Load sway prevention and control in gantry cranes using fuzzy logic

-

Upload

kindson-munonye -

Category

Engineering

-

view

365 -

download

1

description

Transcript of Load sway prevention and control in gantry cranes using fuzzy logic

LOAD SWAY PREVENTION

AND CONTROL IN GANTRY

CRANES USING FUZZY

LOGIC

BY

KINDSON MUNONYE

The rotary crane also known as a tower crane is widely being used in the construction of higher buildings.

The crane is consists of a jib that rotates in a horizontal plane around a fixed vertical axis and a trolley

that holds the load which can move linearly along the jib. This study only focuses on the linear motion of

trolley along the jib. The challenging process in order to control the crane are to make sure the trolley

stop at the desired position and to deal with swing phenomenon introduced by the trolley motion. But, for

the beginning of this study, the position control issue needs to be considered. Since many controllers can

be implemented in this system in order to control the position, thus the implementation of practical

controller must be investigated. A practical controller known as a fuzzy logic controller with various types

of membership functions is implemented to control the position of the trolley. The scope of this study is

limited only for four types of membership function which are common triangular, gaussian, trapezoidal

and generalized bell membership function due to their similarities of symmetry characteristics. The

performance of fuzzy logic controller with those membership functions is recorded and compared by

using Simulink (MATLAB) simulation. In order to evaluate the performance of the proposed fuzzy logic

controllers, two different approaches has been adopted: Fuzzy Logic Controller Implementation using

MATLAB/Simulink with the aid of Fuzzy Logic Toolkit and Implementation using a custom simulator

application based on Microsoft Visual Basic.NET and graphical data generated by in Microsoft Excel

spreadsheets. The results were tabulated and plotted. The resulting graph shows a downward trend in

certain output parameter proving that the Fuzzy Logic Controller based system produced the desired

effect.

ABSTRACT

Statement of the Problem

Nowadays, cranes become larger and higher. Due to that, the transportation

payload along the trolley system to the desired position needs faster time.

Since the payload move with a considerable speed, it will result the payload swing

or sway when it suddenly stop after reach the final position. This excessive swing is

not only reduces the efficiency of the cranes, even can cause hazard and safety

problem in the complicated working environment.

1. Load always sways

2. Swaying load may hit other containers or course other form of hazard

3. Swaying load cannot be released

4. Human operators cannot eliminates sway in the most efficient way

The problem of load sway can be summarized as follows:

Aims and Objectives

Having considered the inherent problems with the existing Crane Operation system, this work aims at developing a control system that automates the operation of the over-head crane and reduces the occurrence of load sway to the possible minimum.The objectives of this project can therefore be summarized as follows:

i) To develop a fuzzy logic controller that automates the operation of the over-

head crane and reduces the occurrence of load sway to the possible minimum.

ii) To compare the performance of position control between PID controller and

fuzzy logic controller

iii) Since the PID controller based system is considered the most efficient so far,

this work produces a system that eliminates the shortcomings of the PID

controller.

iv) To compare the performance of position control between different types of

membership function of fuzzy logic controller

The performance of the proposed intelligent gantry crane

system is evaluated experimentally on a lab-scale rotary

crane.

The rotary crane system used for this study involving lab

scaled Crane System which models the real operational crane

in use in the Saipem Nigeria Base in Port Harcourt, Nigeria.

This lab scale rotary crane system consists of 3 subsystems

namely payload, jib and tower. But, this study focuses only on

the jib part which is the part that is controlled by the fuzzy

engine.

The scope of proposed fuzzy logic controller is limited to four

membership functions which are triangular, Gaussian,

trapezoidal and generalized bell as a proposed controller for

position control.

Scope of Work

A crane consists of a hoisting mechanism (traditionally a hoisting line and

a hook) and as support mechanism( trolley-girder, trolley jib, or a boom).

The cable-hook-payload assembly is suspended from a point on the

supporter mechanism. The support mechanism moves the suspended

point around the crane workspace, while the hoisting mechanism lifts

and lowers the payload to avoid obstacles in the path and deposit the

payload at the target point.

Dynamics of Crane Operation

Azdiana Noor Asyikin(2009) proposed a gantry crane system using Dynamic

Feedback Swing Controller for control of industrial three dimensional overhead

cranes which was implemented using Proportional Integral Derivative(PID) controller.

However, PID controller still approached for position control which is based on model

controller. As such, it did not address the problem of noise or interference with the

derivative term of which small amounts of measurement or process noise can cause

large amounts of change in the output which would result in less definite output.

Literature Review

Wahyudi & Jalani, J. (2005) designed and implemented robust Fuzzy Logic Controller

for An Intelligent Gantry Crane System. The experimental results for anti swing control

successfully proved that fuzzy logic controller is better compared to the conventional

PID controller. However, the application of the fuzzy logic controller that has been

proposed is for boom crane which is their parameter is totally different with gantry

crane.

The Fuzzy Logic Theory states that systems could be developed which accepts

and processes information the way humans do.

In this context, Fuzzy Logic is a problem-solving control system methodology

that lends itself to implementation in systems ranging from simple, small,

embedded micro-controllers to large, networked, multi-channel PC or

workstation-based data acquisition and control systems. It can be implemented

in hardware, software, or a combination of both.

Fuzzy Logic provides a simple way to arrive at a definite conclusion based upon

vague, ambiguous, imprecise, noisy, or missing even input information. Fuzzy

Logic's approach to control problems mimics how a person would make

decisions, only much faster.

The Fuzzy Logic Theory

There are four basic elements in the fuzzy logic controller system structure

which are fuzzifier, rule base, inference engine and defuzzifier. Input

output to the controller passes through a pre-processor while the output

passes through a post-processor.

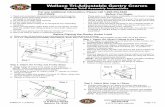

Details of the fuzzy logic controller system structure can be seen in the

figure

Structure of a Fuzzy Controller

Figure 1: Structure of the Fuzzy Controller

This study recommends a fully automated system based on fuzzy logic

controller which reduced the intervention of human operator to the

minimum.

The control system is responsible for controlling the horizontal

movement of the load and the vertical movement of the load such that:

The load is moved to a new position specified by a trajectory, that is, a

particular pathway.

The swinging of the load is well damped to reduce overshoots.

Analysis of the Proposed System

FLC

External

Variable

(dL, dt)

Input

Reference Signal, r

F(Ft, Fh)

Measured Output

Fuzzy Logic Controller for the Proposed System

Figure 2: Fuzzy Logic Controller for Control of Gantry Crane

The processing method used for the implementation can be referred to as batch processing. This choice was made

based on the Fuzzy Logic Rule Base used in the design of the Fuzzy Logic Controller system. This is such that the

Rules are already batched into the Rule Base and then used by the Inference Engine to handle the processing tasks.

Other processing method include: Manual processing, online processing central processing and distributed systems.

Processing Requirements

INPUT OUTPUT

Distance Swing Angle (Power)

NegativeLarge NA NegativeLarge

PositiveLarge NA PositiveLarge

NegativeLarge NegativeLarge NegativeMedium

NegativeLarge PositiveLarge NegativeMedium

PositiveLarge NegativeLarge PositiveMedium

PositiveLarge PositiveLarge PositiveMedium

NegativeMedium NegativeMedium NegativeMedium

PositiveMedium PositiveMedium PositiveMedium

NegativeMedium NegativeLarge NegativeSmall

NegativeMedium PositiveLarge NegativeSmall

PositiveMedium PositiveLarge PositiveSmall

PositiveMedium NegativeLarge PositiveSmall

NegativeSmall NegativeSmall NegativeSmall

PositiveSmall PositiveSmall PositiveSmall

Zero Zero Zero

Zero Negative PositiveSmall

PositiveSmall Negative PositiveSmall

NegativeSmall Negative PositiveSmall

Zero Positive NegativeSmall

PositiveSmall Positive NegativeSmall

NegativeSmall Positive NegativeSmall

Figure 3: Membership Function Plot for output variable, distance

The input variables map into the following sets shown in the next three slides

In the figure below, FIS stands for Fuzzy Inference System showing the three input

variables under consideration(Distance, Power and Angle)

The membership function plot gives us the various ranges of distance between the load and the destination. Here we use a range of 0 to 5 (meters) assuming a linear movement of the load and the trolley in the positive x-direction.

Fuzzy sets for the inputs - Distance

The membership function plot gives us the various ranges of the swing angle for a

particular position of the load along the jib. Here we and experimental maximum range

+30 (degree) and -30 (degrees) to both directions.

Figure 4: Membership Function Plot for output variable, angle

Fuzzy sets for the inputs – Swing Angle

The membership function plot gives us the various ranges of the for the force applied

from the motor to the jib to create a continuous motion form the initial position to

the final destination. For

Figure 5: Membership Function Plot for output variable, Power (Force)

Fuzzy sets for the inputs – Force

Microsoft Visual Studio: An integrated suit of Microsoft Application Development suits that offers and IDE for both coding and form design

MathWorks MatLAB R2007B: MATLAB which stands for Matrix Laboratory is a numerical computing environment and fourth-generation programming language.

MatWorks Fuzzy Logic Toolkit: Fuzzy Logic Toolbox is a collection of functions built on the MATLAB® numeric computing environment.

MatWorks Simulink: Simulink is software for modelling, simulating, and analyzing dynamic systems. Simulink enables you to pose a question about a system, model it, and see what happens.

Microsoft Excel 2007: Microsoft Excel is a spreadsheet application developed by Microsoft. It features calculation, graphing tools, pivot tables, and a macro programming language called Visual Basic for Applications.

Microsoft PowerPoint 2007: Microsoft PowerPoint is a proprietary commercial presentation program developed by Microsoft a part of the Microsoft Office Suite. It consists of a number of pages called slides a number of which make up a presentation.

DEVELOPMENT TOOLS

θ ( 25.00 ( 25.00

Table

4.2: P1(Position 1) x = 0.6 y = 0

P2(Position 2) x = 1.4 y = 10 1.40

Rope Length: 4m

Initial Force 18N θ ( 30.00 ( 20.00

Table 4.3:

P1(Position

1) x = 1.4 y = 0

P2(Position

2) x = 2.2 y = 10 2.20

Rope

Length: 4m

Initial Force 15.0N

Applied force start to decreaseSwing Angle at reducesDistance Increased

Applied force decreasesSwing Angle at reducesDistance Increases

θ ( 30.00 ( 30.00

Table

4.1: P1(Position 1) x = 0 y = 0

P2(Position 2) x = 0.6 y = 10 0.60

Rope Length: 4m

Initial Force 20N

Initial force(maximum) applied:Load starts to swingSwing Angle at maximumDistance at reference/origin

Changes in the Values of Parameter in course of Load Transfer

θ ( 10.00 ( 10.0000

Table 4.5:

P1(Position

1) x = 3.2 y = 0

P2(Position

2) x = 4.8 y = 10 4.8000

Rope Length: 4m

Initial Force 8.0N θ ( 5.00 ( - 0.00 5.00

Table 4.6:

P1(Position

1) x = 4.8 y = 0

P2(Position

2) x = 5.6 y = 10 5.60

Rope

Length: 4m

Initial Force 5N

θ :

1.00 : -

0.00 1.00

Table

4.7:

P1(Position

1)

x =

5.6

y =

0

P2(Position

2) x = 6.2

y =

10

6.2

0

x=6.0(approx

.)

Rope Length: 4m

Initial Force 0.0N

Applied force decreasesSwing Angle at reducesDistance Increases

Applied force decreasesSwing Angle at stabilizesDistance stabilizes

Applied force decreasesSwing Angle at reduces to 0 (approx) Destination reached.

θ ( 30.00 ( 15.00

Table 4.4:

P1(Position

1) x = 2.2 y = 0

P2(Position

2) x = 3.2 y = 10 3.20

Rope

Length: 4m

Initial Force 10.0N

Applied force decreasesSwing Angle at reducesDistance Increases

This section provides a view of the user interface to the fuzzy logic controller of the crane operation as shown in the figure below and the next slide

User Interface (Dashboard 1)

Figure 6: Graphical Interface to the simulation program

with values captured for 7 positions.TEST

User Interface for Continuous Range (Dashboard 2)

Test

User interface for continuous range of values for changes in parameters. The values are Logged in the Spreadsheets.xlsx profile file.

Figure 7: User Interface for Continuous Range

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.000.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

x Position (m)Force (N)Ѳ(degrees)Length(m)Y (m)

Graphical Output

A graph of the input parameters showing a downward trend and highlights the

already outlined points, is given below:

Figure 8: Graphical Output for all variables

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.000.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00 x Position (m)

x Position (m)

Figure 9a: The course of xt for the system applied with pulse at Ft

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.000.00

5.00

10.00

15.00

20.00

25.00

Force (N)

Force (N)

Figure 9b The course of the changes in Force/Power for the system applied with initial Force Ft versus time

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.000.000.501.001.502.002.503.003.504.004.50

Length(m)

Length(m)

Figure 9c: The course of the Length L for the system applied with force Ft

0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.000.00

5.00

10.00

15.00

20.00

25.00

30.00

35.00

Ѳ(degrees)

Ѳ(degrees)

Figure 9d: The course of the sway angle O, for the system applied with initial force Ft

It is noted that the motion of the payload is affected by the applied force which it

will swing according to its path defined earlier. Also, the motion of the payload is

a pendulum like motion where the payload will swing from its initial position to a

final position. By definition, the initial position has a sway angle of zero but this

coincides with the time of application of initial pulse (max swing angle).

As shown, for a positive initial input force, the sway angle will be a negative value,

which swings anticlockwise by definition. Vice versa, when the applied force is

negative, the sway angle, which swings anticlockwise, will be positive in value, as

shown in Figure 4. From the perspective of the transformation of energy, the

initial position point final position point has the maximum potential energy.

Discussion of Results

CONCLUSION

Simulation results have shown that a dynamic feedback swing controller(fuzzy

logic controller)can be applied to control vibration and reduce the effect of

load sway to an insignificant minimum. Satisfactory vibration reduction of a

crane system has been achieved using the proposed fuzzy logic-based

technique.

However, in general, the second method is better than conventional one in the

sense that the error is smaller and more robust to cable length variation.