LUTHER JONES: OEM FUTURE PANEL

Transcript of LUTHER JONES: OEM FUTURE PANEL

October 4, 2017

LUTHER JONES: OEM FUTURE PANEL

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Agenda

• Major Platforms supported

• Vocollect

• Additive Manufacturing

• Other initiatives

• Questions

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Major Platforms supported

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

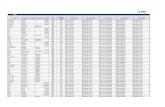

Honeywell Supports All Major Systems

Platform Installed Systems

AH-64D/E

Apache

• 36 Series APU

• Embedded GPS/INS

• COSSI Clutch

• Generators

• Starters, Valves

• Radar Altimeter

• HUMS

M/CH-

47D/F/G

Chinook

• T55 Series Engine

• Flight Controls

• Radar Altimeter

• HUMS - VXP

• Embedded GPS/INS

• Searchlights

M/UH-60 A/L/M/V

Blackhawk

• 36 Series APU

• Generators

• Starters, Valves

• Radar Altimeter

• Embedded GPS/INS

• Searchlights

• Interior/Exterior Lighting

• Fuel Controls

Honey well Internal

M1A2 Abrams

tank

• AGT1500 Series Engine

• Generator

• Voltage Regulator

• DECU

• TALIN

• NBC / ECS

© 2015 by Honeywell International Inc. All rights reserved.

Honeywell Vocollect Voice Technology

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

The Honeywell Voice Directed Inspection System : Overview

• Eyes Free/Hands Free Inspection with precise inspection data capture back to Host System

• Eliminates manual data entry – Drives Inspection Compliance

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Honeywell M&I Inspection Systems Operational in DoD

USMC AAV PMCS – Blount Island

• Voice directed field level maintenance & inspections

• Focus: PMCS, repair component acquisition and performance of vehicle technician checks

• Hands free operation – safety & efficiency improvement

• Rework is reduced. Inspection data automatically generated eliminating manual data entry errors.

• Compliance & optimization of inspection steps

• Voice improvements over manual/paper checklists :

Process Step Time Savings/Productivity Increase

Conducting PMCS 72 minutes faster / 42% productivity increase SL-3 Component Acquisition 30 minutes faster / 23% productivity increase Technician - IETM Checks

18 minutes faster / 27% productivity increase

USAF / AFMC – Hill AFB OLC Ogden, UT(KBRWyle)

• Voice directed APU inductions : GCB, JFS, AMAD, C-130J and C-130H

• Focus : Induction and inspection, repair component acquisition for APU’s and maintainer performance

• Hands free operation – safety & efficiency improvement

• Compliance & optimization of inspection steps

• Voice improvements over manual/paper checklists :

Process Step Time Savings/Productivity IncreaseInduction Time 43 minutes faster / 30% productivity increase Data to

kitting area 99.94% accuracy vs. 88.32% manual entry Technician -IETM Checks 23 minutes faster / 30% productivity increase

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Proven technology since 1987

• With measurable impact on DoD readiness & commercial

supply chain/logistics

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Benefits for DoD - AMC Maintenance & Inspection Operations

What does it enable?

• Strict process compliance and standardization across all sites.

• Better accountability faster by automated accurate data capture

• Detailed visibility into site operations for leadership.

What are the benefits for DoD?

• Increases quality and consistency of service/compliance with DoD PMCS requirements.

• Increases manpower efficiency/capacitythat will improve readiness.

• Enables constant process improvement and streamlining of maintenance & inspection operations within DoD.

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Benefits for DoD – AMC Supply Chain/Logistics OperationsWhat does it enable?

• Utility to support supply receiving, storing, material management to increase AMC readiness.

• Documentation time eliminated while capturing accurate data.

• Detailed visibility into site operations for AMC leadership.

What are the benefits for AMC ?

• Increases quality and consistency of material/inventory management and throughput.

• Modernize AMC supply/support processes by using proven best practice processes to increase worker performance and ensure a leaner operating environment.

• Measureable productivity gains = greater readiness

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

PhoenixBrno

Bangalore

Shanghai

Honeywell Global Footprint with AM Labs

Utilize Global AM Presence for Speed and Cost

• 20+ laser and EB powder bed machines

• Quick turn capabilities

• Labs localized near global design centers

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Initial development of

prototype parts with external vendors

DMLS 718 Tangential

On Board Injector on flight test bed

DMLS 718 swirler on

Airbus flight test bed

Opening of first AM lab in

Phoenix and subsequent Global sites

Honeywell Additive Time Line

Reactive metals lab opens

2007 2010 20112014 2016 2017

AM Pilot Production Factory

2012

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Improving Reliability, Performance, & Cost to Own

• AH-64/CH-47/UH-60

• HON investing/partnering to improve performance, weight, reliability, total life-cycle costs

- Next Generation EGI

Adding capability (ADS-B & WAAS) while reducing weight

Honeywell funded upgrade

- Common Core Radar Altimeter

Design out obsolescence – commonality across all platforms

- LED Exterior Lighting

Solution in development to solve known safety and performance issues

LED solution will significantly improve reliability over current halogen lighting

- Li-Ion Battery

20yr life span and 60% weight reduction

Honeywell funded upgrade

- DVE

Honeywell developed synthetic vision avionics backbone and sensor impartial

Pioneer in synthetic vision – FAA certified in 2008

Part of DARPA Multi-Function RF programAdding Value Via Multiple Methods for All Army Helo Platforms

Honey well Internal

© 2015 by Honeywell International Inc. All rights reserved.

Questions?

Teamwork… Commitment… Execution

in Support of Soldiers

Honey well Internal