Logbook part 2 636547

description

Transcript of Logbook part 2 636547

Week 6 Tutorial and E-Learning notes: Roof systems:

• Primary sheltering element, also collect rainwater carry it away through gutters. • Flat roofs (pitch of 1 to 3 degrees) and pitched/ sloping roofs (pitch greater than 3

degrees) (timber or steel rafters, purlins or beams) • Concrete roofs- Generally flat plates of reinforced concrete. Top surface is sloped

towards drainage points. Section through concrete roof slab needs waterproofing and insulation.

• Structural steel framed roofs- Flat (primary and secondary roof beams), Sloping (Roof beams and purlins and lighter sheet metal roofing) and Portal Frames (Braced rigid frames- two columns and a beam- with purlins for the roof and grits for the walls.

• Trussed roofs- Framed roofs constructed from a series of open web type steel or timber elements. Need to be braced for stability.

• Light framed roofs- Gable roofs- Vertical, triangular section of a wall at one or both ends of the roof. (Timber or cold-formed steel)

• Hip roof- Vertical, triangular section of a wall at one or both ends of the roof- curves around a wall.

Metals:

• Alloys- Combination of two or more metals

• Ferrous- Iron • Good conductors of heat and electricity and generally cost effective but high embodied

energy, easily recycled and reused. • The galvanic series lists their tendency to give up ions to other metals and corrode.

Different metals in contact with one another will corrode. To reduce the corrosion you can separate the metals.

• Steel rusting- Metal turning back into metal oxide • Galvanizing- zinc coating or plastic coating • Corrosion (Oxidation)- Galvanizing (coating of zinc) to stop corrosion.

- Metals (Plus a potential difference between these) - Electrical difference - Medium (Water) to transfer electrons - Oxygen

Ferrous metals:

• Significant and important magnetic properties • Good compressive strength • Wrought iron- Heated and hammered into the desired shape • Cast Iron- Used more commonly- melted and metal is poured into molds to cool and set • Steel- Iron Alloys- Iron and carbon being the primary additional alloy element. Strong

resistance to rusting. Still transfers heat and electricity. Can be formed into different shapes (wires, columns, tubes)

Metals at the top have the highest thermal and electrical conductivity

• Structural steel- Framing- Hot rolled steel (shaped while the metal is hot) Sold formed steel (Folder from sheets) Reinforcing bars (good tensile resistance, steel is used in conjunction with concrete to produce reinforced concrete.

• Steel sheeting- cladding and roofing. Must be protected (galvanizing)

Spanning Spaces • Architecture is about enclosing a space, main problem is how to span space • Support buildings with centering • When was major interior space invented?

Non-Ferrous metals: • Aluminum- A lot in

widow framing (quite light). Easily formed, machined and cast.

• Reacts with oxygen in air with to create a layer of oxide that keeps it from further oxidation.

• Copper- conducts electricity- used it in electrical wiring. Found in its pure form

• Traditionally used a roofing material • Zinc- Plating thin layers of zinc on to iron or steel is know as galvanizing to protect it

from rusting. • Lead- Used to be used for roofs, tank linings

• Tin- Very rare today- Corrugated tin roofs (tend to be steel now) • Titanium- Very expensive material occasionally used as a cladding system. Excellent

corrosion resistance. • Bronze- Used for bearings, clips, electrical connectors and springs. • Brass- Elements where friction is required such as locks, gears, screws, valves.

Trusses • “Fabricated by welding or bolting structural angles and tees together to form the

triangulated framework. Connections usually require the use of steel gusset plates.” • “Trusses require lateral bracing in a direction perpendicular to their planes.”

Plates and Grids

• “Plate structures and rigid, planar, usually monolithic structures that disperse applied loads in a multidirectional pattern, with the loads generally following the shortest an stiffest routes to the supports.”

Roof systems

• Flat roofs- Require a continuous membrane roofing material • Sloping roofs- Low slope roofs and medium to high slop roofs. • Small module- Timber shingle, terracotta tile, concrete tile, slate • Long sheet- Metal-steel (cheapest to manufacture), copper and zinc • Steel rusting- Metal turning back into metal oxide from water, anode/cathode. Protect it

by galvanizing- zinc or plastic coating.

Examples of primary and secondary structural members in flooring systems

Dispersal of applied loads in multiple directions

Primary Member Secondary Member Timber floor Bearer (manufactured timber-

LVL) Joist- Pine

Timber roof Bearer Rafter Steel floor Beam (Hot-rolled steel- UB,

UC, PFC) Purlins (Cold formed)

Lecture 6 Property development

• Space creation • Profits made and lost • Capitalizing on opportunity • Knowing products, market and marketing • Achieving set outcomes • Understanding land use

Successful development • Location • Understanding potential space user needs • Market timing • Window of opportunity

35 Spring street • What type of utilization • Sense of rhythm and solidarity • Respect for masonry buildings • Interest of buyer and interest of city

Glossary: Rafter- A beam forming part of the internal framework of a roof. Purlin- Metal rafter Cantilever- Only one point of support. Portal frame- Type of structural frame Eave- The roof member overhanging- generally used as protection to the outside of a building. Alloy- 2 base metals combined. Copper and zinc are door handles. Top chord- Top and bottom members of a truss (metal) Soffit- The underside of the eaves. Often CFC for weather protection

Week 7 E-learning and Tutorial Detailing for heat and moisture:

• For water to penetrate into a building: these must occur: an opening, water present at the opening, a force to move water through the opening. Remove one of them and water will not enter

• Solutions: Remove opening, keep water away (eaves), neutralizing the forces that move the water.

• Openings: Planned- windows, doors, skylights OR Unplanned- poor construction, chipping.

• Solutions: Seal the openings with: Sealants (silicone) or gaskets (preformed shapes made from artificial rubbers)

• Gutters and downpipes keep water away from the building, not at the base of a wall.

• Water is collected into gutters and roofs are sloped to carry water away

• Overlapping cladding and roofing elements (weatherboards and roof tiles)

• Neutralizing the forces: Gravity (using slopes and overlaps- double cavity wall with slope in wall carried out through a weep hole), surface tension (drip or break between surfaces to prevent water clinging to the underside of surfaces such as a window sill), momentum, air pressure differential PIC

• Air barrier- internal side of the wall, a ventilated and drained Pressure Equalization chamber is created.

• Controlling heat: Heat is conducted though the building envelope and heat is gained and lost

• 3 strategies: Thermal insulation (reduce heat conduction), thermal breaks (rubbers and plastic reduce heat to transfer from outside to inside) and double-glazing.

• Radiation: Reflective surfaces (low e-glass), shading systems (eaves)

• Thermal mass: Capture warmth during sunny winters day and then have that warmth gradually released at night (Materials used: masonry, concrete and water bodies)

• Air leakage: an opening, air and a force. • Strategies: Wrapping the building in polyethylene or reflective foil, sarking, to provide an

air barrier. Also weather stripping around doors and windows and other openings.

Rubber:

• Natural and synthetic rubber- petrochemical origin (plastic)

• High in ductility, high in flexibility and elasticity • All rubbers considered waterproof- seals around

window frames, floor lining, insulation • Poor conductors of heat and electricity • Easily recycled, can be very durable • Deteriorate when in sun exposure

Plastics:

• Able to be molded into different shapes • Thermoplastics- molded when heated and become solid

again when cooled (polyethetyne) • Thermosetting plastics- Can only be shaped once, limits

recyclability (polystyrene) • Elastomers- synthetic rubbers (Silicone) • Medium to low hardness, not fragile, degrade in sunlight

and become brittle, highly flexible, many plastics are waterproof, low density, poor conductors of heat and electricity

• Can be very durable, high recyclability for thermoplastics and elastomers, not for thermosetting plastics.

• Can expand and extract

Paints: • Liquid until applied on surface forming a film that becomes solid when in contact with the

air • Main purpose to protect and color • Oil based and water based paints, water based most commonly used now • Surface has to be good quality as well, affected by rain, air pollution and sunlight.

Arches, domes and shells:

Moisture and thermal protection:

Glossary: Drip: Vapor barrier: A material of low permeance installed into a construction to prevent moisture from entering and reaching a point where it can condense into a liquid. Gutter: a shallow trough fixed beneath the edge of a roof for carrying off rainwater Parapet: A low protective wall along the edge of a roof, bridge, or balcony. Down pipe: A pipe to carry rainwater from a roof to a drain or to the ground level. Flashing: A thin continuous piece of sheet metal or other impervious materials installed to prevent the passage of water into a structure from an angle or joint. Sealant: A material used for sealing something to make it airtight or watertight. Insulation: Material used to insulate something

Week 8 Tutorial and E-learning

Geometry and moment of inertia • Moment on inertia is the sum of the products of each element of an area and the square

of its distance from a coplanar axis of rotation • It is a geometric property that indicates how the cross-sectional area of a structural

member is distributed and does not reflect the intrinsic physical properties of a material

Strategies for openings (doors and windows): • Light and ventilation, allow access, contribute views and add character • Timber doors, aluminum doors and frames, steel doors and frames • Steel doors-can be used for security purposes • Timber windows and frames- brick veneer spaces, aluminum windows and frames- used

in commercial spaces • Steel windows and frames- finer and flatter. More expensive than timber and aluminum.

Frames are welded together. Steel so readily transmits heat, a thermal break is put in to reduce heat loss

• Curtain walls- type of hybrid system- windows and a wall system. Window system is hung off the concrete structure off the building. Transferring loads back into the concrete structure. Loads need to be carried around the window openings.

Glass • Formed from silicone (sand) added to fluxes which help formers melt at a lower

temperature and stabilizers combine formers and fluxes. Stops it from crumbling. • Relatively economic material, no blown glass technologies anymore • It transmits heat and light but not electricity, sometimes used for insulation with electricity,

quite a dense material • Very low ductility, very high flexibility and plasticity when molten, low when cooled, highly

fragile, very hard, little bit elastic until it breaks • Very durable, chemical and rust resistant, high recyclability, high embodied energy-

reduced when glass is recycled, expensive to produce and transport

• 2 types of manufacture: Flat glass (clear or tinted glass, laminated) and shaped glass (curved, blocks, channels) Float glass is the most common glass production process for glass

• Clear float glass- Simplest and cheapest, low risk areas with a lot space • Laminated glass- A tough plastic interlayer is in-between 2 sheets of glass • Tempered glass- toughened glass- Heating glass then cooled rapidly. Increases the

strength of the glass • Glass qualities can be improved by double and triple glazing. Heat loss or heat transition

Deformation

• Resisting moment is an internal moment equal and opposite to a bending moment, generated by a force couple to maintain equilibrium of the section being considered. Bending moment is an external moment tending to cause part of the structure to rotate or bend.

Glass skins • Glass is also a technology- crown glass, cylinder glass, table glass. • Thickness and production and limited size and quality of glass and can create high

wastage in older days has changed. • Glass is now mass produced by computer controlled factories • Glass is cultural artifact, why the need of bigger windows? • Glass is the interface between the building and the sun • Related to health, environmental impacts, materials and technology.

Glossary: Window Sash: A frame placed inside a window frame. They are the members of the moving part of the window. Deflection: The perpendicular distance a spanning member deviates from a true course under transverse loading, increasing with load and span, and decreasing with an increase in the moment of inertia of the section or modulus of elasticity of the material. Door furniture: Also known as door hardware including handles, hinges, bolt, locks, seals and vision panels. Stress: Internal pressure inside a material Shear force: Tearing a material apart inside Moment of inertia: Moment on inertia is the sum of the products of each element of an area and the square of its distance from a coplanar axis of rotation

Drawing The Pavilion exercise

Construction workshop 02/05/14: Our exercise was to make the strongest beam using three pieces of plywood and one piece of softwood. We cut the wood to just over a meter long using a saw. We then screwed and drilled the pieces together. Our idea was to have two pieces of plywood standing the tallest and put the soft wood in the middle. We then screwed the last piece of plywood onto the bottom of the two tall pieces of plywood. We thought this would work because the beam would be stronger if it was taller and slimmer. However when we put the beam under pressure the wood cracked under tension and split the wood.

We measured the plywood so it was 1050cm, making sure it was just over one meter. We had an idea of making the beam tall and slim as we thought that is what would be strongest, as if the wood was flatter it could easily break due to less depth.

We then cut the wood using a saw over the traced line. We made a indentation in the wood and then evenly sawed back and forth

We drilled a hole in the piece of wood as we set them up. We then drilled in a screw alternating top and bottom.

This was our final design, having two pieces of wood standing up tallest with a piece of soft wood screwed in the middle for extra support. The last piece of hard wood was then screwed onto the bottom of the structure to make it taller and slimmer, and therefore stronger. We also had two small pieces of woof left over from our cut so we screwed them into the middle of the top space again to make it stronger as the weight was a point force load in the center of the top of the beam.

When we tested our beam we reached a weight of around 400kilos. The wood started to break under tension and therefore it split and snapped. We started at 140 millimeters and reach 200 millimeters therefore creating a deflection of 60 millimeters. Compared to other groups we had a medium-high deflection measurement and a very high weight.

Week 9 Tutorial and E-Learning

Constructing detailing: • How materials are put together, made by the constructor, builder or the detailer. • Movement joints- compressed, as installed and elongated. Expansion joints (bricks) and

contraction joints (concrete blocks) are then used. • Health and safety- making sure stairs are safe for use through regulations. Part of the

Building code of Australia • Materials are selected on the risk of fire. Fire insulation is also needed. • How buildings age over time, some buildings can deteriorate with water stains. Choosing

materials that do not deteriorate quickly. Matte finishes will age slower that glossy. • Repairable surfaces and resistance to damage. How easily a surface can be repaired.

Corners are particularly susceptible. • Cleanable surfaces and maintenance access. • Constructability- How expensive it is. Detail should be easy to assemble and able to have

minor mistakes, efficient use of construction facilities like tools and labor.

Composite materials:

• Range of materials: bricks, blocks, concrete, reinforced concrete, timber, glass, rubber, and plastic.

• Monolithic materials are single materials; materials are combined so that components are totally different.

• Composite materials are created when two or more materials are combined in such a way that the individual materials remain easily distinguishable.

• A composite is formed from a combination of materials, which different in composition or form, they remain bonded together whilst retaining individual properties.

• Examples: Fibrous, laminar, particulate (gravel and resins) or hybrid. • Fiber reinforced cement- Made from cellulose (or glass) fibers, Portland cement, sand and

water. Used for cladding for exterior or interior walls (wet area) and floor panels (under tiles)

• Fiberglass- made from a mixture of glass fibers and epoxy resins. Used for transparent of translucent roof/wall cladding. They are fire resistant, weatherproof and relatively light weight and strong

• Aluminum sheet composites- made from aluminum and plastic. Used as feature classing material in interior and exterior applications. Weather resistant, unbreakable and shock resistant.

• Timber composites- Made from combinations of solid timber, engineered timber and galvanized pressed steel. Used for beams (floor joists and roof rafters) and trusses. Cost effective, easy to install and minimum amount of materials used for maximum efficiency.

• Fiber reinforced polymers- Made from polymers (plastics) with timber, glass or carbon fibers. Used for decking, structural elements such as beams or columns for public pedestrian bridges used glass or carbon fibers. It has high-strength and corrosion resistant.

Stress and Structural members

• Short, think columns are subject to failure by crushing rather than buckling. Failure occurs when the direct stress from an axial load exceeds the compressive strength of the material available in the cross section.

• Long, slender columns are subject to failure by buckling rather than by crushing. Under a buckling load a column begins to deflect laterally and cannot generate the internal forces necessary to restore its original linear condition.

Joints and Connections: • The manner in which forces are transferred from one structural element to the next and

how a structural system performs as a whole depend on the types of joints and connections used.

• Pinned joints, rigid or fixed joints and roller joints. • Butt joints, interlocking/overlapping joints, molded or shaped joints, point connector: bolt,

linear connector: weld, surface connector: glue, bolted connections, precast concrete connections, welded stele connections, reinforced concrete.

Movement joints: • Expansion joints are continuous, unobstructed slots constructed between two parts of a

building or structure permitting thermal or moisture expansion to occur without damage to either part.

• Control joints are continuous grooves or separations formed in concrete ground slabs and concrete masonry walls to form a plane of weakness and thus regulate the location and amount of cracking resulting from drying shrinkage, thermal stresses, or structural movement.

• Isolation joints divide a large or geometrically complex structure into sections so that differential movement or settlement can occur between the parts.

From Ching Textbook pg. 2.30 this shows the different joints and connections used in a structure.

Glossary: Sandwich panel: is a type of flat panel that consists of two thin aluminum sheets bonded to a non-aluminum core. They are frequently used for external cladding or facades of buildings, insulation, and signage. Bending: Is when before a horizontal member fails it usually causes compression above and tension below the beam. Skirting: a wooden board running along the base of an interior wall Composite beam: A steel beam, which has concrete decking above it, and which is connected to the concrete by shear connectors, which cause the steel and the concrete to act together. Normally the steel will carry the wet weight of the concrete, but when this has set, the two materials will share the load, the concrete mostly acting in compression. Shadow line Joint: When the connection is set back from the edge to create a shadow line around in joints. Cornice: an ornamental molding round the wall of a room just below the ceiling.

Week 10 Tutorial and E-Learning

Collapses and failures: • Construction detailing issues, material selection, materials long-term performance,

environmental and exposure considerations for materials components in selection. • Cracking from sun damage, external cladding from corrosion and salt air problems from

weather exposure. • Glue and plywood sheeting are not strongly bonded anymore. Condensation gets into

cracks and weathers. Plywood is not having a long-term performance. • Aesthetics from buildings can be lost • Problems with the flat steel sheeting on plywood: Corrosion of cut edges, glue failures,

galvanized exposed nails to fix sheeting, and reclad with exterior grade plywood. • Considerations:

- Suitability of the material for application - Compatibility - Strength and deflection - Long-term performance - Maintenance - Construction and detailing

Grooves in-between sheets to allow for tolerances

Timber studs to hold plywood sheets onto studs until glue is set

Heroes and culprits when selecting materials • Issues to consider when selecting materials

- Health and OH&S - Waste/recycling/recycled- Environment - Energy use and embodied energy - Pollution - Life cycleà chose materials that will

last a long time and have a long durability, easy to maintain and assemble.

• Indoor Environment Quality (IEQ) - Problems: - Reduced life span - Asthma/bronchitis - Nausea/ headaches - Sick days - Comfort- More comfortable the more productive individuals are

• Health (IEQ)- How to chose - Choosing paints- Reduced VOC’s - Paints, sealers, adhesives, particleboard, carpets - Reduce particles, dust à minimize horizontal shelves, vacuuming

• Source and waste - How to chose? - Aim for renewable/ abundant resources, natural materials - Aim for agricultural products like timber à earth - Timber à recycled, plantation, RFA, low embodied energy - Waste à Reduce, reuse, recycle, minimize use of composites

• Villain materials: - Plastic- Can not be recycled - Hardwood timber- Old growth - Aluminum- Energy intensive to make

• Hero materials: - Timber- Softwoods- Commercially plantation grown

Dynamic loads • Static loads are assumed to be applied slowly to a structure until it reaches its peak

value without fluctuating rapidly in magnitude or position. Under a static load, a structure responds slowly and its deformation reaches a peak when the static force is maximum.

• Dynamic loads are applied suddenly to a structure, often with rapid changes in magnitude and point of application. Under a dynamic load, a structure develops internal forces in relation to its mass and its maximum deformation does not necessarily correspond to the maximum magnitude of the applied force.

Building materials

• Concrete (cement + water + aggregate)

• Masonry (brick and concrete masonry)

• Steel • Nonferrous metals • Stone • Wood • Lumber • Wood panel products • Plastics • Glass

Lateral Forces

Showing one type of building material: Concrete and the parts used to create concrete

• Lateral forces include forces from wind or earthquakes (vertical loads transfer through to the foundations)

• Wind and earthquake forces are dynamic loads and have different effects on structures.

• Wind forces act on the surface of the structure, have a minimum value on the base, and a maximum value at the highest elevation of the structure. Whereas earthquake forces act on the base of a structure.

• Bracing, shear panel/wall, and moment joints can help resist these forces

• Tall thin structures and cantilever awnings or overhanging items can be vulnerable to wind forces

Types of solutions to resist lateral forces, and make buildings less vulnerable to these forces.

A Tale of Corrosion

• Galvanic corrosion • Statue of Liberty- Designed by Auguste

Bartholdi • The exterior of the statue is copper and

when it is exposed to the atmosphere it starts to oxidize, therefore it becomes a little bit darker and duller.

• Then it forms a green copper oxide patina • Galvanic corrosion between the copper

skin and iron frame was considered at the time of construction and a solution that allowed for the separation of the two metals was devised.

• The first solution was that two materials were separated at their junctions by a layer of shellac- impregnated cloth.

• However over time the shellac- impregnated cloth became porous and held in moisture at the joint between the two different metals. This provided good conditions for galvanic corrosion and the iron began to corrode.

• Iron armature frame was replaced with a Teflon-coated stainless steel structure. • Problem of two dis-similar metals

Glossary: Shear wall: a shear wall is a wall composed of braced panels to counter the effects of lateral load acting on a structure Soft story: A habitable room or rooms above a living, working or storage area such as garage, carport, or other area, that was not engineered to transmit shear and lateral forces appropriately Braced framing: A Braced Frame is a structural system, which is designed primarily to resist wind and earthquake forces Lifecycle: All the components of a building material, to how it was sourced and made, to the reusability and recyclability. Defect: a shortcoming, imperfection, or lack Fascia: a board or other flat piece of material covering the ends of rafters or other fittings Corrosion: Corrosion is the gradual destruction of materials (usually metals) by chemical reaction with its environment IEQ: Indoor Environmental Quality: encompasses IAQ, thermal comfort, day lighting, views, etc.

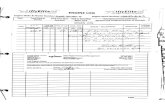

Drawing the Pavilion (1:1 scale) This drawing is a 1:1 (real-life) scale size drawing of the function room of the Pavilion. It is a section cut of the parapet of the roof system. I was unable to identify where my section cut was in the actual building because it is within the building rear.

Metal flashing

Hot rolled PFC

Steel beam holding up rafters

Timber top plate

Insulation

Timber framed wall

Timber studs

Plasterboard (inside lining)

Galvanized steel tray deck- Cold formed because it is not structural. It is about 0.5mm thick and it is galvanized, or zinc alum, so it doesn’t corrode.

Plasterboard (inside lining)

3-D Drawing of the roof system of the Pavilion

Works Cited Ching, F. D. (2008). Building Construction Illustrated. New Jersey: John Wiley & Sons, Inc. Clare Newton, R. C. (2014, March 3). Weekly Guide. Retrieved March 3, 2014, from Blackboard Learn: https://app.lms.unimelb.edu.au/webapps/portal/frameset.jsp?tab_tab_group_id=_5_1&url=%2Fwebapps%2Fblackboard%2Fexecute%2Flauncher%3Ftype%3DCourse%26id%3D_271852 Mark Irving, Tutorials