPHXQWLOFRROLQJXLGFRROLQJXLGOWHULVWREHVHUYLFHG

K13 5HPDLQLQJWLPHXQWLOQHVHSDUDWRULVWREHVHUYLFHGK14 5HPDLQLQJWLPHXQWLOPRWRULVWREHOXEULFDWHGK15 5HPDLQLQJWLPHXQWLOFRPSUHVVRULVWREHVHUYLFHGK

Maintenence number DVKLQJ

Symbol for warnings DVKLQJ

NOTICE

Damage to the system is possible!

Necessary service work appears in the form of warnings.

$FNQRZOHGJHWKHVHZDUQLQJVRQO\ZKHQWKHGHQHGVHUYLFHZRUNKDVactually been carried out!

Service work not carried out degrades the service life reliability of the

system. Please note that damage caused by improper usage is not

covered by the warranty!

Only original spare parts may be used.

Information on service: see Chapter 8.

-

50

5.4.6 Malfunctions Malfunction has occurred when the red light is permanently on.

The compressor is stopped automatically.

The following is shown in the display:

Meaning of fault numbers and texts:

1 Par Incorrect pressure setpoints

2 EPROM Incorrect setting parameters

3 Lo AC Undervoltage

4 No AC Power failure

5 OEFEC Air Control 1 defective

6 Emerg EMERGENCY OFF actuated

7 Rotat Wrong direction of rotation

8 Mot t Excessive motor temperature

9 Hi cur Overcurrent

10 Hi P Overpressure

11 'LI3 'LIIHUHQWLDOSUHVVXUHRIQHVHSDUDWRU12 6HW 6HQVRUIRUQDOFRPSUHVVLRQWHPSHUDWXUH13 6HRLO 6HQVRUIRUFRROLQJXLGWHPSHUDWXUH14 Se P Pressure sensor

15 +LW ([FHVVLYHQDOFRPSUHVVLRQWHPSHUDWXUH16 Hi P Excessive line pressure

Fault number DVKLQJ

Symbol of malfunction DVKLQJ

Fault textDOWHUQDWHVZLWKWKHQDO

compression temperature

0DOIXQFWLRQVFDQRQO\EHDFNQRZOHGJHGZKHQWKHFDXVHKDVEHHQSURIHV-sionally repaired. Troubleshooting and repair should be done exclusively E\TXDOLHGSHUVRQQHO

$FNQRZOHGJHIDXOWPHVVDJHV SUHVVNH\ . SUHVVNH\ in order to restart the compressed air generation.

5. Displays and operating elements

-

51

The display contrast of the control was selected so that it ensures optimum readability under nearly all operating conditions. If it is nevertheless required to adjust the contrast under certain conditions (e.g. unfavourable lighting FRQGLWLRQVGLUHFWVXQOLJKWIROORZWKHVWHSVEHORZ

5.4.7 Adjustment of the display

contrast

2. Open the control cabinet/control box of the compressor.

3. At the rear of the control you can see a small opening at the top.

1. Make sure that the compressor is disconnected from the power

supply by actuating the master switch.

DANGER

Insert a small plain slot screwdriver through this opening to reach the ad-justment screw for correcting the contrast.

7RLQFUHDVHWKHFRQWUDVWVOLJKWO\WXUQFORFNZLVHE\WXUQLQJFRXQWHUFOR-FNZLVH\RXUHGXFHWKHFRQWUDVW

5. Close the control cabinet/control box before recommissioning.

-

52

6. Correcting malfunctions

Error Cause Measures

Compression temperaturetoo high (red lamp is on)

Silencing hood not closed &KHFNDQGVHFXUHVRXQGLQVXODWLRQhood

,QWDNHRUDPELHQWWHPSHUDWXUHtoo high

Ventilate compressor room

&RROLQJDLULQOHWRURXWOHWEORFNHG 0DNHVXIFLHQWURRP

&RROLQJXLGOWHUIRXOHG 5HQHZFRROLQJXLGOWHU

,QVXIFLHQWFRROLQJXLG $GGFRROLQJXLG

([WHUQDOFRROLQJXLGKHDWH[FKDQJHUfouled!Attention: Cooler screw should DOZD\VEHZRUNHGZLWKDFRXQWHUZUHQFKNHHSIURPDSSO\LQJWRUTXHWRthe cooler

Clean with compressed air. In the case of extensive fouling: disassemble cooler and clean with high pressure cleaner. Attention: Danger of short circuit! Do not put electrical elements under power

Line pressure falls Compressed air consumptiongreater than delivery quantityof the compressor

A compressor with larger delivery quantity is required

$LUOWHULVIRXOHG 5HSODFHDLUOWHU

Relief valve blows air during compres-sion

&KHFNUHOLHIYDOYHLIQHFHVVDU\replace seals

Suction regulator does not open &KHFNVROHQRLGYDOYHUHJXODWRUVSRRODQGLIQHFHVVDU\UHSODFH

/HDNDJHLQWKHSLSHZRUN 0DNHSLSHZRUNDLUWLJKW

System pressurereleased by safety valve

Line pressure set too high Adjust line pressure anew

Safety valve defective &KHFNVDIHW\YDOYHLIQHFHVVDU\exchange

0LQLPXPSUHVVXUHYDOYHEORFNHG Exchange solenoid valve

&RROLQJXLGVHSDUDWRUFDUWULGJHfouled

([FKDQJHFRROLQJXLGVHSDUDWRUcartridge

Malfunction over-pressure or line pressure too high (red lamp is on)

&RROLQJXLGVHSDUDWRUIRXOHG 5HSODFHFRROLQJXLGVHSDUDWRU

Higher external pressure in thecompressed air net

Equalize outside pressure or remove from net

-

53

Error Cause Measures

Compressor does notstart automatically ordoes not deliver air after previous switching off XSRQUHDFKLQJWKHQDOpressure or from off-load state.

Net pressure set too high Adjust net pressure anew

Interruption in the control current circuit

&KHFNHOHFWULFFLUFXLWIRULQWHUUXSWLRQ(only by a trained electrician)

$PELHQWWHPSHUDWXUHXQGHU&message &RROLQJXLGtemperature too low

,QVWDOODQDGGLWLRQDOKHDWHURUNHHScompressor room at right temperature

Switching times have been activated in Air Control 3

&KHFNVZLWFKLQJWLPHVDQGSUHVVXUHtimes in Air Control

System does not start on pressing the start button

Line pressure greater than startpressure

Note line pressure value

Remote control activated 6\PEROUHPRWHLVEOLQNLQJ

Missing voltage at the compressor &KHFNLIYROWDJHLVDSSOLHG

Electrical error in the control system Inspect (only by an trained electrician)

Switching times have been activated in Air Control 3

&KHFNVZLWFKLQJWLPHVin the Air Control 3

Compressed aircontaining large amountRIFRROLQJXLGFRROLQJXLGFRQVXPSWLRQWRRgreat)

&RROLQJXLGUHWXUQRZSLSLQJis congested

&OHDQFRROLQJXLGIHHGEDFNSLSLQJ

'HIHFWLYHFRROLQJXLGVHSDUDWRU 5HSODFHFRROLQJXLGVHSDUDWRU

System stopped before UHDFKLQJWKHQDOSUHVVXUH(red lamp is on)

Overtemperature or overpressure Rectify error as required

Interruption in the control current loop &KHFNFXUUHQWORRS(only by a trained electrician)

Water in the piping net Dryer switched off Switch on dryer

Condensation diverteris not functioning

Clean / exchange drain

Bypass open Close bypass

Dew point too high Demand customer service

Pressure decline 3UHVVXUHGLIIHUHQWLDOLQWKHOWHUtoo great

([FKDQJHOWHU

-

54

7. Initial commissioning

&KHFNFRROLQJXLGlevel

7.1 Preparatory activities 0DNHFHUWDLQWKDWZKHQWKHFRPSUHVVRUPDLQVZLWFKLVVZLWFKHGRIIQRillicit or inadvertent switching on can occur.

&KHFNDOOWWLQJVRIWKHFRPSUHVVRU,IUHTXLUHGUHWLJKWHQWKHWWLQJV 0DNHFHUWDLQWKDWWKHV\VWHPLVFRUUHFWO\FRQQHFWHGWRWKHFRPSUHVVHG

DLUQHW0DNHFHUWDLQWKDWZKHQWKHVKXWRIIYDOYHRQWKHSUHVVXUHQHWVLGHLVFORVHGLOOLFLWRULQDGYHUWHQWRSHQLQJFDQQRWRFFXU

7.3 Start-up lubrication of the

compressor stage

$IWHU DQ H[WHQGHG VWDQGVWLOO WLPH IRU H[DPSOH EHWZHHQ IDFWRU\ GHOLYHU\DQGFRPPLVVLRQLQJRUGXULQJDORQJHUFRPSDQ\YDFDWLRQWKHUHPLJKWQRORQJHUEHDQ\FRROLQJXLGLQWKHURWRUFKDPEHURIWKHDLUHQG7KLVFRROLQJXLGLVDEVROXWHO\QHFHVVDU\IRUEHDULQJDQGURWRUOXEULFDWLRQLQWKHVWDUWXSphase.

&KHFNFRROLQJXLGOHYHOFRROLQJXLGUHOO

,IQRH[WUDFRROLQJXLGLVDYDLODEOHRQO\FRROLQJXLGRIWKHVDPHYDULHW\PD\EHHPSOR\HGWKHFRROLQJXLGFDQEHWDNHQIURPWKHFRROLQJXLGGUDLQIf the system is employed only very irregularly or shut down weeks on end,

it should run an hour in the off-load mode once a week in order to avoid

corrosion damage caused by standing condensation.

%HIRUHVZLWFKLQJWKHFRPSUHVVRURQOODSSUR[OLWUHVFRROLQJXLGinto the compressor stage.

2. Rotate the air end only by hand in the correct direction of rotation until WKHQRWLFHDEOHUHVLVWDQFHGZLQGOHVDQGWKHFRROLQJXLGSDVVHVWKURXJKthe air end.

0DNHFHUWDLQWKDWHVFDSLQJFRROLQJXLGFDQEHFROOHFWHG &KHFNWKHFRROLQJXLGOHYHORQWKHVLJKWJODVV7KHVLJKWJODVVPXVW

EHFRPSOHWHO\ZHWWHGZLWKFRROLQJXLG/RRVHQWKHOOLQJVFUHZ'RQRWORVHWKHVHDOULQJ:LWKQHZFRPSUHVVRUVWKHFRROLQJXLGOHYHOPXVWEHDWWKHORZHUHGJHRIWKHOOHUQHFN

,I UHTXLUHG UHOO FRROLQJ XLG VHH&KDSWHU &KHFN FRROLQJ XLGOHYHOUHOOFRROLQJXLG

-

55

6ZLWFKWKHV\VWHPRQZLWKNH\ Switch the system off again with the ZKHQWKHYHQWLODWRUVWDUWVUXQQLQJ

,QRUGHUWRVXSSO\WKHV\VWHPZLWKVXIFLHQWFRROLQJDLUWKHURWDWLRQDOGLUHFWLRQof the ventilator motors must concur with the rotational direction arrow.

,QWKHFDVHRILQFRUUHFWURWDWLRQDOGLUHFWLRQRIWKHFRPSUHVVRUYHQWLODWRUVa trained electrician should correct the phase sequence of the electrical supply in the switching cabinet by exchanging the two supply phases. This should be carried out in a switched-off state secured against accidental switching on.

7.4 Rotational direction control 7KHURWDWLRQDOGLUHFWLRQRIWKHFRPSUHVVRUYHQWLODWRUVPXVWEHFKHFNHGThe rotational direction of the main motor is determined by the frequency FRQYHUWHUDQGPXVWFRQIRUPZLWKWKHDI[HGURWDWLRQDOGLUHFWLRQDUURZ

5HPRYHWKHFRYHUSDQHOVRIWKHV\VWHPVRWKDWWKHHOHFWULFPRWRURIthe ventilator is visible.

2. Switch the compressor main switch on.

-

56

7.5 Basic settings ,QRUGHUWRXQGHUVWDQGFRPSUHVVRUEDVLFVSOHDVHUHDGWKHFKDSWHU&RP-pressor operating elements .

7.5.1 Controlling the unit

by means of Air Control 3

More precise instructions on the basic settings of the system can be found in the following chapters :

&KDSWHU$LU&RQWURO Chapter 5.3.1 Basic display

Chapter 5.3.4 Menu system

The display parameters

SUHVVXUHGLPHQVLRQ WHPSHUDWXUHGLPHQVLRQ language

FDQEHPRGLHGDVGHVFULEHGLQSRVLWLRQ

The limit values

start pressure

stop pressure

FDQEHPRGLHGDVGHVFULEHGLQSRVLWLRQ

,I\RXU$LU&RQWUROKDVEHHQWWHGZLWKWKHVXSSOHPHQWDU\PRGXOH//&carry out settings as in point 5.3.4.7 5.3.4.9 of the description.

,I\RXU$LU&RQWUROKDVEHHQWWHGZLWKWKHVXSSOHPHQWDU\PRGXOHDFFHV-VRULHVFDUU\RXWVHWWLQJVDVLQSRLQWRIWKHGHVFULSWLRQ

7. Initial commissioning

7.5.2 Controlling the unit

by means of Air Control 1

)RUPRUHGHWDLOHGLQVWUXFWLRQVZLWKUHJDUGWRWKHEDVLFVHWWLQJVRIWKHXQLWplease refer to:

&KDSWHU$LU&RQWURO &KDSWHU%DVLFGLVSOD\ &KDSWHU0HQXV\VWHP

Please set the display parameters as described in the following chapters:

3UHVVXUHXQLW&KDSWHU 7HPSHUDWXUHXQLW&KDSWHU

The limit values for

start pressure and

stop pressure

FDQEHVHWDVGHVFULEHGLQWKHVHFWLRQ%DVLFSDUDPHWHUVDWLRQ&KDSWHU5.4.4.2.

-

57

%HIRUHVZLWFKLQJRQWKHV\VWHPPDNHFHUWDLQWKDWQRRQHFDQEHHQ-dangered by doing so. The sound-insulation hood serves as a part of WKHFRQWDFWSURWHFWLRQDPRQJRWKHUWKLQJVIRUWKHFRROLQJDLUFRQGXLWVof the compressor plant. It must be closed during operation.

2. Carefully open the shut-off valve after the compressed air connector and between system compressed air net (receiver). The system is now connected to the net.

3. Switch on the main switch.

0DNHFHUWDLQWKDWQRWRROVRUORRVHREMHFWVDUHO\LQJRQRULQWKHV\V-tem.

3UHVVNH\ to switch on the compressed air generation.

7KHJUHHQ/('LQNH\ OLJKWVXSZKHQWKHFRPSUHVVRULVZRUNLQJ&KHFNRQWKHRSHUDWLQJGLVSOD\GHVNIRUWKHOLQHSUHVVXUHThe line pressure will slowly rise if the compressed air consumption is less than the quantities delivered by the compressors.

7.6 Switch on compressed air

generation

&KHFNDOOSLSLQJRIFRROLQJOLTXLGVDQGSUHVVXUHDLUFRQGXLWVIRUOHDN-age.

&KHFNWKHFRROLQJXLGOHYHORIWKHFRPSUHVVRUVDIWHUDQGEHIRUHPLQXWHVRSHUDWLRQWLPH,IWKHFRROLQJXLGOHYHOLVWRRORZUHOOFRROLQJXLGDVGHQHG LQ&KDSWHU &KHFNFRROLQJXLG OHYHO FRROLQJXLGUHOO

&KHFN WKH FRPSUHVVRU WHPSHUDWXUH7KH FRPSUHVVRU WHPSHUDWXUHshould neither remain below approx. 75 C nor exceed 105 CDWC a warning is outputDW&WKHFRPSUHVVRUis automatically shut down.

We recommend:

WKHXVHRIPLQHUDORLORUV\QWKHWLFRLODWQDOFRPSUHVVLRQWHPSHUDWXUHVbetween 75 and 90C

WKHXVHRIV\QWKHWLFRLODWQDOFRPSUHVVLRQWHPSHUDWXUHVKLJKHUthan 90C

5HWLJKWHQDOOHOHFWULFDOFRQQHFWLRQVDIWHUDZHHN5. Carry out all service intervals according to Chapter 8 Overview of

maintenance intervals.

&KHFNWKHVWDQGDUGRSHUDWLRQRIWKHIXQFWLRQVFDUULHGRXWZHHNO\DF-cording to Chapter 8 Overview of maintenance intervals

7.7 Concluding activities

7KHJUHHQ/('EOLQNVZKHQWKHFRPSUHVVRULVUHDG\IRURSHUDWLRQThe compressor switches on automatically when

the current line pressure drops below the preset start pressure RIWKHFRPSUHVVRULI

WKHPDFKLQHWHPSHUDWXUHULVHVDERYH& WKHWLPHURI$LU&RQWUROLVDFWLYH or the Lead lag control (LLC) is activated.

On blinking green LED, the compressor can start by itself at any

time!

DANGER

-

58 3UHVVNH\ in order to switch off compressed air generation. Please

wait until the compressor has been switched off after a run-on or venti-lation phase. The symbol M for the main motor is then no longer visible in the display.

6ZLWFKWKHFRPSUHVVRUPDLQVZLWFKRIIDQGPDNHFHUWDLQWKDWLWFDQQRWEHWXUQHGRQE\PLVWDNHRULQWHQWLRQDOO\HJZDUQLQJVLJQVSURKLELWLQJswitching).

8.2 Preparatory activities

8. Service

8.1 Overview

Maintenance intervals

1HFHVVDU\VHUYLFHZRUNDSSHDUVLQWKHGLVSOD\DVZDUQLQJVVHH&KDSWHU5.3.5 or 5.4.5)

Preparatory activities 8.2&KHFNFRROLQJXLGOHYHOUHOOFRR-OLQJXLG &KHFNIRUOHDNDJH &KHFNWKHFRPSUHVVRUtemperature 8.5&KHFNWKHFRROHUIRUIRXOLQJ &KHFNIRUFRQGHQVDWH 5HSODFHFRROLQJXLG5HSODFHFRROLQJXLGOWHU 5HSODFHFRROLQJXLGVHSDUDWRU5HSODFHDLUOWHU &KHFNVDIHW\YDOYH &KHFNGULYH Lubrication of electric motor 8.13Concluding activities 8.14

+RWVXUIDFHVKRWFRROLQJXLGMake certain, with appropriate precaution, that no one can be burned

or scalded! Particularly note dangerous situations which can arise

IURPWKHUHOHDVHRIKRWFRROLQJXLGVWHDPDANGER

NOTICE

Use only original spare parts!

* The motor lubrication intervals are 20 000 hours for the entire series.**7KHVSHFLHGUHSODFHPHQWLQWHUYDOVDUHUHOHYDQWIRU

normal industrial atmosphere QDOFRPSUHVVLRQWHPSHUDWXUHRIDSSUR[&

:KHQ$/83V\QWKHWLFRLOLVXVHGWKHUHSODFHPHQWLQWHUYDOVIRUERWKFRRODQWDQGWKHFRRODQWOWHULVH[WHQGHGWRKRXUVThis interval is relevant for: normal industrial atmosphere QDOFRPSUHVVLRQWHPSHUDWXUHRIDSSUR[& Use of ALUB Syn S synthetic oil Oil analysis after 2000 hours

Service activities Chapter After the

UVWoperating

hours

After the

UVWoperating

hours

Every

week

Every 2000

operating h.

but at least

once a year

&KHFNFRROLQJXLGOHYHO 8.3

&KHFNIRUOHDNDJH 8.4

&KHFNFRPSUHVVRUtemperature

8.5

&KHFNFRROHUfor fouling

8.6

&KHFNIRUcondensate

8.7

5HSODFHFRROLQJXLGDQGFRROLQJXLGOWHU

8.8

Replace cooling liquid VHSDUDWRU

8.9

5HSODFLQJDLUOWHU

8.10

&KHFNVDIHW\YDOYH 8.11

&KHFNGULYH 8.12

Lubrication of motor 8.13

General compressor servicing

-

59

&KHFNFRROLQJXLGOHYHOUHOOFRROLQJXLG

2QO\FKHFNWKHFRROLQJXLGOHYHOZKHQWKHV\VWHPKDVEHHQWXUQHGRIIIRUDPLQLPXPRIPLQXWHV7KLVLVWRHQVXUHWKDWWKHFRROLQJXLGKDVsettled down after the running phase.

7KHFRROLQJ XLG OHYHO LV LQ RUGHU LI WKH FRPSOHWH VLJKW JODVV LV IXOO RIFRROLQJXLG

Carry out the Preparatory activities

,IWKHFRPSOHWHVLJKWJODVVLVQRWIXOORIFRROLQJXLGFRROLQJXLGPXVWEHadded as follows: