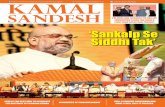

Low Speed Engine Lay Out

description

Transcript of Low Speed Engine Lay Out

-

Low-speed engine lay-out.ppt / TN

Low speed engines propulsion layout

7056-03/F100484

Principal propulsion layout(Ref. Wartsila Marine Propulsion Guide Jan. 2000)

Propulsion layout of low speed engines driving FP-propellers must be given special attention Once a FP-propeller has been designed, it is very limited possibilities to control the torque and power absorbed

-

Low-speed engine lay-out.ppt / TN

Low speed engines propulsion layout

Low speed engines normally drives the propeller directly. The engine should therefore turn at a speed close to the optimum propeller speed

Engine Layout fields have been introduced in order to optimise the engine speed according to the envisaged propeller diameter

The Contract Maximum Continuos Rating (CMCR) can be freely selected within the layout field

Engine Load range is the admissible area of operation once the CMCR has been determined

General remarks

-

Low-speed engine lay-out.ppt / TN

Selection of the CMCR point

Various parameters should be considered

Required propulsive power Propeller efficiency (rpm and diameter influence) Operational flexibility Power and speed margins (weather and ageing reserves) Ship trading pattern Possibility of a shaft generator

Selecting the most suitable engine is vital to achieve an efficient cost/benefit relation for the actual vessel

-

Low-speed engine lay-out.ppt / TN

Selection of CMCR point

Why derating ?

Normally engines are delivered with CMCR close to the maximum R1 rating (Commercial pressure)

Derating may be applied for the following reasons: Reduction of engine speed at constant mep (mean effective

pressure) to improve propeller efficiency Reduction of engine power at full engine speed to reduce specific

fuel oil consumption General derating to increase power and torque margins, and to

reduce engine wear/maintenance cost

-

Low-speed engine lay-out.ppt / TN

Engine layout field - RTA engines

Engine speed

Note : logarithmic scales

*) 90% for RTA96C

Rating line for constant vessel speed

CMCR (Rx) point (example)100%

100%

Engine Power

70%

80% *)

R1

R2

R3

R4

Nominal 100% constant mean effective pressure

80% *)Reduced specific fuel oil consumption

Improved propeller efficiency

-

Low-speed engine lay-out.ppt / TN

Propeller speed influence on power requirement

Lower propeller revolutions combined with larger propeller diameter increases propulsion efficiency. Less power will be needed to propel the vessel at a given speed

The relative change in required power can be approximated by the following relation:

=

1

2

1

2

NN

PP

Pj = Propulsive power at propeller revolution NjNj = Propeller speed corresponding with propulsive power Pj = 0,15 for tankers and general cargo ships up to 10000 dwt

0,20 for tankers, bulk carriers from 10000 to 30000 dwt0,25 for tankers, bulk carriers larger than 30000 dwt0,17 for reefers and container ships up to 3000 TEU0,22 for container ships larger than 3000 TEU

-

Low-speed engine lay-out.ppt / TN

Propeller efficiency task

A VLCC is fitted with a 7 cylinder Sulzer RTA84TCMCR is 28700 kWService rating is 25830 kW at 76 rpm (90% CMCR)

Estimate the reduction in required service rating if the propeller speed is reduced to 61 rpm (assuming a larger optimum propeller diameter)

-

Low-speed engine lay-out.ppt / TN

Hull roughness effect on resistance

Increased hull roughness effects

10 m increased roughness 1 % power increase up to 250 m10 m increased roughness 0,5 % power increase over 250 m

1) Permanent roughness: Due to quality of steel work, surface treatment, type of paint, age etc.2) Temporary roughness: Due to marine growth

Permanent roughness increase / longtime antifouling (5 years): 125 m 300 m 15 % powerPermanent roughness increase / selfpolishing antifouling (5 years):125 m 145 m 2 % power

Total roughness increase / longtime antifouling (4 years): 125 m 300 m 15 % powerTotal roughness increase / selfpolishing antifouling (4 years): 125 m 175 m 5 % power

-

Low-speed engine lay-out.ppt / TN

Definitions of margins

Sea Margin (SM)Power reserve to maintain a given ship speed, allowing for weather, sea force, ageing and fouling of hull, as well as roughening of propeller blades

Engine Margin (EM)Mechanical & thermodynamic power reserve for economical operation of the engine, i.e. low fuel and maintenance cost (also called operational margin OM)

Light Running Margin (LR)Margin in propeller revolutions with new ship (i.e. under sea trial condition) to attain or maintain any power up to 100% in future continuos service. Related to Sea Margin

-

Low-speed engine lay-out.ppt / TN

Light running and heavy running

Light running :- Same power is achieved at a higher rpmHeavy running :- Same power is achieved at a lower rpm

Power

rpm

P

n1 n2

Heavy prop. curve

Light prop. curve

-

Low-speed engine lay-out.ppt / TN

Sea margin & Light running margin

CSR

Engine/propeller speed

100%

Sea margin(10-25%)

Light running margin(3-7%)

Propeller curves

Sea trial condition New and clean ship Calm weather

Hull ageing and fouling

Service condition with fouled hull, wind and waves resistance

-

Low-speed engine lay-out.ppt / TN

Power versus ship speed in trial and service

Power

Vessel speed

CSR

Service Trial

Service condition

Sea trial condition

Difference between service speed and trial speed at CSR depends on how much sea margin that has been selected

Sea margin

-

Low-speed engine lay-out.ppt / TN

Light running margin

Example of light running margin of 5-6% to compensate for expected future drop in revolution for constant power

1,5 - 2% influence from wind and weatherDifference between sea trial (Beaufort 2) and average service condition (Beaufort 4-5)

1,5 - 2% influence from hull resistance and increased wakeRippling of hull, fouling and increased hull roughness, change in hull trim and immersion

1% frictional losses from increased propeller blade roughnessSurface roughness increase from 12 to 40 microns

1% deterioration of engine efficiencyFouling of scavenge air coolers and turbochargers, piston rings condition, fuel injection system etc.

-

Low-speed engine lay-out.ppt / TN

Load range starting point Rx with marginsEngine Power(% Rx)

100

100

Engine speed (% Rx)

90

76,5

10% engine margin (EM)

15% sea margin (SM)

Sea trial propeller curve

Nominal propeller curve

Rx

A

BD

5% light running margin (LR)

-

Low-speed engine lay-out.ppt / TN

Load range limits - RTA engines - 1

100

100

Engine speed (% Rx)

Rx

A

BD

10495

95

70

45

Const. mepOperational range limit

Area reserved for acceleration and operational flexibilityIt is recommended to operate below the nominal propeller curve through the Rx point

Engine Power(% Rx)

90

-

Low-speed engine lay-out.ppt / TN

Load range limits - RTA engines - 2

100

100

Engine speed (% Rx)

Rx

A

BD

108

110

93,8 103,2

Engine Power(% Rx)

Constant torque

Overload range limit>100% load only at shop test

90

Service range with operational time limitOnly to be used for transient conditions i.e. fast acceleration

-

Low-speed engine lay-out.ppt / TN

Load Range with shaft generator (PTO)Engine Power(% Rx)

100

100

Engine speed (% Rx)

85

72,3

Sea trial

Nominal propeller curves

Rx

A

BD

90D

15% sea margin

5% for shaft generator

10% engine margin

With PTO

Without PTO

Example with a shaft generator absorbing 5% of nominal engine power

Constant speed operation range for shaft generator, typically 3,3%

-

Low-speed engine lay-out.ppt / TN

FPP versus CPP layout

FPP

rpm

Power

rpm

PowerCPP

Outer non-controllable conditions moves load curve up/down. Challenge: Correct design (P/D)

Adjustment of propeller pitch (P/D) moves load curve up/down. Challenge: Correct operation (P/D-rpm)

Weather & age Captain

-

Low-speed engine lay-out.ppt / TN

40 60 80 100 120 140 160 180Propeller speed [RPM]

Engine power [kW]5000 P/D=1.6 1.4 1.2

21 kn

1.0

19 kn

17 knP/D=0.8

15 kn210 g

195 g

187 g

183 g

181 g

0500

10001500

200025003000350040004500

oooo

o

oo

o

o

o

oo

o

o

oo

oo

o o ooo

o

o

o

o

o

o

o

o

: combinator curve: nominal pr. curve: 100 % load curve

Cavitationarea

Over

load

Com

binat

or

Performance diagram - CP-propeller operation