List of Major Projects Worked On 2016

-

Upload

michelle-mc-intyre -

Category

Documents

-

view

190 -

download

1

Transcript of List of Major Projects Worked On 2016

4/1

/201

6

1

LIST OF MAJOR PROJECTS WORKED ON BY MICHELLE MC INTYRE

YEAR PROJECT

2014 – 2016 AIBE (Asset Integrity Brownfield Execution) PROJECTS, BG T&T Limited/ SHELL Royal Dutch

AIBE Projects Quality Engineer (Sept 2014 – Mar 2016)

> Executed a wide quality scope to include both assurance and control across all tasks over the AIBE Projects to include ECMA, NCMA, Central Block, Beachfield and any additional onshore and offshore projects.

> In charge of the Quality Control Inspectors (Mechanical and Electrical) who produced assurance reports daily, from which weekly and monthly quality reports were issued highlighting any issues which may have occurred.

> Rolling out of Quality Management system within AIBE and ensuring all QA and QC inspectors are in compliance with BG’s quality standards.

> Auditing of all contractors and vendors ensuring that they are compliant to BG’s system. > Review and approve all quality documentation for projects including ITPs, Quality Plans, and

procedures for NDE as well as closing out of NCRs. Witnessed “hold points” as per ITP.

> Completes monthly KPI report on the departmental performance and accomplishments outlining the quality performance of AIBE group.

2014 Fabrication of Spools, Riser, Guard Frame & Clamps, Technip/BG (Onshore)

QA Inspector

> Chaired the initial inspection meeting outlining ITP and it’s witness/hold points. > Conducted quality assurance on fabrication works for the Starfish Development project onshore at

the Tofco’s Labidco facility. > Assured/audited all MTR’s, work procedures, calibration certificates, personnel certification and

fabrication works are all in conformance and being executed as per the approved specs and standards.

> Attend weekly progress meetings and report progress to Technips’s team comparing personnel availability against schedule.

2013-2014 Rehabilitation on South West Package A, Petrotrin/Trinmar Operations (Onshore & Offshore)

Quality Compliance Auditor

> Audited Contractors who executed rehabilitation works on the Platform structures and ensured their level of compliance is adequate to meet with the standards and requirements of Trinmar, reported all non-conformances on all procedures, equipment, personnel and processes including and not limited to welding and coating processes.

2013 STOW-TT Recertification, C.I.M.S.L.

HSEQ Coordinator

> Prepared CIMSL for Re-certification Audit for STOW-TT Certification. Ensured all previous GAPS were filled and ensured that the system is in full operation and ensured all employees were aware of the system and what their roles were in the system.

> Conducted a series of training sessions in line with training requirement as per the STOW standard.

4/1

/201

6

2

Year Project

2012 8CDU/CCR/ISOM/LPG T&I 2012, Petrotrin Point-a-Pierre

API 570/510/CWI Inspector

> Performed visual inspection activities on welding on repairs on piping and PVs and their associated piping as required at the Shops, onsite and offsite locations and generated reports for handover to day shift.

> Inspection activities included and not limited to Piping inspection, pressure vessel inspection as well as welding inspection on various components at various locations, ensuring that all work was done to specification.

2012 Staatsolie Maatschappij Suriname N.V. - Tout Lui Faut Refinery, Suriname

Asset Integrity Piping Inspector

> Conducted all the “close visual” inspections and retirement calculations on piping of all four (4) facilities of the company, directing and making recommendations to check the integrity of piping via UT and for replacement of insulation.

> Executed out damage assessment on the piping and made recommendations to remove coke blockage from lines to Heater unit.

2012 Trinmar Petrotrin Operations, Point Fortin Offshore

Asset Integrity Lead Inspector

> Co-ordinated and managed teams conducting Topside Integrity Assessments (Visual and UT) on the structural components – assessing both structural and coating integrity of Clusters and Riser Platforms in the East, North and Main fields (46 structures in total). Generated technical reports and anomaly sheets with findings and recommendations.

2012

Trinmar Petrotrin Operations, Point Fortin Offshore

Asset Integrity Lead Inspector

> Co-ordinated and managed teams conducting Topside Integrity Assessments on the structural components of main Platforms and Block stations in the East, North and Main fields (34 structures in total). Generated technical reports and anomaly sheets with findings and recommendations.

2011 UREA Turnaround, PCS Nitrogen

Certified Welding Inspector / API 510 Inspector

> Performed welding inspection on all structural and pipe fabrication and welding works during the TAR, ensuring that all welding was done according to code.

> Assisted with the external visual inspection of Pressure Vessels as well as any welding on associated piping..

2011 HSSE System Development & Implementation, Deo-Con Limited

HSSE Consultant

> Coordinated the generation and implementation of a Health, Safety, Security, Environment and Quality system for Deo-Con Limited, preparing them for STOW and OSH compliance.

4/1

/201

6

3

Year Project

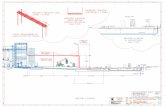

2010 - 2011 NGC NEO Tobago Gas Receiving & Metering Facility

QAQC Coordinator / Senior Auditor

> Generated Auditing Scheme for the operations of the reworks at the NEO Tobago Gas Receiving and Metering Facility.

> Created, implemented and maintained the Quality Auditing System and audited all NGC’s project processes, equipment and personnel performance, whilst keeping the Project Manager in sync with what is being done. Likewise for Contractors on this project such as Technip and API Pipeline.

> In charge of the QC Inspectors who were assigned to different packages during plant construction and installation.

> Created a system for assigning inspection frequencies to the plant and equipment.

2010-2011 NGC NEO Tobago - Phase II Deepwater [Moody International] – Bradero Shaw Pipeyard

CWI/Coating Inspector

> Headed quality control and assurance on the 36ӯ and 12ӯ CS piping, assuring that concrete was properly bonding to the pipes and that the specified reinforcement cap was being achieved. Additionally, all piping were visually inspected for damage and ensured that the piping is free from visible defects.

> Ensured that all works were carried out as per the Inspection and Test Plan (ITP) and that they were carried out in accordance with the relevant codes, client specifications and contract standards.

2010 HSSEQ System Development & Implementation, CIMSL

HSSEQ Coordinator

> Created, implemented and maintained (for a couple months), the Health, Safety, Security, Environment and Quality System for CIMS Ltd., preparing them for STOW and ISO compliance.

2010 Trinmar Petrotrin Operations, Point Fortin Offshore

Asset Integrity Inspector

> Co-ordinated and conducted Asset Integrity Assessment of the Structural Members and Components in the Clusters and Riser Platforms in all the fields of Trinmar (50 structures in total). Generated technical reports and anomaly sheets with findings and recommendations.

2009 Trinmar Petrotrin Operations, Point Fortin Offshore

Certified Welding Inspector

> Conducted audits/surveillances on the works completed by the Contractors, as well as welding inspection for the newly installed piping for the CP4 Platform.

> Co-ordinated the NDE for the welding on the process piping and associated structural works.

2009 Haward Technology Middle East, Dubai UAE

Applications Specialist/Tutor

> Conducted the WE340: API 571 Advanced Knowledge Damage Mechanisms Exam Preparation (5

day theory & practical) course in the City of Dubai. June 2009

4/1

/201

6

4

YEAR PROJECT

2009 Nitrogen 2000 Limited, Point Lisas

Applications Specialist/API 510 Inspector

> Managed and co-ordinated the Pressure Vessel (PV) Inspection project during the Plant Turnaround, ensuring that all inspections were carried out according to the specifications for the implementation of UltraPIPE®, which included coordination of the 3rd party inspectors for the PV UT thickness data collection activities

2009 Haward Technology Middle East, Dubai UAE

Applications Specialist/Tutor

> Conducted the RE555: API 580 Advanced Knowledge Risk Based Inspection Exam Preparation (5

day theory & practical) course at Corel Deira in the City of Dubai. January 2009

2008 – 2009 Nitrogen 2000 Limited, Point Lisas

Applications Specialist

> Implemented, audited and maintained the corrosion monitoring UltraPIPE® program and ensured that all codes and regulations governing the implementation of this program was adhered to.

> Selected team to carry out Risk Assessment on equipment to assign Risk to all statutory equipment to input into UltraPIPE® and spearheaded the data input activities.

2008 – 2009 Caribbean Nitrogen Company Limited, Point Lisas

Applications Specialist

> Implemented, audited and maintained the corrosion monitoring UltraPIPE® program and ensured that all codes and regulations governing the implementation of this program was adhered to.

> Selected team to carry out Risk Assessment on equipment to assign Risk to all statutory equipment to input into UltraPIPE® and spearheaded the data input activities.

2008 TOFCO, La Brea

Welding Inspector

> Carried out Quality Assurance on 3 off-shore platform fabrication projects at Weld Fab’s facility in Claxton Bay. Clients and their platform names were – BG’s Pointsettia, BP’s Savonette and EOG’s Toucan Platforms.

> Ensured that the requirements for all welds, welder and welding activities are correctly specified and carried out in accordance with the relevant codes, client specifications and contract standards.

2007 - 2008 PCS Nitrogen Trinidad Limited, Point Lisas

Applications Specialist

> Assisted with the implementation of Lloyds Capstone RBMI software, assisted with assignment of Risk to certain equipment.

> Generated reports using the RBI matrix to assess inspection data to determine inspection frequencies.

2007 West Indies Oil Company, Antigua

Applications Specialist/ Project Manager

> Managed and co-ordinated Underwater Piping Inspections, including inspections on the piles of the Sea Island Jetty using advanced NDE method INCOTEST.

> Underground Inspection of 5 km of Subsea Piping (concrete coated) using Guided Wave Ultrasonic Testing and INCOTEST (Offshore) was also executed using divers and ROV.

4/1

/201

6

5

YEAR PROJECT

2004 - 2006 Caridoc/CDESL, Chaguaramas

Quality Control / Quality Assurance Manager

> Managed and co-ordinated all projects from destructing of piping to complete recoating of the entire structure on Transocean semi-submersible rig “Sovereign Explorer”.

> Managed all the QA/QC personnel on the project as well as labourers.

2004 - 2006 Caridoc/CDESL, Chaguaramas

Quality Control / Quality Assurance Manager

> Managed and co-ordinated inspections (Visual, NDE) on all major fabrication jobs - such as all major and minor fabrication works for BG Dolphin Deep and BG NCMA Phase 3-A Development Project, as well as all major and minor fabrication on NGC B.U.D. Pipeline Project.

2004 - 2006 Stolt Offshore Services Inc., Trinidad

Quality Control / Quality Assurance Manager/Inspector

> Managed and co-ordinated all QA/QC duties on the ECMA Dolphin Deep Development Project and NCMA Phase 3-A Projects at CDESL and many more miscellaneous Fabrication Projects from S.O. Inc.

2004 - 2006 Caridoc/CDESL, Chaguaramas

Quality Control / Quality Assurance Manager

> Implemented and managed the Quality Management System at CDESL that was designed to conform to the ISO 9001:2000 system.

2004 - 2006 Stolt Offshore Services Inc., Trinidad

Quality Control / Quality Assurance Welding/Coating Inspector

> Conducted QA/QC duties on the NGC B.U.D. Pipeline Project at Superior Machine Shop. Co-ordinated all NDT inspections related to this job.

2004

Mount Hope Medical Complex, Mt. Hope

API 570 Inspector/Coating Inspector

> Managed and co-ordinated and performed the QA inspections and integrity assessment of the Chill Water Underground Supply and Return Headers supplying the Complex.

> Generated all the isometric drawings to accompany technical assessment report.

2004 Trinmar Ltd., Point Fortin Offshore

API 570 Inspector

> Carried out UT thickness survey on BJ Barge T100. Produced technical report to include retirement calculations and assessment of the system as well as recommendations.

> Input data into UltraPIPE® to generate reports.

2004 PCS Nitrogen Ammonia, Plant Point Lisas

API 570/API 510/Coating Inspector

> Conducted external visual assessment on all pressure vessels and heat exchangers on both Urea and 03 Plant sites and produced the technical reports with assessments and recommendations.

4/1

/201

6

6

YEAR PROJECT

2003 - 2004 Hydro Agri Trinidad Ltd., Point Lisas

API 570 Inspector

> Spearheaded the systematic piping inspection project for Braun Plant, liaising with 3rd party inspection companies to perform all QA/QC and NDE activities.

2002 - 2003 Trinmar Ltd., Point Fortin Onshore & Offshore

QA/QC UT Thickness Technician/AutoCAD Draughtsman / Data Logger Personnel

> Implemented and operated with CAIRS (Computer-Aided Inspection Reporting System). > Acquiring thickness readings and inputting them into the CAIRS System. > Producing all Isometric drawings for input into CAIRS and for use out in the field to capture data.

2003 Trinmar Ltd., Point Fortin Offshore

API 570 Inspector

> Carried out Integrity Inspection of Bulk Lines on Platform 5 producing technical report to include findings and recommendations.

> Carried out and supervised Relief Valve Audit on all off-shore structures, and on-land areas that have Relief Valves.

2003 Trinmar Ltd., Point Fortin Onshore

API 570 Inspector

> Performed QA/QC on all welding of the modification works to piping at Tank Farm, on GFU and on CPI Process Piping.

2003 Well Services, Otaheite

QA/QC Inspector

> Supervised the performance of welder’s tests.

2003 IAL ESL, Guapo

QA/QC Inspector

> Lead the qualification of a Welding Procedure and performed welders tests.

2002 Hydro Agri Trinidad Ltd., Point Lisas

QA/QC Inspector

> Performed QC duties on the Tringen II Turnaround to include duties such as Film Interpretation, visual inspections, dimensional checks and Penetrant testing.

2002

BP T&T LLC., Galeota Point Offshore

API 570 Inspector

> Supervised the collection of thickness data on all Flow lines on Samaan ‘A’ Offshore Platform. Using the acquired data, retirement calculations were done and recommendations were made in the technical assessment report.

2001 - 2003 British Gas Trinidad & Tobgo Ltd., Chaguaramas

UltraPIPE® Operator

> Kept track of UT thickness Surveys on Flow lines continuously and logged information into UltraPIPE® for retirement date calculations.

4/1

/201

6

7

YEAR PROJECT

2000 - 2001 Trinidad Inspection Services Ltd., Marabella

Internal Auditor Assistant

> Accompanied external Lead Auditor whilst conducting an Internal Audit at TISL according to the ISO 9000 system.

2000 - 2001 PCS Nitrogen (Canadian). Ammonia Plant Point Lisas

QA/QC UT Thickness Technician / AutoCAD Draughtsperson / UltraPIPE® Operator

> Implemented and operated with UltraPIPE® to carry out Corrosion Monitoring on 01, 02, 03, 04, 050 and off-site plants.

1997 - 1999 Carnival Committee of Grand Stand at Queens Park Savannah. Port-of-Spain

QA/QC MT Inspector

> Performed visual assessment on the structure known as ‘The Grand Stand’ at Port-of-Spain. After which, suspect areas were cleaned and the integrity tested using Magnetic Particle Inspection and Dye Penetrant Testing. Any anomalies found, recommendations were made for change-out.

1997 - 1999 NP House. Sea Lots Port-of-Spain

Painting Inspector

> Performed Coating Inspection on blasting and coating activities on the Horton sphere during the refurbishment project.

1997 - 1999 NGC Gas Line. Point Lisas to Biche. Operator – Spie Capag S.A. - France

RT Technician

> Performed Radiographic Testing on the welding completed by API Pipeline on the 36” Natural Gas carbon steel piping.

1997 - 1999 Texaco, St. Vincent

RT Crew Team Leader

> Lead a group of 3 which performed RT on various schedules of piping during a refurbishment project at the Texaco facility. Film Interpretation was also executed for the reports.

1997 - 1999 Atlantic LNG (Bechtel-Train I), Point Fortin

QA/QC NDE Inspector

> Performed all NDT and QA/QC for plant piping and structural steel construction – including MT, PT, RT and Film Interpretation.