Making Bridle Joints on a Band Saw By Curt...

Transcript of Making Bridle Joints on a Band Saw By Curt...

Making Bridle Joints on a Band SawBy Curt Vevang

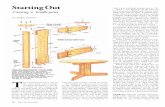

There are many different ways to make a bridle joint. Every woodworker has her or his own method. Perhaps the best reason for making bridle joints on a bandsaw is to demonstrate the versatility of the bandsaw. None the less, making bridle joints on a bandsaw is easy, quick and results in pretty good quality. Here’s how to do it.

Start with two pieces of stock the same size. The bridle joint mortise will be in Stock #1 and the tenon will be in Stock #2. Step 1. - Set your fence to make a cut roughly 1/3 of the thickness of Stock #1. Step 2. Clamp (I use plastic spring clamps) a stop block to your bandsaw table. The stop block should be offset from the front of the blade by the width of your stock measured from the teeth. To position the block place the stock between a scrap of wood (which is held against the blade) and the stop block.

Copyright 2010 Curtis B. Vevang Page 1 of 4

Step 3. - Using the fence as a guide make a cut in Stock #1 as deep as the stop block will allow. This depth will of course be the width of your stock.

Step 4. - Flip Stock #1 over and make another cut in the same manner.

Copyright 2010 Curtis B. Vevang Page 2 of 4

Step 5. - Perform Steps 3 and 4 again on Stock #2. This is the tenon (the mating piece). But first insert a spacer strip between the fence and Stock #2. The width of the spacer should be equal to the width of your saw blade.

Step 6. - Remove the fence but leave the stop block in place. Using the stop block as a guide nibble out the mortise of Stock #1.

Copyright 2010 Curtis B. Vevang Page 3 of 4

Step 7. – Now re-position the stop block to the left of the blade using the same procedure as in Step 2 above. The stop block should be a stock width from the blade, measured from the right side of the blade. Cut the shoulders using a miter gauge to form the tenon on Stock #2.

You should now find that your two pieces of stock fit together forming a near perfect bridle joint.

Perhaps you now have a new way of making bridle joints or maybe all you have done is increase your bandsaw skills. In either case you win!

Copyright 2010 Curtis B. Vevang Page 4 of 4