L&T Hydrocarbon Engineering

Transcript of L&T Hydrocarbon Engineering

13505PI

13501PI

13501FI

13501 AFI

13501FT

13502FI

1111I

13501 API

13503PI

13502FT

13502 AFI

13501LI

13501PT

13502PI

13501LT

13504PI

ATM

ATM

ATM

ST

ATM ATM

13501SG

ATM

ATM

111-R-1102111-11124

AI111-11419-1

MP STEAM111-11416

APPLANT AIR

111-11419-1

APPLANT AIR

111-11419-1

AP111-11419-1

111-SP-1105/1106SPENT CATALYST

111-11134

111-K-1101BLOWER AIR

111-11113

CATALYST TRANSFERV-1101 / 1102

111-11134

111-R-1102FRESH CATALYST

111-11124

V-1102CATALYST TRANSFER

111-11134

APPLANT AIR

111-11419-1

V-2504111-11420

APPLANT AIR

111-11419-1

APPLANT AIR

111-11419-1

APPLANT AIR

111-11419-1

SEE PID #B224-FCC-LT-PID-111-11148

GENERAL NOTES

NOTES:

6367 kg/h

13. NO MORE THAN 30° FROM THE VERTICAL.14. CATALYST LOADER CONTROL SYSTEM TO BE INTERFACED. TO DCS FOR MONITORING AND CONTROL.

12. DELETED.11. PLANT AIR PURGING CONNECTION FOR VALVE SEAT AND VALVE STEM.

4. USE NON-INSULATING TYPE PERSONNEL PROTECTION, E.G., SCREENS, CHAIN GUARDS.

2. ALL BENDS IN CATALYST PIPING TO BE MINIMUM OF 9 PIPE DIAMETERS.3. STRAIGHT VERTICAL DROP INTO TRANSFER LINE.

1. FOR CATALYST TRANSFER LINES, PROVIDE 1" VALVED BLAST AIR CONNECTIONS FROM PIPEBOTTOM/SIDE IN ALTERNATIVE / SINGLE DIRECTION TO FLOW AT 45° ANGLE EVERY 6M IN THEHORIZONTAL PIPE RUNS, 3M IN THE VERTICALRUNS AND AT ALL BENDS AND VALVES.

8. DELETED.

10. PI-13501A TO BE READABLE FROM ASSOCIATED GLOBE VALVE.9. FOR CO PROMOTORS OR OTHER ADDITIVES.

7. FOR CONDENSATE REMOVAL.6. ALL CATALYST SERVICE PIPING TO BE SCHEDULE 80 MINIMUM REGARDLESS OF PIPE CLASS.5. PI-13505 & FI-13505 TO BE READABLE FROM ASSOCIATED GLOBE VALVE.

300#

CVF

VF

35

C

16. VENT TO ATMOSPHERE AT A SAFE LOCATION.15. DEBRIS GAURD

25A

2 25B13

17. ELECTRO MECHANICAL LEVEL TRANSMITTER.

20. FOR PLANT AIR INSTRUMENT PURGE DETAILS, REFER DWG. 111-11142 THROUGH 111-11144.

HOL = 21150mm

18. PROVIDE 1/2" WEEP HOLE AT LOW POINT .19. REFER PID 111-11191, FOR DETAIL 'C'.

-

SD/JM

SD/JMAMREVISED FOR BEDP4

SD/JM

5

AM

2

REVISED FOR BEDP

1

3

SD/JMAMREVISED FOR BEDP

REVISED FOR BEDP

15 Jun 2020

VP10 Feb 2020

VP10 Jan 2020

VP20 Dec 2019

VP08 Nov 2019

SD/CCPM VPREVISED FOR BEDP

AM

INTERNAL DIA : 432 mm T-T LENGTH : 3511 mmDESIGN PRESSURE (MAX / MIN) : 5.27 kg/cm^2g / FV@ 65 °C

DESIGN TEMPERATURE (MAX / MIN) : 65 °C / 3.4 °CTRIM : B49A

HOLDS:

DESIGN PRESSURE (MAX / MIN) : 3.5 kg/cm^2g / FV@ 442 °CDESIGN TEMPERATURE (MAX / MIN) : 442 °C / 3.4 °C

16"

2200

0 MM

N+IH

1. PSV-13501A/B QUANTITY, SIZE, INLET / OUTLET LINE SIZE.2. FOR 111-LZ-1106, PACKAGE DETAILS WILL BE FURTHER DEVELOPED BASED ON VENDOR INPUT.

21. DELETED.

HOLD 1

HOLD 1

3. NUMBER OF STEAM TRAPS BASED ON PIPING LAYOUT.

HOLD 3

22. FOR FRESH CATALYST LOADER PACKAGE DETAILS REFER PID B224-FCC-LT-PID-111-11135-A.

TYPICAL

TYPICAL

1 2

MW36"

6"

MIN

36"MW

14

15

1

B1A-

ISA1

A-NI

SJAM

076405C

076405C-111-111355076405C-111-PID-0021-1135

11

1-1/2"

2 5

13

FF10

H

3/4"

2

3/4"

163/4"

5.27

3"K4"+

5.27

3"K4"+

VAC

TT-12401TT-12414

DRAFT

FE13502

+

PCV13501

+

111-SP-1136

111-LZ-1106

111-V-1103

LC

6"

6"

1

6"

H

4"

STEAM EJECTOR111-J-1101

RATED CAPACITY:DESIGN PRESSURE (MAX / MIN): 20.4 kg/cm^2g / FV@ 442 °C

DESIGN TEMPERATURE (MAX / MIN) : 442.0 °C / 3.4 °C

5

3

3/4"-CL-111-13501-A1A-IH

2"-SS-111-13501-A1A-NI10"-P-111-13511-B1K-IH

6"-C

T-11

1-13

530-

B49A

-NI

10"-PA-111-11305-A1A-IS

2"-AP-111-13506-A3A-TL

4"-P-111-13522-B1A-NI

10"-CT-111-13502-B49A-IS

8"-P-111-13510-A1A-NI

2"-CT-111-13522-A49A-NI

3"-AP-111-13508-B49A-IS

2"-CT-111-13526-B49A-IS

8"-P-111-13513-B1A-IS

3"-AP-111-13507-A3A-TL

2"-CT-111-13505-A49A-NI

6"-P

-111

-135

14-B

1A-N

I

4"-AP-111-13515-A3A-TL

8"-P-111-13412-B1A-IS

8"-SV-111-13516-A1A-NI

8"-SV-111-13517-A1A-NI

2"-AI-111-41925-A3K-NI

3/4"

03

03

03

1-1/2"

1-1/2"

1-1/2"3/4"

3/4"

11

1-1/2" 1-1/2"11

03

03

1-1/2" 1-1/2"

11

6"-CT-111-13518-B49A-NI

300#

300#

3/4"

FF

20

28

19B

27

12

3/4"16

16

6"

2"

111-J-1101

TO SAFE LOCATION

1

FRESH CATALYST STORAGE HOPPER111-V-1103

INTERNAL DIA : 5500.0 mm T-T LENGTH : 23500.0 mmDESIGN PRESSURE (MAX / MIN) : 5.27 kg/cm^2g / FV@ 65 °C

DESIGN TEMPERATURE (MAX / MIN) : 65.0 °C / 3.4 °CTRIM :B49A

17

126 10

34

SUPERSACK TRANSFER PACKAGE111-LZ-1106

FRESH CATALYST HOPPER CYCLONE111-SP-1136

FF

FF

AP 6"x3"

1-1/2"

1-1/2"

11

19A

111-SP-1141

VAC

4 6

6"x3"

18

13515T

NNF

NNF

A49A-NI

B49A-IS

NITL

B49A-IS A3A-NI

3/4"

PSV13501 B

+

3/4"

LO

PSV13501 A

+

LC

A. FOR PIPING AND INSTRUMENTATION LEGENDS AND SYMBOLS SEE P&IDs. 111-11011 THROUGH 11047.B. ALL INSTRUMENTS ARE PREFIXED WITH THE PLANT CODE "111". THE PREFIX IS NOT SHOWN ON THE P&IDs FOR CLARITY.C. FOR VENT AND DRAIN DETAILS OF CONTROL VALVES AND LEVEL INSTRUMENTS, SEE DWG. 111-11028/111-11029 AND 111-11030/111-11031/111-11043/111-11044/111-11045/111-11046/111-11047 RESPECTIVELY.D. FOR SAMPLE CONNECTION DETAILS, SEE DWG. 111-11022/111-11023/111-11041/111-11042.E. FOR VENT AND DRAIN DETAILS OF PUMPS, EXCHANGER AND FILTERS, SEE DWG. 111-11024/111-11025, 111-11026/111-11027 AND 111-11036 RESPECTIVELY.F. FOR INSTRUMENT/VALVE FLUSHING DETAILS SEE DWG. 111-11037,111-11038 AND 111-11039/111-11040.

DETAIL 'C'

STEAM EJECTOR SILENCER111-SP-1141

7

SP13501

FRESH CATALYST LOADER111-LZ-1103

111-LZ-1103

TYPE-O

1-1/2" 1-1/2"

1-1/2"

1-1/2"

11

1/2"

1/2"

11

1-1/2" 1-1/2"11

B1A

A1A

A1A

B2A

B2A

A1A

B2A

A1A

1/2"

9

19

18

13516T

1-1/2"11

1-1/2"

1"-A

P-11

1-13

509-

A3A-

TL

4"-SM-111-13512-B2A-IH

6"-CT-111-13521-A49A-NI

2"-A

P-11

1-13

510-

A49A

-IS

6"-P-111-13515-B1A-NI

3/4"-S

M-11

1-13

513-

B2A-

IH

13502T

13511T

SS / CRWS

B49A

B49AA3A

A3AB49A

B1A

B1A

A1AB1K

A1A

A49A A3A

24 Sep 2021

24 Sep 2021

03NK

VKD

DRZ

1

B224-FCC-LT-PID-111-11135

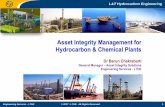

PETROCHEMICAL FCC UNIT (PFCCU) UNIT 111

FRESH CATALYST STORAGE HOPPERCONVERTER

B224-FCC-LT-PID-111-11135

B1K

B1K

B49A-ISA3A-TLB49A-IS

B49A-ISA3A-TL

A3A-TL B49A-IS

6"

NNF

15

1-1/2

"1-

1/2"

11

SS / CRWS

2"

8"x4"

8"x4"

1-1/2

"

2"-AP-111-13502-A3A-TL

2"-AP-111-13503-A3A-TL

SP13503

A49A

-ISA3

A-TL

HOLD 2

6"

6"

ISNI

300#

FB

FB

B49A-ISA3A-NI

A49A

-ISA3

A-NI

A3A-NI

1-1/2"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

B49A-ISA3A-NI

A3A-NI

1-1/2"

SS

03

03

1"-AP-111-13516-A3A-TL8"

x6"

03

03

03

B49AA49A

B49AA1A

03

0303

03

03

03

03

03

03

10"x8"

03

03

B49AB1A

03

22

1-1/2

"x1/2"

1-1/2

"x1/2"

13510T

13504T

2"-CT-111-13535-B49A-NI

13501T

13507T

13505T

6

6

A3A-TLA49A-NI

2"-C

T -11

1-13

5 56-

A49A

- NI

2"-AP-111-13517-A3A-TL

13512T

1"-CT-111-13557-A49A-NI

2"x1"2"x1-1/2"

1"-AP-111-13518-A3A-TL

13503T

03

3/4"

8"-C

T-11

1-13

501-

B49A

-IS

PSET

=3.52

kg/cm

^2g

03

13508T

16

13514T

16

03

2"-AP-111-13519-A3A-TL

1-1/2"x1"

1-1/2"x1"

22

03

1/2"

1/2"

03

1-1/2"x3/4"

1-1/2"x3/4"

1-1/2"x3/4"

1-1/2"x3/4"

03

1/2"

1/2"

03

1-1/2"x3/4"

1-1/2"x3/4"

03

1-1/2"x3/4"

1-1/2"x3/4"

03

1"

1"

1-1/2"x3/4"

1-1/2"x3/4"

03

1-1/2"x3/4"

1-1/2"x3/4"

03

1-1/2"x3/4"

03

3/4"

3/4"

2"-C

T-11

1-13

558-

A49A

-NI

B49A-IS

3/4"3/4"

4"x3"

03

4"x3"

2"

03

03

3/4"

3/4"

1"03

3/4"

3/4"

03

2"x1"

03

3/4"

3/4"

1"03

13506T

6"-CT-111-13520-A49A-NI

03

AL

L R

IGH

TS

RE

SE

RV

ED

TH

IS D

OC

UM

EN

T A

ND

AN

Y D

AT

A A

ND

INF

OR

MA

TIO

N C

ON

TA

INE

D T

HE

RE

IN A

RE

CO

NF

IDE

NT

IAL

AN

D T

HE

PR

OP

ER

TY

OF

L&

T−C

HIY

OD

A L

IMIT

ED

(L

TC

) A

ND

TH

E C

OP

YR

IGH

T IS

TH

ER

EIN

VE

ST

ED

IN L

TC

. NO

PA

RT

OF

TH

IS D

OC

UM

EN

T, D

AT

A, O

R I

NF

OR

MA

TIO

N S

HA

LL

BE

DIS

CL

OS

ED

TO

OT

HE

RS

OR

RE

PR

OD

UC

ED

IN A

NY

MA

NN

ER

OR

US

ED

FO

R A

NY

PU

RP

OS

E W

HA

TS

OE

VE

R, E

XC

EP

T W

ITH

TH

E P

RIO

R W

RIT

TE

N P

ER

MIS

SIO

N O

F L

TC

.

A

1

SH.

REV.APP BY:

CHK BY:

DATE TITLE:

SIGN: DATE:

CODE 1 - NO COMMENTSPROCEED WITH MANUFACTURE / FABRICATION /CONSTRUCTION AS PER THE DOCUMENT

SIGN: DATE:NAME: DISCIPLINE:

DOCUMENT STATUS

STATEMENT OF SUB: 1st

FINAL FOR CODE -1

AS BUILT

CONSTRUCTION

ISSUED FOR

EIL REVIEW/APPROVAL CODE: VPTL NO:

SCH. DATE OF SUBMISSION

DRG. CATEGORY:(USE TICK MARK)

DWG. NO :

PC

PIPING AND INSTRUMENT DIAGRAM

DRN BY:

DEPT:

PROJECT:

PWO NO.:

DRG. NO.:

INFORMATION

REVIEW

AS BUILT

2nd 3rd

R I

CODE 2 - PROCEED WITHMANUFACTURE / FABRICATION / CONSTRUCTION AS PER THECOMMENTED DOCUMENT, REVISED DOCUMENT REQUIREDCODE 3 - DOCUMENT DOES NOTCONFORM TO BASIC REQUIREMENTS AS MARKED.RESUBMIT FOR REVIEW.

CODE R - DOCUMENT IS RETAINED FOR RECORDS.PROCEED WITH MANUFACTURE / FABRICATION

CODE V - VOID

2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

ENGINEERS

(A Govt. of India Undertaking)

EPC / LSTKCONTRACTOR : L&T Hydrocarbon EngineeringPMC :

ई.आई.एलइंजीिनयस

इंिडया िलिमटेड का सरकार( भारत उप म )

INDIA LIMITED

HPCL RAJASTHAN REFINERY LIMITEDRAJASTHAN REFINERY PROJECT

PACHPADRA, BARMER, RAJASTHANEPCC 03 PACKAGE PETROCHEMICAL FLUDIZED CATALYTIC

CRACKING UNIT AND PROPYLENE RECOVERY UNIT

OWNER:

ENGINEERINGSUB-CONTRACTOR : L&T - CHIYODA LIMITED

PROJECT NUMBER REVISIONTECHNIPFMC NUMBER

PROCESS BY DRAWN BYCLIENT NUMBER

ENGINEERS

(A Govt. of India Undertaking)

ई.आई.एलइंजीिनयस

इंिडया िलिमटेड का सरकार( भारत उप म )

INDIA LIMITED

INFORMATION CONTAINED IN THIS DOCUMENT IS THE WORK PRODUCT OF ONE OR MORE LEGAL ENTITIESOF THE TECHNIPFMC PROCESS TECHNOLOGY BUSINESS UNIT AND EMBODIES CONFIDENTIAL AND

PROPRIETARY INFORMATION OF THE APPLICABLE ENTITY AND/OR ITS CLIENT.USE OF THIS INFORMATION IS RESTRICTED IN ACCORDANCE WITH CONDITIONS SPECIFIED BY THE CONTRACT.

TECHNIPFMC PROCESS TECHNOLOGY AND ITS AFFILIATES DISCLAIM ANY AND ALL LIABILITIES FOR ANYCHANGES OR MODIFICATIONS TO THIS DOCUMENT WHICH ARE MADE BY ANY PERSON OTHER THAN

THE ENTITY THAT ISSUED THE DOCUMENT UNDER THE APPLICABLE CLIENT CONTRACT.

REVISION DESCRIPTIONREV DATE CHECKED APPROVED PROJ APR

LICENSOR:

DESCRIPTIONREV DATE DRN CHECKED APPROVED

FCC

B224

SCALE

AL

L R

IGH

TS

RE

SE

RV

ED

TH

IS D

OC

UM

EN

T A

ND

AN

Y D

AT

A A

ND

INF

OR

MA

TIO

N C

ON

TA

INE

D T

HE

RE

IN A

RE

CO

NF

IDE

NT

IAL

AN

D T

HE

PR

OP

ER

TY

OF

L&

T−C

HIY

OD

A L

IMIT

ED

(L

TC

) A

ND

TH

E C

OP

YR

IGH

T IS

TH

ER

EIN

VE

ST

ED

IN L

TC

. NO

PA

RT

OF

TH

IS D

OC

UM

EN

T, D

AT

A, O

R I

NF

OR

MA

TIO

N S

HA

LL

BE

DIS

CL

OS

ED

TO

OT

HE

RS

OR

RE

PR

OD

UC

ED

IN A

NY

MA

NN

ER

OR

US

ED

FO

R A

NY

PU

RP

OS

E W

HA

TS

OE

VE

R, E

XC

EP

T W

ITH

TH

E P

RIO

R W

RIT

TE

N P

ER

MIS

SIO

N O

F L

TC

.

A

1

SH.

REV.APP BY:

CHK BY:

DATE TITLE:

SIGN: DATE:

CODE 1 - NO COMMENTSPROCEED WITH MANUFACTURE / FABRICATION /CONSTRUCTION AS PER THE DOCUMENT

SIGN: DATE:NAME: DISCIPLINE:

DOCUMENT STATUS

STATEMENT OF SUB: 1st

FINAL FOR CODE -1

AS BUILT

CONSTRUCTION

ISSUED FOR

EIL REVIEW/APPROVAL CODE: VPTL NO:

SCH. DATE OF SUBMISSION

DRG. CATEGORY:(USE TICK MARK)

DWG. NO :

PC

PIPING AND INSTRUMENT DIAGRAM

DRN BY:

DEPT:

PROJECT:

PWO NO.:

DRG. NO.:

INFORMATION

REVIEW

AS BUILT

2nd 3rd

R I

CODE 2 - PROCEED WITHMANUFACTURE / FABRICATION / CONSTRUCTION AS PER THECOMMENTED DOCUMENT, REVISED DOCUMENT REQUIREDCODE 3 - DOCUMENT DOES NOTCONFORM TO BASIC REQUIREMENTS AS MARKED.RESUBMIT FOR REVIEW.

CODE R - DOCUMENT IS RETAINED FOR RECORDS.PROCEED WITH MANUFACTURE / FABRICATION

CODE V - VOID

2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

ENGINEERS

(A Govt. of India Undertaking)

EPC / LSTKCONTRACTOR : L&T Hydrocarbon EngineeringPMC :

ई.आई.एलइंजीिनयस

इंिडया िलिमटेड का सरकार( भारत उप म )

INDIA LIMITED

HPCL RAJASTHAN REFINERY LIMITEDRAJASTHAN REFINERY PROJECT

PACHPADRA, BARMER, RAJASTHANEPCC 03 PACKAGE PETROCHEMICAL FLUDIZED CATALYTIC

CRACKING UNIT AND PROPYLENE RECOVERY UNIT

OWNER:

ENGINEERINGSUB-CONTRACTOR : L&T - CHIYODA LIMITED

PROJECT NUMBER REVISIONTECHNIPFMC NUMBER

PROCESS BY DRAWN BYCLIENT NUMBER

ENGINEERS

(A Govt. of India Undertaking)

ई.आई.एलइंजीिनयस

इंिडया िलिमटेड का सरकार( भारत उप म )

INDIA LIMITED

INFORMATION CONTAINED IN THIS DOCUMENT IS THE WORK PRODUCT OF ONE OR MORE LEGAL ENTITIESOF THE TECHNIPFMC PROCESS TECHNOLOGY BUSINESS UNIT AND EMBODIES CONFIDENTIAL AND

PROPRIETARY INFORMATION OF THE APPLICABLE ENTITY AND/OR ITS CLIENT.USE OF THIS INFORMATION IS RESTRICTED IN ACCORDANCE WITH CONDITIONS SPECIFIED BY THE CONTRACT.

TECHNIPFMC PROCESS TECHNOLOGY AND ITS AFFILIATES DISCLAIM ANY AND ALL LIABILITIES FOR ANYCHANGES OR MODIFICATIONS TO THIS DOCUMENT WHICH ARE MADE BY ANY PERSON OTHER THAN

THE ENTITY THAT ISSUED THE DOCUMENT UNDER THE APPLICABLE CLIENT CONTRACT.

REVISION DESCRIPTIONREV DATE CHECKED APPROVED PROJ APR

LICENSOR:

DESCRIPTIONREV DATE DRN CHECKED APPROVED

FCC

B224

SCALE

1-1/2"x3/4"

SP13401

03

6

SP13401

03

03

03

SP13401

03

SP13401

03

1"

SP12401

1

03

SP13401

03

SP13401

03

SP13401

03

SP13401

1" 1"

SP12402

SP12402

03

03

503

AKPAKPAKPAKP

24 Sep 202103 Jul 2021

11 May 202110 Mar 2021

NKVKDDRZINCORPORATING HAZOP RECOMMENDATION03NKVKDDRZISSUED FOR HAZOP02NKVKDDRZISSUED FOR REVIEW01NKVKDDRZISSUED FOR REVIEW00

03 03 03

3/4"-S

V-11

1-13

518-

A1A-

NI3/4

"-SV-

111-

1351

9-A1

A-NI

SP13401

03

SP13402

03

6"-C

T-11

1-13

525-

A49A

-NI

23

03

2"-SV-111-13521-A1A-NI

23. AS PER EDB (DOC. NO.: EDB-B224-999-16-43-EDB-1001), CLAUSE NO. 3.2.10, POINT NO. 5, PIPE STEAMTRAP SHALL BE OF COMPACT TYPE (VENDOR FURNISHED).

03

FE13501

+

SS / CRWS

SS / CRWS

4. PRV ROUTING SHOULD NOT BE MORE THAN 1 m.

24. COP & CATALYST HOPPER CONNECTIONS SHOULD JOIN HEADER LINE AT 45° ANGLE. IN THE DIRECTIONOF FLOW.

03

2424

HOLD 4

MIN.

03

HOLD 4SS / CRWS

2"-SV-111-13520-A1A-NI

16 16

HOLD 4

SS / CRWS13513

T

13509T

HOLD 4

03

18

18

18

18

03A INTERNAL ISSUE 11 OCT 2021