MACHINES AND MECHANISMS - GBV

Transcript of MACHINES AND MECHANISMS - GBV

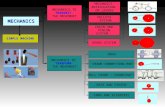

MACHINES AND MECHANISMS APPLIED KINEMATIC ANALYSIS

Fourth Edition

David H. Myszka University of Dayton

PEARSON

ж rentice Hall

Pearson Education International Boston Columbus Indianapolis New York San Francisco Upper Saddle River

Amsterdam Cape Town Dubai London Madrid Milan Munich Paris Montreal Toronto Delhi Mexico City Sao Paulo Sydney Hong Kong Seoul Singapore Taipei Tokyo

CONTENTS

1 Introduction to Mechanisms and Kinematics 1 Objectives 1

1.1 Introduction 1

1.2 Machines and Mechanisms 1

1.3 Kinematics 2

1.4 Mechanism Terminology 2

1.5 Kinematic Diagrams 4

1.6 Kinematic Inversion 8

1.7 Mobility 8

1.7.1 Gruebler's Equation 8

1.7.2 Actuators and Drivers 12

1.8 Commonly Used Links and Joints 14

1.8.1 Eccentric Crank 14

1.8.2 Pin-in-a-Slot Joint 14

1.8.3 Screw Joint 15

1.9 Special Cases of the Mobility Equation 16

1.9.1 Coincident Joints 16 1.9.2 Exceptions to the Gruebler's

Equation 18 1.9.3 Idle Degrees of Freedom 18

1.10 The Four-Bar Mechanism 19

1.10.1 Grashof's Criterion 19

1.10.2 Double Crank 20

1.10.3 Crank-Rocker 20

1.10.4 Double Rocker 20

1.10.5 Change Point Mechanism 20

1.10.6 Triple Rocker 20

1.11 Slider-Crank Mechanism 22

1.12 Special Purpose Mechanisms 22

1.12.1 Straight-Line Mechanisms 22 1.12.2 Parallelogram Mechanisms 22 1.12.3 Quick-Return Mechanisms 23

1.12.4 Scotch Yoke Mechanism 23 1.13 Techniques of Mechanism Analysis 23

1.13.1 Traditional Drafting Techniques 24 1.13.2 CAD Systems 24

1.13.3 Analytical Techniques 24 1.13.4 Computer Methods 24

Problems 25

Case Studies 29

iv

2 Building Computer Models of Mechanisms Using Working Model Software 31 Objectives 31

2.1 Introduction 31

2.2 Computer Simulation of Mechanisms 31

2.3 Obtaining Working Model Software 32

2.4 Using Working Model to Model a Four-Bar Mechanism 32

2.5 Using Working Model to Model a Slider-Crank Mechanism 37

Problems 41

Case Studies 42

3 Vectors 43 Objectives 43

3.1 Introduction 43

3.2 Scalars and Vectors 43

3.3 Graphical Vector Analysis 43

3.4 Drafting Techniques Required in Graphical Vector Analysis 44

3.5 CAD Knowledge Required in Graphical Vector Analysis 44

3.6 Trigonometry Required in Analytical Vector Analysis 44

3.6.1 Right Triangle 44 3.6.2 Oblique Triangle 46

3.7 Vector Manipulation 48

3.8 Graphical Vector Addition ( + >) 48

3.9 Analytical Vector Addition (+ >): Triangle Method 50

3.10 Components of a Vector 52

3.11 Analytical Vector Addition (+ >): Component Method 53

3.12 Vector Subtraction ( - > ) 55

3.13 Graphical Vector Subtraction ( — >) 55

3.14 Analytical Vector Subtraction (— >): Triangle Method 57

3.15 Analytical Vector Subtraction (—> ): Component Method 59

3.16 Vector Equations 60

Contents v

3.17 Application of Vector Equations 62

3.18 Graphical Determination of Vector Magnitudes 63

3.19 Analytical Determination of Vector Magnitudes 66

Problems 67

Case Studies 71

4 Position and Displacement Analysis 72 Objectives 72

4.1 Introduction 72

4.2 Position 72

4.2.1 Position of a Point 72 4.2.2 Angular Position of a Link 72 4.2.3 Position of a Mechanism 73

4.3 Displacement 73

4.3.1 Linear Displacement 73 4.3.2 Angular Displacement 73

4.4 Displacement Analysis 74

4.5 Displacement: Graphical Analysis 74

4.5.1 Displacement of a Single Driving Link 74

4.5.2 Displacement of the Remaining Slave Links 75

4.6 Position: Analytical Analysis 79

4.6.1 Closed-Form Position Analysis Equations for an In-Line Slider-Crank 81

4.6.2 Closed-Form Position Analysis Equations for an Offset Slider-Crank 84

4.6.3 Closed-Form Position Equations for a Four-Bar Linkage 87

4.6.4 Circuits of a Four-Bar Linkage 87

4.7 Limiting Positions: Graphical Analysis 87

4.8 Limiting Positions: Analytical Analysis 91

4.9 Transmission Angle 93

4.10 Complete Cycle: Graphical Position Analysis 94

4.11 Complete Cycle: Analytical Position Analysis 96

4.12 Displacement Diagrams 98

4.13 Coupler Curves 101

Problems 101

Case Studies 108

5 Mechanism Design 109 Objectives 109

5.1 Introduction 109

5.2 Time Ratio 109

5.3 Timing Charts 110

5.4 Design of Slider-Crank Mechanisms 113

5.4.1 In-Line Slider-Crank Mechanism 113

5.4.2 Offset Slider-Crank Mechanism 114

5.5 Design of Crank-Rocker Mechanisms 115

5.6 Design of Crank-Shaper Mechanisms 117

5.7 Mechanism to Move a Link Between Two Positions 118

5.7.1 Two-Position Synthesis with a Pivoting Link 118

5.7.2 Two-Position Synthesis of the Coupler of a Four-Bar Mechanism 118

5.8 Mechanism to Move a Link Between Three Positions 119

5.9 Circuit and Branch Defects 119

Problems 120

Case Studies 121

6 Velocity Analysis 123 Objectives 123

6.1 Introduction 123

6.2 Linear Velocity 123

6.2.1 Linear Velocity of Rectilinear Points 123

6.2.2 Linear Velocity of a General Point 124

6.2.3 Velocity Profile for Linear Motion 124

6.3 Velocity of a Link 125

6.4 Relationship Between Linear and Angular Velocities 126

6.5 Relative Velocity 128

6.6 Graphical Velocity Analysis: Relative Velocity Method 130

6.6.1 Points on Links Limited to Pure Rotation or Rectilinear Translation 130

6.6.2 General Points on a Floating Link 132

6.6.3 Coincident Points on Different Links 135

6.7 Velocity Image 137

6.8 Analytical Velocity Analysis: Relative Velocity Method 137

6.9 Algebraic Solutions for Common Mechanisms 142

6.9.1 Slider-Crank Mechanism 142 6.9.2 Four-Bar Mechanism 142

6.10 Instantaneous Center of Rotation 142

vi Contents

6.11 Locating Instant Centers 142

6.11.1 Primary Centers 143 6.11.2 Kennedy's Theorem 144

6.11.3 Instant Center Diagram 144 6.12 Graphical Velocity Analysis: Instant Center

Method 149

6.13 Analytical Velocity Analysis: Instant Center Method 152

6.14 Velocity Curves 155

6.14.1 Graphical Differentiation 157

6.14.2 Numerical Differentiation 159

Problems 161

Case Studies 168

7 Acceleration Analysis 170 Objectives 170

7.1 Introduction 170

7.2 Linear Acceleration 170

7.2.1 Linear Acceleration of Rectilinear Points 170

7.2.2 Constant Rectilinear Acceleration 171 7.2.3 Acceleration and the Velocity

Profile 171

7.2.4 Linear Acceleration of a General Point 173

7.3 Acceleration of a Link 173

7.3.1 Angular Acceleration 173 7.3.2 Constant Angular Acceleration 173

7.4 Normal and Tangential Acceleration 174

7.4.1 Tangential Acceleration 174

7.4.2 Normal Acceleration 175

7.4.3 Total Acceleration 175 7.5 Relative Motion 177

7.5.1 Relative Acceleration 177 7.5.2 Components of Relative

Acceleration 179

7.6 Relative Acceleration Analysis: Graphical Method 181

7.7 Relative Acceleration Analysis: Analytical Method 188

7.8 Algebraic Solutions for Common Mechanisms 190

7.8.1 Slider-Crank Mechanism 190 7.8.2 Four-Bar Mechanism 191

7.9 Acceleration of a General Point on a Floating Link 191

7.10 Acceleration Image 196

7.11 Coriolis Acceleration 197

7.12 Equivalent Linkages 201

7.13 Acceleration Curves 202

7.13.1 Graphical Differentiation 202 7.13.2 Numerical Differentiation 204

Problems 206

Case Studies 213

8 Computer-Aided Mechanism Analysis 215 Objectives 215

8.1 Introduction 215

8.2 Spreadsheets 215

8.3 User-Written Computer Programs 221

8.3.1 Offset Slider-Crank Mechanism 221 8.3.2 Four-Bar Mechanism 221

Problems 222

Case Study 222

9 Cams: Design and Kinematic Analysis 223 Objectives 223

9.1 Introduction 223

9.2 Types of Cams 223

9.3 Types of Followers 224

9.3.1 Follower Motion 224

9.3.2 Follower Position 224

9.3.3 Follower Shape 225

9.4 Prescribed Follower Motion 225

9.5 Follower Motion Schemes 227

9.5.1 Constant Velocity 228

9.5.2 Constant Acceleration 228

9.5.3 Harmonic Motion 228

9.5.4 Cycloidal Motion 230

9.5.5 Combined Motion Schemes 236

9.6 Graphical Disk Cam Profile Design 237

9.6.1 In-Line Knife-Edge Follower 237

9.6.2 In-Line Roller Follower 238

9.6.3 Offset Roller Follower 239 9.6.4 Translating Flat-Faced

Follower 240 9.6.5 Pivoted Roller Follower 241

9.7 Pressure Angle 242

9.8 Design Limitations 243

9.9 Analytical Disk Cam Profile Design 243

9.9.1 Knife-Edge Follower 244 9.9.2 In-Line Roller Follower 246 9.9.3 Offset Roller Follower 249

9.9.4 Translating Flat-Faced Follower 249

9.9.5 Pivoted Roller Follower 250

Contents vii

9.10 Cylindrical Cams 251

9.10.1 Graphical Cylindrical Cam Profile Design 251

9.10.2 Analytical Cylindrical Cam Profile Design 251

9.11 The Geneva Mechanism 252

Problems 254

Case Studies 258

10 Gears: Kinematic Analysis and Selection 260

Objectives 260

10.1 Introduction 260

10.2 Types of Gears 261

10.3 Spur Gear Terminology 262

10.4 Involute Tooth Profiles 264

10.5 Standard Gears 266

10.6 Relationships of Gears in Mesh 268

10.6.1 Center Distance 268 10.6.2 Contact Ratio 269 10.6.3 Interference 270 10.6.4 Undercutting 271 10.6.5 Backlash 272

10.6.6 Operating Pressure Angle 273 10.7 Spur Gear Kinematics 273

10.8 Spur Gear Selection 275

10.8.1 Diametral Pitch 276 10.8.2 Pressure Angle 276 10.8.3 Number of Teeth 276

10.9 Rack and Pinion Kinematics 281

10.10 Helical Gear Kinematics 282

10.11 Bevel Gear Kinematics 285

10.12 Worm Gear Kinematics 286

10.13 Gear Trains 288

10.14 Idler Gears 290

10.15 Planetary Gear Trains 290

10.15.1 Planetary Gear Analysis by Superposition 291

10.15.2 Planetary Gear Analysis by Equation 293

Problems 295

Case Studies 299

11 Belt and Chain Drives 302 Objectives 302

11.1 Introduction 302

11.2 Belts 302

11.3 Belt Drive Geometry 304

11.4 Belt Drive Kinematics 305

11.5 Chains 308

11.5.1 Types of Chains 308

11.5.2 Chain Pitch 309 11.5.3 Multistrand Chains 309 11.5.4 Sprockets 310

11.6 Chain Drive Geometry 310

11.7 Chain Drive Kinematics 311

Problems 313

Case Studies 315

12 Screw Mechanisms 316

Objectives 316

12.1 Introduction 316

12.2 Thread Features 316

12.3 Thread Forms 316

12.3.1 Unified Threads 317 12.3.2 Metric Threads 317 12.3.3 Square Threads 317

12.3.4 ACME Threads 317

12.4 Ball Screws 317

12.5 Lead 317

12.6 Screw Kinematics 318

12.7 Screw Forces and Torques 322

12.8 Differential Screws 324

12.9 Auger Screws 325

Problems 325

Case Studies 328

13 Static Force Analysis 330

Objectives 330

13.1 Introduction 330

13.2 Forces 330

13.3 Moments and Torques 330

13.4 Laws of Motion 333

13.5 Free-Body Diagrams 333

13.5.1 Drawing a Free-Body Diagram 333

13.5.2 Characterizing Contact Forces 333

13.6 Static Equilibrium 335

13.7 Analysis of a Two-Force Member 335

13.8 Sliding Friction Force 341

Problems 343 Case Study 345

14 Dynamic Force Analysis 346

Objectives 346

14.1 Introduction 346

viii Contents

14.2 Mass and Weight 346

14.3 Center of Gravity 347

14.4 Mass Moment of Inertia 348

14.4.1 Mass Moment of Inertia of Basic Shapes 348

14.4.2 Radius of Gyration 350 14.4.3 Parallel Axis Theorem 350

14.4.4 Composite Bodies 351 14.4.5 Mass Moment of Inertia—

Experimental Determination 352

14.5 Inertial Force 352

14.6 Inertial Torque 357

Problems 363

Case Study 366

Answers to Selected Even-Numbered Problems 367

References 370

Index 371