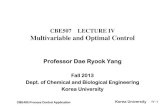

LQR Control for Speed and Torque of ICE

-

Upload

andres-ceverisae -

Category

Documents

-

view

35 -

download

0

Transcript of LQR Control for Speed and Torque of ICE

LQR control for speed and torque ofinternal combustion engines ?

Jose David Lopez ∗ Jairo Jose Espinosa ∗∗

John Ramiro Agudelo ∗∗∗

∗ School of Mechatronichs, Universidad Nacional de Colombia,Medellın (e-mail: [email protected]).

∗∗ School of Mechatronichs, Universidad Nacional de Colombia,Medellın (e-mail: [email protected])

∗∗∗Department of mechanical engineering, Universidad de Antioquia,Medellın, Colombia, (e-mail: [email protected])

Abstract: This paper presents a robust automation model for internal combustion engines testbeds. A Linear Quadratic Regulator (LQR) allows setting the desired engine speed and torqueon both compression and spark ignition engines. With this methodology, the user can changethe engine by another one of different characteristics with few adjustments on the controllerparameters. The controller was implemented using a microcontroller in order to guaranteeoperation in real time.The LQR controller performance has been validated in a wide range of engine operating modes,from low to high speeds and variable loads showing a good response. The description of themodel using first order transfer functions with delay has proven to be a good approximation,despite of the nonlinearities caused by the turbocharger and the electronic control unit (ECU)incorporated in the engines. This low cost automation system has been tested for the last threeyears in a test rig at a university laboratory showing a good performance.

Keywords: Internal Combustion Engine, LQR control, MIMO model

1. INTRODUCTION

Since the late nineteenth century, oil became the mainsource of energy in transportation systems, but by theearly twenty-first century the shortage of this productand its polluting effects force researchers to develop en-vironmentally friendly fuels. Research and developmenttasks for Internal Combustion Engines (ICE) requires pre-cise and reliable control systems in order to guaranteeconsistent experimental conditions, especially when smalldifferences are expected. This is the case in which sev-eral fuels, blends of fuels, additives, fuel saving devicesor postreatment systems (among others) are going to becompared in an engine test bed.

The test bed is composed by an internal combustion enginewhose main shaft is connected to a braking system in orderto simulate and test variable load conditions for the engine.An internal combustion engine is a machine that involvesthermodynamic processes, fluid mechanics and chemicalreactions, its modeling is still difficult and a subject ofdiscussion. Several authors agree that the dynamic of thecombustion chamber is the dominant process of the ICE(Powers (1981); Heywood (1988); Plint and Martyr (1997);del Portillo Valdes et al. (2007)), which implies the use of

? This project was financially supported by the Colombian Ministryof Agriculture and Rural Development, Sofasa-Renault, El AreaMetropolitana del Valle de Aburra, and the Comite para el Desarrollode la Investigacion (CODI) from the University of Antioquia. ProjectNo. 003 2007D3608-67 (Bioethanol E-20 project) and project 0012007D3347-499 (Biodiesel).

different models according to the engine ignition system(compression or spark), this prevents the use of a genericmodel for control design.

The braking system is a magnetic brake based on Eddycurrents where the braking force depends on the currentand the coil inductance, that is defined by the geometryand material characteristics (Lee and Park (1999); Gonza-les (2004); Gosline et al. (2006)). In absence of manufac-turer information, it is possible to retrieve the parametersfrom experimental data, in order to obtain a proper modelsince torque is directly proportional to the current flowingthrough the brake and to the shaft speed (Anwar (2004)).

The inherent difficult of modeling the engine-brake assem-bly using phenomenological first principle models orientedto control systems, has made that some authors only focuson control variables. Powers (1981) stated that for a digitalcontrol, a relatively low order model (quasi-linear) wasenough, due to the restrictions in control implementation;i.e. an approach of transfer functions can be successful inthe vicinity of a given speed-torque point. Bunker et al.(1997) and Cook and Powell (1988) have followed thisapproach and designed models with two inputs and twooutputs with transfer functions of first and second orderwith delays.

In this work, a control system for engine speed and torque,based on a LQR, has been developed. It was designedwith first order transfer functions with delay, and itwas successfully implemented and validated in the whole

Preprints of the 18th IFAC World CongressMilano (Italy) August 28 - September 2, 2011

Copyright by theInternational Federation of Automatic Control (IFAC)

2230

operating range of a diesel and a spark ignition engine-dynamometer assemblies (Lopez (2009)).

2. METHODOLOGY

2.1 Equipments and systems

Two engine test beds were instrumented and automated;one was used for research in diesel engines and the otherin spark ignition engines. Table 1 presents the technicalspecifications of the engines used in this work.

Table 1. Technical specifications of the enginesused

Value/Engine ISUZU R© RENAULT R©

Cylinders 4 4Engine size (cm3) 2.400 1.600

Fuel Diesel GasolineFuel injection Direct Electronic

Air supply Turbocharger NaturalMax speed 5.000 rpm 7.000 rpmMax torque 170Nm @ 2.500rpm 150Nm @ 3.000rpmMax power 55kW @ 3.000rpm 65kW @ 5.500rpm

The diesel engine was coupled to a Schenck W230 Eddycurrents magnetic brake, while the spark ignition enginewas coupled to a Schenck E90 Eddy currents magneticbrake. Both test beds have been instrumented with hot-wire air flow sensors (Magnetrol TA2), K-type thermocou-ples (environment temperature, inlet-outlet engine water,oil, hot gases, turbo compressor inlet and outlet tem-peratures) and strain gauge pressure transducer sensors(ambient pressure, turbo compressor inlet and outlet andoil pressures). The diesel fuel flow was measured with anelectronic weight scale, while the gasoline was measuredwith a Danfoss Massflo 6000 Coriolis-type mass flow sen-sor.

The engine speed sensors were mounted on the electromag-netic brakes. The Schenck E90 brake had an optical sensor,while the Schenck W230 had a magnetic reluctance sensor.A frequency-voltage converter was implemented in orderto generate an analog signal proportional to the speed.

The engine torque was measured with load cells attachedto the brake stators. This signal reached few milliamperesand it was very sensitive to noise. In order to solve theseproblems an instrumentation amplifier was implemented.It rejects the noise that enters through the casing and otherspurious interferences while amplifies the signal between1000 and 5000 times. A low-pass active filter with a cutofffrequency below the minimum engine speed (idle speed)was implemented in order to avoid undesirable variationsgenerated by piston movement.

High speed data were acquired using a LabViewTM basedsoftware together with a National InstrumentsTM dataacquisition system (Model PCI-MIO-16E-4 board). Theprogram developed for real time monitoring and recordingwas called Tone (Figure 1).

The engine speed system is mainly governed by the fuelentering the combustion chambers –which is controlledby the throttle valve position of the acceleration system–and by the torque generated by the brake. The brakingtorque is mainly governed by the electric current through

Fig. 1. Tone main window, a real time monitoring andrecording software developed for the project

the brake, and by the engine speed, i.e. both variables arestrongly related.

For the throttle valve opening, a direct current steppermotor was used. A direct current flowing through the brakecoil, similar to those used to control the speed in DCmotors was used to generate rotation resistance (load). Inorder to guarantee the appropriate operating mode, an 80V – 20 A power supply with a chopper based in MOSFETtransistor was developed and controlled by a Pulse WidthModulation (PWM).

2.2 Automation model description

Several authors agree that the process inside the combus-tion chamber is the dominant dynamic of the engine, soit is advisable to model it with the flow of air or fuelentering the chamber (Powers (1981); Cook and Powell(1988); Van Lith (2002); Ritzen (2003); del Portillo Valdeset al. (2007)). But this approach divides the models bytype of injection system, preventing to use one model ontwo engines with different characteristics, and in manycases, the model is too complex for real time control.

Due to the difficulty to obtain a phenomenological modelsuitable for all engine-dynamometer assemblies, besidesthe enormous effort involved, some authors have chosento focus the model towards the most significant controlvariables. Hopkins and Borcherts (1980) and Morris et al.(1981) have created models with seven state variables,later Powers (1981) reduced it to five. The three authorsstudied spark ignition engines and they included the sparkdynamics on the control variables, but that is not amodifiable parameter in serially manufactured engines.

A more generic approach is desirable, Powers (1981) statedthat if the target is a digital control, then relatively loworder models in discrete time and quasi-linear are wanted.Some authors have followed this philosophy (Bunker et al.(1997); Cook and Powell (1988)), and have designed mod-els of two inputs and two outputs with transfer functionsof first and second order with delay. Based on their work,the internal combustion engines used in this project weremodeled with independent transfer functions according tothe following matrix:

Preprints of the 18th IFAC World CongressMilano (Italy) August 28 - September 2, 2011

2231

Y (s) =

K11e−τ1s

τas+ 1

−K12e−τ2s

τbs+ 1K21e

−τ3s

τcs+ 1

K22

τds+ 1

· U(s) (1)

with:

Y (s) =

[Rpm(s)Torque(s)

]U(s) =

[%Opening(s)%Brake(s)

]where:

Rpm(s) : Engine speed in rpm

Torque(s) : Braking torque in Nm

%Opening(s) : Percentage of the throttle opening

Brake(s) : Current entering the brake represented

in divisions of PWM

Kij : Gains

τi : Delay in seconds

τa, τb, τc, τd : Subsystems time constants

The system inputs are the percentage of throttle openingand the current through the magnetic brake, and theoutputs are the engine speed and torque. In order tofind the parameters of the matrix of transfer functions,the following procedure was implemented covering a widerange of engine operating modes:

(1) A test of acceleration steps (each 5%) without anybrake load was carried out from idle to maximumengine speed.

(2) With the throttle valve fixed in the maximum enginespeed point, current incremental steps (each 5%) wereapplied on the dynamometer coil, increasing the loaduntil engine speed reached the minimum.

(3) Alternating the acceleration and the load, steps 1and 2 were carried out until the engine reached itsmaximum power, in order to obtain relevant datafrom the main operating modes.

The IDENT toolbox of Matlab R© was used after obtainingthese experimental data in order to find the parameters ofeach curve. An average of eight curves located throughoutthe operating range (speed and torque) was used in orderto obtain each subsystem model. All sub-models werevalidated with different datasets from those used on theidentification. The first-order model with delay obtainedfor the spark ignition engine was:

YR(s) =

350e−s

s+ 1

−27e−s

s+ 10.4e−s

s+ 1

0.8

s+ 1

· U(s) (2)

and the model for the diesel engine was:

YI(s) =

100e−s

s+ 1

−30e−s

s+ 1e−s

s+ 1

3.3

s+ 1

· U(s) (3)

The controller response was affected by disturbances asso-ciated with each engine, i.e. the turbocharger and pumpfor the diesel engine and the electronic control unit for thespark ignition engine.

The turbocharger turn-on and the fuel pump turn-off werethe most significant non-linearities of the diesel engine.

Fig. 2. Turbocharger turn on, note that both accelerationsteps had the same percentage of amplitude, but thesecond one (17 - 24 s) started the turbocharger withthe consecuently larger speed increase (About tentimes)

Fig. 3. Fuel pump turn off. At 6 s the engine reachedenough speed to feed the fuel, the fuel pump turnedoff causing a momentary loss of speed, even theacceleration continued increasing

The first one generated a sudden increase of speed, whilethe fuel pump turn-off caused a temporally loose of power(ISUZU (1991)). Figure 2 shows the turbocharger turn-onand the Figure 3 shows the fuel pump turn-off processesfor the diesel engine.

On the spark ignition engine, the non-linearities wereintroduced by the electronic control unit (ECU), governingthe fuel supply while guaranteeing a stoichiometric fuel-airmixture. This means that the fuel supply does not dependexclusively on the throttle valve position (accelerator).Figure 4 shows the ECU effect at 2.550 rpm (without load)where the ECU changed the speed with no throttle action.

2.3 State-space model selection

A Linear Quadratic Regulator (LQR) was implementedin order to fulfill the test bench requirements (speed andtorque control in transient and steady state). It is alinear control technique that offers a simple state controlrule, robust to non-linearities of the engines and simpleto implement in digital systems (Franklin et al. (1997);Espinosa (2003)).

The LQR requires a state-space model of the engine. Atransformation to the state-space with a transfer functioncan be performed using computational tools, but multiple-input and multiple-output systems have a special proce-

Preprints of the 18th IFAC World CongressMilano (Italy) August 28 - September 2, 2011

2232

Fig. 4. ECU effect on the engine. On the electronic sparkengine the ECU controlled the throttle valve based onthe acceleration pedal position and the lambda sensor.At 38 s the internal conditions of the engine changedand the ECU increased its speed even the acceleratorwas fixed

dure for each situation. In this case a simple and practi-cal state-space transformation method developed by Pota(1996) was implemented. The transformation procedurebegan by introducing state-space entries into the matrixof transfer functions of equation (1) with a change ofvariable, and applying the inverse Laplace transformation,resulting: [

x1x2

]=

[−1 00 −1

] [x1x2

]+

[1 00 1

] [u1u2

][y1y2

]=

[K11 K12

K21 K22

] [x1x2

] (4)

With this procedure, the states lost some of their physicalmeaning by making the transformation to time, becausethey could not be represented as physical variables, butthey retained a very simple structure that allowed torecognize the origin of each parameter. The gain matrixvalues (Kij) were replaced by each engine gains. As thecontrol algorithm was implemented on a microcontroller,the matrix was corrected to include the actuators gains,resulting:

CRenault =

[17.54 −3.181.16 2.32

](5)

CIsuzu =

[0.493 −4.440.147 14.52

](6)

In both engines most of the transfer functions coincided inthe delay, it was chosen an average value for each one:

τRenault = 0.15 s τIsuzu = 0.6 s

2.4 LQR controller

LQR technique calculates a matrix K, which being admit-ted to a feedback control must meet

x = A · x+B · uu = −K · x (7)

furthermore, this technique minimizes a cost functiongiven by

J =1

2

∫ ∞0

(xTQx+ uTRu

)dt (8)

Fig. 5. Spark ignition engine on the linear region. Severalfixed size speed and toque steps were performedbetween 1.500 – 2.000 rpm and 10 – 20 Nm with anexpected response on each case

which penalizes the error in the system by applying acorrection proportional to the magnitude of the error.

The matrix K(t) corresponds to the time invariant controllaw:

K = R−1BTP (9)

this means that calculating the matrix K in steady state,its coefficients are constant (Menendez and Simon (2004)),then the controller only needs to find appropriate valuesfor the Q and R matrices.

An integral action was added to compensate the steady-state error. The matrices Q and R were expanded to matchthe structure of the cost function.

On the ICE model proposed, the gain of the engine speedwas punished because it was larger, as the same as thetorque response time because it had a faster actuator.The engine speed and torque did not varied significantlywith different values of Q and R, but the actuators weresensitive to this changes and tended to oscillate, even whenthe system seemed stable, then those matrices must becarefully chosen.

Adjusted the curves of the model to meet the designconditions, R matrices on both engines were identity, andthe Q matrices were:

QR =

0.01 0 0 00 8 0 00 0 0.05 00 0 0 1

QI =

0.1 0 0 00 1 0 00 0 0.1 00 0 0 0.1

3. RESULTS AND VALIDATION

3.1 Spark ignition engine validation

The performance of the controller was tested throughdifferent operating regions of the engine operating mode.Initially several steps were made in the linearized region,Figure 5 shows speed steps between 1.500 rpm and 2.000rpm with changes in torque of 10 Nm to 20 Nm, with agood response of the controller.

Figure 6 shows the controller response to speed steps from3.000 rpm to 3.400 rpm. Responses with damping wereexpected, because in this region the gain was larger thanthat obtained on the model linearization.

Preprints of the 18th IFAC World CongressMilano (Italy) August 28 - September 2, 2011

2233

Fig. 6. Spark ignition engine out of the linear region.Two speed steps performed with a fixed torque of46 Nm show how at higher speed and torque valuesthe controller has an accurate response

Fig. 7. Compression ignition engine without load. Severalincrements on speed (1.000 rpm each) show the con-troller response in the entire operating range of theengine. Note the turbocharger turn on (20 – 30 s)and the fuel pump turn off (128 – 140 s)

3.2 Compression ignition engine validation

The controller performance was tested around the non-linearities exposed before. Figure 7 shows speed stepswithout load from 1.000 rpm up to 4.000 rpm. Between1.200 rpm and 1.800 rpm the turbocharger turn-on isobserved, the controller did not show oscillation or steady-state error, leading the engine to the 2.000 rpm set point.When the ICE switched from 3.000 rpm to 4.000 rpm,there was a drop in the speed produced by the fuel pumpturn-off, the controller response was accurate withoutoverdamping on the final speed value.

Figure 8 shows steps from the region close to the tur-bocharger turn-on until 3.000 rpm, with variations oftorque between 20 Nm and 40 Nm. The controller couldget the final value with an expected overshoot due thelarge set-point change of about 30 % of the span.

3.3 Transient control (Follower of trajectories)

The procedure for conducting this test was to removethe manual control of the set-point, replacing it witha trajectory providing the controller the desired enginespeed and torque at each instant of time. Figure 9 showsthe test result, the ideal trajectories were superimposed(straight lines), the engine speed and torque were followedby most of the trajectory. However, as can be seen at 20s of testing, the change in the slope of torque affected thespeed trajectory, because there was not a fast actuator onthe fuel injection (as expected).

Fig. 8. Compression ignition engine with high amplitudesteps. At 65 s was performed a speed step from3.100 rpm to 2.200 rpm, the speed changed its in-clination three times until it reached its final valuecausing same number of peaks on torque

Fig. 9. Controller response to transient tests. A road con-dition was simulated in order to verify the controllerresponse: the user increases the engine speed beforearriving to a hill, then the torque has two increasesand finally the hill ends and the vehicle begins thedescent. The controller had an accurate response, ashort oscillation appeared at 20 s due the hard torquedemand

3.4 Other results

This control system has been used during the last threeyears in the engine laboratory at the University of An-tioquia in Medellın (Colombia). Both engine test bedshave been used in order to explore the performance andemissions of diesel and spark ignition engines using severalbiofuels and its blends with conventional fuels over a widerange of engine operating modes. The use of blends suchas E20 (20% ethanol + 80% gasoline) and blends suchas B5 and B20 (blends of diesel fuel with 5 and 20% ofseveral indigenous biodiesels) have been analyzed using theinstrumentation, controller and software herein presented.Those results have been published in several scientificjournals (Agudelo et al. (2009a,b); Benjumea et al. (2009);Agudelo et al. (2010)).

4. CONCLUSIONS

A low cost, powerful and robust multivariable controlsystem based on transfer functions was developed, im-plemented and tested on two internal combustion engines(diesel and spark ignition) test beds. The control did notdepend on engine or fuel type. The controller was success-fully tested in a wide range of engine operating modes.It could pass through the engine non-linearities such as

Preprints of the 18th IFAC World CongressMilano (Italy) August 28 - September 2, 2011

2234

turbocharger turning on and some ECU points reachingthe stabilization in neighboring points.

The process of designing a LQR controller from a matrixof first order transfer functions with delay for engine speedand torque, met the requirements of control for engine testbeds used for research activities.

ACKNOWLEDGEMENTS

Authors would like to thank professor Orlando Carrillo forhis valuable help during engine test beds instrumentationand control system development.

REFERENCES

Agudelo, J., Agudelo, A., and Perez, J. (2009a). Energyand exergy analysis of a light duty diesel engine operat-ing at different altitudes. Revista Facultad de Ingenieria,48, 45 – 54.

Agudelo, J., Benjumea, P., and Villegas, A. (2010). Eval-uation of nitrogen oxide emissions and smoke opacityin a HSDI diesel engine fuelled with palm oil biodiesel.Revista Facultad de Ingenieria, 51, 62 – 71.

Agudelo, J., Gutirrez, E., and Benjumea, P. (2009b).Experimental combustion analysis of a HSDI dieselengine fuelled with palm oil biodiesel-diesel fuel blends.Dyna, 159, 103 – 113.

Anwar, S. (2004). A parametric model of an eddy currentelectric machine for automotive braking applications.IEEE transactions on control systems technology, 12(3).

Benjumea, P., Agudelo, J., and Agudelo, A. (2009). Effectof altitude and palm oil biodiesel fuelling on the perfor-mance and combustion characteristics of a hsdi dieselengine. Fuel, 88, 725 – 731.

Bunker, B., Franchek, M., and Thomason, B. (1997). Ro-bust multivariable control of an engine dynamometersystem. IEEE transactions on control systems technol-ogy, 5(2), 189 – 199.

Cook, J. and Powell, B. (1988). Modeling of an internalcombustion engine for control analysis. IEEE powercontrol systems magazine, 20 – 26.

del Portillo Valdes, L.A., Tinaut Fluixa, F.V., Mel-gar Bachiller, A., and Gimenez Olavarria, B. (2007).Validacion de un modelo fenomenologico para el estu-dio de motores diesel de inyeccion directa. In Octavocongreso iberoamericano de ingenierıa mecanica, Cuzco.

Espinosa, J.J. (2003). Control lineal de sistemas multi-variables. Corporacion Universitaria de Ibague.

Franklin, G., Powell, J.D., and Workman, M. (1997).Digital control of dynamic systems. Addison WesleyLongman Inc.

Gonzales, M.I. (2004). Experiments with eddy currentsthe eddy current brake. European Journal of Physics,25, 463 – 468.

Gosline, A., Campion, G., and Hayward, V. (2006). On theuse of eddy current brakes as tunable, fast turn-on vis-cous dampers for haptic rendering. Proc. Eurohaptics,229 – 234.

Heywood, J. (1988). Internal combustion engine funda-mentals. McGraw Hill.

Hopkins, H.G. and Borcherts, R.H. (1980). Discrete TimeModeling of the Torque Response of a Spark-IgnitedFuel-Injected Engine: Applications of Adaptive Control.Academic press, New York.

ISUZU (1991). Technical manual of the diesel engineISUZU 4JA1. ISUZU.

Lee, K. and Park, K. (1999). Optimal robust control of acontactless brake using an eddy current. Mechatronics,9, 615 – 631.

Lopez, J.D. (2009). Automatizacion de un banco deensayos para MCIA. Master’s thesis, Universidad deAntioquia.

Menendez, A. and Simon, S. (2004). Aportacio al con-trol del convertidor CC/CA de tres nivells. Ph.D.thesis, Universitat Politecnica de Catalunya. URLhttp://www.tdx.cat/TDX-0104105-081901.

Morris, R.L., Borcherts, R.H., Warlick, M.V., and Hop-kins, H.G. (1981). Spark ignition engine model building- an identification approach to throttle-torque response.In Workshop on adaptative control.

Plint, M. and Martyr, A. (1997). Engine testing: Theoryand practice. Oxford: Butterworth Heinemann.

Pota, H.R. (1996). Mimo systems, transfer function tostate space. IEEE transactions on education, 39(1), 97– 99.

Powers, W.F. (1981). Internal combustion engine controlsystem research at ford. In 20th IEEE Conf. on Decisionand Control, volume 20, 1447 – 1452.

Ritzen, J. (2003). Modelling and fixed step simulation of aturbo charged diesel engine. Master’s thesis, LinkopingsUniversitet.

Van Lith, P. (2002). Hybrid fuzzy first principles modeling.Ph.D. thesis, University of Twente.

Preprints of the 18th IFAC World CongressMilano (Italy) August 28 - September 2, 2011

2235