Link to VoR: Angewandte Angew. Chem. Angew. Chem. Int. Ed ...

Transcript of Link to VoR: Angewandte Angew. Chem. Angew. Chem. Int. Ed ...

AngewandteInternational Edition

A Journal of the Gesellschaft Deutscher Chemiker

www.angewandte.orgChemie

Accepted Article

Title: Synthesis of structurally controlled poly(N-vinyl amide)sand poly(vinyl amine)s and their block copolymers usingorganotellurium-mediated radical polymerization

Authors: Weijia Fan and Shigeru Yamago

This manuscript has been accepted after peer review and appears as anAccepted Article online prior to editing, proofing, and formal publicationof the final Version of Record (VoR). This work is currently citable byusing the Digital Object Identifier (DOI) given below. The VoR will bepublished online in Early View as soon as possible and may be differentto this Accepted Article as a result of editing. Readers should obtainthe VoR from the journal website shown below when it is publishedto ensure accuracy of information. The authors are responsible for thecontent of this Accepted Article.

To be cited as: Angew. Chem. Int. Ed. 10.1002/anie.201902940Angew. Chem. 10.1002/ange.201902940

Link to VoR: http://dx.doi.org/10.1002/anie.201902940http://dx.doi.org/10.1002/ange.201902940

COMMUNICATION

Synthesis of structurally controlled poly(N-vinyl amide)s and

poly(vinyl amine)s and their block copolymers using

organotellurium-mediated radical polymerization

Weijia Fan and Shigeru Yamago*[a]

Abstract: Controlled polymerization of acyclic N-vinyl amides, i.e., N-

methyl-N-vinylacetamide (NMVA), N-vinylacetamide (NVA) and N-

vinylformamide (NVF), by organotellurium-mediated radical

polymerization (TERP) is reported. The corresponding poly(N-vinyl

amide)s with controlled molecular weight and low dispersity (Ð < 1.25)

were obtained with high monomer conversion in all cases. This is the

first report for the controlled polymerization of NVF. Hydrolysis of the

polymers, in particular PNVF, occurred quantitatively under mild

conditions, giving structurally controlled poly(vinyl amine)s. Block

copolymers containing poly(N-vinyl amide) and poly(vinyl amine)

segments were also synthesized in a controlled manner.

Poly(N-vinyl amide)s are one of the most important water-soluble

polymers and have numerous applications in biomedicals,

pharmaceuticals, cosmetics, foods, printing inks, and textiles.[1] In

particular, hydrolysis of poly(N-vinyl amide)s prepared from

acyclic N-vinyl amides, i.e., N-methyl-N-vinylacetamide (NMVA),

N-vinylacetamide (NVA) and N-vinylformamide (NVF), give

poly(vinyl amine)s (PVAs), which are pH-sensitive polymers and

are utilized in modern biological and materials sciences and

technologies, such as in vehicles for drug and gene delivery.[2]

Therefore, controlling the macromolecular structure of poly(N-

vinyl amide)s and synthesizing block copolymers consisting of

these water-soluble polymers as a segment would provide

advanced materials with improved and/or new properties.

Poly(N-vinyl amide)s are prepared by radical polymerization of

N-vinyl amides. Therefore, the use of reversible deactivation

radical polymerization (RDRP), which is also known as living

radical polymerization, is the method of choice for structural

control and block copolymer synthesis because RDRP is now

widely used for the controlled polymerization of a variety of

functionalized monomers.[3] However, N-vinyl amides are

unconjugated monomers, and their controlled polymerization is

more difficult than that of conjugated monomers. Several

controlled polymerizations of cyclic N-vinyl amides, i.e., N-

vinylpyrrolidone and N-vinylcaprolactam, have been reported

using organostibine-mediated radical polymerization,[4]

organotellurium-mediated radical polymerization (TERP),[5] atom

transfer radical polymerization (ATRP),[6] reversible addition-

fragmentation-chain transfer polymerization (RAFT),[7] and cobalt-

mediated radical polymerization (CRP);[8] however, the cyclic

amide cannot be hydrolyzed to PVA.

A single example has been reported for the controlled

polymerization of NMVA under CRP conditions, giving PNMVA

with controlled molecular weight and low dispersity (Ð), [8b] but the

monomer conversion was rather low (<65%). CRP of NVA also

gave PNVA with low Ð but only moderate monomer conversion

(<50%). Furthermore, though the resulting PNVAs were

hydrolyzed to PVAs with up to 95% conversion, the harsh reaction

conditions (6 mol L-1 aqueous HCl at 120 °C for 64 h) were

unattractive considering the synthesis of functional materials.[9]

The hydrolysis of PNVF would proceed under much milder

conditions than that of PVNA. However, while RDRP of NVF was

attempted using CMRP and RAFT, these methods could not

control the polymerization.[10] Because the successful controlled

polymerization of ethylene [11] and 1,1-difluoroethylene,[12] which

are highly challenging unconjugated monomers by RDRP, has

been recently reported, the controlled polymerization of NVF

appears to be the remaining significant challenge in RDRP.

Among the RDRP methods already reported, such as nitroxide-

mediated polymerization,[13] ATRP,[14] RAFT,[15] and CRP,[16] we

focused on TERP considering its high versatility of polymerizable

monomer families and high flexibility in block copolymer

synthesis[17] originated from its unique polymerization

mechanism.[17c,18] Here, we report the controlled polymerization

of NMVA, MVA, and NVF by TERP, which resulted in the

corresponding PNVAs with controlled molecular weight and low Ð

(Scheme 1). This is the first example of the controlled

polymerization of NVF. Hydrolysis of PNVF proceeded under

much mild conditions than that of PVNA and gave structurally

controlled PVA with quantitative conversion. Furthermore, block

copolymers consisting of PVA segments could also be

synthesized for the first time by hydrolysis of block copolymers

consisting of PNVF segments.

Scheme 1. TERP of N-vinyl amides and subsequent transformations

The feasibility of the controlled polymerization of acyclic N-

vinyl amides by TERP was first examined using NMVA (50 equiv.)

as a monomer in the presence of organotellurium chain transfer

agent 1 and dimethyl 2,2'-azobis(2-methylpropionate) (V-601,

[a] W. Fan, Prof. Dr. S. Yamago

Institute for Chemical Research, Kyoto University

Uji, Kyoto 611-0011 (Japan)

E-mail: [email protected]

Supporting information and the ORCID identification number for

the author of this article can be found under:

https://doi.org./xxxx

10.1002/anie.201902940

Acc

epte

d M

anus

crip

t

Angewandte Chemie International Edition

This article is protected by copyright. All rights reserved.

COMMUNICATION

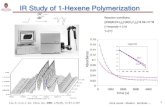

0.40 equiv.) at 60 °C.[18] Monitoring of the polymerization by 1H

NMR spectroscopy and size exclusion chromatography (SEC)

suggested pseudo-first-order kinetics and linear growth of number

average molecular weight (Mn(SEC)) for the monomer conversion

while maintaining a low Ð (Scheme 2a). Monomer conversion

reached 93% after 5 h, and PNMVA with Mn(SEC) = 7000 and

narrow Ð (= 1.08) was obtained after reduction of the polymer end

group by Bu3SnH (Table 1, run 1). The discrepancy of Mn between

Mn(SEC) and the theoretical value (Mn(theo) = 4700) is due to the lack

of appropriate calibration standards, and the Mn values

determined by 1H NMR spectroscopy (Mn(NMR) = 4600) and MALDI

TOF mass spectrometry (Mn(MS) = 4400, Scheme 2b) were very

close to Mn(theo). These results clearly demonstrate the controlled

polymerization of NMVA.

2500 3000 3500 4000 4500 5000 5500 6000

3297.40 (n = 32)

4982.95 (n = 49)3396.51 (n = 33)

3495.59 (n = 34)3495.59 (n = 34)

3594.70 (n = 35)

3693.71 (n = 36)

3891.93 (n = 38)

4586.60 (n = 45)

4387.40 (n = 43)

4288.30 (n = 42)

4189.17 (n = 41)

m/z

4090.13 (n = 40)

4487.45 (n = 44)

4684.72 (n = 46)

4784.73 (n = 47)

4883.89 (n = 48)

3990.92 (n = 39)

3792.87 (n = 37)

5082.14 (n = 50)

0 20 40 60 80 1000.0

2.0k

4.0k

6.0k

8.0k Mn(SEC)

Mn(MS)

Mn(theo)

Mn

Conversion (%)

1.0

1.2

1.4

1.6

1.8

2.0

Ð

Ð

Scheme 2. TERP of NMVA. a) Kinetic monitoring and b) MALDI TOF mass spectra after reduction of the polymer end-group

High molecular weight PNMVAs were also synthesized by

increasing the amount of NVMA (100-500 equiv., runs 2-4). The

monomer conversion reached high values (80-95%) in all cases,

and PNMVAs with low dispersity (Ð = 1.08-1.25) were formed in

all cases. The Mn(SEC) values were higher than the Mn(theo) values

in all cases, and the difference can be explained by the polymer

standards, as the deviation in runs 2-4 (ca. 40-60%) is essentially

the same as that observed in run 1 (50%). The high end-group

fidelity (95%) was ascertained by a chain extension experiment

for a PNMVA (Mn(SEC) = 16700, Ð = 1.06) sample prepared using

100 equiv. of NMVA with 95% monomer conversion by adding

NMVA (500 equiv.) and further polymerization (see Supporting

Information). These results indicate the successful controlled

polymerization of NVMA.

Table 1. TERP of acyclic N-vinyl amides

Run Monomer Equiv. t

(h) Conv. (%) [a]

Mn(theo) Mn [b] Ð[b]

1 NVMA 50 5 93 4,700 7,000 1.08

(4,400)[c]

(4,600)[a]

2 100 7 95 9,500 15,200 1.08

(9,700) [a]

3 200 10 90 18,000 25,600 1.10

4 500 24 80 43,200 65,600 1.25

5 NVA 50 6 96 4,200 7,000 1.08

(4,300)[c]

(4,500)[a]

6 100 12 88 7,600 12,800 1.08

(7,500)[a]

7 200 25 85 14,600 20,100 1.25

8 500 25 70 29,900 38,500 1.28

9 NVF[d] 50 7 90 3,300 5,200 1.12

(3,400)[a]

10 100 12 81 5,900 6,850 1.08

(5,900)[a]

11 200 20 87 12,500 14,500 1.15

12 500 30 81 28,900 27,700 1.20

[a] Determined by 1H NMR. [b] Determined by SEC calibrated with PMMA

standards. [c] Determined by MALDI TOF mass spectrometry. [d] Mn and Ð were

determined by SEC calibrated with PEO standards.

Next, TERP of NVA was examined under the same conditions

used for that of NMVA (runs 5-8). The polymerization of NVA also

proceeded in a controlled manner, as indicated by the pseudo-

first-order kinetics and linear growth of Mn by monomer

conversion in the experiment using 50 equiv. of NVA (see

Supporting Information). Nearly quantitative conversion (96%)

occurred after 6 h, and PNVA with Mn(SEC) = 7000 and Ð = 1.08

was obtained (run 5). The discrepancy between Mn(SEC) and

Mn(theo) was again due to the polymer standards, as Mn(NMR) and

Mn(MS) are almost identical to Mn(theo). PNVAs with high molecular

weights were also prepared in a controlled manner by increasing

the amount of NVA (runs 6-8). The corresponding high molecular

weight PNVAs (Mn(SEC) = 12800-38500) with low dispersity (Ð =

1.08-1.28) were obtained with high monomer conversion (70-

88%) in all cases. The amount of dead polymer for the PNVA

prepared with 100 equiv. of NVA was 3%, as determined by a

chain extension experiment (see Supporting Information). These

results illustrated the successful control of NVA polymerization by

TERP.

Finally, TERP of NVF was examined under otherwise identical

conditions (runs 9-12). The controlled polymerization also took

place, as indicated by the pseudo-first order kinetics and linear

growth of Mn by monomer conversion in the polymerization of 50

equiv. of NVF. After 90% monomer conversion, PNVF with Mn(SEC)

10.1002/anie.201902940

Acc

epte

d M

anus

crip

t

Angewandte Chemie International Edition

This article is protected by copyright. All rights reserved.

COMMUNICATION

= 5200 and Ð = 1.12 was obtained (run 9). The difference

between Mn(SEC) and Mn(theo) was also clarified by determining Mn

by NMR spectroscopy. Additionally, high molecular weight PNVFs

were synthesized in a controlled manner by increasing the

amount of NVF from 100 to 500 equiv. (runs 10-12). The Mn(SEC)

became close to Mn(theo) and the dispersity slightly increased as

the amount of NVF increased, suggesting a slight loss of control.

However, the dispersity of PNVF synthesized using 500 equiv. of

monomer was still low (Ð =1.20), clearly suggesting the

successful control of NVF polymerization for the first time.

During these studies, we recognized that these acyclic N-vinyl

amide monomers are highly sensitive to acid; we experienced the

selective formation of a dimer derived from an acid-catalyzed

reaction instead of the desired polymerization.[19] While we could

not ascertain the origin of the acid, the addition of a catalytic

amount of a weakly nucleophilic base, such as N,N-

diisopropylethylamine or 2,6-lutidine, was effective in such cases.

Poly(N-vinyl amide)s with controlled Mns and low Ðs were

obtained in the presence of the base (see Supporting Information).

Also, when we carefully control the generation of acid in a hood

and a glove box, the desired controlled polymerization proceeded

reproducibly.

All poly(N-vinyl amide)s synthesized in this study were

successfully converted to the corresponding poly(vinyl N-

methylamine)s and PVAs (3) by acid- or base-catalyzed

hydrolysis (Scheme 1). PNMVA and PNVA were hydrolyzed

under acidic conditions as reported previously by Debuigne.[9] For

example, PNMVA (Mn = 12,300, Ð = 1.11) was heated with 6.0

mol L-1 HCl aqueous solution at 120 °C for 64 h in a sealed tube,

and poly(vinyl N-methylamine) with Mn = 11,000 and Ð = 1.26 was

obtained in 90% after neutralization of the product and purification

by dialysis. 1H NMR analysis of the product revealed quantitative

hydrolysis of the acetyl group. PNVA (Mn = 15,300, Ð = 1.08) was

also hydrolyzed to PVA with Mn = 11,800 and Ð = 1.15 under the

same acidic conditions. The hydrolysis of PNVF (Mn = 15900, Ð =

1.22) took place under much milder conditions than that for

PNMVA and PNVA, i.e., 2.0 mol L-1 aqueous HCl solution at 80 °C

for 6 h, giving PVA with Mn = 12,800 and Ð = 1.20. The hydrolysis

under basic conditions took place much faster than that under

acidic conditions; treatment of PNVF (Mn = 15,900, Ð = 1.22) with

aqueous 2.0 mol L-1 NaOH solution at 80 °C for 3 h afforded

quantitative conversion to PVA with Mn = 10800 and Ð = 1.17.[20]

The 1H NMR and FT-IR spectra clearly showed the complete

removal of the formyl group, and the unimodal SEC trace of PVA

with low Ð demonstrated successful hydrolysis while maintaining

a well-controlled polymer structure. Moreover, PVAs with higher

molecular weights (Mn up to 25,700) were readily synthesized by

the hydrolysis of the corresponding high molecular weight PNVFs

(see Supporting Information).

Block copolymers consisting of PVA segments were

synthesized (Scheme 3a). For example, the PNVF macroinitiator

(Mn(SEC) = 18300, Ð = 1.20) prepared from 1 and NVF (300 equiv.)

with 85% monomer conversion was dissolved in water and heated

at 60 °C with N,N-dimethylacrylamide (DMAA, 500 equiv.) in the

presence of 4,4'-azobis(4-cyanovaleric acid) (ACVA, 0.2 equiv.)

for 20 h. The formation of desired block copolymer 4 (R3 =

CONMe2) consisting of two water-soluble block segments was

confirmed by SEC by the disappearance of the PNVF macro

initiator and the formation of a new unimodal peak corresponding

to PNVF-b-PDMAA with Mn(SEC) = 78,400 and Ð = 1.42. Moreover,

the obtained copolymer was dissolved in 2.0 mol L-1 aqueous

NaOH solution and heated for 3 h; PNVF was quantitatively

hydrolyzed to PVA according to the 1H NMR spectra (Figure S7

in Supporting Information), while the acrylamide segments of

PDMAA could not be hydrolyzed to carboxylic acid under such

16 18 20 22 24

PSt

Mn = 19300,

Ð =1.20

6 (PSt-b-PNVA)

Mn = 31900,

Ð =1.08

Elution time (min)

18 20 22 24

Elution time (min)

PNVF

Mn = 18300, Ð = 1.20

4 (PNVF-b-PDMAA)

Mn = 78400, Ð = 1.42

Mn = 70000, Ð = 1.40

5 (PVA-b-PDMAA)

Scheme 3. a) Synthesis of block copolymers 5 and 6. Conditions: i: 1, NVF (300

equiv.), AIBN (0.2 equiv.), 60 °C, 15 h, 85% conversion of NVF, Mn = 18300, Ð

= 1.20. ii: DMAA (500 equiv.), ACVA (0.2 equiv), water, 60 °C, 20 h, 85%

conversion of DMAA, iii: Bu3SnH (1.5 equiv.), h (3 W white LED), 60 °C, 5 h,

Mn(SEC) = 78400, Ð = 1.42. iv: 2 mol L-1 NaOH/H2O, 80 °C, 3 h, >99% conversion,

Mn(SEC) = 70,000 and Ð = 1.40. v: 1, styrene (200 equiv.), 100 °C, 17 h, 96%

styrene conversion, Mn(SEC) = 19,300, Ð = 1.20. vi: NVA (200 equiv.), AIBN (0.2

equiv.), DMF, 60 °C, 20 h, 57% NVA conversion, Mn(SEC) = 31,900, Ð = 1.08. b)

SEC traces for the synthesis of block copolymer 5, and c) those of 6.

mild conditions due to the different reactivity of vinylamide and

acrylamide. Finally, PVA-b-PDMAA 5 was selectively obtained

(Mn(SEC) = 70,000, Ð = 1.40). (Scheme 3a).

An amphiphilic diblock copolymer consisting of polystyrene

(PSt) and PNVA was also synthesized; PSt macroinitiator (Mn(SEC)

10.1002/anie.201902940

Acc

epte

d M

anus

crip

t

Angewandte Chemie International Edition

This article is protected by copyright. All rights reserved.

COMMUNICATION

= 19,300, Ð = 1.20) prepared by 1 and styrene (200 equiv.) at

100 °C for 17 h (96% conversion) was dissolved in DMF and

heated with NVA (200 equiv.) at 60 °C for 20 h. Conversion of

NVA reached 57%, and the target diblock copolymer 6 was

obtained (Mn(SEC) = 31,900, Ð = 1.08). The SEC traces before and

after the blocking polymerization clearly demonstrated the

successful synthesis of the desired diblock copolymer. (Scheme

3b)

In summary, TERP of acyclic N-vinyl amides, i.e., NVMA, NVA,

and NVF, proceeded in a controlled manner with high monomer

conversion in all cases. This is the first example of the successful

controlled synthesis of PNVF. Hydrolysis of the acetyl and formyl

groups of the resulting polymers afforded structurally controlled

polyamines. The mild conditions for the hydrolysis of PNVF are

highly attractive for the fabrication of functional polymer materials

consisting of PVA segments. This approach was exemplified by

the synthesis of a block copolymer with a poly(N-vinyl amide)

segment. These results expand the synthetic scope of RDRP as

well as materials design based on poly(N-vinyl amide)s and PVAs.

Acknowledgements

This work was partly supported by the JSPS KAKENHI Grant No.

16H06352. We thank Profs. Keita Sakakibara and Yoshinobu

Tsujii of ICR, Kyoto University, for assistance with the SEC

measurements of the water-soluble polymers and for helpful

suggestions and discussions.

Keywords: vinyl amides • reversible deactivation radical

polymerization • TERP • poly(vinyl amine)

[1] Y. E. Kirsh, Water soluble poly-N-vinylamides: synthesis and

physicochemical properties, John Wiley & Sons, Chichester, 1998.

[2] R. Pelton, Langmuir 2014, 30, 15373.

[3] a) K. Matyjaszewski, T. P. Davis, Handbook of Radical

Polymerization, Wiley-Interscience, New York, 2002; b) G. Moad, D.

H. S. Eds, The Chemistry of Radical Polymerization, Elsevier,

Amsterdam, 2006; c) K. Matyjaszewski, M. Möller, Polymer Science:

A Comprehensive Reference, Vol. 3, Elsevier BV, Amsterdam, 2012.

[4] a) S. Yamago, B. Ray, K. Iida, J. Yoshida, T. Tada, K. Yoshizawa,

Y. Kwak, A. Goto, T. Fukuda, J. Am. Chem. Soc. 2004, 126, 13908-

13909; b) B. Ray, M. Kotani, S. Yamago, Macromolecules 2006, 39,

5259-5265.

[5] a) S. Yusa, S. Yamago, M. Sugahara, S. Morikawa, T. Yamamoto,

Y. Morishima, Macromolecules 2007, 40, 5907-5915; b) W. J. Fan,

Y. Nakamura, S. Yamago, Chem. Eur. J. 2016, 22, 17004-17008.

[6] a) X. J. Lu, S. L. Gong, L. Z. Meng, C. Li, S. Yang, L. F. Zhang,

Polymer 2007, 48, 2835-2842; b) P. Singh, A. Srivastava, R. Kumar,

J. Polym. Sci. A Polym. Chem 2012, 50, 1503-1514.

[7] a) D. C. Wan, K. Satoh, M. Kamigaito, Y. Okamoto, Macromolecules

2005, 38, 10397-10405; b) D. C. Wan, Q. Zhou, H. T. Pu, G. J. Yang,

J. Polym. Sci. A Polym. Chem. 2008, 46, 3756-3765.

[8] a) A. Debuigne, N. Willet, R. Jerome, C. Detrembleur,

Macromolecules 2007, 40, 7111-7118; b) M. Hurtgen, J. Liu, A.

Debuigne, C. Jerome, C. Detrembleur, J. Polym. Sci. A Polym.

Chem. 2012, 50, 400-408; c) A. Debuigne, C. Jerome, C.

Detrembleur, Polymer 2017, 115, 285-307.

[9] M. Drean, P. Guegan, C. Detrembleur, C. Jerome, J. Rieger, A.

Debuigne, Macromolecules 2016, 49, 4817-4827.

[10] a) A. Debuigne, A. N. Morin, A. Kermagoret, Y. Piette, C.

Detrembleur, C. Jerome, R. Poli, Chem. Eur. J. 2012, 18, 12834-

12844; b)L. J. Shi, T. M. Chapman, E. J. Beckman, Macromolecules

2003, 36, 2563-2567.

[11] a) C. Dommanget, F. D'Agosto, V. Monteil, Angew. Chem. Int. Ed.

2014, 53, 6683-6686; b) Y. Nakamura, B. Ebeling, A. Wolpers, V.

Monteil, F. D'Agosto, S. Yamago, Angew. Chem. Int. Ed. 2018, 57,

305-309.

[12] S. Banerjee, V. Ladmiral, A. Debuigne, C. Detrembleur, R. Poli, B.

Ameduri, Angew. Chem. Int. Ed. 2018, 57, 2934-2937.

[13] J. Nicolas, Y. Guillaneuf, C. Lefay, D. Bertin, D. Gigmes, B. Charleux,

Prog. Polym. Sci. 2013, 38, 63-235.

[14] a) M. Ouchi, T. Terashima, M. Sawamoto, Chem. Rev. 2009, 109,

4963-5050; b) K. Matyjaszewski, Macromolecules 2012, 45, 4015-

4039.

[15] G. Moad, E. Rizzardo, S. H. Thang, Aust. J. Chem. 2012, 65, 985-

1076.

[16] A. Debuigne, R. Poli, C. Jerome, R. Jerome, C. Detrembleur, Prog.

Polym. Sci. 2009, 34, 211-239.

[17] a) S. Yamago, K. Iida, J. Yoshida, J. Am. Chem. Soc. 2002, 124,

2874-2875; b) S. Yamago, K. Lida, J. Yoshida, J. Am. Chem. Soc.

2002, 124, 13666-13667; c) S. Yamago, Chem. Rev. 2009, 109,

5051-5068; d) W. J. Fan, M. Tosaka, S. Yamago, M. F. Cunningham,

Angew. Chem. Int. Ed. 2018, 57, 962-966.

[18] a) A. Goto, Y. Kwak, T. Fukuda, S. Yamago, K. Iida, M. Nakajima,

J. Yoshida, J. Am. Chem. Soc. 2003, 125, 8720-8721; b) Y. Kwak,

A. Goto, T. Fukuda, Y. Kobayashi, S. Yamago, Macromolecules

2006, 39, 4671-4679.

[19] N. Iqbal, G. Blakstad, A. Fiksdahl, Tetrahedron 2014, 70, 1317-1325.

[20] L. Gu, S. Zhu, A. N. Hrymak, J. Appl. Polym. Sci. 2002, 86, 3412-

3419.

10.1002/anie.201902940

Acc

epte

d M

anus

crip

t

Angewandte Chemie International Edition

This article is protected by copyright. All rights reserved.

COMMUNICATION

Entry for the Table of Contents (Please choose one layout)

Layout 1:

COMMUNICATION

Structurally controlled poly(vinyl amide)s and poly(vinyl amine)s are synthesized by organotellurium-mediated polymerization of acyclic vinyl amides and subsequent hydrolysis of the amides. A block copolymer having poly(vinyl amine) segment was also synthesized.

Weijia Fan, Shigeru Yamago*

Page No. – Page No.

Synthesis of structurally

controlled poly(N-vinyl

amide)s and poly(vinyl

amine)s and their block

copolymers using

organotellurium-mediated

radical polymerization

10.1002/anie.201902940

Acc

epte

d M

anus

crip

t

Angewandte Chemie International Edition

This article is protected by copyright. All rights reserved.

![Link to VoR: Angewandte Angew. Chem. Angew. Chem. Int. Ed ...liuyi-group.dlut.edu.cn/yjcg/28.2018-Angewandte_In... · [9a,9b] Second, microwave-assisted hydrothermal Figure 1. Schematic](https://static.fdocuments.us/doc/165x107/5f926cbb573a2573600d1a2e/link-to-vor-angewandte-angew-chem-angew-chem-int-ed-liuyi-groupdluteducnyjcg282018-angewandtein.jpg)