L 20

-

Upload

shrikant-jahagirdar -

Category

Engineering

-

view

69 -

download

0

Transcript of L 20

-

L-20Sludge Disposal Methods

Industrial Waste treatment

-

Definition Sludge is defined as the residual material

removed from wastewater treatment facilities.

A new term, biosolids, suggests the A new term, biosolids, suggests the beneficial usage of sludge.

The definition of biosolids is now accepted as those primarily organic solid products produced by wastewater treatment processes that can be beneficially recycled.

-

A] SLUDGE TREATMENT Thickening Conditioning Dewatering Drying Incineration Disposal

-

1. Thickning Reduces moisture content of sludge,

thereby reducing volume of sludge. Three types of thickening1. Gravity thickening2. Air floatation3. Centrifugation

-

Gravity Gravity Thickening

-

2. Conditioning Conditioning improves the drainability

of digested sludge. Methods adopted 1. Elutriation (involves passage of air to 1. Elutriation (involves passage of air to

separate particles)2. Chemical conditioning (addition of

coagulants)3. Freezing etc.

-

3. Dewatering

Purpose is to reduce volume ofsludge and increase concentrations ofbiosolids.biosolids.

Dewatering can be achieved on sanddrying beds.

-

Sludge Processing Dewatering - removes liquids Drying beds

solids concentration up to 40% used for well digested, stabilized residuals used for well digested, stabilized residuals

Centrifuges solids concentration 20 to 40 % rotates liquids at high speeds & spins the

water away

-

Sludge Processing Vacuum Filters

solids concentration 15 to 30 % rotating filter media passes through vat of residuals,

residuals coat the filter and water is extracted by vacuum, polymers may be used vacuum, polymers may be used

Pressure filters solids concentration up to 50% series of vertical plates, belts, or frames, water

squeezed out under pressure, solids are retained between the belts or plates

-

Sludge drying beds

-

Sludge drying beds

-

4. Heat drying

Reduces water content Temp @ 350oC Process carried out in kiln. Dried sludge used as soil conditioner

-

Heat drying unit

-

Sludge Reuse or Disposal OptionsIncineration burning sludge at high temperatures in furnace volume is reduced ash is stabilized ash is stabilized requires air permit & pollutant removal high operating costs complex Temp @ 650oC to 750oC

-

SludgeIncineration:

MultipleMultipleHearth

-

Fluidized bed sludge incineration

-

Incinerator

-

Sludge Reuse or Disposal Options

Landfill disposal of sludge in a lined landfill leachate collection required odor potential local regulatory requirements inexpensive Trucking (Transportation) costs

-

Sludge Reuse or Disposal OptionsSurface disposal trench, waste pile, lagoon biosolids remain longer than 2 years surface impoundment surface impoundment dedicated disposal sites

-

Disposal site

-

Sludge Reuse or Disposal OptionsLand Application application of sludge to condition the soil or

fertilize crops / other vegetation sprayed or spread on soil surface tilled into soil or injected directly below the

surface must be applied at agronomic rates, meet

pollutant limits, and pathogen & vector attraction reduction requirements

requires 30 days or more of storage

-

Land Application

-

Sludge filling station

-

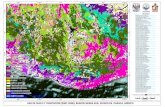

Land disposal of sludge

-

Disposal into the sea

-

Sludge Lagooning

-

Sludge lagoons

-

Economic Aspects

-

Waste to Wealth

-

INCORPORATING BIOMASS INTO BRICKSINCORPORATING BIOMASS INTO BRICKSINCORPORATING BIOMASS INTO BRICKSINCORPORATING BIOMASS INTO BRICKS

-

Objective questions 1. Sludge drying beds are used for _________

of sludge. 2. ____________ reduces volume of sludge

considerably as compared to other methods. 3.Pick out odd one w r t sludge 3.Pick out odd one w r t sludge Biogas recovery, metal extraction, use in

building materials, odour and pathogen

-

Theory questions Write detailed note on 1. Sludge disposal 2. Sludge drying bed 2. Sludge drying bed