Maccaferri PPT Templates · • Polymer products (even with Carbon Black additives) deteriorate...

Transcript of Maccaferri PPT Templates · • Polymer products (even with Carbon Black additives) deteriorate...

Maccaferri PA6 4th Generation Coatings

Maccaferri PA6 – 4th Generation Coatings

4th Generation Coatings

Maccaferri History:

1879:

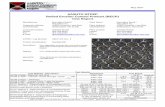

Mild steel wire double

twist woven gabions.

Light zinc coating.

Inventor of modern

gabion & original

Patent owner

Mid 1950s:

Galvanised and PVC

Coated wire mesh

products

4th Generation Coatings

Maccaferri History:

Mid 1990s:

GalMac (Zn/Al)

Galvanized Coating,

with or without PVC

2012: Galmac (Zn/Al) Galvanized Coating with PA6 Coating!

Assessing product suitability

Environ-mental Impact

UV Physical Water

Ice

Chemical Biological Industrial

ENVIRONMENTAL & DESIGN LIFE REQUIREMENT

What happens to polymers over time?

Exposure to environment leads to the:

• Reduction in flexibility

• Reduction in tensile strength

• Reduction in resistance to physical abrasion/damage

• Possible shrinkage as polymer degrades

CONCLUSION:

Products should be selected which

account for this deterioration

RESULT:

Reducing capability of the polymer to

protect the wire

Select Maccaferri PA6 when you need….

Greater…

…Environmental benefits

…Design life

…Mechanical damage

resistance

…Exposure resistance

…Safety factors

…Client reassurance

PA6

Galvanised +

PVC / HDPE

Galvanised only

P e

r f

o r

m a

n c

e

When do I use Maccaferri PA6?

• Maccaferri PA6 is NOT designed to replace PVC or

HDPE coated wire mesh products

• It is used when the performance of PVC or HDPE is not

sufficient

• PA6 is more environmentally friendly than PVC

• PA6 offers higher performance than PVC or HDPE coated

products

• Maccaferri still offers PVC coated products as well

• Maccaferri PA6 is an addition to the range of coatings

enabling clients to select from the family of coatings to suit

their needs

Introducing Maccaferri PA6

Compared to PVC coated steel wire products:

+25% Elongation at 3000hrs UV

+ 50% Harder and more durable

3x Better adhesion to wire

+30% Design Life

CLIENT

SATISFACTION

P

Environmental benefits

P

Maccaferri PA6 – 4th Generation Coatings

• Environmental impact improvements

• Better corrosion resistance = Longer design life

• Can be used in more locations for longer durations:

• Watercourses

• Coastal Protection

• Product can be used in many applications:

• Soil reinforcement

• Rockfall protection

• Technological advancement

Environmental

• No phthalates unlike PVC

• No Ozone depleting chemicals

• No migration of plasticiser when aging unlike PVC

• No emission of Hydrogen Chloride during combustion unlike

PVC (becomes Hydrochloric acid in presence of moisture)

• Longer lasting, so less replacement product needed

• More robust, so less maintenance/repair product needed

Evidence & Testing

• Adhesion of Polymer to Wire

• Elongation at Break after UV Exposure

• Hardness

• Product Life

Evidence & Testing – Adhesion of Polymer to Wire

Why is this important?

• Under normal exposure conditions:

• Not significant

• PVC coated product suitable

• Under severe exposure conditions, or requirement for

longer design life

• Significant

• Need something more robust than PVC coating

Evidence & Testing – Adhesion of Polymer to Wire

Why is this important?

Mild Steel Wire

Galvanising

Polymer

Protective Coating Potential

penetration point

Evidence & Testing – Adhesion of Polymer to Wire

Why is this important?

Potential

penetration point

Evidence & Testing – Adhesion of Polymer to Wire

Force required to

pull sheath of

polymer from

coated steel wire.

3x better

than PVC

Evidence & Testing – Adhesion of Polymer to Wire

Result: Maccaferri PA6 is nearly 3x better than

PVC:

• Better adhesion to base wire

• Harder for aggressive materials to penetrate imperfections

• Better resistance to peeling when damaged

Evidence & Testing – Elongation after 3000hrs UV

Why is this important?

• Polymer products (even with Carbon Black additives)

deteriorate over time when exposed to UV

• Coating becomes less flexible (more brittle) over time

• Loads upon aged wire may cause cracking of polymer

coating

• Some polymers shrink as they degrade

• Different polymers offer different resistance to UV

degradation

Evidence & Testing – Elongation after 3000hrs UV

Exposure to

3000hrs UV.

Tensile/elongation

tests throughout.

25%

better

than PVC

Result: Maccaferri PA6 is 25% better than PVC:

• Greater flexibility for longer

• More resistant to aggressive physical conditions

• Stretches more before tearing / breaking

• Greater conformance with deformed mesh (Rockfall mesh, Reno

mattresses)

Evidence & Testing – Elongation after 3000hrs UV

• After 4000hrs UV, polymer retains 75%

of initial performance (ISO 4892-2)

Evidence & Testing - Hardness

Why is this important?

• Better resistance to physical damage during:

• Transportation

• Installation

• Installation of rocks within gabions / mattresses

• Compaction of backfill on reinforcement

• In-use

• Heavy bedload within watercourse

• Ice damage

• Impact from rocks or other debris/object

Evidence & Testing - Hardness

Cross referenced:

• Shore D

• Rockwell M

50%

better

than PVC

Evidence & Testing - Hardness

Result: Maccaferri PA6 is 50% better than PVC:

• Harder and more durable

• More resistant to aggressive physical conditions / impacts

Evidence & Testing - Design Life prediction

Why is this important?

• Accelerated Aging tests

• Samples exposed to aggressive heat over time to accelerate

normal aging process.

• Results extrapolated to determine product life at ambient

temperatures

Tested:

• Elongation at

Break

• Tensile strength

at Break

Evidence & Testing - Design Life prediction

30%

better

than PVC

Other Physical Properties

Maccaferri

PA6

PVC

Cold Weather Performance / Brittleness Temp.

(ASTM D746)

-30oC

(-22oF)

Depends on

Polymer

Tensile Strength

(ASTM D412 / ISO 527 and ASTM D638)

>60 Mpa

(Min. 30Mpa; ISO 527-2)

>20 MPa

Modulus of Elasticity

(ASTM D412 and ASTM D638)

>2000 MPa >20 MPa

Conclusion

• Maccaferri PA6 is an addition to the range giving clients

more choice

• Maccaferri PA6 is not designed to replace PVC or HDPE

coated wire mesh products

• It offers greater performance in those situations when PVC

and HDPE coated products cannot offer:

• The environmental performance required

• The design life required

• The abrasion resistance required

• The robustness required

• The chemical / biological resistance required

Summary: Maccaferri PA6

Compared to PVC coated steel wire products:

+25% Elongation at 3000hrs UV

+ 50% Harder and more durable

3x Better adhesion to wire

+30% Design Life

CLIENT

SATISFACTION

P Environmental benefits

P

For tough conditions,

think Maccaferri PA6.