L03 VA NVA

-

Upload

meenakshisach4963 -

Category

Documents

-

view

260 -

download

1

Transcript of L03 VA NVA

02/02/2014

1

What is “ValueWhat is “Value--Added” Added” ??

02/02/2014

2

Lean and Eliminating Waste

Value Added

Typically 95% of all lead time is non value-added

Non-Value Added

02/02/2014

3

Lean focuses on the elimination of Waste

Typically, 90-95% of Total Lead Time is Non value Added activities and Waste

Does this look familiar?Typically, we tend to focus on and improve the Value Added

rather than attacking the Waste..the larger opportunity

Does this look familiar?Typically, we tend to focus on and improve the Value Added

rather than attacking the Waste..the larger opportunity

ValueAdded

Hand offs, Multiple reviews, waiting and more waiting,Rework, Checking Status, Multiple approvals, extra copies, searching for information, finding the “right person”

with the “right information”, expediting, getting dumped…..

Value vs. Waste• Three elements of Work:

– Value Added Activities:• An activity that transforms or shapes material or

information• And the customer wants it• And it’s done right the first time

– (Required) Non Value Added Activities:• Activities that cause no value but which cannot be

eliminated based on existing technology, equipment or thinking

• Regulatory, customer mandated, legal• Necessary because of risk tolerance, ‘buffer’

– Waste….Non Value Added Activities:• Activities that consume resources but create no value in

the eyes of the customer• If you can’t get rid of it, it turns to Required, Non Value

02/02/2014

4

Waste adds cost and time

Lean Thinking--- Defining Value

02/02/2014

5

Definition of WasteDefinition of Waste

Anything that does not add value to the Anything that does not add value to the product is product is wastewaste and must be reduced or and must be reduced or

eliminatedeliminated

Japanese Waste Definition: 3M

02/02/2014

6

What is MUDA?Muda means any wasteful activity or any obstruction to smooth flow of an activity

Activity = Work + MudaExpenditure = Cost + waste

That is, for each activity there is expenditure and every work there is a cost associated. Any expenditure on the Muda is a waste!

What is Mura?Mura = Inconsistencies in the system

• Happens sometimes? • Happens some places • Happens to some people • One side is ok; the other side is not ok

02/02/2014

7

What is Muri?Muri = Physical Strain

– Bend to work? – Push hard? – Lift weight? – Repeat tiring action? – Wasteful walk?

All this is Muri

Japanese Waste Definition: 3M

1 Ton X 12 = 12 Tons Truck Capacity = 4 Tons

How should I transport these materials?

02/02/2014

8

Japanese Waste Definition: 3M

The operator loads 6 tons and makes 2 trips to

The operator loads 2 tons and makes 6 trips

The operator loads 6 tons and makes 1 trips then loads 4 tons and make a trip then loads the balance 2 tons

02/02/2014

9

Japanese Inventory

Japanese Inventory

02/02/2014

10

Excess Motion

The brick weighs about 2.3 kg. How much is the worker actually raising and lowering every time he bends over for another brick?

Bricklaying, after Frank Gilbreth• Lesson: waste can, by long habit ("living with it," "working around

it") become built into a job.

02/02/2014

11

fabric folding operation

Henry Ford principle: "Pedestrianism is not a highly-paid line of work."

This shows the value of videotaping real operations(e.g. for kaizen blitz, SMED).

Office Waste

• NVA Processing• Overproduction• “Inventory”• Waiting• Defects• Excess Motion• Transportation• Underutilized People

• Too many approval levels• Premature quotes• Filled “In-boxes”• System downtime• Order Entry errors• Poor office layout• Movement of paperwork• Limited functional responsibilities

Examples?!

02/02/2014

12

7 Wastes in the OfficeWaste Definition To eliminate this

waste… Defects ANY rework of product or

information is waste. • Establish standard work procedures

and forms • Mistake proof

Inventory Excess stock of anything…extra copies, extra supplies, extra files etc.

• Produce only enough to satisfy the work requirement of the customer.

• Standardize work locations & quantities.

• Eliminate queues. Motion All motion should add value

to the product or service for the customer. Ineffective layouts or processes create more walking, reaching then necessary.

• Standardize folders, drawers, cabinets, locations etc. Color code as much as possible.

• Arrange files and information for easy reference.

• Arrange work areas and equipment into central areas.

Waiting Waiting for people, paper, machines or information…

• Review and standardize signatures • Cross train so that work can continue

to flow even if someone is out or busy• Balance the workload • Make sure equipment & supplies are

available.

7 Wastes in the OfficeWaste Definition To eliminate this waste… Motion Unnecessary work

movements…searching, walking, carrying, lifting, reaching, choosing, arranging…

• Standardize folders, drawers, cabinets

• Color code • Arrange files for easy reach and use. • Arrange work areas to support the

flow of your process. • Update forms and document layouts • Eliminate the “ings”…

Transportation Moving materials and information from place to place. Using temporary locations.

• Make the distance traveled as short as possible.

• Eliminate temporary locations. • Review the office layout…where

are you wearing down the carpet. • Duplicate equipment if an analysis

of savings supports it. Over-producing

Producing a product, service, or information before the customer needs it.

• Establish a work flow sequence geared toward the downstream customer

• Create standards/ metrics. • Create signal devices

02/02/2014

13

The Need: The 8 Wastes

Extra ProcessingMotionMaterial Movement

WaitingOver ProductionInventory

Unused Employee CreativityDefects

Lack of TrainingCurrent Roles & Responsibilities

Office Layout Performance MeasuresNo Standardized WorkSystem Limitation

Identifying Root Causes of Visible Waste

Operational InnovationAnything that does not add value to the product is waste and must be

eliminated

• Value Adding activities• Room readiness• Food on time• Registration open at customer specified times

• Non-value adding activities• Booking an event in computer system• Internal sharing of information• Accounting procedures

02/02/2014

14

Evaluate the processes, where is the waste?

Get the Waste out--- Understanding and Eliminating Waste

� The Secret:Be Systematic� Work with a versatile team� Measure, evaluate� Find the 5 Whys� Follow up� Standardize, make uniform� Simplify� Combine� Prevent� Make waste ugly

Elimination of Wastes and Continuous Improvement

02/02/2014

15

Improving Performance

People Process Results

Rs

Time More

Better

Faster

Cheaper

Improving Performance

People Process

Rs

Time More

Better

Faster

Cheaper

Results

02/02/2014

16

Improving Performance

People Process Results

Rs

Time More

Better

Faster

The same...

… or less

IMPROVE

IMPROVE

Cheaper

Delivery lead timeThis is life!

If not, it’s torture…

When the delivery lead-time is bigger than the manufacturing lead time:

Manufacturing lead time

Delivery lead time

Manufacturing lead time

02/02/2014

17

Solution…

What is the solution?

Generate and support stocks

Delivery lead time

Manufacturing lead time

Delivery lead time

Manufacturing lead time

False appearance of a solution

Identify and eliminate all wastes in our operation processesExample: manufacture a

Total operations: 6 hoursMfg. lead-time: 40 days = 320 hoursDifference: 314 hours

How to reduce the manufacturing lead time?

Delivery lead time

Manufacturing lead time

?

02/02/2014

18

Example: manufacture a Total operations: 6 hoursMfg. lead-time: 40 days = 320 hoursDifference: 314 hours

What are processes made of ?

Delivery lead time

Manufacturing lead time

Storage,

Transport,

Waiting time98%

Kaizen ExampleShrinking Lead Times

Order Lead Times Manufacturing Lead Times Delivery Lead Times

Manufacturing Lead TimesOrder Lead Times Delivery Lead Times

Reducing the overall time from receiving the order to delivering the product makes your company more responsive to the customer. This can become the deciding factor when the customer makes their selection.

As can be seen, manufacturing is only one part of the entire process. Inputting, processing, and issuing orders is an area for improvement, as well as, assembly, loading and delivery to the customer`

02/02/2014

19

Kaizen ExampleWhere’s the Time in Lead Time

This timeline represents an overall lead-time, with very little time spent on adding value to the product.

Non-Value Added Time (NVA)99% of Total Lead time

Value Added Time (VA)1%

Improvement EffortsConcentrated on reducing VA time, with no attention given to NVA.

Non-Value Added Time (NVA)99% of Total Lead time

VA1/2 %

Results of Common Improvement efforts, did not improve response time. VA time is reduced, but, the costs for those improvements in lead time was substantial.

Common

Kaizen ExampleWhere’s the Time in Lead Time

NVA Time95% of Total Lead time

VA5%

When we look at attacking the NVA Activities in the Timeline and compare that to the original timeline:

Non-Value Added Time (NVA)99% of Total Lead time

Value Added Time (VA)1%

This shows a 5X improvement in lead timeGreat Job!!

Greatest Opportunities are actually here!

02/02/2014

20

Focus on Blockages to Flow & NVA

Eliminating Non Value Add has a major impact on

Quality, Cost and Service Delivery

•Value-Add activity

Non-Value-Add activityTime

Right First Time Every Time

• Everything must be of acceptable quality– Sub-standard items or information will cause delays

�Make no defects�Pass no defects

�Accept no defects

• Find the root cause of defects fast– Ask the “5 whys” and 1 “how”

02/02/2014

21

Flexible Staff

• Focus on giving the next in line what they want when they want it

• Be prepared to– do what needs to be done to keep the work flowing

smoothly– learn new skills and new ways of operating

Standardisation

• Standardisation• Current best way to do the task

– Least waste way

• Everyone must adhere to the procedure– Until it is changed for all

• Procedures must be continuously upgraded– Continuous search for improvement

02/02/2014

22

Perf

orm

ance

Time

Why Standardise?

Businessas usual

StandardOperatingProcedures

Kaizen orcontinuous

improvement

Pull Process

• “Typical” Business: Push Process

Imagine each Paperclip represents an individual process within the Value Chain

PushBottlenecks

Space

Waiting

WIP

Finished Goods

Inventory

02/02/2014

23

Pull Process

Customer Pull

Reduced bottlenecksReduced work in progressReduced operating space

Improved quality

Do MORE with LESS

Waste Productivity

Staffing Productivity

02/02/2014

24

Typical Problems Observed in Organization

Value: From the perspective of the customerUnderstanding Customer Requirements – Example: Not meeting timing needs

Flow: No Waiting – No Rework – Information AvailableMany handoffs, Interrupts, Waiting for decisions and approvals

Work: Standardized Built in QualitySignificant Rework, Standards not being followed (workarounds) or no standard

Manage, Improving and Learning: Milestones and Checkpoints, Learning EmbeddedOver processing, no management corrective action, limited feedback

InitialCustomerContact

PROCESS

VALUE STREAM

AgentDelivery to

PROCESSPROCESSDistribution

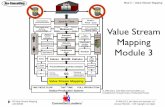

ValueValue--Stream Improvement vs. Stream Improvement vs. Process ImprovementProcess Improvement

Insurance Policy Writing Process

PROCESSUnder-writing

Rating PolicyWriting

Value Stream = ALL steps, both value-added and NVA, required to complete a service from beginning to end.

02/02/2014

25

Making the Work Flow

Step 1 Value Stream Chunks or Loops

Step 2 Apply basic Lean concepts� Reduce handoffs by combining steps

� Eliminate waiting for decisions with a “proceed unless halted” agreement

� Maximize flow by managing interrupts

Step 3 Apply Lean tools � Standard/balanced work – reduce variation in work

� Visual workplace – identify problems (defects, backlog)

� Built-in-quality – eliminate rework

� Pull systems – a method to control process flow by replacing only what is consumed

• Reduce handling, storage and paperwork

• Production based on consumption

A Shift in Mindset

Waste

Waste is not defined or easily visible.

Reacting to ‘big issues’.Reactive improvement.

Waste is visible.Identify small opportunities that

together create large overall change.Continuous improvement.

Transport

Defects

Over Processing

MotionWaiting

Over Producing

WasteInventory

LEAN

02/02/2014

26