Liquifil Ds

-

Upload

ahmet-metin -

Category

Documents

-

view

220 -

download

0

Transcript of Liquifil Ds

8/9/2019 Liquifil Ds

http://slidepdf.com/reader/full/liquifil-ds 1/2w w w . b r e w e r s c i e n c e . c o m

Where innovation takes flight! SM

Page

Brewer Science has engineered, developed, and qualified an extremelyadaptable automatic filling machine ideal for bottling electronics-grade

high-purity materials in a clean room environment.

Brewer Science ®

LiquiFil ™Automated Bottle-Filling System

Benefits

The Brewer Science® LiquiFil™ system has a compact, highlyflexible design that provides automated bottling and capping formedium-volume and pilot-scale chemical manufacturing needs.

This automated bottle-filling tool features a flexible configurationwith a small footprint and accommodates a variety of contain-ers including NOWPak® bottles, Aicello glass or plastic bottles,and Kodama bottles. The LiquiFil™ system enables acceleratedproduct development cycles and low- to medium-volumechemical manufacturing for semiconductor, life sciences, andadhesive industries. It is intended for use in a class 100clean room.

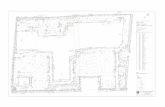

Bottler front view` Container type flexibility including NOWPak®, Aicello,

PurePak, Kodama, and Nalgene® bottles

` Compact footprint with self-contained structure

` U-shaped continuous process flow

` PC controller and user interface

` High throughput (30 bottles per hour)

` High performance precision, repeatability, and reliability

` Better than class 1 cleanliness at point of fill and class 10 in

other areas per Federal Standard 209; class 4 at point of fill

per ISO 14664-1 standards

Bottler rear view

8/9/2019 Liquifil Ds

http://slidepdf.com/reader/full/liquifil-ds 2/2w w w . b r e w e r s c i e n c e . c o m

Page 2Brewer Science ® LiquiFil™ Automated Bottle-Filling System

Utility Requirements

` Electrical: 100-240 VAC, single phase;

50/60 Hz, 360 W (600 W at user-specified voltage for fan

filter unit)

` Nitrogen or CDA: 100 psi N (20 cfm), 3/8” push to connect(PTC) or 1/4” NPT (female thread)

Hazard Rating

` Point of fill: NEC Class 1, Division 1

` Remainder of machine: NEC Class 1, Division 2

BottleSize

BottleType

FillerDesignSpeed(bph)

FillVolume

FillWeight

FillAccuracy(% of FillWeight)

BottleHeight

w/o Cap(in)

BottleDiameter

(in)

4 L NOWPak®

Ultrapure30 4.0 L 3.0 -

4.2 kg0.1% 11 1.8” 6 15/16”

4 L Aicello 30 4.0 L 3.0 -4.2 kg

0.1% 12 1.4” 6 5/8”

4 L Aicello w/Glass Neck

Threads

30 4.0 L 3.0 -4.2 kg

0.1% 12 3/16” 6 5/8”

4 L AicelloGlassBottles

30 4.0 L 3.0 -4.2 kg

4 L Kodama 30 4.0 L 3.0 -4.2 kg

0.1% 12 3/8” 6 5/8”

10 L NOWPak®

Ultrapure

12 10.0 L 7.5 -

10.5 kg

0.1% 13 1/2” 9”

©2013 Brewer Science Inc. All statements, technical information and recommendations contained herein are based on tests we believe to be accurate, but the accuracy or completeness t hereof is not guaranteed and t he following is made in lieu of warranty expressed or implied.Neither the seller nor manufacturer shall be liable for any injury, loss or damage, direct or consequential, arising from the use or inability to use the product. Before using, user shall determine the suitability of the product for his intended use, and user assumes all risk and liabilitywhatsoever in connection therewith. No statement or recommendation not contained herein shall have any force or effect unless in an agreement signed by officers of the seller and manufacturer.

NOWPak® is a registered trademark of ATMI, Inc.

Nalgene® is a registered trademark of Thermo Fisher Scientific F.6.6.7089.A Effective Date: 6/12/2013

Bottle Specifications and Service Conditions

Specifications

Dimensions

` Bott ling module: 48” W × 132” L × 83” H

` Exhaust: 6” OD duct, 500 cfm (dependent upon fume removal

requirements)

Other Features ` Alarm system triggered by detection of leaks and bottle

positioning

` Manual operation of each automated sequence through

operator interface terminal

` Real-time transfer of data via Ethernet connection

` Process data logging