Laminar flow (16-10-10) - Associated Scientific FLOW BENCH... · The horizontal laminar air flow...

Transcript of Laminar flow (16-10-10) - Associated Scientific FLOW BENCH... · The horizontal laminar air flow...

INSTRUMENT DIVISION

www.associatedscientific.com SSI

MICROPROCESSOR BASED LED + LCD CONTROLLER

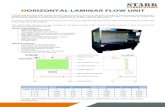

LAMINAR FLOW BENCH - HORIZONTAL

SALIENT FEATURES • Ergonomic Design• Versatile Usage• Energy Efficient Mechanism• Low Noise and Vibration Levels• Long Life and Low maintenance• Conforms to US Federal Standard Class 100• Supplied with spares kit• Modular Design (can be disassembled & assembled within

10 minutes at customer’s sight.• Guaranteed supply of spares for 10 years• Onsite installation and after sales service by company trained

engineers

DOCUMENTATION AVAILABLE• Factory Testing Certificate for

a) Particle Counting which prove the Class 100 working of the instruments (Optional)

b) Air velocity test certificate (Optional) c) Lighting intensity certificate. d) Working Manual

• IQ/OQ/PQ/DQ Certificates (Optional) • ISO 9001:2000 Certificate • CE Certificate • NSIC & SSI Registration Certificates

USESONAR laminar air flow cabinets are conceptualized to provide a work area completely bathed in high efficiency perfect air which is free from any kind of particulate contamination or impurities. These units are ideally suited in all the applications requiring protection of biological specimens or products from the possible contamination during the process or test. SONAR laminar air flow bench is popular in pharmaceutical production, electronic industries and various other manufacturing applications.

• Password protection (Programmable) for authorised operation

• Initial self cleaning cycle with programmable time• Real time Clock• UV timer showing used time and balance available life

in hours• Total HEPA Filter timer showing used time and balance

available life in hours• HEPA filter alarm after HEPA filter life is over and

guideline for further action through LCD controller• UV light/Door/Fluorescent Light Inter Lock i.e. UV

switches ON only when door is closed, and automatically switches OFF fluorescent lights.

• If UV light is ON & the operator tries to open the door, it raises audio visual alarm.

PRINCIPLEThe Laminar Air Flow Cabinets are based on the principle to provide a work area completely bathed in a high efficiency perfect air, which is free from any kind of particulate contamination or impurities.HORIZONTAL Laminar air flow are clean benches which have their own supply of highly purified air in which the total air present in the enclosure moves in a unit directional velocity flowing in parallel lines, which is free from macroscopic fluctuations. The horizontal laminar air flow units directs the air in mono direction which is away from the specimen and towards the user, giving ultimate protection to the product, which is susceptible to contamination induced by diffusion of contaminated air carrying air transported contaminants from the outside environment.

IOVA METRA

INSTRUMENT DIVISION

www.associatedscientific.com SSI

CONSTRUCTIONThe Work Table is made of S.S. 304. Side panels and front door are made of thick plexiglass of special grade to resist the UV effect. Front door has a unique feature of double fold system. It can be half/full open during working. The entire unit rests on four castor wheels. The unit is completely modular & can be disassembled/assembled by the user within 10 minutes.

SPECIAL FEATURES • Password protection (Programmable) for authorised operation• Initial self cleaning cycle with programmable time• Real time Cock• UV timer showing used time and balance available life in hours• Total HEPA Filter timer showing used time and balance available life

in hour• HEPA filter alarm after HEPA filter life is over and guideline for

further action through LCD controller

SPECIFICATIONS1. Direction of Flow : Horizontal2. Cleanliness Level : Class 1003. Velocity : 70 cfm ±20%4. Noise Level : 65 db A ± 5%5. Manometer : Acrylic transparent manometer with Red Gel mounted on the front to

show the differential pressure 5. Controller : Microprocessor Controller based with LCD display, menu control,

automatic filter alarm system and a large number of very useful controlled features.

6. Working Table : Made of perforated stainless steel sheet stain finished.7. Front Door : Made of clear perpex sheet.8. HEPA Filter : Media : Glass Fiber Paper

Particle Retention : 0.3 micron & aboveEfficiency : 99.97% at Hot DOP & 99.99% at Cold DOPPressure Drop : 23mm WG

9. Pre Filter : Media : Non woven synthetic Polyester with metallic wire mesh, pleated

Particle Retention : 10-15 micron Efficiency : 90% Pressure Drop : 6mm WG

10. Blower Assembly : Single phase,1440 rpm motor, directly coupled with a pair of metallic centrifugal impeller. Low noise & low vibration with dynamically balanced blower.

11. Ultra Violet Lamp : Provided as per table below12. Illumination : Provided with diffusers as per table below13. Standard Accessories : Pressure manometer, Gas inlet nozzle, floor leveling screws & wire cord14. Power Supply : 220 V 50 Hz, Single Phase, AC supply15. Construction Options : I) Full body made of Mild Steel / G.I. Sheet duly powder coated (totally in white colour) with S.S. table top; or

ii) Full body made of Wooden (termite and insect resistant board) with S.S. Top; or (ii) Full body made of S.S. 304.

OPTIONAL

f) Onsite Particle Counting Test with Air velocity & other tests. (g) IQ/OQ/PQ/DQ certificates

SAFETY FEATURES1. M.C.B. is provided at the mains of the connection2. Fuses are provided on every electrical line to safeguard each and every component.

• UV light/Door/Fluorescent Light Inter Lock i.e. UV switches ON only when door is closed, and automatically switches OFF fluorescent lights.

• If UV light is ON & the operator tries to open the door, it raises audio visual alarm.

Option-II Wooden

a) AMH-2 ASH-2 SSH-2 600x600x600 600x600x150 1 1 2 x 20 W 1 x 15 W

(2’ x 2’ x 2’) (2’ x 2’ x6”)

b) AMH-3 ASH-3 SSH-3 900x600x600 900x600x150 1 1 2 x 20 W 1 x 30 W

(3’ x 2’ x 2’) (3’ x 2’ x6”)

c) AMH-4 ASH-4 SSH-4 1200x600x600 1200x600x150 1 1 2 x 40 W 1 x 30 W

(4’ x 2’ x 2’) (4’ x 2’ x6”)

d) AMH-6 ASH-6 SSH-6 1800x600x600 900x600x150 2 2 4 x20 W 1 x 30 W

(6’ x 2’ x 2’) (3’ x 2’ x6”)

(x 2 filters)

e) AMH-8 ASH-8 SSH-8 2400x600x600 1200x600x150 2 2 4 x40 W 2 x 30 W

(8’ x 2’ x 2’) (4’ x 2’ x6”)

(x 2 filters)

STANDARD MODEL

Metallic Wooden Stainless WORKING SIZE OF HEPA NO. OF NO. OF ILLUMINATION DETAILS OFSteel TABLE (in mm) FILTER PRE-FILTER MOTORS UV TUBE

* Other sizes available on request.