Large Scale Industry

description

Transcript of Large Scale Industry

UNIT 12 MAJOR LARGE SCALE INDUSTRIES

Structure

12.0 Objectives

12.1 Introduction

12.2 Cotton Textile Industry 12.2.1 Growth During Five Year Plans

12.2.2 Output in the lndustry

12.2.3 Pattern of Consumption

12.2.4 Recent Trends

12.2.5 New Textile Policy, 2000

12.3 Sugar Industry 12.3.1 Growth During Five Year Plans

12.3.2 Current Problems of the Sugar lndustry

12.3.3 Mission Mode Project

I 12.4 Iron and Steel Industry 124.1 Growth During Five Year Plans

12:42 Production and Consumption

12.4.3 Current Problems of the Industry

1 2.5 Engineering Industry 12.5.1 Progress During Five Year Plans

12.5.2 Current Problems of the Industry

12.6 Other Major Industries 12.6.1 Cement lndustry 12.6.2 Paper lndustry 12.6.3 Petrochemicals lndustry

12.6.4 Fertilisers lndustry

12.7 ~ e t Us Sum Up - .

12.8 Key Words

12.9 Some Usehl Books and References

12.10 Answers or Hints to Check Your Progress Exercises I

12.0 OBJECTIVES

After going through this Unit, you will be able to:

appreciate thechanging structure of industrialisation in India;

identify the relative weights of different industries in India's industrial system;

measure the pace at which different types of large industries have developed in India since independence;

explain the different types of problems confronting the large-scale industries, and '

develop a fairly good idea about the attitude of the government towards different large industries in Ihdia.

12.1 INTRODUCTION

As you have already studied (in Block 3, Unit 7), India inherited a very weak industrial base from the Britishers. This was in spite of'the fact that industry had flourished in a large part of the world; many of the countries, including the Great Britain, had experienced industrial revolution. Independent India was keen to put the past behind it. It looked ahead to rapid industrialisation 'and fast economic growth.

On the eve of independence we had a couple of large-scale industries, notably cotton textile, steel and to a little extent jute. The core of industrialisation, i.e., the capital goods industries, was almost totally missing. With the onset of economic planning (the First Five Year Plan began on April 1, 195 I), we set on a course whose principal objective was to remove tlle distortions of the past.

To begin with, as you have already studied (in Block 3, Unit 1 O), top priority was provided to the growth of heavy industries (heavy industries are those industries which produce mother capital goods, i.e., those capital goods which help in production of more producer's goods).

The first four decades of economic planning saw rapid additions to production capacity in number of large-scale industries like iron and steel, engineering, cement, fertilisa, etc. Subsequently, and as direct fallout of easy availability of critical inputs like iron and steel, and power, white goods industries have developed phenomenally in India.

We review, in brief, the essential features of a few important large-scale industries in India.

12.2 COTTON TEXTILE INDUSTRY

The cotton textile industry is the first of modem industries - the base on which the pyramid of industrialisation has been built. More than a century old, the industry, which started largely as a spinning enterprise, gradually developed into a full-fledged composite one.

12.2.1 Growth During Five Year Plans

In April 195 1, i.e., on the eve of economic planning in India, there were 378 cotton mills. consisting of 103 spinning m,ills and275 composite mills(compositemills spin the yarn, w!ave fabrics and process them under one roof).

Tl~e general policy during the Five Year Plans has been to expand the spinning capacity of the industry so that inore yam is made available for weaving both in the organised and unorganised sectors of the economy. In pursuance of this policy, during the last five decades, the number of con~posite inills has shown a marginal decline to come down presently to 270 froin 275 in 195 1. The number of spinning mills, on the other hand, llas shown a nine-fold increase; their number has increased to 905 from 103 in 195 1. Similarly, whereas the spindles installed in the industry have more than doubled during tl~e last five decades fiom 1 1 mil lion in 195 1 to 33.53 inillion presently the automatic loon~s have shown a fall from 1.95 lakh in 195 1 to 1 -23 lakh.

The capital invested in cotton textile industry is estimated at Rs.2.70 crores; the annual value of output amounts to about Rs. 2,500 crores. The industry provides direct employment to about 260 lakh persons. which forms about 20 per cent of the total en~ploynlent in the orgmird sector. 1ndirec:t enlployment provided by the industry runs into several milliol~.

Major Large Scale

Induatrier

I 12.2.2 Output in the Industry I ' The cotton textile industry has three mutually exclusive and disparate sectors. namely. the mills, the handlooms and the power looms. The mills manufacturing cloth collie under the organised sector. while; thte other two are generally included in the unorganised sector.

Till the early sixties, a major proportiori of cloth output in India was prqtiuced in the mill sector (72.5% in 1960). Since the rnid-sixties the role ofthe unorganised sector in cotton textile industry has been exp\anding; presently. the major share of cloth output (about 95%) comes fiom this sc:ctor,

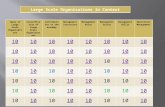

Table 12.1 below shows the sector-wise share in output in more recent years.

Table 12.1: ~roduc:tionof ~abr ics in India

I 1. (Percentage Share in Output) I

1 Others

Powerloon~s (including Hosiery)

I Total 1 100.0 100.0 , 100.0 100.0 100.0 100.0 100.01

69.0 69.6 71.4 73.0 74.7 75.4 76.5

Source: Economic Survey 2008-0 1.

It would clearly be seen from irable 12.1 thait the share of powerlooins in total output ofcloth in India hasbeen c:ontinuously increasing, and that of mills declining.

This has been in pursuance of the textile policy adopted by the government, which over the years has tilted heavily in favour of the unorganised sector; restrictions have been placed on f i h e r expansioil in the mill sectlor, whereas liberal iiicentives have been given for expansion in the unorganised sect or.

In addition to cloth, yarn is another important ~ ~ r o d u c t of the industry. The total plaoduction ofyarn in India has increased by more than four timesrto go up from 53.4 crores kg. in 1950-5 1 to 2 10.1 crores kg. in 1999-2000.

12.2.3 Pattern of Consumption

The pattern of consumption can be studied unde~.two heads, viz., (a) trends in the consumption of cloth, and (b) composition of consumption.

'i. ,

As to the first, the consumption o cloth is directly dependent on the growth rate of output in the textile industry. Production of cloth har not kept pace with the growth rate of population. During the last five:decades, cloth uutput has increased only at an annual average rate of about 1 .?per cent, whereas population has beep increasing at the annual avcrage rate of more than 2:0 per ceint, As a result, the per capita availability of doh over the' years ha ; fallen from a peak- of 16.8 metres in 1964-65 to 13.5 metres in 1977-78, but it picked up after that ro go up to 30.6 metres in 1999-2000.

As to the second, consumption of cotton as apercentage of all fibres and filaments is about 60:40 in our country. This is because of various inherent advantages that India has in terms of cotton produce and its quality. However, the world over the ratio is about 5050. We seem to be heading towards this global trend. This is because the wash 'n wear qualities of polyester and blended fabric reduce the maintenance cost in terms of washing and ironing.

12.2.4 Recent Trends

In wake of recent policy reforms, some changes in textile industry, as follows, may be noted.

9 Cotton has emerged as the leading sector in India's overall exports, textile production and overall income growth.

ii) There is stable preference for cotton in home consumption, led by new goods, led in turn by new competence of domestic producers acquired in the course of exporting.

i Emergence of informal sector as the leader in textile export and production.

iv) ~mprovedcapability in formal, and seemingly, the informal sector via access to world market for inputs and machinery.

v) Uneven adaptation due to the presence in both formal and informal sectors of firms that are too rigid or too constrained to adapt. As a result, segments of excess capacity and excess demand co-exist in all major sectors of the industry touched by reforms.

vi) Trends in global costs making India a major potential producer in man-mades.

12.2.5 New Textile Policy,, 2000

A new textile policy, based on the Satyarn Committee Report, was finalised by the government on November 3,2000.

The new policy has been formulated in the background ofthe following two facts:

One, the international trade in tbextiles is regulated by the Multi-Fibre Arrangement (MFA). The MFA has worked as a big constraint on textile exports from developing countries in as much as it sets a ceiling on textile imports. With the setting up ofthe .

World Trade Organisation ( WTO) i6 has been decided to terminate this arrangement h m January 0 1,2005. This should open immense opportunities of p w t h for India's textile industry.

Two, recent development:; in the textile industry, as listed in sub-section 12.2.4 above have influenced the policy decisions.

The aims of the new policy are as follows:

i) To increase apparel and textiles exports to $50 billion h m the present level of $11 billion.

To encouage the priv~ ~te sector in setting up specialised financial arrangements to h d the diverse net :ds of the industry.

i To encourage the priv, ate sector to set up integrated complexes and units.

The new policy is expected to ensure that the textile industry would be fdly prepared to meet global competition, particularly in the context of the total dismantling ofthe MFA by 2005.

klojur Iargc Sca le

lndustrics

Size of Industry in India 12.3 SUGAR INDUSTRY

The sugar industry is the second largest industry in India, next to cotton textiles, playing an important role in the economy.

The sugarcane crop and its processing provide employment to about 36 million skilled and unskilled workers. Besides, a large number are employed in the sugar trade and in the transport of sugarcane and sugar. Some of the by-products of the sugar industry are raw materials for other industries, such as, alcohol, plastics, paper, kc. The extension of sugarcane cultivation for the modern industry has contributed to the socio-economic development of many of rural area arld a sharp improvement in the well being of the local people. Further, the industry contributes an estimated Rs. 1600 crores annually to the central and state exchequers. India has emerged as the largest sugar consumer as well as the producer in the world.

12.3.1 Growth During Five Year Plans

With the launching of the programmes of planned economic development and enforcement of the Industries (Development and Regulation) Act, 195 1, a regulated and planned development of the sugar industry became possible.

The licensing policy of the government brought about two important changes in the structure of the Indian industry:

3 Alarger proportion of the capacity licensed after 1952 went to the tropical belt (i.e., Gujarat, Maharashtra, Karnataka, Andhra Pradesh, Tamil Nadu, Kerala, etc.), whereas in the earlier years the development took place in the sub-tropical belt (i.e., U.P., Bihar, Madhya Pradesh, ~ajasthan; Orissa, Assam-pd West Bengal).

ii) Due to the deliberate policy of the government encouragement to cooperatives there has been a significant development of the sugar industry in the cooperative sector.

The performance of the industry during the various plans has been remarkable, as is clearly brought out by the following facts.

9 The number of sugar mills in the country has increased fiom 139 in 1950-5 1 to 572 presently1 3 14 in the cooperative sector, 1 88 in the joint and private sector and 70 in the public sector).

n The total production of sugar has increased from 1 1.34 lakh tonnes in 1950- 5 1 (and 1.5 lakh tomes in 193 1 -32) to about 165 lakh tonnes in 1999-2000 enabling India to fwther consolidate its position as the single largest producer of sugar in the world.

iii Whereas in the early thirties of the last century, sugiu production represented just 3 per cent of the total cane sugar, production in the country, it has risen to 20 per cent presently.

The fortunes of the sugar industry have been fluctuating. Although the production has maintained an upward trend, it has frequently dipped to low levels also, as would be seen fiom Table 12.2 below:

Table 12.2: Sugar Production in India (Lakh Tonnes)

YEAR OUTPUT YEAR OUTPUT

1990-91 120.47 1995-96 147.8 1

1991 -92 132.77 1996-97 153.03

1992-93 105.62 1997-98 131.60

1 993-94 98.00 1998-99 155.20

1994-95 126.10 1999-2000 1 65 .OO -- -

As a matter of fact, during the last twenty years sugar production has followed a pattern in which surplus production causes profitability to drop and arrears of farmers to rise. Growers then plant less cane in the next season and production falls. It is then the next phasc of cycle sets in.

l11e government response has been to pelmit imports and exports in alternate periods to adjust supplies to domestic requircments.

12.3.2 Current Problems of the Sugar Industry

The current situatioil is 'characterised by the followii~g features:

One, the sugar economy, specially during the last decade or so, has been characterised by instability represented by the large and recurring imbalance between the denland for and supply of sugar. The emergence of acute shortages at one time and surpluses at another has led to the alteration of control and decontrol of the industry. The swings in the policy have affected not only the growth of industry but also the agrarian ecoilomy vitally. It also typified an absence of any clearly thought-out policy in regard to the problen~ of price parities, and of the limited land resources in the country.

Two, tile sugar economy continues to be a highly controlled one although the sugar industry has been delicensed since August 1998. There is a Statutory Minimum Price (SMP) for sugarcane fixed by the centre and the state advised price (SAP), over and above the SMP, fixed by the state governments. Prices of levy sugar are fixed zone-wise, on the basis of SMP of sugarcane plus conversion costs as recommended by the Bureau of Industrial costs and prices. There is no price control on fiee sale sugar; fixing monthly release quotas to maintain stability regulates its market supplies. Export quota is determined by the government and a nonliilatcd agency handles sugar export.

Thrcc, sickness is seen to inflict all sugar producing regions of the country.

12.3.3 Mission Mode Project

Tlle Government has set up the mission nlode project. The Project aims at developiilg 30 inodel sugar factories. The Government has also set up a Sugar Technology Mission and has identified a couple of advanced technologies for sugar factories. Identification of technology gaps in the existing sugarlnills and R&D support for zn~erging technologies has given a much-needed push to the whole process.

Check Your Progrcss 1

i ) Bring out the importance of cotton textile industry in the Indian economy.