Machining Processes

-

Upload

numpon-mahayotsanun -

Category

Documents

-

view

213 -

download

1

description

Transcript of Machining Processes

numponmahayotsanun

department of mechanical engineeringfaculty of engineering

khon kaen universitythailand

P R O C E S S E SMACHINING

Content

Cutting ProcessesTheoriesCommon processesCommon toolsTool wearMachining economics

Abrasive ProcessesGrindingHoning & superfinishingLappingUltrasonic machining (UM)

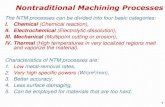

Advanced Machining ProcessesElectrochemical machining (ECM)Electrical-discharge machining (EDM)Wire EDMWater-jet machining (WJM)

Sigma CNC Milling MachineReference: www.qrbiz.com

Machining describes a group of processes that consist of material removal on a workpiece and modi-fication of its surfaces. The major advantages of machining process-es are their ability to produce flex-ible geometry and high precision parts. However, these processes usually give high material waste, require a lot of energy, and need extremely careful process control.

Three major machining processes will be described here: cutting pro-cesses, abrasive processes, and advanced machining processes.

Aluminum chips

CUTTING PROCESSES

Mechanics of Chip Formation

Machining processes remove material from the workpiece surface by producing chips as shown on the left image. The model of chip formation called Merchant model is illustrated on the right. In this model, known as orthogonal cutting, the thick-ness of the chip, tc, can be determined through the cutting ratio, r. Note that chip thickness is always greater than the dept of cut.

During cutting, the material also undergoes shear strain and can be expressed as:

Note that high shear strains are associated with low shear angles.

(a) Schematic illustration of the basic mechanism of chip formation in metal cutting(b) Velocity diagram in the cutting zone

( )sin 1

coso

c

trt

ϕϕ α

= = <−

( )αφφγ −+=+== tancotOCOB

OCAO

OCAB

ααφ

sin1costanr

r−

=

( )sin

coscVV φφ α

=−

Merchant model

Theories

CUTTING PROCESSES

Cutting Forces &Power Requirements

The knowledge of cutting forces and pow-er requirements are essential to proper design machine tools and avoid exces-sive distortion of the workpiece. Here are the steps to calculate cutting forces and power requirements:

Friction force between the tool and chip along the rake surface

Normal force to friction

Resultant force

Coefficientoffriction

Forces acting on a cutting tool in two-dimensional cutting. Note that the resultant force, R, must be colinear to balance the forces.

Shear force causing shear defor mation to occur in shear plane

Normal force to shear force

Cutting force in the direction of cutting

Thrust force

Note: and can be measured by dynamometer

F N R+ =

tanFN

µ β= =

F

NRµ

s nF F R+ =

sF

nF

c tF F R+ =

cF

tF

cF tF

Theories

CUTTING PROCESSES

Cutting Forces &Power Requirements

Shear force

Normal force

Coefficientoffriction

Merchant equationForces acting on a cutting tool in two-dimensional cutting. Note that the resultant force, R, must be colinear to balance the forces.

Specificenergy

Material removal rate

Processefficiency

Average diameter of workpiece

Dept of cut

Feed (distance per revolution)

Workpiece rotational speed

( )Power t

avg

u MRR

MRR D dfNη

π

=

=

tu

MRR

ηavgD

cos sins c tF F Fϕ ϕ= −

sin cosn c tF F Fϕ ϕ= +

cos sincos sin

t c

c t

F FFN F F

α αµα α+

= =−

tantan

t c

c t

F FF F

αµα

+=

−

o452 2α βϕ = + −

df

N

Theories

CUTTING PROCESSES

Milling

Common processes

1. Slab milling

In this operation, the axis of cutter rotation is parallel to the surface of the workpiece to be machined as shown on the right. Two types of milling methods can also be used

1.1 Conventional milling (up milling) is the milling direction where cutting ends at the thickest location of the chip. This method pro-vides high clamping forces. However, it also givespoorsurfacefinish,atendencyfortheworkpiece to be pulled upward.

1.2 Climb milling (down milling) is the milling direction where the cutting starts at the thickest lo-cation of the chip. This method

offers low clamping force, smoothcut,nicesurfacefinish,and less tool wear. However, this method is not recommended for hard material and requires a rigid setup.

CUTTING PROCESSES

Milling

Common processes

2. Face milling

In this operation, the cutter is mounted on a spindle with an axis of rotation perpendicular to the workpiece surface and removes mate-rial.

3. End milling

In this operation, the cutter usually rotates on an axis perpendicular to the workpiece, although it can be tilted to produce tapered sur-faces as well.

CUTTING PROCESSES

Turning

Common processes

Turning processes produce parts that are basically round in shape. Various types of turning pro-cesses are shown here:

CUTTING PROCESSES

Turning

Common processes

Schematic illustration of a turning operation showing depth of cut, d, and feed, f. Cutting speed is the surface speed of the workpiece at the Fc, is the cutting force, Ft is the thrust or feed force in the direction of feed, Fr is the radial force that tends to push the tool away from the workpiece being machined.

CUTTING PROCESSES

Tools

Common tools

Milling cutters

Face-milling cutter

Turning cutters

CUTTING PROCESSES

Tool wear

Tool wear

(a) Flank wear(b) Thermal cutting on rake face(c) Crater wear(d) Catastrophic failure (fracture)(e) Chipped cutting edge

Most cutting tools are subjected to high forces, elevated temperatures, and sliding. As a result, tool wear usually occur as shown above.

Tool-life curves can be approximated by the following equations:

1. Taylor’s tool life equation

Cutting speed Tool life in minutes Constant

2. Modified Taylor’s tool life equation

Dept of cut (mm) Feed rate (mm/rev)

Here are the range of values for various cutting tools:

High-speed steels 0.08-0.20 Cast alloys 0.10-0.15 Carbides 0.20-0.50 Ceramics 0.50-0.70

Note: The values of x and y must be obtained from the experiments.

CVT n =V nT C

n x yVT d f C=d f

n

Minimum cost

Maximum production

CUTTING PROCESSES

Machining Economics

Machining economics

Cost-per-piece Machining cost Setup cost

Loading cost

Tooling cost

Whether or not machining processes should be selected, the economics of machining must be considered. The most two important parameters are the minimum cost per part, and the maximum production rate.

p m s l tC C C C C= + + +

pC

mC

sC

lC

tC

Labor cost per hour Overhead charge of the machine Time to change tool

Time to grind tool

Labor cost for grinding the tool

Depreciation of the tool in dollars per grind

mL

mB

cT

gT

gL

( )

( ) ( )_ min

1 1

nm m

o n

c m m g g g c

C L BV

T L B T L B Dn

+= − + + + +

_ max1 1

o n

c

CVT

n

= −

cD

ABRASIVE PROCESSES

Grinding

Grinding

The types of workpieces and operations typical of grinding: (a) cylindrical sur-faces,(b)conicalsurfaces,(c)filletsonashaft,(d)helicalprofiles,(e)concaveshape, (f) cutting off or slotting with thin wheels, and (g) internal grinding.

Sometimes the workpiece material is either too hard or too brittle, or its shape isdifficulttoproducewithsufficientdimensionalaccuracy.Usingabrasivescanbe an alternative because they are capable of removing small amount of mate-rial from a surface. Here are some examples of abrasive processes:

Grinding is basically a chip removal process in which the cutting tool is an individual abrasive agent.

ABRASIVE PROCESSES

Honing & Superfinishing

Honing & superfinishing

Honing is an operation used primarily to give holesafinesurfacefinish

Schematic illustration of a honing tool used to improve the surfacefinishofboredorgroundholes.

Schematicillustrationsofthesuperfinishingprocessfora cylindrical part. (a) Cylindrical mircohoning, (b) Center-less microhoning.

ABRASIVE PROCESSES

Lapping

Lapping

(a) Schematic illustration of the lapping process. (b) Pro-ductionlappingonflatsurfaces.(c)Productionlappingoncylindrical surfaces.

Lappingisafinishingoperationonflatorcylindricalsurfaces

A double lapping pol-ishing process was used to give the phone the highest level of pol-ish possible. These images are from www.aesir-copenhagen.com

ABRASIVE PROCESSES

Ultrasonic Machining

Ultrasonic machining

ULTRASONIChardmachiningof a fullyautomatic dental crown made of lithium disilicate (glass ceramic) with a thinning margin (Ref: http://ids-cologne.de)

In ultrasonic machining, material is removed from a workpiece surface by the mechanism of microchipping or erosion with abrasive particles. The picture on the right is a glass ultrasonic machine sample (Ref: http://kikkawashoji.com.)

(a) Schematic illustration of the ultrasonic machining process. (b) and (c) Types of parts made by this process. Note the small size of holes produced.

ADVANCED MACHINING PROCESSES

Electrochemical Machining (ECM)

ECM

In electrochemical machining, an electrolyte acts as current carrier, and the high rate of electrolyte movement in the tool-workpiece gap washes metal ions away from the workpiece (anode) before they have a chance to plate onto the tool (cathode).

The middle picture is the SEM image of electrochemically machined Au-pillars, 4 µm high (Ref: http://www.cfn.kit.edu)

The bottom right picture is the chematic illustration of the electrochemicalmachining process.

ADVANCED MACHINING PROCESSES

Electrical-Discharge Machining (EDM)

EDM

In electrical-discharge machin-ing, when two current-conduct-ing wires are touched, an arc is produced eroding away a small portion of the metal. The bottom left picutre shows the schematic illustration of the electrical-dis-charge machining process.

The left picture shows the cavi-ties produced by the EDM pro-cess, using shaped electrodes. The bottom right picture shows A spiral cavity produced by EDM using a slowly rotating electrode, similar to a screw thread.

ADVANCED MACHINING PROCESSES

Wire Electrical-Discharge Machining (Wire EDM)

Wire EDM

This process is a variation of EDM where a slowly moving wire travels along a precribed path, cutting the workpiece with the discharge sparks. The top left picture is the schematic illustration of the

EDM process. As much as 50 hours of machining can be performed with one reel of wire, which is then discarded. The top right image shows the sample parts of collets and in-ternal splines.

www.microwireedm.com

www.engineeringcapacity.com www.alltechprecision.com

ADVANCED MACHINING PROCESSES

Water-Jet Machining (WJM)

WJM

In this process, the force from the jet is utilized in cutting and debur-ing. The water acts like a saw and cuts a narrow groove in the material.

The top left image is the schematic illustration of water-jet machining. The bottom left image is the exam-ples of various nonmetallic parts produced by the water-jet cutting process. The right image shows the water-jet nozzle. www.wordson.com

MACHINING PROCESSES

References

References

- S. Kalpakjian, S. R. S. (2003). Manufacturing Engineering and Technology. New Jersey, Pearson Prentice Hall.

- Groover, M. P. (2010). Principles of Modern Manufacturing: Materials, Processes, and Systems, John Wiley & Sons Ltd.