Lintel Brochure 1

-

Upload

chris-evans -

Category

Documents

-

view

56 -

download

12

description

Transcript of Lintel Brochure 1

CI/SfB (31.9) Hh2 (M2)

JULY 2012

The only complete range of lintels hot-dip galvanized after manufactureBirtley Building Products Ltd

Mary Avenue, Birtley, County Durham DH3 1JF.

Tel: 0191 410 6631 Fax: 0191 410 0650

Email: [email protected] Internet: www.birtley-building.co.uk

A member of the Hill & Smith Holdings Plc Group. Registered No:00602575 England.

Registered Office: Springvale Business & Industrial Park, Bilston, Wolverhampton WV14 0QL

32

Contents

AT 50 25

AT 70 25

AT 90 25

CB 50 14

CB 70 15

CB 90 16

CB 110 17

CB 130 18

CB 150 19

CB 50/130 20

CB 70/130 21

CB 90/130 22

CB 125/90/100 24

CB 50 HD 14

CB 70 HD 15

CB 90 HD 16

CB EV 50 24

CB EV 90 24

DC 200 27

DC 200 HDX 27

EV 100 28

HS 50 14

HS 70 15

HS 90 16

HS 110 17

HS 130 18

HS 150 19

HS 50/130 20

HS 70/130 21

HS 90/130 22

HS 90/200 23

HS 125/90/100 24

Lintel PageReference No

HDX 50 14

HDX 70 15

HDX 90 16

HDX 110 17

HDX 130 18

HDX 150 19

HDX 50/130 20

HDX 70/130 21

HDX 90/130 22

INT 100 30

INT 100 HD 30

LA 28

MBL 28

OB 190 27

SB 100 26

SB 100 HD 26

SB 100 HDX 26

SB 140 26

SB 140 HD 26

SB 140 HDX 26

SBL 200 27

SEMICIRCULAR

ARCHES 30

SX 90 23

TF 50 29

TF 50 HD 29

XHD 90 23

ACCESSORIES:

ARCHFORM 31

SOFFIT COVER 31

RENDER KEY 31

BAY6 32-33

Lintel PageReference No

Commitment to Quality:Supergalv Performance Features 4 - 6

Constructive Innovation:Product Specification 7

Custom-built Versatility:Purpose Made Lintels 8 - 9Technical Advisory Service 10

Firm Foundations:Design and Building Practice 11 - 12

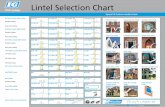

Supergalv:The Complete Range of Lintels 13 - 30

Accessories:Archform and Soffit Cover 31

Bay 6:Corner Window Support System 32 - 33

Custom Specification:Fax Back Specification Form 34 - 35

5

Commitment to Quality

With over 40 years experience in the specification, design and manufacture of steel lintels, Birtley Building Products stands at the forefront of technological change and innovation.

Investment in manufacturing technology continues to underpinBirtley’s commitment to the UK lintel market, and to ensure that theSupergalv range maintains its leading position when measured by quality, performance, durability, design and cost-effectiveness.

At the heart of Birtley’s lintel production today is a fully automated,computer-controlled manufacturing line that processes the product from raw coil to finished item in a single sequence. This maintains a consistent, precision, quality lintel while achieving extraordinary levels of output. The plant was custom designed to Birtley’s specification and manufactured by Europe’s leading suppliers of metal-formingmachinery, and this multi-million pound investment underlines the long-term commitment of Birtley to the lintel industry.

Beyond the automated lintel line lies the state-of-the-art technologybuilt in to the Company’s galvanizing facility, the UK’s first fully-automated, hot-dip galvanizing plant. Commissioned at a cost of over£2.5 million, it incorporates one of the UK’s largest galvanizing baths.This computer-controlled facility utilises proven European technology to achieve a level and consistency of quality never before seen in thiscountry, while substantially increasing Birtley’s capacity and lowering manufacturing costs.

We have a fully-computerised lintel scheduling function where theexpertise of our Technical Advisory Service provides support and advice in the specification of lintels, including the provision of structuralcalculations for building regulation submissions, and the design of special lintels or steelwork to suit particular projects or unusual forms of construction.

All this is supported by extensive stocks held at Birtley of all themost popular lintel types, offering ready availability at all times. Flexible production systems ensure a rapid response to all other lintelrequirements. Most important of all, though, is the close partnershipwhich exists between Birtley and its nationwide network of builders’ merchants and distributors, whose commitment to stocks of Supergalvlintels allows them to provide an excellent level of service, whenever and wherever required.

4

Performance Features

Corrosion Protection

All Supergalv lintels are protected by hot-dip galvanizing the complete lintel after fabrication. This process out performs allother protection systems by:

Fully protecting every surface, cut edge and weld with ametallurgically bonded zinc coating, where other systemsactually remove zinc during fabrication and do not provide full protection to all surfaces.

Creating a build-up of zinc coating at the most vulnerable points (edges etc.) which are more susceptible to damage on site and are the least protected in other systems.

Depositing a minimum zinc coating thickness of 65µmin a metallurgical bond over the base steel.

Optional ‘Ultragalv 2000’ (U2k) corrosion protection system.This achieves a coating thickness of 150µm by shotblastingthe steel prior to galvanising. This is up to 7 times more Zinc corrosion protection than other lintels, and the life of a Zinccoating is directly proportional to its thickness.

Insulation

All external cavity wall lintels are insulated with expandedpolystyrene blocks to BS EN 13163. The insulation is CFC, HCFC and HFA free and these agents are not used at any stagein manufacture. All lintels comply with Parts L1 and L2 of theBuilding Regulations approved documents.

The insulation has an ozone depletion potential of zero, andbeing blown with pentane achieves a BREEAM credit for having a global warming potential of zero.

The underside of the insulation is ridged to act as an efficientplaster key and the absence of a baseplate removes any possibility of a coldbridge occurring at the window head.

Structural Performance

The structural performance of Supergalv lintels is supportedby systematic and extensive in-house testing and confirmed by independent testing. Lintels have been tested for structural performance, flexural strength and shear load resistance by the University of Wales School of Engineering and the University of Teesside Heavy Structures Test facility. The safe working loadsshown are derived from calculations on the physical propertiessupported by tests, and refer to uniformly distributed loadsapplied in the ratio of:‘CB’ range 1:1 to 1:3‘CB HD’ range 1:1 to 1:5‘HS’ ‘AT’ range 1:5 to 1:19‘HDX’ range 1:5 to 1:19‘SX’ range 1:5 to 1.19‘XHD’ range 1:5 to 1:19

For loads ratios beyond this range, or for any unusual loadingconditions, please contact our Technical Department for advice.

6

Relative Performance of Corrosion ProtectionSystems as Applied to Steel Lintels

The current British/European standard (BS EN 845-2:2003) allows various grades of corrosion protection, with the responsibility for compliance resting with thespecifier, who must take into account exposure categories and local climatic conditions. Don’t be caught out, specify the correct system for the job.

Life to First Maintenance Chart

Based on category 3 exposure (moderate to severe), as defined by ‘Galvanizers Association’ (1.5µm per annum Zinc atmospheric corrosion rate).

Zinc Corrosion Rates

Category 1 : 0.5µm per annum Category 2 : 1.0µm per annum Category 3 : 1.5µm per annum Category 4 : 2.0µm per annum Category 5 : 2.5µm per annum

For other information and localised conditions, see the ‘Architects and Engineers Guide to Hot-DipGalvanizing’, published by the Galvanizers Association,or check the web site www.galvanizing.org.uk

Birtley ‘Ultragalv 2000’ (optional) 150µm

Birtley ‘Supergalv’ (standard) 65µm

Other manufacturers 42µm

110

100

90

80

70

60

50

40

30

20

10

0

Regulatory Authority

Supergalv lintels are designed and manufactured taking into account the requirements of:

- BSI

- NHBC

- HAPM (Housing Association Property Mutual)

- Zurich Municipal

- BRE

All lintels conform fully to EN 845-2:2003.

The Supergalv CB Range - feature-packeddesign for the 21st Century.

The CB range is designed for ease of installation and to exceed the performance requirements of all existing standards. In applying state of the art technologyto improve design standards, we have also recognised our duty to the environment by selecting an insulation system which is 100% CFC-free, HCFC free and has both an ozone depletion of zero, and a global warmingpotential of zero.

Just compare the features of the CB:

No need to cut blocks.

Thermal values of wall construction maintained through lintel.

Easily installed, locating entirely within cavity.

Simple plastering and curtain-batten fixing etc. to blockwork.

Design provides firm location for masonry to maintain dimensions and integrity of cavity.

Fully insulated lintel - no air gaps, no interruptions,pure insulation.

High-grade, flame retardant EPS insulation.

Risk of cold bridging eliminated by thermal barrierof insulating foam and absence of steel bridgebetween outer and inner skin.

Integral plaster-key in base flange eliminates need for messy and dangerous mesh.

Base of insulating material provides additional plaster-key.

Single thickness of steel simplifies locating withinbrickwork joint.

The CB is designed to suit standard duty applications up to 3900mm long, with a Medium Dutyrange to 3000mm for loads up to 36kN.

YEARS

Material

Supergalv lintels are manufactured from steel to BSEN 10025 Fe 430 A, having a minimum yield stress of 300 N/mm2.

Corrosion protection is provided by zinc to BS EN 1179: 2003

Although the Supergalv and Ultragalv processes offer the highest level of corrosion protection available, there may beinstances where the use of stainless steel may be more appropriate, e.g. certain industrial applications, or marine environments. To satisfy these requirements we can offer our full range of lintels fabricated from stainless steel to BS EN 10088-2 (304 S15). Other grades may also be available, please contact Technical Department for advice.

Where appropriate external wall lintels are insulated withCFC-free expanded polystyrene manufactured under BS EN ISO 9001 and BS 13163.

Health & Safety

The Supergalv range is considered non-hazardous to healthunder normal conditions of use, as laid down by the COSHH regulations 1994. Please refer to page 11 for advice on the correct storage, handling and installation of lintels.

Manufacture

Supergalv lintels are produced from decoiled slit steel, cut to length and cold formed by press-braking. Where appropriate,seam welding to BS6265 1982 or spot welding to BS 1140 1980completes fabrication.

All lintels are then hot-dip galvanized following an extensivechemical pre-treatment, by immersion in our own galvanizingbath operating at a temperature of 450˚C. Lintels are thenallowed to air cool to avoid any risk of distortion.

Fire Resistance

Supergalv lintels have been tested and approved to BS476 :Part 20 : 1987 for determination of the fire resistance of load-bearing elements of construction. Test reports are available onrequest.

Quality Assurance

Birtley Building Products is a British Standards Institute (BSI)registered firm, with a quality system conforming to BS EN ISO9001 : 2008, covering procedures for lintel manufacture and galvanizing. This commitment to quality is reinforced by theaward of the BSI Kitemark to lintels within the range. AllSupergalv lintels fully satisfy the requirements of EN 845-2:2003.

Constructive Innovation

7

9

Custom Options

As well as an infinite range of special lintel designs tosuit any architectural design or loading requirement,Supergalv lintels are available in all cavity wall stylesadapted to suit special circumstances. Please contact our Technical Advisory service for details and informationon price and availability. Examples of these special servicelintels are:

CP Where the underside of the lintel is completelyexposed, e.g. porches, driveways, etc., a closer plate can be welded prior to galvanizing to provide a neat, aesthetically pleasing finish to the soffit of the lintel.

To specify, add ‘CP’ to the end of the lintel reference, e.g. CB50 CP. (Lintel will be supplied uninsulated, unlessspecified otherwise).

NM Where the inner leaf of a cavity wall is fair-facedand the inner flange of the lintel is not plastered, the plaster key on this flange can be omitted.

To specify, add ‘NM’ to the end of the lintel reference, e.g. CB50 NM.

ND To minimise the mortar bed thickness at the end bearings, e.g. when using stone heads and surrounds, the weather drip on the front flange of the lintel can beomitted.

To specify, add ‘ND’ to the end of the lintel reference, e.g. CB50 ND.

U2K ‘Ultragalv 2000’ maximum corrosion protection with 150µm Zinc coating. To specify add ‘U2K’ to the end of the lintel reference, e.g. CB50 U2K.

98

Purpose Made Lintels

When the building design demands something out of the ordinary, Supergalv lintels can be custom-designed and manufactured to suit a wide variety of opening shapes, dimensions and loadings. Typical special applications include:

Arch lintels, e.g. Natural Arch, Gothic Arch, Radius Arch

Corner lintels Curved in Plan lintels

Apex lintels Cant brick lintels

Extra heavy duty lintels Roller shutter lintels

Extra long span lintels (to 9.5m)

Purpose-made lintels are designed and manufactured inclose liaison with the specifier and contractor, including the provision of full structural calculations where required, ensuring that all requirements are satisfied and that installation is straightforward.

Manufactured within Birtley utilising CAD and CNC fabrication facilities, all purpose-made lintels comply fully withEN 845-2:2003, are manufactured within the QA systems of BS EN 9001 and, very importantly, are finished to the same standard of corrosion protection as the standard range ofSupergalv lintels - i.e. 65µmzinc coating to all surfaces, appliedby hot-dip galvanizing after fabrication. Optional ‘Ultragalv 2000’offers minimum of 150µm of Zinc projection. Purpose made lintels are also available in stainless steel to BS EN 10088-2.

Our technical department can also offer guidelines for installationof special lintels, as some designs, such as curved on plan and lengths over 4.8m which may need to be propped duringinstallation.

Patents

Supergalv lintels and Birtley Building Products are protected bythe following Patents and Trade Marks:

2 019 250 2 063 331 2 063 953 2 083 093

2 103 680 2 185 764 2 271 367 7 936 481

2001478 120787 Eire

Custom-built Versatility

111110

Technical Advisory Service

For details of which lintel rangeshave been assessed see website

Specifications

BS 5977: Part 1: 1981 (1986) AMD. 4796 Method forAssessment of Load.

EN 845-2:2003 Specification for Prefabricated Lintels.

BS 476: Parts 20 - 23 Test methods and criteria for the fire resistance of elements of building construction.

BS EN ISO 1461:1999 Specification for Hot DipGalvanized Coatings on Iron and Steel Articles.

BS7668, BS EN 10029, BS EN 10025 Parts 1, 3, 4 and 5,and BS EN 10210 Part 1 Weldable Structural Steels.

BS EN ISO 14713-2:2009 Protective Coating of Iron andSteel Structures Against Corrosion.

PD 6697:2010 Recommendations for the design of masonry structures to BS EN 1996-1-1 and BS EN 1996-2.

Building Regulations

REGULATION 4: Requirements relating to building work.

REGULATION 6: Requirements relating to material change of use.

REGULATION 7: Materials and workmanship.

Schedule 1 RequirementsPart A: StructurePart B: FirePart C: Resistance to MoisturePart L: Conservation of Fuel and Power

Approved DocumentsA1: LoadingB3: Internal Fire Spread (Structure)B4: External Fire SpreadC4: Resistance to Weather and Ground MoistureL2: Resistance to the Passage of Heat (Dwellings)L3: Resistance to the Passage of Heat (Buildings

other than Dwellings)

Materials and Workmanship to Support Regulation 7.

Design & Building Practice for Steel Lintels

NHBC Standards

Part 6: SUPERSTRUCTURE6.1 External Masonry Walls

Clause D6 (b) DesignD9 DesignM8 MaterialsS6 Sitework

6.2 External Timber Framed Walls and Wall PanelsClause 8.2 (b)

6.3 Internal WallsClause D5 Design

S3 (F) Sitework

Design Considerations

All Supergalv Lintels are designed to satisfy the followingrequirements:

Loadings

• The proportion of Live Load to Total Load carried by the Lintel must not exceed 50%. A safety factor of 1.6 is allowed in all published Safe Loads.

• Point Loads are permissible in certain circumstances.

• A lintel shall have a maximum Horizontal or VerticalDeflection of 1/200 x the Effective Span* when subjected to the Safe Working Load.*(Effective Span = Distance between the Centres ofBearings)

Dimensional DeviationsLength +/- 15mmWidth & Height +/- 5mmStraightness or bow 0.5% of the length,

up to a maximum of 10mm

Bearings

• The end bearings for lintels should normally be not lessthan 100mm. In no case should the lintel tray extend lessthan 50mm beyond the cavity side of the solid masonryreturn to drain clear of a vertical dpc.

• The width of a lintel bearing on an inner leaf should beequal to at least 80% of the thickness of that leaf.

• The overhang of masonry supported by lintel should notexceed 25mm.

• The cavity widths shown in our tables are maximum dimensions and must not be exceeded.

Birtley Building Products provides comprehensive technical support to designers, specifiers, builders and merchants covering all aspects of the design, specification and installation of Supergalv lintels. The service includes :

Computer-based preparation of Lintel Schedules from drawingssupplied (preferably plans, elevations and sections including floor joist layout and loadings, concrete floor directional spans and loading, and roof layout as appropriate).

Provision of structural calculations for Building Regulation approvalby individual calculation for specific locations.

Advice on the use of lintels for unusual situations, e.g. reducedend bearings, point loadings, use of lintels in refurbishment projects, etc.

Detailed drawings to illustrate the use of lintels in particular situations.

1312

Damp Proof Systems

• Good building practice encourages the use of a separate damp proof course to a lintel in all external wall-situations, and Birtley Building Products endorsesthis approach in all circumstances.

• Regardless of lintel profile or corrosion protection system,BRE and NHBC require the application of a separate dpc in all buildings in Scotland, Northern Ireland and all coastal regions and areas of Severe Exposure (asdefined in BRE Digest 127) in England.

• The cavity tray should have a vertical height of at least140mm with a minimum rise of 100mm from the front of the cavity. The length of the tray should be such that it extends 150mm beyond the inner face of the cavity closer. The cavity tray should extend beyond the front toe of the lintel to protect door and window heads, with the upstand returned into the inner leaf masonry.

• Stop ends should be provided by turning up the ends of the tray, or by the use of separate self-adhesive units. A minimum of two bedweeps should be used at 450mm centres.

Fire Resistance

• The BRE Fire Research Station ‘Guidelines for theConstruction of Fire Resisting Structural Elements’ givesdesign recommendations applicable to lintels.

• Independent test reports in accordance with BS 476 areavailable from Supergalv Lintels.

Thermal Insulation

• Normally the thermal conductivity of an exposed wall islimited to a maximum U Value of 0.35 W/m2K indwellings and other residential buildings, industrial orstorage buildings, where the prescribed maximum areafor glazing and minimum standards of insulation for solid areas are adhered to.

• To avoid cold bridging over the wall face area behind thelintel, the masonry or insulation system of the designedvalue should be maintained to the head level of the lintel.

• Lintels of Open Back design achieve the same U value as the wall by being filled with the same blockwork andinsulation material. This allows an increase in singleglazed window area. Lintels of Box design can be supplied with expanded polystyrene blocks for additional insulation.

HAPM Rating

• The HAPM Component Life Manual assesses the life to first maintenance for Supergalv lintels as 45 yearswhen used in accordance with the manufacturer’sinstructions. This exceeds the maximum 35+ year ratingof Class A standard.

Material Compatibility

• Mortar must comply with the requirements of BS 5628(Part 3: 1985).

• Timber preservatives used for the protection of joinerycomponents (e.g. windows) are unlikely to affect galvanized steel except that preservatives based on copper-chrome-arsenic (CCA) and inorganic flame retardants may attack galvanized steel (ref. BRE IS 11/77).

• If possible, provision of all necessary fixing holes shouldbe arranged so as to be carried out at the time of fabrication and before galvanizing.

Installation Advice

• Do not use damaged lintels, inspect at delivery stage.

• Do not bear lintels onto cut blocks, always use fullmasonry units or padstones.

• Do not dry bed lintels on bearings. Mortar beds shouldbe used to prevent lintel settling under load.

• Do use an additional DPC.

• Do use stop ends and bedweeps (at 450mm centres) to all lintels in fairfaced masonry walls.

• Do ensure that open back lintels are filled with properlybonded masonry before work proceeds over.

• Do ensure that both leaves of the cavity wall are raisedequally to avoid eccentric loading of lintel flanges.

• Do position concrete floor units carefully and gently toavoid impact damage and shock loads which may temporarily over stress the lintel with resultant excessivedeflection or distortion.

• Do make sure that the lintel toe projects beyond the window head to prevent water ingress.

• Do ensure that the maximum cavity width is not exceeded, and that masonry does not overhang by more than 25mm.

Supergalv Lintels cannot be held responsible for any errors or omissions

in this listing, nor for any consequences which may arise directly or

indirectly from its use. As part of our policy of continuous product

improvement we reserve the right to change specifications without notice.

Design & Building Practice for Steel Lintels

THE ONLY COMPLETE

RANGE OF

L I N T E L SHOT DIP GALVANIZED

AFTER MANUFACTURE

CB 70 HD

MEDIUM DUTY

750 - 1500 36 148 10.1

1650 - 2100 36 200 14.2

2250 - 3000 36 208 14.6

Not recommended for the support of P.C.Concrete floors

CB 70

STANDARD DUTY

750 - 1200 15 106 5.8

1350 - 1650 15 106 7.3

1800 - 2100 20 148 8.1

2250 - 2400 22 148 10.1

2550 - 3000 26 185 11.6

3300 - 3900 26 200 14.2

Not recommended for the support of P.C.Concrete floors

HS 70

HEAVY DUTY

750 - 1200 70 225 19.4

1350 - 1800 70 225 19.4

1950 - 2100 60 225 19.4

2250 - 2700 60 225 19.4

2850 - 3000 55 225 19.4

3300 - 3900 50 2225 19.4

4200 - 4500 40 225 19.4

4800 35 225 19.4

5100 25 225 19.4

HDX 70

EXTRA HEAVY DUTY

750 - 2100 100 225 31.1

2250 - 3300 80 225 31.1

3600 - 4200 70 225 31.1

4500 - 4800 60 225 31.1

5100 45 225 31.1

HDX 50

EXTRA HEAVY DUTY

750 - 2100 100 225 31.1

2250 - 3300 80 225 31.1

3600 - 4200 70 225 31.1

4500 - 4800 60 225 31.1

5100 45 225 31.1

HS 50

HEAVY DUTY

750 - 1200 70 225 19.4

1350 - 1800 70 225 19.4

1950 - 2100 60 225 19.4

2250 - 2700 60 225 19.4

2850 - 3000 55 225 19.4

3300 - 3900 50 225 19.4

4200 - 4500 40 225 19.4

4800 35 225 19.4

5100 25 225 19.4

CB 50 HD

MEDIUM DUTY

750 - 1500 36 153 10.1

1650 - 2100 36 205 14.2

2250 - 3000 36 205 14.5

Not recommended for the support of P.C.Concrete floors

CB 50

STANDARD DUTY

750 - 1200 15 112 5.8

1350 - 1650 15 112 7.3

1800 - 2100 20 143 8.1

2250 - 2400 22 148 9.9

2550 - 2700 26 175 11.0

2850 - 3000 26 190 11.6

3300 - 3900 26 205 14.2

Not recommended for the support of P.C.Concrete floors

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

250 to 270

100

50 to 70

100 to 115

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

Length Range Max UDL Depth Weightmm kn mm kg/m

15

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

270 to 290

100

70 to 90

100 to 115

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

14

Denotes Plaster Key Denotes Plaster Key

HS 110

HEAVY DUTY

750 - 2100 60 225 21.7

2250 - 2700 60 225 21.7

2850 - 3000 55 225 21.7

3300 - 3900 50 225 21.7

4200 - 4500 40 225 21.7

4800 35 225 21.7

5100 35 225 21.7

HDX 110

EXTRA HEAVY DUTY

750 - 2100 100 225 31.1

2250 - 3300 80 225 31.1

3600 - 4200 70 225 31.1

4500 - 4800 60 225 31.1

5100 45 225 31.1

Versions also available for 125 to 140 inner leaf

CB 110

STANDARD DUTY

750 - 1500 20 138 8.6

1650 - 2100 20 143 10.7

2250 - 2700 25 173 11.8

2850 - 3300 30 195 14.9

Not recommended for the support of P.C.Concrete floors

HDX 90

EXTRA HEAVY DUTY

750 - 2100 100 225 31.1

2250 - 3300 80 225 31.1

3600 - 4200 70 225 31.1

4500 - 4800 60 225 31.1

5100 45 225 31.1

HS 90

HEAVY DUTY

750 - 1200 70 225 19.4

1350 - 1800 70 225 19.4

1950 - 2100 60 225 19.4

2250 - 2700 60 225 19.4

2850 - 3000 55 225 19.4

3300 - 3900 50 225 19.4

4200 - 4500 40 225 19.4

4800 35 225 19.4

5100 25 225 19.4

CB 90 HD

MEDIUM DUTY

750 - 1500 36 138 10.5

1650 - 2100 36 195 13.9

2250 - 3000 36 202 14.2

Not recommended for the support of P.C.Concrete floors

CB 90

STANDARD DUTY

750 - 1200 15 106 5.9

1350 - 1650 15 106 7.4

1800 - 2100 20 138 8.4

2250 - 2400 22 151 10.4

2550 - 3000 26 187 12.0

3300 - 3900 26 202 14.2

Not recommended for the support of P.C.Concrete floors

17

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

310 to 330

100

110 to 130

100 to 115

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

16

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

290 to 310

100

90 to 110

100 to 115

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

Denotes Plaster Key Denotes Plaster Key

HDX 130

EXTRA HEAVY DUTY

750 - 2100 100 225 34.7

2250 - 3300 80 225 34.7

3600 - 4200 70 225 34.7

4500 - 4800 60 225 34.7

5100 45 225 34.7

Versions also available for 125 to 140 inner leaf

HS 130

HEAVY DUTY

750 - 2100 60 225 21.7

2250 - 2700 60 225 21.7

2850 - 3000 55 225 21.7

3300 - 3900 50 225 21.7

4200 - 4500 40 225 21.7

4800 35 225 21.7

5100 25 225 21.7

CB 130

STANDARD DUTY

750 - 1500 20 129 8.6

1650 - 2100 20 137 10.7

2250 - 2700 25 166 11.8

2850 - 3300 30 188 14.9

Not recommended for the support of P.C.Concrete floors

19

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

350 to 370

100

150 to 170

100 to 115

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

18

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

330 to 350

100

130 to 150

100 to 115

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

Denotes Plaster Key Denotes Plaster Key

HDX 150

EXTRA HEAVY DUTY

750 - 2100 100 225 34.7

2250 - 3300 80 225 34.7

3600 - 4200 70 225 34.7

4500 - 4800 60 225 34.7

5100 45 225 34.7

Versions also available for 125 to 140 inner leaf

HS 150

HEAVY DUTY

750 - 2100 60 225 21.7

2250 - 2700 60 225 21.7

2850 - 3000 55 225 21.7

3300 - 3900 50 225 21.7

4200 - 4500 40 225 21.7

4800 35 225 21.7

5100 25 225 21.7

CB 150

STANDARD DUTY

750 - 1500 20 115 8.6

1650 - 2100 20 118 10.7

2250 - 2700 25 152 11.8

2850 - 3300 30 174 14.9

Not recommended for the support of P.C.Concrete floors

CB 70/130

STANDARD DUTY

750 - 1200 15 100 7.6

1350 - 1650 20 128 10.3

1800 - 2400 22 140 12.5

2550 - 2850 30 177 14.3

3000 - 3900 26 192 15.0

Not recommended for the support of P.C.Concrete floors

HS 70/130

HEAVY DUTY

750 - 1200 60 225 16.5

1350 - 2100 60 225 18.0

2250 - 2700 60 225 19.5

2850 - 3000 55 225 19.5

3300 - 3900 50 225 19.5

4200 - 4800 40 225 19.5

5100 25 225 19.5

HDX 70/130

EXTRA HEAVY DUTY

750 - 2100 100 225 34.5

2250 - 3300 80 225 34.5

3600 - 4200 70 225 34.5

4500 - 4800 60 225 34.5

5100 45 225 34.5

HDX 50/130

EXTRA HEAVY DUTY

750 - 2100 100 225 34.5

2250 - 3300 80 225 34.5

3600 - 4200 70 225 34.5

4500 - 4800 60 225 34.5

5100 45 225 34.5

HS 50/130

HEAVY DUTY

750 - 1200 60 225 16.5

1350 - 2100 60 225 18.0

2250 - 2700 60 225 19.5

2850 - 3000 55 225 19.5

3300 - 3900 50 225 19.5

4200 - 4800 40 225 19.5

5100 25 225 19.5

CB 50/130

STANDARD DUTY

750 - 1200 15 108 5.9

1350 - 1500 15 108 7.4

1650 - 1800 20 140 8.5

1950 - 2400 22 148 10.4

2550 - 2850 26 177 11.6

3000 - 3900 26 185 13.9

Not recommended for the support of P.C.Concrete floors

21

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

295 to 330

100

70 to 90

125 to 140

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

20

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

275 to 310

100

50 to 70

125 to 140

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

Denotes Plaster Key Denotes Plaster Key

SX 90

HEAVY DUTY

750 - 4200 90 212 40.9

4500 - 4800 80 212 40.9

5100 - 5400 70 212 40.9

5700 65 212 40.9

6000 55 212 40.9

6300 50 212 40.9

6600 45 212 40.9

Versions also available for other cavity widths.To achieve above loads lintels should be laterally restrained and propped during installation.

XHD 90

EXTREME DUTY

750 - 4200 120 240 56.6

4500 - 4800 100 240 56.6

5100 - 5400 90 240 56.6

5700 - 6600 65 240 56.6

Versions also available for other cavity widths.To achieve above loads lintels should be laterally restrained and propped during installation.Note: This lintel is supplied uninsulated. If required thisshould be carried out on site.

HS 90/200

HEAVY DUTY

750 - 1350 60 225 22.4

1500 - 2100 60 225 27.2

2250 - 3300 60 225 31.0

3600 - 4800 50 225 32.6

5100 35 225 32.6

Versions also available for other cavity widths

HDX 90/130

EXTRA HEAVY DUTY

750 - 2100 100 225 34.5

2250 - 3300 80 225 34.5

3600 - 4200 70 225 34.5

4500 - 4800 60 225 34.5

5100 45 225 34.5

HS 90/130

HEAVY DUTY

750 - 1200 60 225 16.5

1350 - 2100 60 225 18.0

2250 - 2700 60 225 19.5

2850 - 3000 55 225 19.5

3300 - 3900 50 225 19.5

4200 - 4800 40 225 19.5

5100 25 225 19.5

CB 90/130

STANDARD DUTY

750 - 1200 15 90 7.6

1350 - 1650 20 118 10.3

1800 - 2400 22 130 12.5

2550 - 2850 30 167 14.3

3000 - 3900 26 182 15.0

Not recommended for the support of P.C.Concrete floors

23

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

380 to 425

100

90 to 110

190 to 215

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

22

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

315 to 350

100

90 to 110

125 to 140

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

Cavity Walls

Denotes Plaster Key Denotes Plaster Key

HS 125/90/100

HEAVY DUTY

750 - 2100 60 225 17.7

2250 - 3300 50 225 17.7

3600 - 4200 40 225 19.0

4500 - 4800 35 225 19.0

Versions also available for other cavity widths

CB 125/90/100

MEDIUM DUTY

750 - 1500 25 150 9.5

1650 - 2400 30 190 13.9

2550 - 3000 30 210 17.0

Not recommended for the support of P.C.Concrete floors

Versions are also available for other cavity widths

AT 50

HEAVY DUTY

750 - 1800 35 150 9.8

1950 - 2400 35 150 12.2

2550 - 2700 35 150 14.7

AT 90

HEAVY DUTY

750 - 1800 35 150 9.8

1950 - 2400 35 150 12.2

2550 - 2700 35 150 14.7

AT 70

HEAVY DUTY

750 - 1800 35 150 9.8

1950 - 2400 35 150 12.2

2550 - 2700 35 150 14.7

Overall Width

Outer Leaf

Cavity

Inner Leaf

270 to 305

100

70 to 90

100 to 115

Overall Width

Outer Leaf

Cavity

Inner Leaf

290 to 325

100

90 to 110

100 to 115

Cavity

Inner Leaf

50 to 90

100 to 115

Cavity

Inner Leaf

90 to 130

100 to 115

CB EV 50750 - 1200 15 103 5.2

1350 - 1500 15 103 6.4

1650 - 1800 20 131 7.4

1950 - 2100 20 138 7.6

2250 - 2700 26 192 11.3

25

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

250 to 285

100

50 to 70

100 to 115

Attic Truss

Denotes Plaster Key

24

Overall Width

Outer Leaf

Cavity

Inner Leaf

Length Range Max UDL Depth Weightmm kn mm kg/m

Supports attic trusses in open eaves condition

Cavity Walls (Stonework)

Eaves (Closed)

Denotes Plaster Key

320 to 350

125 to 150

95 to 110

100 to 115

We recommend the use of an

additional cavity tray with all

external cavity wall lintels

CB EV 90750 - 2100 20 160 7.9

2250 - 2700 20 185 13.0

SB 100

STANDARD DUTY

750 - 1500 15 73 5.1

1650 - 1800 20 140 6.6

1950 - 2700 20 140 8.3

2850 - 3600 25 215 11.2

3900 - 4500 30 215 16.8

4800 28 215 16.8

5100 24 215 16.8

27

Length Range Max UDL Depth Weightmm kn mm kg/m

Denotes Plaster Key

26

Length Range Max UDL Depth Weightmm kn mm kg/m

Denotes Plaster Key

SB 140 HD

HEAVY DUTY

750 - 1500 35 140 10.2

1650 - 2700 40 215 16.3

2850 - 3600 45 215 19.5

SB 140

STANDARD DUTY

750 - 2100 25 140 8.2

2250 - 2700 25 140 10.2

2850 - 3600 25 215 13.0

3900 - 4200 45 215 19.5

4500 - 4800 35 215 19.5

5100 28 215 19.5

SB 140 HDX

EXTRA HEAVY DUTY

750 - 1500 60 140 14.5

1650 - 2700 60 215 19.5

Note: Max UDL figures may reduce if end bearings are less than 150mm. If in doubt check Technical Department

SB 100 HDX

EXTRA HEAVY DUTY

750 - 1500 60 140 11.5

1650 - 2700 60 215 16.8

SB 100 HD

HEAVY DUTY

750 - 1500 25 140 6.6

1650 - 2700 40 215 14.0

2850 - 3600 45 215 16.8

SBL 200

MEDIUM DUTY

750 - 1500 20 142 9.0

1650 - 2100 20 142 10.1

2250 - 2700 20 142 11.3

2850 - 3000 25 218 13.8

3300 - 3600 40 219 17.2

3900 - 4500 35 220 20.3

4800 30 220 20.3

5100 28 215 20.3

Can be supplied pre-insulated at small extra charge

DC 200

HEAVY DUTY

750 - 2100 60 225 15.3

2250 - 3000 50 225 15.3

3300 - 3900 50 225 18.4

4200 - 4800 30 225 18.4

DC 200 HDX

EXTRA HEAVY DUTY

750 - 2100 100 225 31.1

2250 - 3900 60 225 31.1

4200 - 4800 50 225 31.1

5100 30 225 31.1

OB 190

MEDIUM DUTY

750 - 1500 9 90 5.7

1650 - 2100 12 95 9.3

2250 - 2550 20 160 10.2

2700 - 3000 20 160 12.2

27

200-215 Solid Walls

26

100 Internal WallsLintels can be supplied insulated

(extra charge)

Plastered both sides

140 Internal WallsPlastered both sides

EV 100

HEAVY DUTY

Lintels above 3000 longshould be propped. See notes opposite

750 - 1500 15 150 5.2

1650 - 2100 20 150 7.7

2250 - 3000 15 225 9.6

3300 - 4800 20 225 15.5

LA

MEDIUM DUTY

Lintels above 1500 longshould be propped. See notes opposite

750 - 1500 6 90 4.5

1650 - 1800 6 119 5.3

1950 - 2400 10 158 6.2

2550 - 3000 13 215 7.5

3300 - 3900 8 215 7.5

Use to carry outer leaf and provide support for cavity tray where inner leaf is existing or supported separately.

MBL

LIGHT DUTY

Lintels above 1500 longshould be propped. See notes opposite

750 - 900 2 50 2.4

1050 - 1350 4 80 2.7

1500 - 2100 5 85 4.7

Use in lightly loaded locations such as meter boxes, garage personnel doors etc.

29

Length Range Max UDL Depth Weightmm kn mm kg/m

28

Length Range Max UDL Depth Weightmm kn mm kg/m

TF 50

Pinch batten must be usedwith TF 50 lintels

750 - 2100 8 185 4.6

2250 - 3000 10 185 5.9

3300 - 3900 10 185 7.0

Versions also available for other cavity widths

TF 50 HD

with cavity closer

750 - 2100 12 185 8.8

2250 - 300 15 185 10.1

3300 - 4800 10 185 11.2

Versions also available for other cavity widths

29

Timber Frame

28

100 External Walls

Lintels above 1200 long should be propped until lintel is fully loaded and

brickwork has matured. Use horizontal timber spreader to avoid distorting lintel.

Use single central prop for openings up to 2100.

For larger openings use multiple props (max spacing 1200).

Restraining clips (supplied) should be fixed to timber frame using

3 No 3.3mm Dia x 50 long galvanised nails.

Clip should overlap lintel by 12mm as indicated by line on clip.

Pinch batten must be

used with TF 50 lintels

INT 100

LIGHT DUTY

900 - 1200 5 20 1.9

Overall Width

Outer Leaf

Cavity

Inner Leaf

275 to 315

100

75 to 100

100 to 125

Semicircular Arches

Max UDL Weight Opening Radius Lengthkn kg mm mm mmLintel Reference

SC600

SC 630

SC 900

SC 915

SC 1200

SC1500

A separate shaped cavity tray should be used with all semicircular lintels

140 wide mesh to inner leaf

3130

Length Range Max UDL Depth Weightmm kn mm kg/m

Denotes Plaster Key

3131

INT 100 HD

MEDIUM DUTY

750 - 2100 10 50 3.3

30

Internal WallsNon load bearing

Span Opening Width Rise Span Opening Width Rise

Accessories

ARCHFORM

Supports arched soldiercourse over standard doorand window openings. Canbe used with all standard

external wall lintels.

475 450 - 500 75

625 600 - 650 75

675 650 - 700 75

775 750 - 800 75

925 900 - 950 75

1025 1000 - 1050 75

1075 1025 - 1100 75

1125 1100 - 1150 75

1225 1200 - 1250 75

1375 1350 - 1400 75

1525 1500 - 1550 75

1675 1650 - 1700 75

1775 1750 - 1800 75

1925 1900 - 1950 150

Lengths Available

900

1200

1500

1800

2100

2400

2700

4500

Lengths Available

900

1200

1500

1800

2100

2400

2700

4500

SOFFIT COVER

RENDER KEY

SLEEVE

Manufactured from UPVC, the soffit cover fits over the frontflange of standard lintels to provide an aesthetically pleasing finish to the exposed soffit of the lintel. Available in white only.

This heavier gauge version of the soffit cover has keyingribs on the underside to accept a rendered finish, thusavoiding the need for special lintels, and the Health &Safety implications of welded mesh.

20 10 600 300 900

20 11 630 315 930

20 15 900 450 1200

20 15 915 457.5 1215

20 20 1200 600 1500

20 25 1500 750 1800

Other sizes and cavity widths can be made to order

2125 2100 - 2150 150

2225 2200 - 2250 150

2375 2350 - 2400 150

2425 2400 - 2550 150

part description recommended weightnumber lintel (kg)

P1645 support post - 1645 long 9

P3000 support post - 3000 long 14

T90/250 90° cap plate - 250-270 walls CB50 8

T90/270 90° cap plate - 270-290 walls CB70 8

T90/290 90° cap plate - 290-310 walls CB90 8

T135/250 135° cap plate - 250-270 walls CB50 7

T135/270 135° cap plate - 270-290 walls CB70 7

T135/290 135° cap plate - 290-310 walls CB90 7

S10 spacer shim - 10 deep

All measurements are shown in millimetres.

3332

The Birtley

BAY 6Corner Window Support System

The Birtley

BAY 6Corner Window Support System

The easy way to support cavity walls above corner windows, bay windows etc.

• Uses standard components available ex-stock

• Easy to transport and handle

• No special drawings or design work needed

• Suits most standard wall constructions

• Hot-dip galvanized after fabrication

System is intended for use in domestic loading conditions with

timber floors and roofs. Do not use to support pre-cast concrete

floors. If in doubt contact technical department for advice.

Standard ex-stock lintels have hole

punched in each end of rear flange

for galvanizing purposes, this

locates over dowel on top plate

of post cap

Cap plate manufactured in 6 types, to suit

90˚ and 135˚ angles, and for 50, 70, and 90

cavity widths, 150 long spigot on underside

locates into post

Post stocked in two lengths, 1645 long for below

sill fixing and 3000 long for fixing at foundation level

(cut to required length on site) 48.3 dia x 5 circular

section allows post to be rotated to desired position

All components are hot-dip galvanized after fabrication

to BS1461.

Spacer shims for height adjustment

Bay 6 system is designed to support vertical loadsonly in standard duty loading conditions i.e. normaldomestic construction with timber floor loads.

Bay 6 system can be used for sun lounges on thebasis that separate provision is made for horizontal or windloads by structural engineer.

Maximum vertical load per support post : 10kn.

With baseplate set 10mm from face of wall,

post sits in cavity immediately behind outer leaf.

This is the optimum position to accommodate post

within junction of window frames.

Unique baseplate

shape allows use

with 90˚ and 135˚

angles and 50 to

100 cavity widths

All measurements are shown in millimetres.

Note: Due to manufacturing limitations and tolerances, it is possible that in some instances the locating dowels may not quite line up with the punched holes in lintels. If this occurs please open up or re-drill holes in lintels. This will not affect the structural performance of the product.

Gothic Arch

Lintel is hot-dip galvanized after manufacture. Minimum coating weight 920G/M2 (Inc. both sides).

We recommend the use of an additional damp proof tray with this lintel.

WALL CONSTRUCTIONOuter Leaf:Cavity Width:Inner Leaf:

LOADING CONDITIONSUnless stated otherwise, we will select a steel thickness which will give the following safe loads.Up to 2100 long 20Kn2100 to 3000 long 30KnAbove 3000 long Check with technical

dept or supply working drawings.

REMARKSPLASTER/RENDER REQUIREMENT.

Please tick: No Mesh Half Mesh Full Mesh

Extended Semicircular Arch

Lintel is hot-dip galvanized after manufacture. Minimum coating weight 920G/M2 (Inc. both sides).

We recommend the use of an additional damp proof tray with this lintel.

WALL CONSTRUCTIONOuter Leaf:Cavity Width:Inner Leaf:

LOADING CONDITIONSUnless stated otherwise, we will select a steel thickness which will give the following safe loads.Up to 2100 long 20Kn2100 to 3000 long 30KnAbove 3000 long Check with technical

dept or supply working drawings.

REMARKSPLASTER/RENDER REQUIREMENT.

Please tick: No Mesh Half Mesh Full Mesh

Semicircular Arch

Lintel is hot-dip galvanized after manufacture. Minimum coating weight 920G/M2 (Inc. both sides).

We recommend the use of an additional damp proof tray with this lintel.

WALL CONSTRUCTIONOuter Leaf:Cavity Width:Inner Leaf:

LOADING CONDITIONSUnless stated otherwise, we will select a steel thickness which will give the following safe loads.Up to 2100 long 20Kn2100 to 3000 long 30KnAbove 3000 long Check with technical

dept or supply working drawings.

REMARKSPLASTER/RENDER REQUIREMENT.

Please tick: No Mesh Half Mesh Full Mesh

3534

Fax BackPlease fill in required dimensions and fax to 0191 411 2558

MARY AVENUE, BIRTLEY,

CO.DURHAM DH3 1JF

Telephone: 0191 410 6631

General Fax: 0191 410 0650

Sales: 0191 410 0132

Technical: 0191 411 2558

e mail: [email protected]

Internet: www.birtley-building.co.uk

www.lintels.com

Fax back to

Name

Company

Project

Fax No

Telephone

e mail

Three-Centred Lintel

Lintel is hot-dip galvanized after manufacture. Minimum coating weight 920G/M2 (Inc. both sides).

We recommend the use of an additional damp proof tray with this lintel.

WALL CONSTRUCTIONOuter Leaf:Cavity Width:Inner Leaf:

LOADING CONDITIONSUnless stated otherwise, we will select a steel thickness which will give the following safe loads.Up to 2100 long 20Kn2100 to 3000 long 30KnAbove 3000 long Check with technical

dept or supply working drawings.

REMARKSPLASTER/RENDER REQUIREMENT.

Please tick: No Mesh Half Mesh Full Mesh

Arched Lintel

Lintel is hot-dip galvanized after manufacture. Minimum coating weight 920G/M2 (Inc. both sides).

We recommend the use of an additional damp proof tray with this lintel.

WALL CONSTRUCTIONOuter Leaf:Cavity Width:Inner Leaf:

LOADING CONDITIONSUnless stated otherwise, we will select a steel thickness which will give the following safe loads.Up to 2100 long 20Kn2100 to 3000 long 30KnAbove 3000 long Check with technical

dept or supply working drawings.

REMARKSPLASTER/RENDER REQUIREMENT.

Please tick: No Mesh Half Mesh Full Mesh

Apex Lintel

Lintel is hot-dip galvanized after manufacture. Minimum coating weight 920G/M2 (Inc. both sides).

We recommend the use of an additional damp proof tray with this lintel.

WALL CONSTRUCTIONOuter Leaf:Cavity Width:Inner Leaf:

LOADING CONDITIONSUnless stated otherwise, we will select a steel thickness which will give the following safe loads.Up to 2100 long 20Kn2100 to 3000 long 30KnAbove 3000 long Check with technical

dept or supply working drawings.

REMARKSPLASTER/RENDER REQUIREMENT.

Please tick: No Mesh Half Mesh Full Mesh

Fax BackPlease fill in required dimensions and fax to 0191 411 2558

MARY AVENUE, BIRTLEY,

CO.DURHAM DH3 1JF

Telephone: 0191 410 6631

General Fax: 0191 410 0650

Sales: 0191 410 0132

Technical: 0191 411 2558

e mail: [email protected]

Internet: www.birtley-building.co.uk

www.lintels.com

Fax back to

Name

Company

Project

Fax No

Telephone

e mail