Lecture 3 feldspar group and its application

-

Upload

hassan-harraz -

Category

Education

-

view

5.206 -

download

1

description

Transcript of Lecture 3 feldspar group and its application

- 1. Topic 3: Feldspar Group A short series of lectures prepared for the Third year of Geology, Tanta University2012- 2013byHassan Z. [email protected] April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups1

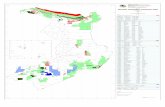

2. OUTLINE OF TOPIC 2: Introduction Structures Compositions Chemistry Properties Phase Relationships Feldspar Resources Possible substitutes of feldspar Feldspar Products Terminology Feldspar Beneficiations Processing Technologies Feldspar Application7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 2 3. Introduction This group of minerals consists of framework tectosilicates. Feldspar is the most common rock-forming mineral (~ 60% of the earths crust) (Kauffman and Van Dyk, 1994). The mineral name feldspar is derived from the German words feld + spar. The word "feld" is "field" in German and "spar" is a term for light colored minerals that break with a smooth surface. The feldspars are by far the most abundant group of mineralsand are found in igneous, metamorphic and many sedimentaryrocks and thus can be found throughout different geologicalenvironment. It is more commonly found in igneous and metamorphicrocks. Feldspar minerals are essential components in igneous, metamorphicand sedimentary rocks, to such an extent that the classification of anumber of rocks is based upon feldspar content.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 3 4. Structure Felsdpars are framework silicates whereeach silica tetrahedra share all cornerswith its four neighbouring tetrahedra. A portion of the tetrahedra contain Al3+instead if Si4+. The charge is balanced by incorporatingNa+, Ca2+ or K+.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 4 5. Framework silicate (feldspars): all corners shared; no octahedral sites.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 5 6. Feldspars are tectosilicates with every oxygen atom shared by adjacent silicon or aluminum tetrahedra. The tetrahedra are arranged in four-member rings that are stacked to form crankshafts parallel to the a-axis of the monoclinic or triclinic structure. The crankshafts are joined together in an open structure with large voids to hold the alkali metals K+ or Na+, or the alkaline earth ion Ca++ .7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 6 7. High Sanidine is fully disorderedwith a statistically random Al-Sidistribution: each tetrahedron has,on averaging over a reasonablevolume, 0.25 Al atoms and 0.75 Siatoms. The Al+3 can be anywhere. Low Sanidine and Orthoclase are more ordered. For these minerals to be monoclinic, the center of symmetry in each ring must be preserved. At still lower temperatures, the Al+3 will be completely ordered: always on the two t1 tetrahedra. This ordering will destroy the center of symmetry and the mineral will become triclinic Microcline.Looking down the a-axis7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 7 8. 7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 8 9. Looking down c-axis7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 9 10. Compositions A second group of alumino-silicates, tetrahedra form three-dimensional frameworks with Ca, Na and K as the balancingcations Feldspar is a common name that applies to a group of minerals with a general chemicalformula of: xAl(Al,Si)3O8 where: x can be sodium (Na) and/or calcium (Ca) and/or potassium (K).Chemically, the feldspars are silicates of aluminium, containing sodium, potassium, iron, calcium, or barium or combinations of these elements.Most deposits offer sodium feldspar as well as potassium feldspar and mixed feldspars. The term feldspar encompasses a whole range of materials.The mineralogical composition of most feldspars can be expressed in terms of the ternary system Orthoclase (KAlSi3O8), Albite (NaAlSi3O8) and Anorthite (CaAl2Si2O8).Compositions of major elements in common feldspars can be expressed in terms of three endmembers: Potassium-Feldspar (K-spar) endmember : KAlSi3O8 Albite endmemberNaAlSi3O8 Anorthite endmember CaAl2Si2O8 Feldspar are subdivided into: K-Na bearing alkali feldspars and Ca-Na solid-solution series called the plagioclase feldspars.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups10 11. 7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 11 12. Alkali FeldsparsSanidineThe K-feldspars or alkali felspars: Microcline: Potassium aluminum silicate Sanidine: Potassium sodium aluminum silicate Orthoclase: Potassium aluminum silicate7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 12 13. Alkali Group [Orthoclase] [Albite] 1) Sanadine (K,Na)AlSi3O8 monoclinic high temperature Al randomly distributed often see carlsbad twinning 2) Microcline (K,Na)AlSi3O8 triclinic much more ordering of Al in the structure any heating will randomly redistribute the Al often see tartan twinning7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 13 14. At low temperatures solid solution(ss) is unstable, ss exsolves toAlbite + Microcline. We say the twophases are immiscible Triclinic K-spar MicroclineAlbitePerthite (albite exsolution in microcline)7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 14 15. Limited Solid Solution and Subsolidus Exsolution: e.g. Alkali Feldspar Increasing Pressure7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 15 16. TWO-COMPONENT SYSTEM WITH SOLID SOLUTION, A EUTECTIC AND A SOLVUSPLAGIOCLASE AND ALKALI FELDSPAR SOLID SOLUTION WITH A EUTECTIC Subsolidus Solvus Perthitic Exsolution7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 16 17. Two-Component System with a Solvus Pressure EffectsIncreasing Pressure7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 17 18. Plagioclase Feldspars Series Essential minerals in mostigneous, sedimentary, andmetamorphic rocks Complete (temperaturedependant) solid solutionbetween: Albite (NaAlSi3O8) Anorthite (CaAl2Si2O8) Minor solid solution of K+increasing withincreasing Ab content187 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 18 19. Plagioclase Feldspars Series (Cont.) Plagioclase series: complete solid solution Because of the similarity inionic radius between Na+1(0.95 ) and Ca+2 (0.99 ) Isomorphous solid solutionbetween end members Coupled substitution (CaxNa1-x)(Al1+xSi3-x)O8 Ex: Ca.20Na.80(Al1.2Si2.8)O8 Oligoclase7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 19 20. Plagioclase Feldspars Series (Cont.) In the plagioclase series, there is usually high and low temperature structuralstates. At high temperatures the structure remains the same over thecomplete solid solution. e.g., anorthite has the same structure as high albite. This would be the case for rapidly quenched volcanic rocks. At lower temperatures the series is often not continuous but containsstructural divisions (due to position of Al in the crystal structure).An0-3, Ab97-100 low albiteAn3-22,Ab78-97PeristeritesAn22-73, Ab27-78Intermediate StructureAn73-100 Ab0-27 Anorthite Structure Peristerites: sub-microscopic intergrowth of Na rich and Ca rich phases withalternate low albite structure and intermediate structure. Optically peristeritesproduce a schiller (iridescent) effect on cleavage surfaces. If you reheated these low temperature inhomogeneous mixtures you would get a member of the series with high albite structure. All the Plagioclase is triclinic but in High Albite, the position of the Al is random, while in Low Albite the Al position is more ordered and fixed.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 20 21. Properties Feldspar minerals are usually:i) They usually crystallise in the monoclinic or triclinic system. The crystalline structure of feldspars consists of an infinite network of SiO2 and AlO4 tetrahedra.ii) white or very light in color andiii) have a hardness of 6 on the Mohs Scale of Hardness andiv) perfect to good cleavage (plane of breakage) in two directions.v) Another physical property of the feldspar group is that the mineral has good cleavage in two directions. The cleavage breaks are about 86o for plagioclase feldspars (albite, oligoclase, andesine, labradorite and anorthite), at 90o for orthoclase and 89.5o for microcline.vi) Feldspar weathers to kaolin which is the main clay mineral used in ceramics and fine pottery.Feldspars are primarily used in industrial applications for their alumina and alkali content.Most of the products we use on a daily basis are made with feldspar: glass for drinking, glass for protection, fibreglass for insulation, the floor tiles and shower basins in our bathrooms, and the tableware from which we eat. Feldspar is part of our daily life.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 21 22. Optical and Physical Properties Plagioclase Colour: Colourless Form: Laths or euhedral xtls RI, Bire, 2V and Optic Figure: All vary systematically with composition. Cleavage: 3 directions (two good) Extinction: Varies with composition. Twinning: Albite twinning present 227 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 22 23. Compositional Zoning (Oscillatory)7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 23 24. Plagioclase Composition from Albite TwinsAlbite twins inPlagioclasereveal solidsolutioncomposition. Albite Twinning7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups24 25. Alkali Feldspars Colour: Colourless Form: Phenocrysts or euhedral to anhedral crystals Relief: Low Birefrincence: Weak Cleavage: 3 directions (2 good) Interference figure: Biaxial negative 2VAngle: Varies with composition Extinction: Varies with composition and axial plane Twinning: Carlsbad, Albite and Pericline can be present7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 25 26. Chemistry The feldspar group approximates a ternarysystem consisting of three components: Albite,Anorthite and Orthoclase. There are continuous and limited solid solutionbetween the three groups. Plagioclase -solid solution (continuous) betweenAnorthite (CaAl2Si2O8) and Albite (NaAlSi3O8). Alkali feldspars -solid solution between Albiteand Orthoclase (KAlSi3O8) is limited (dependenton temperature).7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 26 27. Plagioclase Feldspar Solid Solution Series There is a complete solid solution between Albite and Anorthite. Intermediate phases are Oligoclase, Andesine, Labradorite and Bytownite. The amount of water in the melt PH2O will change the crystallization range of plagioclase e.g., PH2O of 5000 bars will drop the crystallization temperature of Anorthite from 1553C to 1234C.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 27 28. Alkali Feldspar Solid Solution Series1) Volcanics -rapidly quenched, at very high temperatures getHigh AlbiteSanadine. It would appear to be uniform(homogeneous) in thin section.e.g: Or25 Or60 on Fig 46. However,submicroscopically, every crystal has twocomponents: Laths of plagioclase in a sanadinehost. X-ray diffraction would show two peaks.2) Plutonic -called PERTHITES if they can be seen(cryptoperthite appears homogeneous). They consist of Na richplagioclase intergrowths in K rich feldspar host (Fig 34 handout). low albite -Microcline Or20Or80 Perthite most common Perthite is orthoclase or microcline hostwith albite lamellae. Called Antiperthite If you haveAlkali feldspar in a plagioclase host.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 28 29. AlterationThe feldspar chemically weather to kaolinite.Sericite (a mica) is also an alteration product of feldspars.The feldspars often have a dirty or dusty appearance when altered.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 29 30. Phase Relationships First examine the Alkali Feldspar Series (Or-Ab)7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 30 31. Alkali Feldspar: Miscibility gap Alkali Feldspar: Miscibility gap Because of dissimilarity in size between the Na+1 (0.95 ) and K+1 (1.33 ) complete solid solution occurs only at high temp Wrong size bricks results in alkali feldspar polymorphs Single alkali feldspars formed at high temp exsolve (unmix) at lower temp (if slowly cooled) Orthoclase-rich-> perthite Albite-rich-> antiperthite7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups31 32. This diagram (Fig 6-4a) is for 1 atms and a dry melt (no H2O). a) There is a minimum temperature E (eutectic) that all melts move towards. Example: Melt of composition O cools and hits the liquidus at point P. Start to crystallize crystals ofcomposition C. As cooling continues the melt becomes more Ab rich. The final product ishomogeneous crystals of phase D. Only a melt of eutectic composition would ever crystallize E. b) What happens when the temp drops below the solidus? There is no longer complete miscibility in thealkali feldspar series. c) At lower cooling temperatures we get immiscing in the middle range of feldspar compositions into 2separate solid phases. This occurs below the area called the solvus and where immiscing occurs,defines the solvus line. d) Any quick cooling would freeze the reactions and immiscing would not occur. e) The exsolution of K rich phase results lamellae. The slower the cooling, the more time for diffusionand exsolution and the larger the lamellae. Figure 6-4b and Figure 20. When a melt contains H2O the fields of the phase diagrams change drastically.i) The leucite field disappears with increasing H2O. Only occurs in volcanics (quenched).ii) Crystallization temperatures are reduced.iii) Composition changes continuously along liquidus-solidus during cooling.iv) On Figure 6-4b a liquid L cools to N. At point N crystals of M form. The liquid cools and changes to E while the crystals change to composition D. This is the limit of the solid solution. At E, the eutectic you get crystallization of two solids D and F until all the melt is used up. Coolingcontinues. The composition of 2 stable, co-existing phases would occur along the solvus from DGJand FHK. Na and K end members. Get lamellae. Perthite intergrowths should occur, but aredependent on the kinetics of diffusion of K and Na ions in the solid media. Kinetics are slow with lowertemperatures. Slow cooling in nature usually does not produce perthitic intergrowths. Usually twoseparate feldspars will occur.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups32 33. Remember the Plagioclase solid solution series (An-Ab), Figure 4-4. If water is added, the wholecurve is depressed by300C. If pressure fluctuates,you get zoned crystalsCa Na7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 33 34. Eskola Experiment Took Ca plagioclase, added crushed SiO2, H2O and soda (NaHCO3) and heated to 300Cfor three days. The result was that much of the plagioclase had converted to albite. Therefore, in many low temperature and metamorphic rocks, albite is a stable endmember. [Implications to hydrothermal, seawater regional metamorphism]. Ca plagioclase is the high temperature end member. Now lets look at the system NaAlSiO4-KAlSiO4-SiO2 There is no solid solution between these end members. They are simple binary eutectic systems.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups34 35. Note, however, that there is the complication of incongruent melting in the Leucite-K-feldspar portion of the right diagram. Point R is a Peritectic. Leucite is not stable in the presence of melt below 1150C and will undergo the reaction:KAlSi2O6 + SiO2 KAlSi3O8(leucite) (quartz)(k-feldspar) This phase diagram is similar to the Forsterite- Enstatite-Silica system we looked at before (previous handout Figure 13-7). Depending on the original composition we can end up with K- feldspar and Quartz or K-feldspar and Leucite. BUT, we can not end up with Leucite and Quartz because they are not stable together (the same way olivine and quartz can not occur together).7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 35 36. Examine Figure 8-13 and note some of its complications: Now lets look at the 3-D version of this system : (NaAlSiO4-KAlSiO4-Si2O)1) Structure is temperature dependent (i.e., from orthoclase to albite).2) As discussed before, there is limited solid solution at low temperatures but almost complete solid solution at high temperatures.Under low pressure, dry conditions,can get quite a large portion ofleucite (Figure 8-14).7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 36 37. Lets look at an example of a quartz rich melt. Initially tridymite (quartz) crystallizes. The composition moves along the line to a minimum point where feldspar +tridymite precipitate at T1. After this temperature, the phases are governed by what we say in Figure 6-4 or Figure 20 (ie are pressure PH2O dependent). As temperature drops and moves along the hoop shaped solvus, lamellae form and change composition. This is dependent on ion mobility and temperature. In plutonic conditions (slow cooling) formation of perthite is favoured. If the PH2O is raised, the solidus and liquidus are depressed and the leucite field would shrink and disappear at 5000 atm (Figure 8-14). Also, the addition of iron into the system would cause pyroxene or iron oxides to crystallize (Figure 8-15).7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 37 38. In general:a) Silica saturated compositions end crystallization at the minimum along the SiO2-Feldspar join (Peralkaline, oversaturated rocks).b) Silica undersaturated compositions end crystallization at the Ternary Eutectic (syenites and trachyte) (Figure 8-12).7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 38 39. 7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 39 40. Feldspathoids (Si-poor)Common in Alkaline (Si-undersaturated) igneous rocksLeucite KAlSiO4Nepheline (Na,K)AlSiO4Sodalite Na8(AlSiO4)6Cl27 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 40 41. Scapolite Hydrous TectosilicatesAnalcime (Scapolite Gp)NaAlSi2O6H2ONatrolite (Zeolite Gp)Na2Al2Si3O102H2OHeulandite (Zeolite Gp)CaAl2Si7O186H2OStilbite (Zeolite Gp)NaCa2Al5Si13O3614H2O7 April 2013 41 42. Feldspar Resources Feldspar raw materials are rocks with the prevalent portion of minerals of the feldspar group or their mixtures in such a form, quantity and quality, which allow their industrial processing. Feldspars are a group of monoclinic (orthoclase, sanidine) and triclinic (microcline, plagioclases) potassium and sodium-calcium alumosilicates, and together with quartz they represent the most common rock forming minerals. For industrial use are suitable are potassium feldspars (orthoclase, microcline) and acid plagioclases (albite, oligoclase, andesite). Suitable feldspar resources are dyke rocks (pegmatites, aplites), igneous rocks (granites) and sediments (feldspar bearing sands and gravel), eventually also residues of incompletely kaolinized rocks. The major impurities are high content of iron in the feldspar structure (unremoveable) or in the form of admixture (removeable). Most often, commercial feldspar are mined from pegmatite or feldspatic (sand) Placer deposits. Aplite, which is a fine-grained igneous rock with the same mineralogical composition as granite, also is mined frequently for its feldspar content. Alaskite is a granitic rock with few or no dark minerals, and a texture ranging from granitic to pegmatic. The average mineral composition of the alaskites is oligoclase feldspar (40%), quartz (25%), microcline feldspar (20%), and muscovite mica (15%). Alaskite also contains minor accessory minerals such as biotite, garnet, epidote, apatite and pyrite. Another source of feldspar is phonolite, the effusive equivalent of nepheline syenite, which contains feldspathoids and biotite? Phonolite is produced commercially in West Germany. In the same country, rhyolite is also exploited for feldspar. Amongst the numerous rocks in which they are present, feldspars are particularly abundant in igneous rocks like granite, which contains from 50 to 70% of alkaline feldspar. Granite is however rarely used for its feldspatic content.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups42 43. Feldspar Resources (Cont.)a) Pegmatiteb) Feldspar (sand) placerc) Aplite Feldspar-quartzmixtured) Nepheline Syenite Potassium feldspare) Phonolite Sodium feldsparf) Granite Feldspar from Pegmatite: The initial production of feldspar was from pegmatite bodies. Pegmatites are bodies of rock commonly of graniticcomposition that consist mainly of unusually large crystals or masses of quartz, feldspar, and mica. Some pegmatites alsocontain potentially economic minerals such as fluorspar, beryl, and spodumene. The constituent minerals may occursegregated in zones, an advantage in commercial extraction. Pegmatites crystallize during the last stages of injection ofgranitic magma. The magmatic fluids are rich in water and cool so slowly that the crystals grow larger than usual. Thegrain size can range from less than an inch to more than a foot but rarely greater than three feet. Pegmatites range insize from small lens, one to a few feet in thickness, to large tabular bodies tens of feet thick and hundreds of feet long. Past production came from the larger pegmatites. Mining was labour intensive. Ore was hand cobbed (hand-size piecesare broken by hammer) and sorted by hand. Conventional open-mining methods including removal of overburden,drilling and blasting, loading, and transport by trucks are used to mine ores containing feldspar. The ore is crushed byprimary and secondary crushers and ground by jaw crushers, cone crushers, and rod mills until it is reduced to less than841 m (20 mesh). A froth flotation process is used for most feldspar ore beneficiation. Feldspar from Placer deposits: Beach sand and alluvial deposits may contain economic quantities of feldspar, and are mine in Spain. Under certainconditions feldspar decomposes to koalinitic clay; if the alteration is only partial, the deposits may contain feldspar,kaolin and quartz.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups43 44. Possible substitutes of feldspar Feldspar substitutes are materials having alkali metalsconfined to other minerals than feldspars, likenepheline syenites or nepheline phonolites (in theCzech Republic). These replace feldspars as a melting agent. In other applications (fine abrasives, filler in rubber,plastics and paints), feldspars can be replaced bybauxite, corundum, diatomite, garnet, magnetite,nepheline syenite, olivine, perlite, pumice, silica sand,staurolite, ilmenite, barite, kaolin, mica, wollastonite,calcined alumina hydrate, clays, talc, spodumene,pyrophyllite or their mixtures.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 44 45. Feldspar Products Terminology: The supplier and user of feldspar worldwide normally have agreed on a standardized definition of the feldspar products which are placed in the world market. According to that harmonised definition, feldspar products are aluminosilicates with: SiO2 content > 58%, Alkali content (Na2O+K2O) > 2%, Alumina content (Al2O3) > 3% and loss on ignition < 3%. Basically, the two properties which make feldspars useful for downstream industries are their alkali andalumina content.On those elements we can distinguishThree families: 1) Feldspatic sand: with an alkali content (Na2O+K2O) < 6% or alumina content (Al2O3) < 8% 2) Pegmatite: with an alkali content (Na2O+K2O) >6% and alumina content (Al2O3) comprised between 8 and 14% 3) Feldspar: with an alkali content (Na2O+K2O) >6% and alumina (Al2O3) content > 14%. A further distinction can be made betweenNote:Sodium, Potassium and mixed feldspars, For the same purposes there are also used feldspardepending on the type of alkali they contain.substitutes, which are rocks with alkali metals confined to some other minerals (mostly nepheline - anhydrous sodium-potassium alumo-silicate). Nepheline syenites are particularly used abroad to substitute for feldspar raw materials.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups45 46. Pegmatites:i) Potash Feldspars: The presence of potash feldspar in a glaze or clay body has a more refractory effect on the ceramic surfacecompared to equivalent amounts of soda feldspar. Although potash feldspar actually begins its melt at a lower temperature than soda feldspar, once the meltbegins, the formation of leucite crystals causes a slower and more viscous flow.ii) Soda Feldspars: Kona F-4 and NC-4 feldspars contain a fair amount of potassium oxide, and their total sodium content is not ashigh as the total content of potassium in potash feldspars. These feldspars are hybrids that incorporate some qualities of both potash and soda feldspars. This is especially evident when theyre compared to stronger sodium materials, such as nepheline syenite.Hence, its often possible to substitute some soda feldspars for potash feldspars without causing a dramaticsurface change.Nepheline Syenite: Nepheline syenite is a low-silica, high-soda, high-alumina mineral referred to as a feldspathic rock. The fluxing power and shrinkage rate of nepheline syenite depends on the grade number. The finest grades (A400 and 700) have the greatest melting power and shrinkage rate and are used in electrical porcelain and by manufacturers of ceramic wares. Grade A270 has a medium melting and shrinkage rate and is the most commonly used form of nepheline syenite in ceramic studios and schools. Grades A40-A200 (used by glass manufacturers) are the coarsest grades and produce the lowest melting and shrinkage rates.Cornwall stone (feldspathic rock): Cornwall stone, also a feldspathic rock, contains more silica and less melter oxides than do the feldspars. Sincesilica has a high melting point, Cornwall stone has a higher melting temperature than the feldspars and appearsstiffer and less melted when fired alone to stoneware temperatures. This is especially apparent at the lower stoneware temperatures. Even the potash feldspars show more fusionat the cone 5-6 oxidation firing temperatures than does Cornwall stone, so this would not be a first choice as aglaze core at these firing temperatures unless a stiffer surface is desired.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 46 47. Feldspar Beneficiations and Processing Technologies Feldspars are either selectively mined or processed by flotation and/or magnetic separation, in order to remove the accessory minerals (e.g. quartz, mica, rutile, etc.) present in the ore. The feldspar may then undergo a milling step which allows to adapt the particle-size to the intended use. The degree of refining and possible milling is very dependent upon the final use of the product. For a number of uses, it is perfectly acceptable, and even advantageous, that the product retains some accessory minerals, e.g. quartz, while at the other extreme some applications require extremely pure and fine-grounded grades. Basically, the two properties which make feldspars useful for downstream industries are their alkali and alumina content. Normally feldspar concentrates should meet the following requirements: To maintain a proper ratio of (K2O+Na2O) to SiO2 To be low in iron content7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 47 48. Mineral processing Feldspars are either selectively mined or processed by optical, flotation and/or electrostatic separation, in order to removethe accessory minerals (e.g. quartz, mica, rutile, etc.) present in the ore. The feldspar then undergoes a comminution step.The degree of refining and possible comminution is very dependent upon the final use of the product. For a number of uses,it is perfectly acceptable, and even advantageous, that the product retains some accessory minerals, e.g. quartz, while atthe other extreme some applications require extremely pure and fine grounded grades. Basically, the two properties whichmake feldspars useful for downstream industries are their alkali and alumina content. The flotation process is only used by AKW, INCUSA, and SP Minerals. The feldspar recovered by flotation only representsabout 10 % of the European feldspar production. The flotation process is essential to get a high quality grade (low ironcontent and high alumina content) required for some specific and important applications (e.g. TV/computer screens). Forinstance, although the Italian producer Maffei is the biggest producer in Europe, the three abovementioned companiessupply the Italian market with these high quality grade products. The essential use of the flotation process may be explained by the following figure:Figure Feldspar particle vs.recovery graph [39, IMA, 2002]In Sections I and III a primary mechanical separation In Section II, either optical, flotation or electrostatic(hydrocycloning, centrifugation) can be achieved. separation can be used to separate feldspar from quartz,depending on both the intrinsic characteristics of the rawmaterial, and the final product requirements.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 48 49. The following flow sheet shows the stepsinvolved in the recovery of feldspar. In the feldspar process, one may distinguish three different flotation steps, namely the micas flotation, the oxides flotation, and the feldspar flotation.Each of these requires a different reagent regime.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 49 50. Feldspar Application Generally, feldspar is used in the manufacture of glass products (70%), in ceramics and other products (30%). Feldspar is also used Filler (in paint, in mild abrasives, urethane, latex foam, and as a welding rod coating).In the manufacture of ceramics, feldspar is the second most important ingredient after clay.Feldspars are an important glaze raw material used as the main flux in ceramic industries.Feldspar is a source for the simultaneous introduction of SiO2, Al2O3, Na2O, K2O and CaO and is the most suitablematerial for introducing alkaline oxides into glazes.Feldspars are used as fluxing agents to form a glassy phase at low temperatures and as a source of alkalis and alumina inglazes.Feldspars play an important role as fluxing agents in ceramics and glass applications, and also are used as functionalfillers in the paint, plastic, rubber and adhesive industries. Because of their low melting point, feldspars are used as a melting agent in ceramic mixtures, glass batches,glazes, enamels and also as casting powders in the last years.Feldspar does not have a strict melting point, since it melts gradually over a range of temperatures. This greatlyfacilitates the melting of quartz and clays and, through appropriate mixing, allows modulations of this important step ofceramic making.Feldspars melt at ~1150oC.The feldspathic glass they produce surrounds the refractory clay particles and fills up the pores between them.Due to the free fluxes they contain, feldspathic glasses will also bind to the surfaces of the refractory particles thushelping to bind the ceramic body together.The more feldspathic glass a ceramic body contains, the denser the fired body will be.They improve the strength, toughness, and durability of the ceramic body, and cement the crystalline phase of otheringredients, softening, melting and wetting other batch constituents.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 50 51. Glazes Defination: Glazes are thin glassy coatings usually 0.15 to 0.5 mm thick formed in place on a ceramic body, after blending the raw materials, spreading the mixture on the surface and firing at a high temperature. Important and uses: Glazes are usually applied to make the bodies non- porous, smooth, glossy, mechanically stronger and chemically more resistance. They improve the aesthetic appearance of ceramic ware glazes are required to fit different ceramic bodies, to mature at different temperatures and to exhibit various specific properties, which explains the great variety of grazes.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 51 52. Feldspar (Naturally occurring forms of devitrified glass) Potassium Feldspar (OrthoclaseorK2O Al2O36SiO2 microcline) Sodium Feldspar (Albite)Na2OAl2O36SiO2 Lime Feldspar (Anorthite) CaO Al2O32SiO2Flux StabilizerGlass FormerEach of the three components of feldspar is discussed below7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 52 53. i) Fluxes The Na2O, K2O and CaO in the above formulas are called alkaline metal oxides because they are strong bases when added to water. These oxides are used as fluxes. Fluxes have very active molecular structures at high temperature, and they attach to and combine with the surface molecular structure of otherwise hard crystalline materials, causing the surface molecules in the crystals to "dissolve". This exposes deeper layers of the crystal to the dissolving action of other flux molecules and so on until the entire crystal melts away. In other words, fluxes cause crystalline structures to melt at lower temperatures than would otherwise be possible, a bit like water melts a cube of sugar at room temperature. Without fluxes present, none of the other constituents in the ceramic body would be able to melt at normally attainable temperatures, and the fabrication of pottery would have been beyond the reach of prehistoric peoples.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 53 54. ii) Stabilizer Aluminum oxide (Al2O3) (Stabilizer). Aluminum oxide exists in two separate forms within clay and porcelain bodies. When chemically combined in molecular form with the other constituents of feldspars, aluminum oxide acts as a stabilizer, and is a part of the glass melt. Aluminum atoms can bond with silicon via a shared oxygen atom and can thus be an integral part of the amorphous silicon matrix. In this form, it does NOT affect the transparency of the glass. However, aluminum oxide is also added to clays as a separate constituent in the form of kaolinite. Because of the large amount of flux contained in the feldspar, some of the kaolinite also melts into a glass, like the feldspar itself. But the by-product left over when the kaolinite melts is a precipitate of pure crystalline aluminum oxide called alumina. The alumina crystals remain unmelted (i.e., they are refractory particles) and scattered throughout the glass melt, and in this form, aluminum oxide causes the glass to become cloudy or opaque.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 54 55. iii) Glass Former Silicasilicon dioxide (SiO2) (Glass Former) Silica is silicon dioxide, The SiO2 portion of the feldspar formulas shown above. Like alumina, silica also exists in two entirely separate forms within clay and porcelain bodies. When chemically combined with flux and aluminum oxide, as it is in feldspar, silica exists as a molecular component in the amorphous melted glass gel. Silica also exists as unmelted crystalline particles of quartz scattered throughout the glass melt. This form is part of the refractory substructure which supports clay and porcelain bodies.7 April 2013Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 55 56. References Bourne, H.L., 1994, Glass raw materials: in Carr, D.D. and others, eds., Industrial minerals and rocks (6th edition): Littleton, CO, Soc. for Mining, Metallurgy and Exploration, Inc., p. 543-550. Kauffman, R.A. and Van Dyk, D., 1994, Feldspars: in Carr, D.D. and others, eds., Industrial minerals and rocks (6th edition): Littleton, CO., Soc. for Mining, Metallurgy, and Exploration, Inc., p. 473-481. Lesure, F.G., 1968, Mica deposits of the Blue Ridge in North Carolina: U.S. Geol. Sur. Prof. Paper 577, 129 p. Potter, M.J., 1991, Feldspar, and Nepheline Syenite, and Aplite: Annual Report, US Dept. of Interior, US Bureau of Mines. Potter, M.J., 1996, Feldspar and Nepheline Syenite: Minerals Yearbook, US Dept. of Interior, US Geological Survey; (//minerals.er.usgs.gov/minerals). Potter, M.J., 1997, Feldspar: Mineral Commodity Summaries, US Dept. of Interior, US Geological Survey; (//minerals.er.usgs.gov/minerals). USM 1993, Short Course on : Industrial Processing of Kaolin, quartz/silica sand and Feldspar, 20th-22nd. April 1993, School of Materials and Mineral Resources Engineering in Collaboration with The Department of Mining and Metallurgical Engineering, University of Queensland, Australia.7 April 2013 Prof. Dr. H.Z. Harraz Presentation Feldspar Groups 56