Lewis Gun Mech

Transcript of Lewis Gun Mech

-

8/12/2019 Lewis Gun Mech

1/20

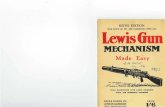

SIXTH E ITIONWITII NOTES ON THE 3 (AMERICAN) LEWIS GUNsMECH NISM

Made Easy~ N r;t: :iT

V ~ 2 2

FULLY ILLUSTRATED WITH LARGE COLOUREDPLATE AND NUMEROUS DIAGRAMS

GALE POLDEN LTLONDONAL DERSHOT

PRICEl

-

8/12/2019 Lewis Gun Mech

2/20

BOOKS SPECIALLY RECOMMENDEDElementary Drill Memory Card for Squad Commanders.Gives in concise form action to be taken by a Squad Commanderon commands being given by Company or Platoon Commanders.By PostCONTENTS.-Formlng Up-Action of Markers-Falling ln-Dresslnc-SquadDrill Movemenu When to give words of commandDrill In Threes and Elementary Drill By PostGeneral Instructions for Drilling Recruits-Squad Drill without ArmsSquad Drill with Arms-Platoon and Company Drill.Reproduced from Training Pamphlet No. 18, and Manual of Elementary DrillAll Arms . 1935, by permrssion of The Controller of H.M . Stationery Office.Small Arms Anti-Aircraft Training Arranged by Major T. J.Edwards, M.B.E., F.R.Hlst.Soc. .. . .. . ... ... ...By Post

Reproduced from S.A.T., Vol. I, Pamphlet5 Nos . 4, 6 and 20, by permission of theController of H.M . Stationery Office.The Complete lewis Gunner. A practical sequence of Instruction, in simple language and as few technicalities as Is compatiblewith efficiency. Fully illust rated wi th plates and diagrams .. .By Postlewls Gun Mechanism Made Easy. By Major C. H. B. Pridham,The Duke of Wellington s Regt. (late Officer Instructor, Schoolof Musketry, Hythe). In handy book form with large foldingColour ed Plate. (Revised to date.) With comparable notes onthe American weapon ... .. . . . . eachBy PostBren l ight Machine Gun. Folder In cover, of handy pocket size.Printed in colours .. . ... .. . . .. . ... . .By PostThe Browning Heavy Machine Gun Mechanism Made Easy(.300 Calibre Model 1917, Water Cooled) ... ... .. . . .By PostThe Mechanism of the Browning Automatic Rifle In pocketform. Illustrated with plates and diagrams. By Post

Vickers Machine Gun Mechanism Made Easy . Fully illus-trated with half-tone plates .. . .. . . . .. . ...By postThis book Is applicable to both the English and American Vickers Gun .lantern Slides for lecture Purposes. Lantern slides In Blackand White cif any of the illustrations in this book can be suppliedat 2s. 6d. each. These slides are invaluable for indoor lecturingpurposes.Log Book and History Sheet for Automatic Weapons. Size,11x 6, In bag container to keep the book clean ... . .. eachper doz.Extra History Sheets, per doz.VIsual Training and Application of Fire .. .

eproduad from Small Arms Training, Vol . 1 1937, by permission By Postof The Controller of H.M . Stationery Office.

s. d0 60 7

36

36

2 02 3

680I680I68

0 98 03 00 90 11

LEWIS GUN MECH NISMM DE E SY

ByMAJOR C. H. B PRIDHAM

The Duke of Wellington s Regiment(Late Officer-Instructor, School of Musketry, Hythe

SIXTH EDITIONWITH NOTES ON

THE .300 (AMERICAN) LEWIS GUN

ALDERSHOTGALE POLDEN LTD .

-

8/12/2019 Lewis Gun Mech

3/20

:P-8510

First Published J anuaTy, 1919Fifth Edition July 1940

ireth Edition November, Hl40Eighteenth Impression March, 1941

PRINTJm DY Gl lE POLDEN LTD.,WELLINGTON WORKS, ALDERSHOT

1941

PREFACE TO REVISED EDITIONNOVEMBER, 1940)

RAPID TRAININGTHis handbook for Lewis Gunners 1st Edition in 1919)was the first of its kind to supplement the old officialtextbooks, which were not specially adapted for rapidtr aining purposes.Method of arrangement Text and Diagrams) isintended:a) To Save Time in Training.b) To arouse interest in the gunner, with a viewto increasing his skill in rapidly applyingaccurate bursts of fire on to any target.Text has been set out to catch the eye.The intricate design of the mechanism is thus madeclear to the understanding of any sailor, soldier,airman-gunner, or A.A. gunner of the Mercantilel\Iarine or Mine-Sweeping Flotillas, Auxiliary MilitaryPioneer Corp s and The Home Guard, whose tim eavailable for Lewis Gun training is limited by his othernumerous duties.Care of Arms. Experience in action shows thegreat importance of this old sub ject. A thoroughknowledge of mechanism, particularly fascinating inthe case of the Lewis Gun, ensures this.Cooling System. A unique feature is the Cooling ofthe Bar rel see page 10 and Fig. Ill), the most effectivesystem of Air Cooling ever invented.This enables the Lewis Gun to fire, at a rate of 10rounds per second, for a prolonged period.

No Barrel Changing is necessary.Diagrams at end of book) can be spread out andexamined whilst reading the text.IMPORTANT. Faulty foreign manufactured )ammunition has, in the past, been the main cause ofSTOPPAGES. Proper care of the Gun see pages 12and 13) and use of good ammunition of British make)reduce Stoppages to a minimum.

C. H. B. PRIDH M Major).

-

8/12/2019 Lewis Gun Mech

4/20

CONTENTSPAGE

DESCRIPTION OF GUNLOADING OF GUNUNLOADING GUN 3ACTION OF MECHANISM IN DETAIL--

DUR ING TilE BACKWARD l\lOVEMKNT 4DUR ING TilE FORWARD 1\fOVEMENT . . 7

I\1ECHANISM OF l\IAGAZINE AND FUNCTIONS OF PARTS 9ACTION OF GASES AND COOLING SYSTEM 10POINTS TO BE CARRIED OUT BEFORE, DURING, AND AFTER

FIRL'IG 12

NOTES ON STOPPAGEShtMEDIATE AcTIONT AB L E OF STOPPAGES (SECTION A )T AB L E OF STOPPAGES (SECTION B )Fws . I, II ND Il l (CoLOURED PLATE OF LEwrs GuN)FIGS . IV, V AND VA ( F E E D ARM AND PAWLS)FIGs. V I AND VI I (EJECTOR AJ. 'D STRIKER PosT)FIG. VI I I (MAGAZINE)

14161920

t end

.. . ofBook

LEWIS GUNMADE

I

MECHANISMEASY

"THE .303 (and the .300 American type) Light DescriptionAutomatic Gun-Air cooled-Gas operated- of GUNMagazine fed."Weight of Gun: 26 to 28 lbs.; Weight ofMounting, 2 lbs.Weight of Magazine: Empty, It lbs.; full4l lbs. (Holds 47 rounds.)*Length of Gun : 50 inches.Length of Barrel : 26l inches.Initial Velocity of Bullet : 2,440 feet persecond.

Two forces work the Gun automatically viz. :1. The pressure of the Gases caused by explo

sion of the Charge.2. The Return Spring contained in the Pinion.These two forces alone enable the Gun to flreat an average rate of ten rounds per second.A trained Lewis Gunner should be able to fuewith accuracy 150 rounds per minute.The Position of the Cocking Handle normallyshows whether the Gun is Safe or Loadedi.e. when a Filled Magazine is in position on theGun : -

A. When C.H. is fully forward vide Fig. II)-Gun is Safe.

NoTE. -Magazines (double-sized, holding about 94rounds) are also in use by the Royal Navyand the R.A.F .

-

8/12/2019 Lewis Gun Mech

5/20

To LOAD

To FIRE

2B. When C.H. is in rear position vide Fig. I)

Gun is Loaded.Note that when Gun is not in use, C.H. shouldbe always in Forward Position, to avoid unneces-sary strain or tension on the Return Spring.

1. See that Cocking Handle is in ForwardPosition.2. Place Filled Magazine on the Magazine Post-Catch to Right-White of Centre Disc to Rear;press down Magazine, and at the same time rotateslightly in both directions without undue force,till the Hook of the Catch engages n the Recessinside the Magazine Post.3. Rotate Magazine with Right Hand untilresistance is met with.4. Pull back C H to rear as far as it will go.*

N.B .-This action places a Live Round inposition in the Cartridge Way in theBody by action of the Feed-Arm andCartridge Guide, ready to be pushedforward by the Bolt into the Chamber-vide Fig. 1.

GUN is Now READY to FIRE.A. f Trigger is Pressed Gun fires.B. pressure on Trigger is 1eleased C.H. willstop in the Rear Position, and Gun is Loaded andready to cont inue firing, by Nose of Sear beingengaged with Bent on Rack.C f pressure on Trigger is maintained, andGun reRses to fire owing to Empty Magazine-

NoTE.-Thc .800 Amt>ricnn type) Lcwis Gun hasCocking Handle on left side of Body. To pullback Cocking Ilaml.le left hand must thereforeLe used.

3C.H. will be in Forward Position, and Gun willbe Unloaded Automatically.

N.B.-An Empty Magazine rotates freely on EMPTYthe Gun f resistance is met with, this MAGAZINEis caused by a Live Round coming upagainst the Cartridge Stop on the FeedArm.)Ill

A. NORMAL-viz., at a Firing Position or whenFront is clear.1. Remove Magazine.2. Raise Butt into shoulder and press Trigger,and repeat i .e., pull back C.H. and press Trigger)for safety.Gun is now Automatically Unloaded.

B WITHOUT FIRING, or when CHAMBER isnot Clear1. Pull back C.H.

2. Remove Magazine.3. Depress Ba c;e of Live Round under CartridgeGuide with Point of Bullet or Stripping Tool),and draw Bullet of Round forward until its Pointrests a bove Opening in F eed Arm.4 . Hold C.H. back with Right Hand, pressTngger with Left, and allow C.H. to come half-way forward. Bolt will then tap Base of Roundclear of Cartridge Guide and underneath CartridgeStop.Pull back C.H. to full extent, and releasepressure on Trigger. Round can now be removedeasily.

To UNLOADNormal

To UNLOADWITHOUTFIRING

-

8/12/2019 Lewis Gun Mech

6/20

Action ofGASES.

PISTONROD.

Action ofRETURNSPRING.

STRIKERPOST.

SAFETYLOCKINGDEVICE.

45. Press Trigger.N.B.-Above is the method recommendedfor Unloading without Firing.)

VACTION of MECHANISM described in detail,giving Names of each Part and how they Function.All Parts shown in the Diagrams I, II and Ill ,and in the other Diagrams, are numbered alike.

ACTION of MECHANISM during the BACKWARDMOVEMENT.When a round is fired, the gases force theBullet (1) up the barrel : a portion of themescapes through the Gas-Vent 2) into the Gas*Chamber 3) and Gas Regulator (4),* thence intothe Gas Cylinder 5), where they strike against theHead 6) of the Piston Rod, forcing the PistonRod 7) to the rear.As the Piston Rod travels backwards theTeeth on the Rack 8), being engaged with theTeeth on the Pinion 9), rotate the Pinion and

wind up the Return Spring 10).The Striker Post 11 , being one with the PistonRod, an d si tua ted inside the Cam Slot (12) , movesback a distance of 1 inches along the straightportion of the Cam Slot.

N.B.-This is a device to insur e Locking ofthe Bolt until the Bullet is clear of theMuzzle.) NoTE.-Gas Chamber of .300 Gun has also a GasChamber Gland. Gas Regulator has 4 holesNos. 1, 2, 3, 4) varying in size. .303 Gunhas 2 holes only. Smallest hole that givessufficient gas should be used.

The Rear of the Striker Post then pressesagainst the Curved Part (13) of the Cam Slotand rotates the Bolt (14) to the Left, thus re-leasing the Lugs (15) on the Bolt from the LockingRecesses (16) in the Body.

The Lugs are now clear of the Recesses and inline with the Guide Grooves 17), which run alongthe inside of the Body. The Rear of the Str;kerPost then comes against the Rear end of tht CamSlot, and the Piston Rod, continuing on its badward travel, thus carries the Bolt to the Rear.1N oTE.-When the TRIGGE'R is pressed. titPiston Rod is ab le to run free during both 13ackward and Forward Movements--i.e., th . Bent(18) behind the Rack passes over the Nose HJof the Sear 20) , which is kept dep ressed.When the TRIGGER is released the Bent ridesover the Nose of the Sear towards the end of theBackward Movement; when the Bent oassPd,the Sear rises again under the influence ol the*Trigger Spring 21 , and engages with th e Bentdirectly after the commencement of th e Forward

Movement.)Th e two Extractors 22) on the Bolt withdrawthe Empty Case (23) from the Chamber (24) videF1g. I l l .The Left Lug 25) vide Fig. VI) on the RearEnd of the Bolt (26) moving to the Rear , pushesthe Tail 27) of the Ejector 28) out of the Boltway, and, the Ejector being pivoted, the Head(29) swings in and ejects the Empty Case throughthe Ejection Slot.The Feed Arm Actuating Stud 30} working in

BackwardMovementcontinued)BOLT andLOCKINGLUGS.

SEAR.

EXTRACTORS.

EJECTOR.

the Grooved Tail (31) of the Feed Arm (32), F.A.A.S. and NoTE.-The .300 Gun has the Spring itted to the Sear, FEED ARM.and not to the Trigger, as in the .303 Gun.

-

8/12/2019 Lewis Gun Mech

7/20

BackwardMovementcontinued)

FEED ARMPAWL.

MAGAZINE.Mechanism,videFig. VIII.)

LIVROUND.

No. 2RIGHT)STOPPAWL.

No. 2LEFT)STOPPAWL.

6carries the Feed Arm across to the Left videFig. IV).

The Feed Arm Pawl 33), being engaged behinda Projection 34) on the Magazine, and beingcarried across with the Feed Arm, thus rotatesthe Magazine one space to the Left.

In the Magazine a Live Round is forced downthe Slope of the Centre Block until the Bulletend is clear of the Lip, when it drops on to theBody and into the Cartridge Opening in theFeed Arm, being assisted down by the ProjectingTongue 35) of the Body Cover.The Round is carried to the Left and forcedinto position under the Cartridge Guide) by theIndentations 36) and Separating Pegs 37) inthe Magazine, assisted by the Right Side ofthe Cartridge Opening in the Feed Arm.The Feed Arm Pawl Spring Retaining Stud 38),moving to the Left across the Face of the No. 2

Right) Stop Pawl 39), allows the latter to comeforward [under the influence of the Stop PawlSpring 40)] and engage n front of a Projection41) on the Magazine, thus preventing the Magazine from rotating too far in the feeding direction.The No. 1 Left) Stop Pawl 42) is pressed backas a Projection on the Magazine rides over it , butit cumes forward again when the Projection isclear and engages behind it, thus preventing theMagazine from counter rotating.

FEED ARM At the end of the Backward Movement theTAIL STUD. Feed Arm Actuating Stud disengages from the

7Grooved Tail of the Feed Arm, which is held inposition ready for the next Forward Movementby the Positioning Stud on the tail of the FeedArm engaging with the Left Side of the TopLocking Lug on the Bolt.

VACTION of MECHANISM during FORWARDMOVEMENT.[For Position of Mechanism at commencement ofForward Movement, see Fig. 1 ]

When the Gun is Cocked the Return Spring isheld compressed by the Nose 19) of the Sear 20),being engaged n the Bent 18) in rear of the Rackon the Piston Rod.On pressing the Trigger, the Nose of the Searis released from the Bent, and the Return Spring10) comes into play and rotates the Pinion 9).The Teeth of the Pinion being engaged with

the Teeth on the Rack 8), the Piston Rod 7) isdriven forward.The Striker Post 11 , being now held n theRear end of the Cam Slot 13) in the Bolt 14),tries to rotate the Bolt, but cannot, owing to theLugs 15}, which are prevented from turning inthe Guide Grooves 17).The Bolt is therefore carried forward by theStriker Post.

ForwardMovement.Action o

SEAR andBENT.

PINION andRETURNSPRING.

STRIKERPOST andBOLT.

The Feed Arm Actuating Stud 30) is also car- F.A.A.S. andried forward with the Bolt, and, riding inside the FEED ARM.Grooved Tail 31) of the Feed Arm, carries theFeed Arm 32) over to the Right vide Fig. V).

-

8/12/2019 Lewis Gun Mech

8/20

-

8/12/2019 Lewis Gun Mech

9/20

10M G ZINE 2. The Pan is now able to rotate, and the Centreon thet.Gu:) Block is forced to remain stationary by the Keycon tnue on the exterior of the Magazine Post, which fits

into the Keyway on the Centre Block.

GASESandCOOLINGSYSTEM.

3. The Pan rotating with the Inner Ringaround the Centre Block causes a round to becarried by the Indentations and Separating Pegsfree of the Lip at the end of the Spiral Channelin which the Bullet end lies.4 The Round then falls out, being e n s ~ ~ dfalling by the Tongue of the Body Cover.

VIIACTION of GASES and COOLING SYSTEM videFig. Ill).

When a Round has been fired, the Bullet isforced up the Barrel by the Gases which pass outof the Muzzle and expand, striking against theCone-shaped Interior of the Barrel Mouthpiece48), which concentrates them and increases theirpressure.Passing out of the Barrel Mouthpiece, theymeet, rebound, and strike against the ForeRadiator Casing 49) about It inches from theend), expelling all the Air in front of them.This causes Suction behind them , and drawsCool Air through the Flanges 50) of the Radiator.The Radiator, being made of Aluminium,which is a good conductor of Heat, and being inclose contact with the Barrel throughout itslength, quickly draws the Heat from the Barrel,and thus cools the Gun.N.B.-Note the shape of the Fore RadiatorCasing, which is tapered, and thus assists inexpelling the Air and increasing the Suction.)

NOTE.-The .300 American type) Lewis Gun-as issuedto the Home Guard-has no Radiator or RadiatorClUiing and is therefore similar in appearanceto the Lewis Gun as used by the R .A.F.

11VIII

1 Withdraw Pistol Grip with Right Hand,thereby allowing Pi nion Pawl to engage in Teethof Pinion. At the same t im2. With the Left Hand press up Pinion Casing,so that the Teeth of the Pinion are engaged withthe Teeth on the Rack.

3. Draw back Cocking Handle the requireddistance.4. Release Pinion, and replace C.H. in theforward position.5. Reassemble Pinion and Pistol Grip.6. Weigh Return Spring with the SpringBalance.NoTE.-Care must be taken to hold Pinion uptip ht wlule drawing back C.H. by placingleft thumb over top of Body and fingersunder Pinion Casing, or damage may hedone to the Te1 th of Rack or Pinion. Toavoid possibility of this occurring whenadding considerable Weight, pull backC.H. about 2 inches only two or threetimes.)1 Withdraw Pistol Grip and allow Pinior>Casing to drop, so as to disengage Pinion with

Rack.2. Draw back C.H. the required distance 1 mcbgives 2 to 3 lbs.).3. Press up Pinion Casing (with Left Hand)to engage Pinion with Rack.4. Push Pistol Gnp home to connect withPinion Pawl ; Piston Rod then flies forward, and

Rack unwinds Return Spring.5. Reassemble and Weigh Return Spring.

ToINCREASETENSION ofRETURNSPRING.

ToDECREASETENSION ofRETURNSPRING.

-

8/12/2019 Lewis Gun Mech

10/20

POINTSBEFOREFIRING

POINTSDURINGFIRING

12IX

I.-POINTS which should always be carriedout BEFORE FIRING1. Remove oil from Bore and Gas Cylinder

(if oily). All gas parts to be absolutely dry.2. Oil all Frictional Parts behind Body LockingPin, and smear Bolt and Striker Post withgraphite grease.3. Weigh and adjust Return Spring (normally12 to 14 lbs. with C.H. in Forward Position).4. Test Feed Mechanism i.e., the Pawls).5. Make sure that Barrel Mouthpiece andClamp Ring are screwed up tight.6. Examine Magazines and Ammunition whenfilling.7. Examine Spare Parts and adjust SpareReturn Spring to same tension as that on the Gun.8. Examine Mounting to see wheth er in goodorder, correctly fixed on, and firm in the ground.

H.-POINTS DURING FIRING-i.e. to becarried out during aTemporary Cessation of Fire.1. Replace empty Magazines in carriers, andsend back for Refilling.2. Sl igh tly Oil as in Point 2 ( Before Firing ),especially Bolt, Striker Post, and Maga:tine Post(owing to Heat caused by firing).3. See that Clamp Ring is tightly screwed up.4. Examine and, if necessary, adjust Mounting.5. Turn Gas Regulator slightly to preventseizing of threads.6. Weigh Return p r i n ~7. Place a Full Magazine on the Gun andReload.

13IlL-POINTS toFIRING

be carried out AFTER POINTSFTERFIRING

1. Immediately after FIRING -1) Unload and clear Gun.2) Release Te nsion off the Return Spring.3) Clean Barrel, leaving Oily.

2. In Billets or after return from Firing4) Strip down Gun , c1ean thoroughly,.and Oil. (Clean Barrel with BoilingWater, if available.)(5) Clean and scrape Fouling off GasChamber, and all Gas parts.(6) Examine, dry and Oil Magazines.7) Examine and Clean Mounting.8) Carry out any necessary Repairs.9) Clean Barrel thoroughly da ily for atleast ten days, leaving Ouy.(10) Enter up approximate number ofRounds fired, Breakages and num-ber of Barrel used in ~ u n 's HistorySheet.

CARE and CLEANING Notes1. Never put too much Oil on the FrictionalParts, as they work better with a little, especially

in cold weather.2. Oil n Gas Cylinder causes Fouling, andrenders Gun very liable to Frictional Stoppages.3. To clean Gas Parts, use Mineral BurningOil (Paraffin); this will reduce Fouling Stoppagesto a minimum.4. Clean Gun daily in damp climates ; weeklyin dry atmospheres.5. In Gas affected areas, or where Gun hasbeen sprayed with Gas, clean thoroughly withPetrol or Paraffin. Burn all rags used.

CLEANINGNOTES

-

8/12/2019 Lewis Gun Mech

11/20

STOPPAGES.

TEMPORARYSTOPPAGES.

PROLONGEDSTOPPAGES.

POSITIONof C.H.

14X

NOTES on STOPPAGES.1. In common with other Automatic Guns, theLewis Gun is liable to Accidental Cessation ofFire or Stoppages.The object of the Lewis Gunner is to get theGun firing again in the shortest possible time.2. Roughly, about 90 per cent. of p ll Stoppagescan be rectified at once by the application of whatis known as " Immediate Action. Others can beremedied quickly by Examination of the Gun, athorough knowledge of Mechanism, and practicein rectifying Stoppages.3. STOPPAGES may be either TEMPORARYor PROLONGED.1) Temporary: Those which can be curedby Immediate Action; these aregenerally due to neglect of the Points

to be observed Before During or AfterFiring.(2) Prolonged: These involving strippingdown the Gun to remove a jambcaused by Breakage, or to rectifyany failure in the Mechanism whichcannot usually be carried out underFire, and which put the Gun out ofAction for a more or less prolongedperiod.4. In any STOPPAGE the COCKING HANDLEstops in one of two different POSITIONS known

a s lst Position2nd Position C.H. is fully forward.C.H. in any po >itionbetween 1st (as above)and Gun fully cocked.

15Knowledge of the Causes of Stoppage peculiarto each position, and how to rectify them in theshortest possible time, is essential.N.B. These Positions can be quickly deter-mined by TOUCH as followsWith Butt in Shoulder, raise Fingers (extended)of Right Hand straight up from the Pistol Grip.f C.H. is felt t the Tips of the Fingers1st Position.f C.H. is felt on any other part of he Hand2nd Position.

5. When STRIPPING a GUN to clear a STOP-PAGE take care not to alter the Tension on theReturn Spring. Whenever possible, see thatC.H. is forward before removing or replacingPistol Grip.Correct way to remove the Bolt. Take off Butt-Hold up Pinion with Left Hand-DisengagePistol Grip--Drop Pinion-Pull out Piston Rod.Caution. Bolt will not go into Boltway -

(1) Tail of Ejector protrudes into Boltway.(2) Rear End of Bolt is not properly screwedup.6. To remove a Separated Case from theChamber use of the Clearing Plug is necessary, asfollows:-To remove Separated Case:

(1) Insert tapered end of Clearing Plug intoChamber, with centre pin pushed back.(2) Press Trigger, allowing Bolt to forcecentre pin forward.(3) Give Clearing Plug Handle an up-anddown rocking motion.

POSITIONFOUND BYTOUCH.

NOTE ONSTRIPPING.

HOW TOUSECLEARINGPLUG.

-

8/12/2019 Lewis Gun Mech

12/20

HOW TOUSECLEARINGPLUGcontinued)

IMMEDIATEACTION.

FURTHERACTION.

164) Pull back C.H., and withdraw ClearingPlug from Chamber.5) Press Trigger, load, and carry on Firing.6) To remove Separation from ClearingPlug, knock centre pin back.

IMMEDIATE ACTION.7. Definition.-The initial attempt to remedythe Stoppage and get the Gun firing again asquickly as possible.First Always feel for Position of CockingHandle.1) f in 1st Position. Rotate MagazinePull back C.H.-Relay Gun, and carry

OD Firing.2) f in 2nd Position. Pull back C.H.Counter-rotate Magazine-Relay Gun,and carry on Firing.

This application of Immediate Action must bepractised until it becomes a habit. t should beInstantaneous and Automatic.8. f IMMEDIATE ACTION fails to remedy theSTOPPAGE, proceed at once to apply any furtherAction that may be necessary to get the Gunfiring again, as follows :-After application of IMMEDIATE ACTION-Again Feel for Position of Cocking Handle.

1) C.H. again stops in 1st Positiorz.-Proceed t oa) Remove Magazine.b) Examine Feed Mechanism i.e., thePawls).c) Pull back C.H., and examineStriker.

172) .C.H. again stops in 2nd Position. Pro-ceed t oa) Pull back C.H.

b) Remove Magazine.c) Examine Chamber, Ejection Opening, Cartridge Slot and Guide.Any further Action which may still be necessarywill be found in the TABLE OF STOPPAGESColumns 4 and 6).9. The following TABLE OF STOPPAGESpages 19 and 20 is arranged in TWO Sections

A) Giving PROBABLE STOPPAGES, whichare cured by IMMEDIATE ACTION,ndB) Giving POSSIBLE STOPPAGES, forwhich FURTHER ACTION is neces

sary.FirstLearn how to recognize and rectify allStoppages in Section A before proceeding toSection B. Those in Section B should o urvery seldom.

Column 1 shows Position of Coclcing Handle.Column 2 emphasizes the importance of

Immediate Action.Column 3 gives the Result of Applying Im-mediate Action.Column 4 shows How to Remedy the Stoppage.

Column 5 indicates the Cause of the Stoppage,Column 6 gives any Fmther Action or Informa-

tion not already indicated.The Abbreviations LA. and C.H. indicateImmediate Action and Cocking Handle r s p

tively.

FURTHERACTIONont nuecl)

EXPLANATIONOFTABLE OFSTOPPAGES.

-

8/12/2019 Lewis Gun Mech

13/20

STOPPAGES.HowArranged.

IMPORTANCEOF GOODAMMUNITION.

MULTIPLELEWISGUNS.

1810. STOPPAGES in the TABLE are numberedconsecutively, and arranged-

( ) According to Position of Cocking Handle.(2) In order of Probability.

Note.-Order of Probability of Stoppages in theTABLE was originally compiled as a result ofexperience gained in the War of 1915-18, on manyfronts. From 1915 onwards, and for many yearsaf terwards, vast quantities of Ammunition ofFaulty (Foreign) Manufacture were used, causingBreakages, Blowbacks and Burst Cases.l l . With good Ammunition of British make,very few Stoppages that are not cured by ImmediateAction should be incurred-especially if thePoints Before, During, and After Firing are dulycarried out.STOPPAGES during the PRESENT WAR._.cc01ding to information recently received (October, 1940) extremely few Stoppages are nowincurred.12. The use of Lewis Guns in pairs (preferably

used a lternately), or in multiple form , increasesVolume of Fire and also minimises the importance of Stoppages.

19~ e - g . : ~ t 5 . s ~ : :8c ~ ~ ~ ~ ~ ~ u . o ~ d s ' i i ~

.: 1 ~ . s ~ g ; i T ~ ~ ~ ~ rJ.:; I "' . ... -:; o r ..,eoCD E gq ~ e = o . c o . ~ 0 :::1 ; 0z .. Q)'N - Cl."C "0 - z g c . , : ( ~ CU"'' :5'= gJ, a . : f ~ . 1 """ ~ ~ ~ P l E ifj~ ~ ~ ~ ~ ~ ~ ~ ~ ~ $ ~ E ~ e ~cC i :IZ Z ;:::: : : : lp: ;

oS o< t4 l< Q I :ll

.,;tl"0'0;;:"'0cii.,.0

Il l .. . I I I IQ -.; .. 0:::, ::l 8 ~ . . '0Ll.l :: : cS .3 0 . 0 . , _ , f:< '.sCi I a. ~ 0 1 9 ....... . , ~ : ; 3 6 = M Fo1: ~ ~ ~ " 0 ~ ' ~ ~ - 8 JJ:a ; j A ~ :; :: 8 ~ : : 8 ::l g g.;;> ~ l ~ l:q m lXI::;Q I - < > ~ > - . .... . I I' V :g .:: g,.c : : : . ~ < 0 .D: I . r-t &.. - = = 4 u 1--4 . , ~0 1-t M ~ ~ ' E ~ ~ 81 ..,. ... ~ > > ' ~ > > .o_ u 8-. . .o :I ~ > >eh 0 & "0 ' d ~w o= 4) u . , c i = ' 3 ~ c>o:;;8 .,( I :z: "' l3 .c l3 lJ ..: .. 0 ' l3 l3cC 0 0 0 0 0 0 0

.g"0

.,;:0"c.c::c

I ~ , 9 3 8 .9 ge ..; 0 . :: e ~ = ~ ~ . s a . /l)~ : : : 0 ~ : ; - > . ~ . ,1.1 Q.C _ 8 ~ ~ ~ . , , .a ~ o c S

..I : : 8 ~ ~ 8g ... ~ ~ ~ ~ c;a:fl M-, L.o:zt o..., :z3 ... 0 0 ._. _ O,o " =:'< C) g} . , eo ~ u . 8 ~ ~ > - O ~ lf ~ b t ga:t . 3J t .g_bij.,'i: ac; .3 ~ . 90 E :;o ..,.SZ ~ ~ 1 > - B ~ g ~ F :1 cu- mIll: :rll g :; -s.g oo;::l g r : . ~ 3'2.:ao=o o o o o;::l .. - - 8c c . . - ~ ~ . . . :I l l .. < "i --; --;.8 >. ". ..., ""' c

. . . u .....t 1-4 " " " " ' ~ = ~ o o t ~ s : : l - Cl' ~ ~ ~ ~ "'cC gI I I 1 c .o:Z:.:;:: .-:: I Ea.o ..,:: ..... '0ll '0tl.El ...,c-