KSKV Transmission System Maintenance

-

Upload

mohamad-nadzri-yahaya -

Category

Documents

-

view

225 -

download

0

Transcript of KSKV Transmission System Maintenance

-

8/16/2019 KSKV Transmission System Maintenance

1/43

December Edition 2013

MINISTRY OF EDUCATION, MALAYSIA

VOCATIONAL COLLEGE STANDARD CURRICULLUM

COURSE INFORMATION

COURSE NAME

CODE NAME

:

:

TRANSMISSION SYSTEM MAINTENANCE

GMA 201

LEVEL : 1 SEMESTER 2

CREDIT UNIT : 3.0

CONTACT HOUR :FACE TO FACE : 6.0 HOURS/WEEK (1T!"#

NON FACE TO FACE :

COURSE TY"E : VOCATIONAL

"RE$RE%UISITE : $

CORE RE%UISITE : $

Last Edited 10-13Nov 2013

Module Page 1/48 Document Page 1

-

8/16/2019 KSKV Transmission System Maintenance

2/43

December Edition 2013

COURSE OUTCOMES

At the end of the course, the students should be able to:-

• Replace drive shaft assembly

• Service gear box assembly

• Service differential assembly

• Repair clutch system

• Replace steering ball joints

• Service parking brake system

• Service hydraulic lines

• Repair hydraulic cylinders

COURSE DESCRI"TION

This unit identifies the competence reuired to replace drive shaft assembly using hand tools set, ne! drive shaft unit, grease, drive shaftassembly service manual, jack, machine safety stand and maintenance check sheet so that drive shaft assembly service manual obtained, driveshaft removed, ne! drive shaft installed and check sheet recorded in accordance !ith manufacturer"s specification#

This unit identifies the competence reuired to service gear box assembly using hand tools set, lifting euipment, gear box assembly servicemanual, gear box oil, ne! gear box mounting so that gear box assembly service manual obtained, attached components disconnected, gear box assembly removed, gear box assembly installed, attached components connected and check sheet recorded in accordance !ithmanufacturer"s specification

This unit identifies the competence reuired to service differential assembly using hand tools set, differential assembly service manual, torue

!rench, special puller, and maintenance check sheet so that differential assembly service manual obtained, attached components anddifferential assembly removed, differential assembly and attached components installed and check sheet recorded in accordance !ithmanufacturer"s specification#

Last Edited 10-13Nov 2013

Module Page 2/48 Document Page 2

-

8/16/2019 KSKV Transmission System Maintenance

3/43

December Edition 2013

This unit identifies the competence reuired to repair clutch system using hand tools set, clutch assembly service manual, ne! clutch plate, ne!bearing, measuring euipments, grease and maintenance check sheet so that clutch assembly service manual obtained, gearbox assembly andclutch assembly removed, clutch components dismantled, clutch components checked, clutch components assembled, clutch assembly andgearbox assembly installed and check sheet recorded in accordance manufacturer"s specification#

This unit identifies the competence reuired tor Replace steering ball joint using hand tools set, steering ball joint puller, torue !rench, steeringball joint service manual, ne! ball joint and log book so that steering ball joint service manual obtained, steering ball joint removed, steering ball

joint installed and steering system operation tested in accordance !ith manufacturer"s specification#

This unit identifies the competence reuired to service parking brake system using hand tools set, grease, parking brake service manual and logbook so that parking brake service manual obtained, parking brake cable condition checked, adjust parking brake cable tension, test parkingbrake performance in accordance !ith manufacturer"s specification

This unit identifies the competence reuired to service hydraulic lines using hand tools set, hydraulic system service manual, hydraulic oil,sealing tape, !renches, industrial tissue and log book so that hydraulic system service manual obtained, leakage piping checked and damage

pipe replacement !orks executed in accordance !ith manufacturer"s specification#

This unit identifies the competence reuired to Repair hydraulic cylinders using hand tools set, hydraulic cylinder service manual, hydraulic oil,dial testing indicator $%T&', !rench, jig, industrial tissue, copper rod and log book so that hydraulic cylinder service manual obtained, hydrauliccylinder assembly removed, hydraulic cylinder components dismantled, hydraulic cylinder components checked, hydraulic cylinder componentsassembled, hydraulic cylinder assembly installed and hydraulic cylinders performance tested in accordance !ith manufacturer"s specification#

Last Edited 10-13Nov 2013

Module Page 3/48 Document Page 3

-

8/16/2019 KSKV Transmission System Maintenance

4/43

December Edition 2013

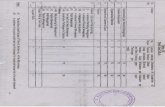

CONTENT AND LEARNING STANDARDS

"ROGRAM : AGRICULTURAL MECHANI&ATION

COURSE NAME : TRANSMISSION SYSTEM MAINTENANCE

CODE NAME : GMA 201

COM"ETENCY : 1

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

1. RE"LACE DRIVE SHAFTASSEM'LY

(#(# )btain %rive Shaft AssemblyService *anual

(#(#(# +xplain sources of drive shaft assembly servicemanual in according !ith standard servicemanufactured#

(#(## +xplain rocedures of acuiring drive shaft assemblyservice manual in according !ith standard servicemanufactured#

(#(#.# &dentify %rive shaft assembly service manual inaccording !ith standard service manufactured#

(#(#/# %etermine source of drive shaft assembly servicemanual in according !ith standard servicemanufactured#

(#(#0# Acuire drive shaft assembly service manual inaccording !ith standard service manufactured#

Last Edited 10-13Nov 2013

Module Page 4/48 Document Page 4

-

8/16/2019 KSKV Transmission System Maintenance

5/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

(#(#1# &nterpret drive shaft assembly service manual inaccording !ith standard service manufactured#

(#(#2# %escribe precaution !arnings given by manual inaccording !ith standard service manufactured#

(## Remove %rive Shaft (##(# 3ist types of !heel jack

(### 3ist types of ball join

(##.# +xplain procedure of removing drive shaft !ithstandard service manufactured#

(##/# 3ifting up machine !heel !ith standard servicemanufactured#

(##0# 3ift up machine !heel accordance !ith servicemanual !ith standard service manufactured#

(##1# 4ninstall ball join accordance !ith service manual !ithstandard service manufactured#

(##2# 4ninstall outer shaft accordance !ith service manual!ith standard service manufactured#

(##5# ull out inner shaft accordance !ith service manual!ith standard service manufactured#

(##6# 4se tools or euipment accordance !ith user tools

Last Edited 10-13Nov 2013

Module Page /48 Document Page

-

8/16/2019 KSKV Transmission System Maintenance

6/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

manual standard#

(#.# &nstall %rive Shaft (#.#(# 3ist types of !heel jack accordance to manufacturerspecification

(#.## 3ist types of ball join accordance to manufacturerspecification

(#.#.# +xplain procedure of removing drive shaft accordance !ith service manual

(#.#/# ush in inner shaft accordance !ith service manual

(#.#0# Apply method of reinstall outer shaft accordance !ithservice manual

(#.#1# 7ix ball join accordance !ith service manual

(#.#2# 4se careful !hen lubricants and greases, it"s may splitto the eyes accordance !ith user tools manualstandard#

(#/# Record 8heck Sheet (#/#(# 8heck sheet format accordance !ith service manual

(#/## 3ist methods of fill in maintenance check sheetaccordance !ith service manual

(#/#.# 3ist techniues of recording check sheet accordance

Last Edited 10-13Nov 2013

Module Page !/48 Document Page !

-

8/16/2019 KSKV Transmission System Maintenance

7/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

!ith service manual

(#/#/# %etermine check sheet format accordance !ith

service manual

(#/#0# 7ill in maintenance check sheet accordance !ithservice manual

(#/#1# Apply recording check sheet techniue accordance!ith service manual

Last Edited 10-13Nov 2013

Module Page "/48 Document Page "

-

8/16/2019 KSKV Transmission System Maintenance

8/43

December Edition 2013

CONTENT AND LEARNING STANDARDS

"ROGRAM : AGRICULTURAL MECHANI&ATION

COURSE NAME : TRANSMISSION SYSTEM MAINTENANCE

CODE NAME : GMA 201

COM"ETENCY : 2

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

2. SERVICE GEAR 'OASSEM'LY

#(# )btain 9ear box AssemblyService *anual

#(#(# +xplain source of gear box assembly accordance !ithservice manual

#(## +xplain procedures of acuiring gear box assembly accordance !ith service manual

#(#.# 3ist drive gear box accordance !ith service manual

#(#/# %etermine source of gear box assembly accordance!ith service manual

#(#0# Acuire gear box assembly accordance !ith servicemanual

#(#1# &nterpret gear box assembly accordance !ith servicemanual

#(#2# Apply and observe precaution !arnings given bymanual

Last Edited 10-13Nov 2013

Module Page 8/48 Document Page 8

-

8/16/2019 KSKV Transmission System Maintenance

9/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

## %isconnect Attached8omponents

##(# 3ist types of gear box mounting according tomanufacturer specification

### 3ist types of gear box oil according to manufacturerspecification

##.# State disconnecting external attachment procedure accordance !ith service manual

##/# 4nscre! gear box mounting bolt accordance !ithservice manual

##0# %rain out gear box oil accordance !ith service manual

##1# Release bottom guards accordance !ith servicemanual

##2# Avoid splash gear box oil to skin, floor and eyesaccordance precaution !arnings given by manual

#.# Remove 9ear box Assembly #.#(# 3ist types of lifting euipment according tomanufacturer specification

#.## 3ist methods of removing gear box unit according tomanufacturer specification

Last Edited 10-13Nov 2013

Module Page #/48 Document Page #

-

8/16/2019 KSKV Transmission System Maintenance

10/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

#.#.# *oving out gear box unit according to manufacturerspecification

#.#/# 7ix lifting shackles or support gear box !ith jack according to manufacturer specification

#.#0# 4nscre! gear box bolt accordance !ith servicemanual

#.#1# *ove out gear box unit accordance !ith servicemanual

#.#2# 3ift and handle all heavy components using liftingeuipment

#/# &nstall 9ear box Assembly #/#(# State function of lifting euipment accordance !ithservice manual

#/## State function of gear box shaft accordance !ithservice manual

#/#.# +xplain techniues of tighten gear box boltaccordance !ith service manual

#/#/# 4se lifter to place gear box assembly at location accordance !ith service manual

#/#0# Slot gear box shaft accordance !ith service manual

#/#1# Tighten gear box bolt accordance !ith service manual

Last Edited 10-13Nov 2013

Module Page 10/48 Document Page 10

-

8/16/2019 KSKV Transmission System Maintenance

11/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

#0# 8onnect attached 8omponents #0#(# +xplain function of gear box mounting accordance!ith service manual

#0## +xplain function of bottom guards accordance !ithservice manual

#0#.# &dentify type of gear box oil accordance !ith servicemanual

#0#/# Tighten gear box mounting bolt accordance !ithservice manual

#0#0# 7ix bottom guards accordance !ith service manual

#0#1# Top up gear box oil accordance !ith service manual

#0#2# 3ift and handle all heavy components using liftingeuipment

#1# Record 8heck Sheet #1#(# +xplain sheet format accordance to manufacturerbook manual

#1## &dentify methods of fill in maintenance check sheet accordance to manufacturer book manual

#1#.# Techniues of recording check sheet accordance to

Last Edited 10-13Nov 2013

Module Page 11/48 Document Page 11

-

8/16/2019 KSKV Transmission System Maintenance

12/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

manufacturer book manual

#1#/# %etermine check sheet format accordance to

manufacturer book manual

#1#0# 7ill in maintenance check sheet accordance tomanufacturer manual service book

#1#1# Apply recording check sheet techniue accordance tomanufacturer manual service book

#1#2# *eticulous !hen recording maintenance check sheet accordance to manufacturer manual service book

#1#5# *eticulous !hen recording schedule maintenance

book accordance to manufacturer manual servicebook

Last Edited 10-13Nov 2013

Module Page 12/48 Document Page 12

-

8/16/2019 KSKV Transmission System Maintenance

13/43

December Edition 2013

CONTENT AND LEARNING STANDARDS

"ROGRAM : AGRICULTURAL MECHANI&ATION

COURSE NAME : TRANSMISSION SYSTEM MAINTENANCE

CODE NAME : GMA 201

COM"ETENCY : 3

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

3. SERVICEDIFFERENTIALASSEM'LY

.#(# )btain %ifferential AssemblyService *anual

.#(#(# +xplain sources of differential assembly service manual

.#(## +xplain procedures of acuiring differential assembly service

manual

.#(#.# State differential assembly service manual

.#(#/# %etermine source of differential assembly service manual

.#(#0# Acuire differential assembly service manual

.#(#1# &nterpret differential assembly service manual

.#(#2# 4se carefully and observe precaution !arnings given bymanual

.## Remove Attached 8omponents .##(# +xplain disconnecting propeller shaft and differentialassembly accordance !ith service manual

Last Edited 10-13Nov 2013

Module Page 13/48 Document Page 13

-

8/16/2019 KSKV Transmission System Maintenance

14/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

.### &dentify types of differential oil accordance !ith servicemanual

.##.# &dentify method of releasing external components !ithdifferential assembly accordance !ith service manual

.##/# %isconnect propeller shaft and differential assembly accordance !ith service manual

.##0# %rain out differential oil accordance !ith service manual

.##1# Release external components !ith differential assembly accordance !ith service manual

.##2# Avoid splash differential oil to skin, floor and eyes

.#.# Remove %ifferential Assembly .#.#(# &dentify types of differential unit accordance !ith servicemanual

.#.## +xplain pulling out !heel shaft from centre housingtechniue accordance !ith service manual

.#.#.# +xplain procedure of removing differential assembly accordance !ith service manual

.#.#/# %etermine types of differential unit correctly accordance !ithservice manual#

.#.#0# ull out !heel shaft from centre housing correctly accordance !ith service manual#

Last Edited 10-13Nov 2013

Module Page 14/48 Document Page 14

-

8/16/2019 KSKV Transmission System Maintenance

15/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

.#.#1# Removing differential assembly accordance !ith servicemanual#

.#.#2# 3ift and handle all heavy components using lifting euipment accordance !ith service manual

.#/# &nstall %ifferential Assembly .#/#(# +xplain function of differential unit accordance !ith servicemanual

.#/## &dentify pressing in !heel shaft from centre housingtechniue accordance !ith service manual

.#/#.# +xplain procedure of &nstalling differential assembly accordance !ith service manual

.#/#/# %etermine function of differential unit correctly# accordance!ith service manual

.#/#0# ress in !heel shaft from centre housing correctly accordance !ith service manual

.#/#1# &nstalling differential assembly accordance !ith servicemanual

.#0# &nstall Attached 8omponents .#0#(# +xplain connecting propeller shaft and differential assembly accordance !ith service manual

.#0## %escribe function of differential oil accordance !ith servicemanual

Last Edited 10-13Nov 2013

Module Page 1/48 Document Page 1

-

8/16/2019 KSKV Transmission System Maintenance

16/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

.#0#.# %efine fixing external components to differential assembly accordance !ith service manual

.#0#/# 8onnect propeller shaft and differential assemblyaccordance !ith service manual

.#0#0# 7ix external components to differential assembly correctly accordance !ith service manual

.#0#1# Top up differential oil accordance !ith service manual#

.#1# Record 8heck Sheet .#1#(# 8heck sheet format according to standard form

.#1## 3ist methods of fill in maintenance check sheet according to

standard filling form

.#1#.# &dentify techniues of recording check sheet according tostandard filling form

.#1#/# %etermine check sheet format according to standard fillingform

.#1#0# 7ill in maintenance check sheet correctly according tostandard form

.#1#1# Apply recording check sheet techniue according tostandard filling form

.#1#2# *eticulous !hen recording maintenance check sheet

.#1#5# *eticulous !hen recording schedule maintenance book

Last Edited 10-13Nov 2013

Module Page 1!/48 Document Page 1!

-

8/16/2019 KSKV Transmission System Maintenance

17/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

CONTENT AND LEARNING STANDARDS

"ROGRAM : AGRICULTURAL MECHANI&ATION

COURSE NAME : TRANSMISSION SYSTEM MAINTENANCE

CODE NAME : GMA 201

COM"ETENCY : )

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

4 RE"AIR CLUTCH SYSTEM /#( )btain 8lutch Assembly Service*anual

/#(#( %escribe source of clutch assembly service manual accordance !ith service manual

Last Edited 10-13Nov 2013

Module Page 1"/48 Document Page 1"

-

8/16/2019 KSKV Transmission System Maintenance

18/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

/#(# &dentify procedures of acuiring clutch assemblyservice manual accordance !ith service manual

/#(#. +xplain clutch assembly service manual accordance!ith service manual

/#(#/ %etermine source of clutch assembly accordance !ithservice manual

.#1#6# Acuire clutch assembly service manual accordance!ith service manual

.#1#(# &nterpret clutch assembly service manual accordance!ith service manual

/# Remove 9earbox Assembly /##( +xplain types of lifting euipment accordance !ithservice manual

/## State list methods of removing transmission unit accordance !ith service manual

/##. +xplain ho! to 4nscre! transmission bolt accordance!ith service manual

/##/ *oving out transmission unit accordance !ith servicemanual

/##0 %isconnect external attachment correctly accordance!ith service manual

Last Edited 10-13Nov 2013

Module Page 18/48 Document Page 18

-

8/16/2019 KSKV Transmission System Maintenance

19/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

/##1 7ix lifting shackles or support transmission !ith jack accordance !ith service manual

/##2 erfom method of unscre! transmission boltaccordance !ith service manual

/##5 erform move out transmission unit accordance !ithservice manual

/##6 erfom lift and handle all heavy components usinglifting euipment of adeuate capacity accordance !ithservice manual

/#. Remove 8lutch Assembly /#.#( 3ist types of clutch unit according to manufacturer

specification

/#.# %escribe function of clutch unit according tomanufacturer specification

/#.#. +xplain procedure of removing clutch unit accordance!ith service manual

/#.#/ 3ist method of unscre! clutch unit bolts accordance!ith service manual

/#.#0 3ist method of 4ninstall clutch assembly accordance!ith service manual

/#.#1 %etermine types of clutch unit correctly accordance!ith service manual

Last Edited 10-13Nov 2013

Module Page 1#/48 Document Page 1#

-

8/16/2019 KSKV Transmission System Maintenance

20/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

/#.#2 %etermine function of clutch unit correctly accordance!ith service manual#

/#.#5 4nscre! clutch unit bolts accordance !ith servicemanual

/#.#6 4ninstall clutch assembly accordance !ith servicemanual

/#.#( Apply removing clutch unit procedure accordance !ithservice manual

/#.#(( *eticulous !hen dealing !ith heavy components

/#/ %ismantle 8lutch 8omponents /#/#( +xplain types of clutch components such as

• 8lutch plate

• ressure plate

• 8lutch bearing

accordance !ith service manual

/#/# +xplain function of clutch components accordance !ithservice manual

/#/#. %escribe procedure of dismantling clutch components

accordance !ith service manual

/#/#/ %etermine types of clutch components correctly according to manufacturer specification #

Last Edited 10-13Nov 2013

Module Page 20/48 Document Page 20

-

8/16/2019 KSKV Transmission System Maintenance

21/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

/#/#0 %etermine function of clutch components correctly#

/#/#1 Apply dismantling clutch components procedure

accordance !ith service manual

/#0 8heck 8lutch 8omponents /#0#( +xplain types of clutch components defect accordance!ith service manual

/#0# State checking clutch components method accordance!ith service manual

/#0#. 3ist using measuring euipment accordance !ithservice manual

/#0#/ %etermine types of clutch components defectaccordance !ith service manual

/#0#0 &nspect clutch components such as

• Thickness of clutch plate

• ;ear and tear of pressure plate diaphragm

• Roughness of bearing accordance !ith service

manualaccordance !ith service manual

/#0#1 4se measuring euipment correctly accordance !ith

service manual

/#1 Assemble 8lutch 8omponents /#1#( &dentify types of clutch components accordance tomanufacturer specification

Last Edited 10-13Nov 2013

Module Page 21/48 Document Page 21

-

8/16/2019 KSKV Transmission System Maintenance

22/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

/#1# +xplain function of clutch components accordance tomanufacturer specification

/#1#. %escribe procedure of assembling clutch components accordance !ith service manual

/#1#/ %etermine types of clutch components correctly accordance !ith service manual#

/#1#0 %etermine function of clutch components correctlyaccordance !ith service manual#

/#1#1 Apply assembling clutch components procedureaccordance !ith service manual

/#2 &nstall 8lutch Assembly /#2#( +xplain operation of clutch assembly accordance !ithmanufacturer"s specification#

/#2#

/#2#. State function ability of clutch unit accordance !ithmanufacturer"s specification#

/#2#/ %escribe procedure of installing clutch unit accordance!ith manufacturer service manual

/#2#0 3ist reinstall clutch assembly accordance !ith servicemanual

/#2#1 erform tighten clutch unit bolts accordance !ithservice manual

Last Edited 10-13Nov 2013

Module Page 22/48 Document Page 22

-

8/16/2019 KSKV Transmission System Maintenance

23/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

/#2#2 %etermine operation of clutch unit correctly accordance !ith manufacturer"s specification##

/#2#5 %etermine function ability of clutch unit accordance!ith service manual

/#2#6 Reinstall clutch assembly accordance !ithmanufacturer"s specification#

/#2#( Tighten clutch unit bolts accordance !ithmanufacturer"s specification#

/#2#(( Apply procedure of installing clutch unit correctly accordance !ith manufacturer service manual

/#5 )btain install 9earbox Assembly /#5#( +xplain function of lifting euipment accordance !ithservice manual

/#5# +xplain function of transmission shaft accordance !ithservice manual

/#5#. %escribe procedure of adjusting clutch free-playaccordance !ith manufacturer service manual

/#5#/ %efine connecting external attachments accordance

!ith service manual

/#5#0 4se lifter to place transmission assembly at locationcorrectly accordance !ith service manual#

Last Edited 10-13Nov 2013

Module Page 23/48 Document Page 23

-

8/16/2019 KSKV Transmission System Maintenance

24/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

/#5#1 &nstall slot transmission shaft accordance !ith servicemanual

/#5#2 Tighten transmission bolt accordance !ith servicemanual

/#5#5 8onnect external attachments accordance !ith servicemanual

/#5#6 Adjust clutch free-play accordance !ith service manual

/#5#( Acuire accuracy !hen setting torue !renchaccordance !ith service manual

/#6 Record 8heck Sheet /#6#( 8heck sheet format according to standard form

/#6# 3ist methods of fill in maintenance check sheet according to standard filing system#

/#6#. +xplain techniues of recording check sheet according to standard form

/#6#/ %etermine check sheet format according to standardfiling system#

/#6#0 7ill in maintenance check sheet according to standard

filing system

/#6#1 Apply techniue of recording check sheet according to standard filing system#

Last Edited 10-13Nov 2013

Module Page 24/48 Document Page 24

-

8/16/2019 KSKV Transmission System Maintenance

25/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

/#6#2 *eticulous !hen recording maintenance check sheetaccording to standard filing system#

CONTENT AND LEARNING STANDARDS

"ROGRAM : AGRICULTURAL MECHANI&ATION

COURSE NAME : TRANSMISSION SYSTEM MAINTENANCE

CODE NAME : GMA 201

COM"ETENCY : !

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

5 RE"LACE STEERING 'ALL*OINTS

0#( )btain Steering

-

8/16/2019 KSKV Transmission System Maintenance

26/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

0#(# +xplain rocedure of acuiring steering ball jointservice manual according to service manual book

0#(#. +xplain Steering ball joint service manual according tomanufacturer service manual book

0#(#/ Apply source of steering ball joint service manual according to manufacturer service manual book

0#(#0 Acuire steering ball joint service manual according tomanufacturer service manual book

0#(#1 &nterpret steering ball joint service manual accordingto manufacturer service manual book

0# Remove Steering

-

8/16/2019 KSKV Transmission System Maintenance

27/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

0##1 %etermine types of steering ball joint according tomanufacturer specification

0##2 %etermine function of steering ball joint according tomanufacturer service manual book

0##5 3ift up euipment according to manufacturer servicemanual book

0##6 4se special tool to remove steering ball join from itlocation according to manufacturer service manualbook

0##( Apply removing steering ball joint procedure

according to manufacturer service manual book

0#. &nstall Steering

-

8/16/2019 KSKV Transmission System Maintenance

28/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

0#.#1 %etermine ability of steering ball joint function according to manufacturer service manual book

0#.#2 lug steering ball join to location according tomanufacturer service manual book

0#.#5 Tighten steering ball join nut to proper torue according to manufacturer service manual book

0#.#6 Apply procedure of installing steering ball jointaccording to manufacturer service manual book

0#.#( 3ifting do!n euipment according to manufacturerservice manual book

0#/ Test Steering System )perat ion 0#/#( +xplain engine starting procedure $&f necessary forpo!er steering system' according to manufacturerservice manual book

0#/# +xplain steering system inspection procedure according to manufacturer service manual book

0#/#. +xplain ho! updating log book

0#/#/ Apply procedure of engine starting according to

manufacturer service manual book

0#/#0 Turn !heel to left and right to check function ability ofsteering ball joint and end play according tomanufacturer service manual book

Last Edited 10-13Nov 2013

Module Page 28/48 Document Page 28

-

8/16/2019 KSKV Transmission System Maintenance

29/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

0#/#1 Apply steering system inspection procedure accordingto manufacturer service manual book

0#/#2 4pdating log book

Last Edited 10-13Nov 2013

Module Page 2#/48 Document Page 2#

-

8/16/2019 KSKV Transmission System Maintenance

30/43

December Edition 2013

CONTENT AND LEARNING STANDARDS

"ROGRAM : AGRICULTURAL MECHANI&ATION

COURSE NAME : TRANSMISSION SYSTEM MAINTENANCE

CODE NAME : GMA 201

COM"ETENCY : 6

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

6 SERVICE"ARKING 'RAKESYSTEM

6.1 )btain arking

-

8/16/2019 KSKV Transmission System Maintenance

31/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

6.2 8heck arking

-

8/16/2019 KSKV Transmission System Maintenance

32/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

1##. ulling parking brake lever and count the >click? according tomanufacturer service manual book

1##/ %etermine parking brake cable tension according tomanufacturer service manual book

1##0 ull parking brake lever and count the >click? according tomanufacturer service manual book

1##1 Apply adjusting parking brake cable tension procedure according to manufacturer service manual book

6.4 Test arking

-

8/16/2019 KSKV Transmission System Maintenance

33/43

December Edition 2013

CONTENT AND LEARNING STANDARDS

"ROGRAM : AGRICULTURAL MECHANI&ATION

COURSE NAME : TRANSMISSION SYSTEM MAINTENANCE

CODE NAME : GMA 201

COM"ETENCY : +

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

7 SERVICE HYDRAULIC

LINES

2#( )btain @ydraulic System Service*anual

2#(#( &edentify source of hydraulic system service manual according to manufacturer service manual book

2#(# rocedures of acuiring hydraulic system service manual according to manufacturer service manual book

2#(#. +xplain hydraulic system service manual according to

Last Edited 10-13Nov 2013

Module Page 33/48 Document Page 33

-

8/16/2019 KSKV Transmission System Maintenance

34/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

manufacturer service manual book

2#(#/ %etermine source of hydraulic system service manual according to manufacturer service manual book

2#(#0 Acuire hydraulic system service manual according tomanufacturer service manual book

2#(#1 &nterpret hydraulic system service manual according tomanufacturer service manual book

2#(#2 &nterpret hydraulic system circuit according to manufacturerservice manual book

2# 8heck 3eakage iping 2##( +xplain types of hydraulic pipes according to manufacturerspecification

2## &dentify hydraulic piping circuit according to manufacturerspecification

2##. State types of hydraulic oil according to manufacturerspecification

2##/ +xplain checking leakage procedure according tomanufacturer service manual book

2##0 +xplain )perating all hydraulic system according tomanufacturer service manual book

2##1 *arking leakage area according to manufacturer servicemanual book

Last Edited 10-13Nov 2013

Module Page 34/48 Document Page 34

-

8/16/2019 KSKV Transmission System Maintenance

35/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

2##2 %etermine types of hydraulic pipes such as

• Single point

•

.-point linkagesaccording to manufacturer service manual book

2##5 &nterpret hydraulic piping circuit according to manufacturerspecification

Apply checking leakage procedure according to manufacturer service manual book

2##6 %etermine types of hydraulic oil according to manufacturerspecification

2##( Apply engine starting procedure according to manufacturerspecification

2##(( )perate all hydraulic system according to manufacturerservice manual book

2##( *ark leakage area according to manufacturer service manualbook

2##(. S!itch of engine according to manufacturer service manualbook

2#. +xecute %amage ipe Replacement 2#.#( +xplain types of hydraulic pipes damage according to

Last Edited 10-13Nov 2013

Module Page 3/48 Document Page 3

-

8/16/2019 KSKV Transmission System Maintenance

36/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

;orks manufacturer service manual book

2#.# +xplain depressuriing hydraulic system method according tomanufacturer service manual book

2#.#. +xplain replace pipe line procedure according tomanufacturer service manual book

2#.#/ %escribe change pipe line according to manufacturer servicemanual book

2#.#0 Apply replacing pipe line procedure according tomanufacturer service manual book

1#(#( 4pdating log book according to standard form#

2#.#1 %etermine type of hydraulic pipes damage

2#.#2 %epressurie hydraulic system according to manufacturerservice manual book

2#.#5 %isconnect damage pipe line according to manufacturerservice manual book

2#.#6 8hange pipe line according to manufacturer service manualbook

2#.#( Apply replacing pipe line procedure according tomanufacturer service manual book

1#(# 4pdate log book according to standard form#

Last Edited 10-13Nov 2013

Module Page 3!/48 Document Page 3!

-

8/16/2019 KSKV Transmission System Maintenance

37/43

December Edition 2013

CONTENTSTANDARD

LEARNING STANDARD "ERFORMANCE CRITERIA

CONTENT AND LEARNING STANDARDS

"ROGRAM : AGRICULTURAL MECHANI&ATION

COURSE NAME : TRANSMISSION SYSTEM MAINTENANCE

CODE NAME : GMA 201

COM"ETENCY :

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

RE"AIR HYDRAULICCYLINDERS

5#( )btain @ydraulic8ylinder Service *anual

5#(#( +xplain source of hydraulic cylinder service manual accordingto manufacturer service manual book

5#(# rocedures of acuiring hydraulic cylinder service manual according to manufacturer service manual book

5#(#. +xplain hydraulic cylinder service manual according tomanufacturer service manual book

5#(#/ %etermine source of hydraulic cylinder service manual according to manufacturer service manual book

5#(#0 Acuire hydraulic cylinder service manual according tomanufacturer service manual book

Last Edited 10-13Nov 2013

Module Page 3"/48 Document Page 3"

-

8/16/2019 KSKV Transmission System Maintenance

38/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

5#(#1 &nterpret hydraulic cylinder service manual according tomanufacturer service manual book

5#(#2 &nterpret hydraulic cylinder circuit according to manufacturerservice manual book

5# Remove @ydraulic8ylinder Assembly

5##( +xplain hydraulic system according to manufacturer servicemanual book

5## +xplain types of hydraulic oil according to manufacturerspecification

5##. State procedure of removing hydraulic cylinder assemblyprocedure according to manufacturer service manual book

5##/ +xplain to draining hydraulic oil from the ram according tomanufacturer specification

5##0 %epressurise hydraulic system according to manufacturerservice manual book

5##1 %isconnect hydraulic linkages according to manufacturerservice manual book

5##2 4ninstall hydraulic cylinder assembly according tomanufacturer service manual book

5##5 %rain hydraulic oil from the ram according to manufacturerservice manual book

5##6 lug hoses and piping end for safety according to

Last Edited 10-13Nov 2013

Module Page 38/48 Document Page 38

-

8/16/2019 KSKV Transmission System Maintenance

39/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

manufacturer service manual book

5#. %ismantle @ydraulic8ylinder 8omponents

5#.#( +xplain hydraulic cylinder components according tomanufacturer specification

5#.# State procedure of dismantling hydraulic cylinder componentsaccording to manufacturer specification

5#.#. +xplain ho! %isassemble piston seals, rod seal and rod!iper according to manufacturer specification

5#.#/ +xplain soaking components !ith detergent according tomanufacturer service manual book

5#.#0 4ninstall front cap according to manufacturer service manualbook

5#.#1 4ninstall piston rod from cylinder housing according tomanufacturer specification

5#.#2 %isassemble piston seals, rod seal and rod !iper accordingto manufacturer service manual book

5#.#5 Soak components !ith detergent according to manufacturerservice manual book

5#.#6 *eticulous !hen removing piston rod according tomanufacturer service manual book

Last Edited 10-13Nov 2013

Module Page 3#/48 Document Page 3#

-

8/16/2019 KSKV Transmission System Maintenance

40/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

5#/ 8heck @ydraulic8ylinder 8omponents

5#/#( State Types of hydraulic cylinder components defect according to manufacturer specification

5#/# +xplain inspecting rod alignment method according tomanufacturer specification

5#/#. &dentify inspection of hydraulic cylinder parts and componentsdefect procedure according to manufacturer specification

5#/#/ +xplain checking hydraulic cylinder components procedure according to manufacturer specification

5#/#0 +xplain changing defect parts and components according tomanufacturer specification

5#/#1 %etermine types of hydraulic cylinder components defect according to manufacturer specification

5#/#2 Auire inspect rod alignment according to manufacturerspecification

5#/#5 erform check hydraulic cylinder parts and components fromdefect according to manufacturer specification

5#/#6 erform procedure of checking hydraulic cylindercomponents according to manufacturer specification

5#/#( erform change defect parts and components according tomanufacturer specification

Last Edited 10-13Nov 2013

Module Page 40/48 Document Page 40

-

8/16/2019 KSKV Transmission System Maintenance

41/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

5#0 Assemble @ydraulic8ylinder 8omponents

5#0#( %escribe hydraulic cylinder components according tomanufacturer specification

5#0# +xplain assembling hydraulic cylinder components procedureaccording to manufacturer specification

5#0#. +xplain reinstalling front cap according to manufacturerspecification

5#0#/ rocedure of assembling hydraulic cylinder components according to manufacturer service manual book

5#0#0 Reassemble piston seals, rod seal and rod !iper according tomanufacturer service manual book

5#0#1 Reinstall piston rod from cylinder housing according tomanufacturer service manual book

5#0#2 erform reinstall front cap according to manufacturer servicemanual book

5#0#5 7ollo! procedure of assembling hydraulic cylindercomponents according to manufacturer service manual book

5#1 &nstall @ydraulic 8ylinder

Assembly

5#1#( +xplain @ydraulic system according to manufacturer service

manual book

5#1# &dentify types of hydraulic oil according to manufacturerspecification

Last Edited 10-13Nov 2013

Module Page 41/48 Document Page 41

-

8/16/2019 KSKV Transmission System Maintenance

42/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

5#1#. +xplain Removing cylinder ram assembly procedure according to manufacturer service manual book

5#1#/ Reinstall cylinder ram assembly according to manufacturerservice manual book

5#1#0 8onnect hydraulic linkages according to manufacturer servicemanual book

5#1#1 erform top up hydraulic oil according to manufacturerservice manual book

5#1#2 +nsure unplug hoses and piping before installation !orks according to manufacturer service manual book

5#2 )btain test @ydraulic8ylinders erformance

5#2#( +xplain engine starting procedure accordance !ith standardmanufactured service manual

5#2# +xplain operating hydraulic system accordance !ith standardmanufactured service manual

5#2#. &dentify hydraulic performance method accordance !ithstandard manufactured service manual

5#2#/ &dentify inspecting system from leakage accordance !ithstandard manufactured service manual

5#2#0 +xplain s!itching of engine accordance !ith standardmanufactured service manual

5#2#1 &dentify updating log book

Last Edited 10-13Nov 2013

Module Page 42/48 Document Page 42

-

8/16/2019 KSKV Transmission System Maintenance

43/43

December Edition 2013

CONTENT STANDARD LEARNING STANDARD "ERFORMANCE CRITERIA

5#2#2 Apply engine starting procedure accordance to manufactureroperation manual

5#2#5 erform operate hydraulic cylinder system accordance tomanufacturer operation manual

5#2#6 Apply testing hydraulic performance method accordance !ithstandard manufactured service manual

5#2#( erform &nspect system from leakage accordance !ithstandard manufactured service manual#

5#2#(( erform S!itch of engine accordance !ith standardmanufactured service manual

5#2#( Able to 4pdate log book accordance to standard form

Last Edited 10-13Nov 2013

Module Page 43/48 Document Page 43