Limits of the current VTCS

description

Transcript of Limits of the current VTCS

Limits of the current VTCS

Ann Van Lysebetten

Bart Verlaat

Martin van Beuzekom

VELO upgrade meeting 14/11/2008

pix module construction kick-off 09/11/2009

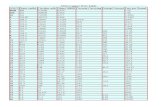

Limits & “bottlenecks”Limits & “bottlenecks”

prim. System H2O 20C

Sec. System (freon)

Tert. System (CO2)

Detector waste heat (max 800W)

2

Tert. System (CO2)

Detector waste heat(max 800W)

Heat Transfer to the module!

• Limited by current compressor, freon injection, heat exchanger to CO2

•Max massflow of pumps 18g/s

• Min CO2 temp -30 C

• heat exchanger to freon?

prim. System

air

20 stations * 10 Velopix -> 4 Watts/velopix

= ~ 2W/cm2

T > 15 ‘C

Minimal upgrade allows ~ 6W/cm2Minimal upgrade allows ~ 6W/cm2

prim. System H2O 20C

Sec. System (freon)

Tert. System (CO2)

Detector waste heat (max 2.5kW)

3

Tert. System (CO2)

Detector waste heat(max 2.5kW)

• new compressor,

• new freon injection,

• new heat exchanger to CO2

• with CO2 massflow of 18g/s

• min at -35 C

• If necessary new heat exchanger to freon

prim. System

air

But!

• to keep silicon at < -5 C lower temp needed if interface not changed!

Cooling interface• Current cooling interface (cookie) is one of limiting factors• Try to integrate cooling pipe into module

– But, no high pressure connectors in vacuum

-> Orbital welding of module to cooling pipe

Cut here

5

SummarySummary Current system can cool up to 800W With some modifications it can reach 2.5 kW -> CO2 cooling plant can do the job! Large T due to large thermal resistance and long path

• this means either lower CO2 temp needed• OUTSIDE range of current system• new freon/CO2 chiller, this has limits! • module on/off temp difference large

Integrate cooling pipe into module/station• shorter path, smaller T over module• small temp differences on/off• connect modules to cooling system via orbital welding

The VTCS cooling principleThe VTCS cooling principle

Con

dens

er

PumpHeat exchanger

Flooded evaporator

Restriction

2-Phase Accumulator

He

at

in

He

at

in

He

at

ou

t

He

at

ou

t

1

2 59

1013

prim. System H2O 20C

Sec. System (freon)

Tert. System (CO2)

Detector waste heat (max 800W)

Tertiary System: two phase accumulator controlled system

7

Tert. System (CO2)

Detector waste heat(max 800W)

Fre

on

sy

stem

prim. System

air

SP -25C