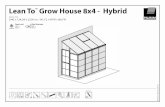

Lean Marketing House InfoGraphic

-

Upload

business901 -

Category

Business

-

view

702 -

download

0

description

Transcript of Lean Marketing House InfoGraphic

Marke ng with Lean Book Series

Understanding the value that you create with the customer is the star ng point and

will determine the rest of the structure.

Below the roof of the house lays the substructure of a five‐step Lean process. Lean is a system focused on and driven by customers. Op mizing value from their eyes and in an efficient manner takes your processes to a level not experienced before.

The company is supported by several value streams. Each value stream represents a product (service)/market.

Value Streams

Value Stream

Each Value Stream is supported by the pillars. These Pillars represent

the Customer’s Journey. It does not ma er how many pillars you have, just that each customer journey is depicted. They may represent; di‐

rect sales, web sales, dealer sales or may concentrate on other channels

that make more sense.

In a typical customer group, I have defined three stages or cycles of working with a cus‐tomer: collabora on, sales/buying and repeat/upsell. There is nothing to say that there can‐not be one stage or 12 stages. These stages were simple created for clarity and explana on of the process. The nomenclature within each cycle depicts what might be happening during that decision process.

You may have one team handling the en re journey or different teams working

on each sec on. You may have other groups working horizontally and ver cal‐

ly. It is what makes sense for you and more importantly your customers.

Overview of People: 1. The Value Stream Manager (VSM) represents the product/service markets and the business. 2. The Sales and Marke ng Team (Team) is a cross‐func onal group whose number and exper se are derived from the decision‐making path of the customer. This Team does the sales, providing content, technical func ons, trials, tes ng, etc. 3. The Team Coordinator (TC) maintains the integrity of the processes through coaching and predefined control points.

Using a Kanban board for this process will help you iden fy where the process is not working or where the bo leneck is occurring. Each seg‐ment or swim lane may have a single or mul ‐ple teams working on it. It really just depends on how you structure it. Don‘t think of Kanban as a planning tool; think about it as an execu‐

on tool. Improving your marke ng process does not have to cons tute wholesale changes nor increased spending.

Inventory for sales and marke ng is prospects! As you think about what stops your marke ng from being effec ve it is about trying to appeal to the masses and as a result losing effec veness both in me and money. Work in process is waste‐ful. It is wasteful in your personal life when not managed well, it is bad in manu‐facturing, it is bad from a sales and marke ng perspec ve. Quit marke ng at the top of your funnel. Instead learn how to manage your Work in Process!

The benefits of Kanban can become a driver for crea ng a culture of con nuous

process improvement. It also allows for other crea ve ideas for visual manage‐

ment of budgets, conversion rates, me spent, ac vi es and more.

Collabora on

It doesn’t necessarily ma er which tools the organiza ons use, but which tools are effec ve with the customer or the par cular value stream segment, repre‐sented by the pillars. The number and depth of blocks will differ with each or‐ganiza on. What is important is that they are all considered and that the foun‐da on is strong enough to support the pillars. Below the founda on is a sub‐structure of A3 problem solving that will be the prac ce that is implemented throughout the founda on. This allows us constant feedback and will alert us if the founda on starts to weaken.

![What Does It Mean to be Lean Six Sigma? [Infographic]](https://static.fdocuments.us/doc/165x107/55a9d9131a28abf5788b48eb/what-does-it-mean-to-be-lean-six-sigma-infographic.jpg)

![REGIONAL PROPERTY: What's Happening With House Prices in Regional Australia [Infographic]](https://static.fdocuments.us/doc/165x107/58d0333e1a28ab04288b5ec7/regional-property-whats-happening-with-house-prices-in-regional-australia.jpg)

![Selling a House in Ireland [infographic]](https://static.fdocuments.us/doc/165x107/55bad2c0bb61eb9c4f8b47ca/selling-a-house-in-ireland-infographic.jpg)

![“Lean Thinking House”agileasiapacific.com/lean-conference-india/pdf/LeanThinkingHouse.pdf · • Shu Ha Ri [Progressive learning] Video source: Will Garate 1 3 2 4 6 5 • Watch](https://static.fdocuments.us/doc/165x107/5f888c96faba7c0dbe069181/aoelean-thinking-housea-a-shu-ha-ri-progressive-learning-video-source-will.jpg)