KCC Silicone · 2011-11-07 · KCC Worldwide Service Network KCC Silicone I Introduction About KCC...

Transcript of KCC Silicone · 2011-11-07 · KCC Worldwide Service Network KCC Silicone I Introduction About KCC...

KCC SiliconeRTVRTV-1 is a one-component vulcanizing silicone that cures to silicone rubberon exposure to atmospheric moisture at room temperature.RTV-2 is a two-component room temperature vulcanizing silicone. Depending on its curing mechanism, two types of RTV-2 are available- a condensation cure type and an addition cure type.

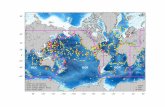

KCC Worldwide Service Network

KCC Silicone I Introduction

About KCC

GermanyRussiaLyon, FranceGreeceTurkeyDubai, UAEBeijing, ChinaKunshan, ChinaKoreaJapanGuangzhou, ChinaHongkongVietnamMalaysiaSingaporeIndiaNewJersey, USA

A precision chemical corporation growing rapidly based on customer’s confidence

With state-of-the-art technology and ultra-modern productionfacilities, KCC seeks perfection in the quality of its products and customer service. Each product that KCC introduces to the marketplace is the result of creative and intensive R&D activities benefiting the diverse needs of every customer. KCC continues to remain deeply committed to improving the living environment and does this by leading the building andindustrial materials industry through continuous research and development.

We are reaching out to the world with quality and technology

KCC Silicone I Introduction

We produce and distribute various silicone products including silicone rubber, sealants for construction and industrial use, silane, silicone oil, silicone emulsion, and silicone dispersion products.

Introduction to KCC Silicone Business

Today’s building materials are essential blends or composites of organic and inorganic chemical products. KCC takes pride in being a market leader in these particular chemical fields. In the past, the two divisions within KCC operated separately, but they are now merged together to provide enhanced synergy, cost efficiency, and service to our multitude of highly valued customers. Korea Chemical Co. Ltd., that specialized in organic chemical products (mainly paints and resins for paints) has merged with Kumgang Chemical Co. Ltd., into a single legal entity entitled Kumgang Korea Chemical Co. Ltd. The company is known as KCC for short. The technical integration of the organic and inorganic chemistry business under the same roof ensures better products, better technical service, and more competitive prices. KCC continues to be a worldwide industrial player in the 21st century and continues to invest in innovative R&D activities.

KCC constructed the first silicone monomer production plant in Korea in 2003. KCC has madegreat R&D advances for the silicone industry with researchers specialized in the field of siliconemonomer, polymer synthesis, and the development of applicable products. Thus, KCC has completedthe development in the silicone-related field successfully. KCC is ready to produce and provide siliconeproducts including silicone sealant for construction, industrial RTV, silane, fluids, emulsion anddispersion, as well as rubber.Moreover, KCC makes contributions to promote the competitive power of ourcustomers by supplying products corresponding to their needs and by concentratingour energies on R&D activities.

Advantages : Easy to handle, with no curing inhibitions. Heating is unnecessary.

Advantages : Can be used in areas which cannot be heated. Heating is unnecessary.

Advantages : Excellent deep-curing characteristics.By-products not be generated.

Advantages : Rapid curing with deep-curing characteristics.

Room Temperaturecuring type(Condensation cure)

Room Temperaturecuring type(Condensation cure)

Heat curing type(Addition cure)

Heat curing type(Addition cure)

RTV

One-component

Two-component

Parameter Addition Cure, 1-part & 2-part

Condensation Cure 1-part

Condensation Cure 2-part

Moisture Unnecessary Required Unnecessary

By-products NO YES YES

Curing inhibition YES NO NO

Availability at closed areas YES NO (Deep or wide areas) NO (Deep or wide areas)

Deep section cure Good Bad Good

Features of RTV Rubber RTV Classification

06

KCC Silicone

RTVKCC Silicone

RTV

Heat and cold resistance Suitable for heat-resistant seals of heatingdevices such as microwave ovens

Adhesion Suitable for heat-dissipating seals ofheat devices

Electrical properties For moisture proof coating of electrodesand other applications

Non solvent formulations For coating various substrates

Shock resistance For applications such as vibration devices

Oil and chemical resistance For sealing and potting of equipment and sensors for automotive use

Weather resistance For sealing equipment used outdoors

Encapsulant For potting various substrates

RTV-1 General Purpose(Flowable)

Classification General Purpose Flame Retardant High Temperature ThermalConductive FIPG

Non-flowable

QS9118 W / HB

QS9119 G,W / HB

SS7972A G / (UL V - 0)

QS9112 W / V - 0 QS9114 BK, R / HB QS9100 R, W

QS9102 W, G, BK / HB QS9110 R, W

QS9106 W, G, BK / HB QS9144 R, W

QS9109 W, G, BK / HB

Semi-Flowable

SS7944 A TL 60 Pas

SS4100 W 60 Pas HB QS9115 BK 210 Pas HB

FlowbleHigh viscosity

SS4000I-25 K TR 25 Pas HB

SS7970 A G 20 Pas

SS7870 W W 18 Pas

QS9122 TR 12 Pas QS9117 W 20 Pas (V - 0) QS9113 BK, R 18 Pas HB

QS9177B, TR, W 10 Pas

FlowbleLow viscosity

SS7982 A W 6.2 Pas

SS4000 I-6 K TR 6 Pas HB

SS7983 A W 3.8 Pas

SS7981 A W 1.0 Pas

Coating

SS7065 TR 0.12 Pas

SJ6000 P TR 1.00 Pas

SJ6001 P TR 0.10 Pas

Product No - Black letter : Alkoxy, Red letter : OximeColor Viscosity - BK : Black, G : Gray, R : Red, TL : Translucent, TR : Transparent, W : White - HB : UL94 HB, V - 0 : UL94 V - 0, (V - 0) : UL94 V - 0 equivalent

RTV-1 is a one-component room temperature vulcanizing silicone that cures to silicone rubber on exposure to atmospheric moisture at room temperature. RTV-1 performs excellent adhesion to most of all substrates.

ProductViscosity

(cPs)Character-

isticTFT (min)

Hardness(Shore A)

Color Shelf life

ApplicationUL

Certi

QS9177 12,500 Flowable 40 15Transparent, White, Black

1 yearElectronic,

PottingHB

QS9122 12,000 Low

hardness40 5

Transpar-ent

1 year Electronic,

Potting-

SS4100 50,000 Fast cure 20 15 Red, Black 1 year Hepa-filter,

Heat resistant sealingHB

ProductViscosity

(cPs)Character-

isticTFT (min)

Hardness(Shore A)

Color Shelf life

ApplicationUL

Certi

SS4000I 6,000 Fast cure 15 20Transparent, White, Black

1 year Electronic part HB

SS7944 30,000Flame

retardant15 30

Transpar-ent

1 year Electronic part, V0

Oxime type

Alkoxy type

RTV-1 Product table

08

KCC Silicone

RTVKCC Silicone

RTV

RTV-1 General Purpose(Non flow)

RTV-1 performs excellent adhesion to most all substrates without primers. It has outstandingweatherability assuring semi-permanent use and excellent heat resistance suitable for using in the range of - 50 ºC... to 200 ºC. With excellent electrical properties, RTV-1 is used primarily as an adhesive as well as sealing and coating materials for various industries including electrical, electronics, appliances, transportation, and mechanical.

ProductAppear-

anceCharacter-

isticTFT (min)

Hardness(Shore A)

Color Shelf life

ApplicationUL

Certi

QS9118 Soft paste Non-corrosive 30 30 White 6 month CRT, Wedge HB

QS9119 Soft paste Non-corrosive 45 30White,

Black, Gray6 month Sealing, inside HB

SS7988 Soft paste Non-corrosive 20 28 Black 1 yearCRT. Wedge

Sealing-

ProductAppear-

anceCharacter-

isticTFT (min)

Hardness(Shore A)

Color Shelf life

ApplicationUL

Certi

QS9102 Soft paste Highly elastic 10 25White,

Black, Gray1 year General HB

QS9106 Soft pasteGeneralpurpose

10 30Transparent, White,

Black, Gray1 year

Electric, Elec-tronic

HB

Oxime type

Alkoxy type

10

KCC Silicone

RTV

Heat resistant RTV Heat resistant RTV has good adhesion to most of industrial substrates and isexcellent for heat resistant sealing or coating. * Door sealing of microwave ovens * Sealing for industrial ovens* Condenser sealing * Heat resistant sealing for electronic parts * Heat coating for any machine parts* Temp range : Continuously -40º ~ 250º, occasionally 300º

ProductViscosity

(cPs)Character-

isticTFT (min)

Hardness(Shore A)

Color Shelf life

ApplicationUL

Certi

QS9113 20,000 Flowable 23 20 Red, Black 1 yearHepa-filter,

Heat resistantHB

QS9114 - Non-flowable 30 23 Red, Black 1 yearHepa-filter,

Heat resistant sealing

HB

QS9115 200,000Semi–flow-

able10 41 Black 6 month

Microwaveoven

HB

RTV-1 Heat resistanceKCC Silicone

RTV

Non-flow

ProductAppear-

anceTFT (min)

Hardness(Shore A)

Color Shelf life ApplicationUL

Certi

QS9109 Soft paste 5 35 White, Black 6 months General Purpose HB

Oxime type

ProductViscosity

(cPs)TFT (min)

Hardness(Shore A)

Color Shelf life ApplicationUL

Certi

SS7972A 150,000 8 75 White 6 months PCB sealing VO

SS7973A 60,000 10 58 White 6 months PCB sealing VO

Alkoxy type

RTV-1 Fast cure

ProductViscosity

(cPs)TFT (min)

Hardness(Shore A)

Color Shelf life ApplicationUL

Certi

SS7970A 19,500 7 24 White, Gray 1 year PDP Terminal VO

SS7870W 18,000 5 22 White 1 year Eletric sealing -

Alkoxy type

FlowableProduct

Viscosity (cPs)

Non vola-tile (%)

SolventTFT (min)

Hardness(Shore A)

Color Shelf lifeUL

Certi

SS7065A 150 80 ~ 90 None 5 30 Transparent 1 year V0

SJ6000P 1000 60 Toluene 5 23 Transparent 1 year V0

SJ6001P 100 70 Toluene 5 23 Transparent 1 year -

Alkoxy type

RTV-1 ConformalCoatings (Flowable)

12

KCC Silicone

RTVKCC Silicone

RTV

Flame retardant RTV-1is applied for electric, electronic, automotive and aerospace part where flame etardant sealing is necessary. It is certified with UL 94 V0.

RTV-1 Flame Retardant

14

ProductAppear-

anceCharacter-

isticTFT (min)

Hard-ness

Color Shelf life

ApplicationUL

Certi

QS9112 Soft pasteFlame

retardant20 40 White 6 month

SMPS,Electronic part

VO

Oxime type

KCC Silicone

RTV RTV-2 Product table

Index Characteristic Product

Fire form Fire form SS8114A/B

Thermal conductivity

0.8W SL3905A/B

0.9W SL3925A/B

1.1W SL3955A/B

MMR

condensation cure, Hardness 30 SS1500A/B

Addition cure, Hardness 40 SL2501A/B

Addition cure, Hardness 70 SL2541A/B

Potting

Hardness 35, Viscosity 2000cps SL3000A/B

Low hardness, self adhesive SL3311A/B

self adhesive SL3302A/B

high transparent

Low viscosity SL3500A/B

High viscosity SL3800A/B

Low reflective LED encapsulant (nD 1.41) SL3812A/B

High reflective LED encapsulant (nD 1.52) SL3820A/B

Transper type LED encapsulant (nD 1.41) SL3870A/B

GEL2 part, High viscosity, 1:1 type SL5100A/B

1 part type, Low viscosity SL5230A/B

Coating

Sleeve coating SC5000A/C

Sleeve coating SL2600A/C

High transparent coating, Low viscosity, Hardness 50 SL9905A/B

High transparent coating, Low viscosity, Hardness 70 SL9907A/B

High transparent coating, Low viscosity, Hardness 40 SL9940A/B

Coating for fabric SL3359A

KCC Silicone

RTV

RTV-1

Description QS9101 QS9102 QS9106 QS9118 QS9119 SS7988

Benefits General Purpose General Purpose General Purpose General Purpose General Purpose General Purpose

Features Non-Flow Non-Flow Non-Flow Non-Flow Non-Flow Non-Flow

Cure chemistry OXIME OXIME OXIME ALKOXY ALKOXY ALKOXY

USE

Adhesion & Sealing • • • • • •

Coating

Potting

Viscosity (23 ºC) Pa•s (p) • • • • • • 100 (1000)

Tack free time min 10 10 10 10 30 45 20

Density (23 ºC) g/cm3 1.03 1.02 1.25 1.02 1.35 1.36 1.46

Hardness 30 25 30 25 30 30 28

Tensile strength Mpa (psi) 12 (174) 1.9 (276) 1.2 (174) 1.2 (174) 2.44 2.2 2.5

Elongation % 350 350 450 450 500 500 650

Thermal conductivity W/m•K 0.25104 0.25104 0.25104 • 0.75312 0.75312

Volume resistivity MΩ•m 2.5 x 106 2.5 x 106 5.0 x 106 • 1.3 x 107 1.3 x 107 1.5 x 108

Dielectric strength kV/mm 20 22 21 • 22 25 19

Dielectric constant (60 Hz) 2.8 @ 1 MHz 3.0 @ 1 MHz 2.52 @ 1 MHz • 2.8 @ 1 MHz 2.8 @ 1 MHz

Dissipation factor (60 Hz) 5.0 x 103 @ 1 MHz 5.0 x 103 @ 1 MHz 5.0 x 103 @ 1 MHz • 1.3 x 103 @ 1 MHz 1.3 x 103 @ 1 MHz

LMW constant (D3 - D10) wt % • • • • • •

Flame retardant UL94 HB UL94 HB UL94 HB UL94 HB UL94 HB

Color

White • • • • •

Black • • • •

Red

Transparent / Translucent • •

Blue grey

Gray • • • •

Pack-aging

100 g / PU tube

300 ml / cartridge • • • • • • •

18 kg / Pail • •

20 kg / Pail • • •

100 kg / DRUM

180 kg / DRUM •

200 kg / DRUM

Description QS9122 QS9177 SS4100A SS4000I SS7944 QS9113 QS9114 QS9115

Benefits General Purpose General Purpose General Purpose General Purpose General Purpose Heat Resistance Heat Resistance Heat Resistance

Features Flowable Flowable Flowable Flowble Semi-Flowble Flowable Non-Flow Semi-Flowable

Cure chemistry OXIME OXIME OXIME ALKOXY ALKOXY OXIME OXIME OXIME

USE

Adhesion & Sealing • • • • • • •

Coating • • • •

Potting • • •

Viscosity (23 ºC) Pa•s (p) 12 12.5 50 6 30 (300) 20 • 200

Tack free time min 40 40 20 15 15 23 30 10

Density (23 ºC) g/cm3 1.00 1.03 1.03 1.02 1.02 1.07 1.26 1.34

Hardness 5 15 15 20 30 20 23 41

Tensile strength Mpa (psi) 1.06 1.44 1.44 1.18 1.8 1.9 1.9

Elongation % 400 300 300 250 300 350 210

Thermal conductivity W/m•K • • 0.25104 0.25104 • • 0.48

Volume resistivity MΩ•m • • 4.3 x 106 4.3 x 106 • • 4.44 x 107

Dielectric strength kV/mm • • 25 25 • • 22

Dielectric constant (60 Hz) - • 2.5 @ 100 Hz 2.5 @ 100 Hz • • 8.25 @ 1 MHz

Dissipation factor (60 Hz) 1.5 x 103 @ 1 MHz 1.5 x 103 @ 1 MHz 1.0 x 103 @ 1 MHz

LMW constant (D3 - D10) wt % • • • • • • •

Flame retardant UL94 HB UL94 HB UL94 HB UL94V0 UL94 HB UL94 HB UL94 HB

Color

White • •

Black • • • • • •

Red • •

Transparent / Translucent • • • •

Blue grey •

Gray

Pack-aging

100 g / PU tube •

300 ml / cartridge • • • • •

18 kg / Pail • • • •

20 kg / Pail • •

100 kg / DRUM

180 kg / DRUM

200 kg / DRUM

KCC Silicone

RTV

16

Description SS7065A QS9109 SS7972A SS7973A SS7970A

Benefits Conformal coating Fast Cure Fast Cure Fast Cure Fast Cure

Features Flowble Non-Flow Non-Flow (H.Vis) Non-Flow (H.Vis) Flowble (H.Vis)

Cure chemistry ALKOXY OXIME ALKOXY ALKOXY ALKOXY

Components

Flowability

USE

Adhesion & Sealing • • • •

Coating •

Potting

Viscosity (23 ºC) Pa•s (p) 0.15 (1.5) • 150 (1500) 60 (600) 195

Mix ratio

Tack free time min 5 5 8 10 7

Working time (23 ºC) h

Density (23 ºC) g/cm3 0.97 1.29 1.7 1.33 1.17

Cure condition ºC/h

Hardness 30 35 75 58 24

Tensile strength Mpa (psi) 1.34 (194) 5.9 4.2 1.57

Elongation % 250 70 140 230

Thermal conductivity W/m•K 0.75312 0.76 •

Volume resistivity MΩ•m 1.0 x 107 0.5 x 109 2 x 109 3.0 x 107

Dielectric strength kV/mm 25 22 20 •

Dielectric constant (60 Hz) 2.52 @ 1 MHz •

Dissipation factor (60 Hz) 2.3 x 102 @ 1 MHz •

LMW constant (D3 - D10) wt % - CV grade CV grade CV grade

Flame retardant UL94 HB UL94 HB

Color

White • • • •

Black •

Red

Transparent / Translucent •

Blue grey

Gray •

Pack-aging

100 g / PU tube

300 ml / cartridge • • • •

18 kg / Pail • •

20 kg / Pail

100 kg / DRUM

180 kg / DRUM

200 kg / DRUM

Description SS7870W SS7981A QS9112 SL5230

Benefits Fast Cure Fast cure Flame Retardant

Features Flowble (H.Vis) Flowble (L.Vis) Non-Flow Silicone gel

Cure chemistry ALKOXY ALKOXY OXIME

Components One part

Flowability Flowable

USE

Adhesion & Sealing • • •

Coating

Potting •

Viscosity (23 ºC) Pa•s (p) 18 1 (10) • 0.7

Mix ratio 1 phase (RTV-1)

Tack free time min 5 15 20

Working time (23 ºC) h 2 weeks

Density (23 ºC) g/cm3 1.14 1.02 1.4 0.99

Cure condition ºC/h 150 / 1

Hardness 22 20 40 -

Tensile strength Mpa (psi) 1.27 1.5 2.45 -

Elongation % 210 130 210 -

Thermal conductivity W/m•K • 0.75312 0.17

Volume resistivity MΩ•m 3.0 x 109 1.5 x 109 1.0 x 107 6.6 x 107

Dielectric strength kV/mm • 20 23 20.1

Dielectric constant (60 Hz) • 5 @ 1 MHz -

Dissipation factor (60 Hz) • 1.0 x 102 @ 1 MHz -

LMW constant (D3 - D10) wt % • CV grade •

Flame retardant UL94 V - 0

Color

White • • •

Black •

Red

Transparent / Translucent • •

Blue grey

Gray

Pack-aging

100 g / PU tube

300 ml / cartridge • • •

18 kg / Pail •

20 kg / Pail

100 kg / DRUM

180 kg / DRUM

200 kg / DRUM •

RTV-1

18

KCC Silicone

RTV

Protection of Electronic Parts - Protection from polluted substances - Protection of electronic parts from mechanical and heat impact - Able to act as an insulator - Protecting circuits from moisture & other polluted substances - Lessen mechanical and heat stress on electronic parts

ProductAppear-

anceViscosity

(cPs)Pot life (min)

Hard-ness

Mix Ratio

Shelf life Characteristic UL Certi

SL3905 Light grey 8,000 3 hr 75 1:1 1 yearThermal conductivity

0.8 W/mK-

SL3925 Gray 26,000 30 72 1:1 1 yearThermal conductivity

0.9 W/mK-

SL3955 Light Gray 60,000 1 day 70 1:1 1 yearThermal conductivity

1.1 W/mK

SL3000 Black 2,000 30 45 1:1 1 year Flowable V0

SL3000 (D) Black 1,200 30 32 1:1 1 year Flowable V2

SL3000(SS)

Black 1,200 30 32 1:1 1 year Flowable -

SL3000W White 1,200 30 32 1:1 1 year Flowable -

SL3000-TrTranspar-

ent700 40 25 1:1 1 year Flowable -

SL3311 Black 1,000 1 day 15 1:1 1 year Self Adhesion -

SL3302 Black 3,100 1 day 60 1:1 1 year Self Adhesion -

Addition type

RTV-2 Addition typePotting

20

RTV-2 Addition type,High transparency

High transparent RTV-2 is designed for high transparency which is necessary for items such as slimcell phones, nose pads of glasses, LED lights, and optical instrument lens protection.

ProductAppear-

anceViscosity

(cPs)Pot life Hardness

Refrac-tive Index

Mix Ratio

Shelf life

Application

SL3812 Transparent 3,300 24 hrs 62 1.41 1:1 1 year Lens, potting LED

SL3820 Transparent 7,000 24 hrs35

(Shore D)1.53 1:2 1 year

Keypad, LED encapsulant, Nozzle pad

SL3870 Transparent 28,000 72 hrs 73 1.41 1:1 1 yearKeypad, LED encapsulant,

Nozzle pad

SL3500 Transparent 40,000 72 hrs 55 1.40 1:1 1 year Optical Lense

SL3800 Transparent 4,000 4 hrs 50 1.40 10:1 1 yearKeypad, LED encapsulant,

Nozzle pad

SL3812(NCRP-25)

Transparent 3,300 50 hrs 74 1.41 1 : 1 1 year Lens, potting LED

SL3875 Transparent 58,000 72 hrs 70 1.41 1 : 1 1 year LED encapsulant

SL3877 Transparent 100,000 72 hrs 75 1.41 1 : 1 1 year LED encapsulant

SL3880 Transparent 50,000 72 hrs 75 1.41 1 : 1 1 year LED encapsulant

SL3100 Transparent - 48 hrs - 1.41 1 : 1 1 yearPrimer

for LED Encapsulant

Addition type

KCC Silicone

RTVKCC Silicone

RTV

Product Appearance Viscosity(cPs) Pot life Hardness Mix Ratio Shelf life

SC5000 Transparent 22,000 3 day 39 10 : 1 1 year

SL2600 Transparent 65,000 1 day 40 10 : 1 1 year

SL9905 Transparent 15,000 3 day 57 1 : 1 1 year

SL9907 Transparent 15,000 3 day 70 1 : 1 1 year

SL9940 Transparent 45,000 1 day 46 10 : 1 1 year

SL9950 Transparent 45,000 3 day 43 10 : 1 1 year

SL3359 Translucent 50,000 24 20 - 1 year

SL3310 Transparent 100,000 3 day 5 1 : 1 1 year

SL3331 White 40,000 3 day 35 10 : 1 1 year

Gel

MMR

SL5100 is a two component type silicone gel with a mixing ratio of part A to part B as 1 : 1.It can be cured either at room temperature or with the use of heat. Part A & Part B are easily mixed due to low viscosity and after it has good adhesion andno oil-bleeding.Long pot life allows for good workability. After curing, it has high transparency and good adhesion.It is environmental friendly.

Product Type viscosity(cPs) Color Penetration Shelf life

Applica-tion

UL Certi

SL5100 2-part 1,000 Transparent 20 mm(50 g, needle,10 s) 1 year Thermal Pad -

SL5110 2-part 1,000 Transparent 60 (1/10 mm)(Quarter cone) 1 year IGBT Potting -

SL5230 1-part 700 Transparent 85(Quarter cone)

4 months / 4℃ IGBT Potting -

SL5150 2-part 1,000 Transparent 33 (1/10 mm)(Quarter cone) 1 year Thermal Pad -

Product Type Appearance Viscosity(cPs)

Pot life (min)

Hardness Mix Ratio Shelf life

SL2551 2-Part Transparent 26,000 85 23 10 : 1 1 year

SL2501 2-Part Transparent 55,000 60 40 10 : 1 1 year

SL2541 2-Part Transparent 140,000 60 70 10 : 1 1 year

SS1500 2-Part White 35,000 60 30 10 : 1 1 year

SS1501 2-Part White 25,000 60 30 10 : 1 1 year

RTV-2 Addition type

22

KCC Silicone

RTV

Textile / Sleeve coating

Description SL3905 SL3925 SL3000 SL3000(D) SL3000(SS)

Flowability Flowable Flowable Flowable Flowable Flowable

Features Thermal potting Thermal potting

USE

Adhesion & Sealing

Coating

Potting • • • • •

Mix ratio 1 : 1 1 : 1 1 : 1 1 : 1 1 : 1

Color Light gray Gray Black Black Black

Viscosity (23 ºC) Pa•s (p) 8 (80) 26 (260) 2 1.2 1.2

Working time (23 ºC) h 24 0.5 30 30 30

Cure condition ºC/h 125 / 1 25 / 2 80 / 20 min 50 / 30 min 50 / 30 min

Density (23 ºC) g/cm3 2.13 2.39 1.2 1.1 1.1

Hardness 75 72 45 32 32

Tensile strength Mpa (psi) 1.8 1.5 1.5

Elongation % 100 90 90

Shear strength Mpa(psi) _

Thermal conductivity W/m•K 0.8 0.9 0.35

Volume resistivity MΩ•m 3.8 x 107 2.3 x 108 3.1 x 107

Dielectric strength kV/mm 18.7 17.8 19

Dielectric constant (60 Hz) 3.2

Dissipation factor (60 Hz)

Flame retardant UL94 V - 0

Thermal conductivity W/m•K 0.8 0.9

Pack-aging

500 g glass bottle

1 kg / CAN • • • •

18 kg / Pail

20 kg / Pail • • • • • • • • • •

180 kg / Drum

Description SL3000W SL3000N SL3000-Tr SL3311 SL3302 SL3500

Flowability Flowable Flowable Flowable Flowable Flowable

Features Self-Adhesive Self-Adhesive

USE

Adhesion & Sealing •

Coating

Potting • • • • •

Mix ratio 1 : 1 1 : 1 1 : 1 1 : 1 1 : 1 1 : 1

Color White White Transparent Black Black Transparent

Viscosity (23 ºC) Pa•s (p) 1.2 1 0.7 1.0 (10) 3.1 (31) 40 (400)

Working time (23 ºC) h 30 40 40 24 24 72

Cure condition ºC/h 50 / 30 min 60 / 30 min 60 / 30 min 125 / 1 125 / 1 130 / 10 min

Density (23 ºC) g/cm3 1.1 1.1 1 1.3 1.5 1.03

Hardness 32 45 25 15 60 55

Tensile strength Mpa (psi) 1.5 1.8 1 1.2 1.5 6

Elongation % 90 100 60 200 80 300

Shear strength Mpa(psi) 1.3 (HPA) _

Thermal conductivity W/m•K 0.6 0.6 _

Volume resistivity MΩ•m 2.8 x 108 2.8 x 108 _

Dielectric strength kV/mm 17.4 18.8 _

Dielectric constant (60 Hz) _

Dissipation factor (60 Hz)

Flame retardant _

Thermal conductivity _

Pack-aging

500 g glass bottle

1 kg / CAN • • • •

18 kg / Pail

20 kg / Pail • • • • • • • • • • • •

180 kg / Drum

RTV-2KCC Silicone

RTV

24

RTV-2

Description SL3800 SL3812 SL3820 SL3870

Flowability Flowable Flowable Flowable

Features High refraction High refraction LED lens

USE

Adhesion & Sealing •

Coating

Potting • • •

Mix ratio 10:1 1:1 1:2 1:1

Color Transparent Slightly haze Transparent Transparent

Viscosity (23 ºC) Pa•s (p) 4 (40) 3.3 (33) 7 (70) 28 (280)

Working time (23 ºC) h 4 24 24 72

Cure condition ºC/h 150 / 1 150 / 1 150 / 1 170 / 0.17 (10 min)

Density (23 ºC) g/cm3 1.12 1.04 1.16 1.04

Hardness 50 62 35 (Shore D) 73

Tensile strength Mpa (psi) 5.4 (785) 3

Refactive index : 1.53Transmittance : 91%

CTE : 210 ppm”

10 (1450)

Elongation % 380 50 83

Shear strength Mpa (psi) 3.1 (450) Refractive index : 1.41 -

Thermal conductivity W/m•K 0.23 Transmittance : 93.8 % (350 nm) -

Volume resistivity MΩ•m 1.0 x 107 1.3 x 108 -

Dielectric strength kV/mm 211 18.7 -

Dielectric constant (60Hz) 3 CTE : 270 ppm -

Dissipation factor (60Hz) 0.001 -

Pack-aging

500 g glass bottle • • • •

1 kg / CAN • •

18 kg / Pail

20 kg / Pail • • • •

180 kg / Drum

Description SL5100 SL5110 SL2501 SL2541 SL2551

Flowability Flowable Flowable Flowable Flowable Flowable

Features Silicone gel Silicone gel MMR MMR MMR

USE

Adhesion & Sealing

Coating • • •

Potting • •

Mix ratio 1:1 1:1 10:1 10:1 10:1

Color Transparent Transparent Transparent Transparent Transparent

Viscosity (23 ºC) Pa•s (p) 1 (10) 1 (10) 55 (550) 140 (1400) 26 (260)

Working time (23 ºC) h 2 1.5 1 1 1

Cure condition ºC/h 130 / 0.33 (20 min) 130 / 0.33 170 / 0.1 170 / 0.1 170 / 0.1

Density (23 ºC) g/cm3 0.98 0.98 1.07 1.28 1.08

Hardness Penetration 20 Penetration 60 40 70 23

Tensile strength Mpa (psi) - 5.2 6.5 4.0

Elongation % - 340 100 500

Shear strength Mpa (psi) -

Thermal conductivity W/m•K -

Volume resistivity MΩ•m -

Dielectric strength kV/mm 21

Dielectric constant (60Hz) -

Dissipation factor (60Hz) -

Pack-aging

500 g glass bottle

1 kg / CAN

18 kg / Pail • •

20 kg / Pail • • • •

180 kg / Drum • •

KCC Silicone

RTV

26

RTV-2

Description SS1500 SS1501 SC5000 SL2600

Flowability Flowable Flowable Flowable Flowable

Features MMR MMR Sleeve coating Sleeve coating

USE

Adhesion & Sealing

Coating • • • •

Potting

Mix ratio 10 : 1 10 : 1 10 : 1 10 : 1

Color White White Transparent Transparent

Viscosity (23 ºC) Pa•s (p) 35 25 22 (0.22) 65 (0.36)

Working time (23 ºC) h 1 1 72 24

Cure condition ºC/h RT / 72 RT / 72 170 / 0.1 170 / 0.1

Density (23 ºC) g/cm3 1.09 1.1 1.06 1.07

Hardness 30 30 39 40

Tensile strength Mpa (psi) 4.4 3.5 4.4 6.3

Elongation % 400 300 250 380

Shear strength Mpa (psi)

Thermal conductivity W/m•K

Volume resistivity MΩ•m

Dielectric strength kV/mm

Dielectric constant (60 Hz)

Dissipation factor (60 Hz)

Pack-aging

500 g glass bottle

1 kg / CAN • • •

18 kg / Pail

20 kg / Pail • • • •

180 kg / Drum • • • •

Description SL9905 SL9907 SL9940 SL3359

Flowability Flowable Flowable Flowable Non-Flow

Features Coating Coating Coating High elongation

USE

Adhesion & Sealing

Coating • • • •

Potting

Mix ratio 1 : 1 1 : 1 10 : 1 100 : 1

Color Transparent Transparent Transparent Translucent

Viscosity (23 ºC) Pa•s (p) 15 (13) 15 (5) 48 (0.3) 50

Working time (23 ºC) h 72 72 6 24

Cure condition ºC/h 150 / 0.2 170 / 0.1 170 / 0.1 150 / 1

Density (23 ºC) g/cm3 1.02 1.04 1.07 1.06

Hardness 57 70 44 20

Tensile strength Mpa (psi) 6.8 8 4.3 Min. 20

Elongation % 120 130 300 Min. 400

Shear strength Mpa (psi) -

Thermal conductivity W/m•K -

Volume resistivity MΩ•m -

Dielectric strength kV/mm -

Dielectric constant (60 Hz) -

Dissipation factor (60 Hz) -

Pack-aging

500 g glass bottle

1 kg / CAN •

18 kg / Pail

20 kg / Pail • • • • • • •

180 kg / Drum • • • • •

KCC Silicone

RTV

28

RTV-2

Description SC6102Z SC6490C SC6530C SC6540C

Cure chemistry NON CURE NON CURE NON CURE NON CURE

Features Thermalcomp

Thermalcomp

Thermalcomp

Thermalcomp

USE

Adhesion & Sealing

Coating • •

Potting

Viscosity (23 ºC) Pa•s (p) 700 120

Tack free time min

Density (23 ºC) g/cm3 2.3 2.65 3.5 3.5

Hardness

Tensile strength Mpa (psi)

Elongation %

Tear strength Mpa (psi)

Thermal conductivity W/m•K 1 1.8 3 4

Volume resistivity MΩ•m

Dielectric strength kV/mm

Dielectric constant (60 Hz)

Dissipation factor (60 Hz)

LMW constant (D3 - D10) wt% 0.05

Color

White • •

Black

Red

Transparent / Translucent

Blue grey

Grey • • •

Packaging

1 kg / CAN • •

18 kg / Pail

20 kg / Pail

180 kg / DRUM

200 kg / DRUM

Description SJ6000P SJ6001P

Cure chemistry Moisture cure Moisture cure

Features Conforml coating Conforml coating

USE

Adhesion & Sealing

Coating • •

Potting

Viscosity (23 ºC) Pa•s (p) 1 0.1

Tack free time min

Density (23 ºC) g/cm3 1.01 1.01

Hardness 23 23

Tensile strength Mpa (psi) 3 3

Elongation % 31 31

Tear strength Mpa (psi)

Thermal conductivity m•K

Volume resistivity MΩ•m

Dielectric strength kV/mm

Dielectric constant (60Hz) 3.2 3.2

Dissipation factor (60Hz)

LMW constant (D3 - D10) wt%

Color

White

Black

Red

Transparent / Translucent • •

Blue grey

Grey

Packaging

1 kg / CAN • •

18 kg / Pail • •

20 kg / Pail

180 kg / DRUM

200 kg / DRUM

KCC Silicone

RTV

30

KCC Silicone

RTV

Beijing, ChinaKCC Chemical (Beijing) Co.,Ltd. / No.51 Shuntong Rd, Renhe town, Shun YiDistrict, Beijing, P.R.China 101300Tel : (86)-10-8949-8852, Fax : (86)-10-8949-8144, e-mail : [email protected]

SingaporeKCC (Singapore) Pte. Ltd. / 1 Tuas Avenue 2, Singapore 639441Tel : (65)-6862-0100, Fax : (65)-6863-0679, e-mail : [email protected]

TurkeyKCC Boya Sanayi Ve Ticaret Ltd.Sti. / Gebze Organize Sanayi Bolgesi(Tembelova mevkii)3100 Cad. No:3107, Gebze-Kocaeli / Turkey (zip code:41400)Tel : (90)-262-645-0200, Fax : (90)-262-645-0209 , e-mail : [email protected]

VietnamKCC (Vietnam) Co., Ltd. / Rood No.1, Long Thanh IZ, Longthanh District,Dongnai Province, VietnamTel : (84)-61-3514-678, Fax : (84)-61-3514-684, e-mail : [email protected]

IndiaKCC India Office / Plot No K20 Sipcot Industrial Park (Phase II) Mambkkam,Sriperumbudur, Kancheepuram, Tamil Nadu, 602 106, IndiaTel : (91)-044-2714-2000, Fax : (91)-044-2714-2020, e-mail : [email protected]

Hamburg, GermanyKCC Hamburg Office / Osterbek Str., 90c 22083 Hamburg, GermanyTel : (49)-40-2780-9267/68/73, Fax : (49)-40-2780-9269/71e-mail : [email protected]

New Jersey, USAKCC New Jersey Office2 Executive Drive Suite 720 Fort Lee, New Jersey 07024, USATel : (1)-201-242-1400/1470, Fax : (1)-201-242-1480, e-mail : [email protected]

Hong KongKCC Hong Kong OfficeRm 1903 19th Floor, Goldmark, 502 Hennessy Road, Causeway Bay, Hong KongTel : (852)-2577-0476/0489, Fax : (852)-2577-0497, e-mail : [email protected]

Tokyo, JapanKCC Tokyo OfficeKanda Ekimae Plaza 6th, 3-7-33, Kandakajich, Chiyoda-Ku, Tokyo 101-0045, JapanTel : (81)-3-5207-9363, Fax : (81)-3-5207-9364, e-mail : [email protected]

Dubai, UAEKCC Dubai OfficeOffice No. 304-B, Al Salemiyah Tower P.O. Box 184453, Deira, Dubai, UAETel : (971)-4-229-3496/3497, Fax : (971)-4-229-3498, e-mail : [email protected]

MalaysiaKCC Paints Sdn. Bhd / Lot13, Jalan Anggerick Mokara, Seksyan 31,Kota Kemuning, 40460 Shah Alam, Selangor Darul, MalaysiaTel : (603)-5122-2900, Fax : (603)-5122-1800/1900, e-mail : [email protected]

Lyon, FranceKCC France Office17th floor, 129 Rue Servient 69326 Lyon Cedex 03, FranceTel : (33)-4-7863-7966, Fax : (33)-4-761-9265, e-mail : [email protected]

GreeceKCC Greece OfficeFilonos Str. 107-109, 18535 Piraeus, GreeceTel : (30)-210-428-2424~5, Fax : (30)-210-428-2422, e-mail : [email protected]

Moscow, Russia1108 Room, WTC 12 Krasnopresnenskaya nab, Moscow, 123610, RussiaTel : (7)-495-258-24-10, Fax : (7)-495-258-24-11, e-mail : [email protected]

Shanghai, China

Guangzhou, China

KCC Chemical (Kunshan) Co.,Ltd.#1, Wusongjiang-Lu, Qingdeng-Zhen, Kunshan-Shi, Jiangsu-Sheng, P.R.China,215341 / Tel : (86)-512-5746-9000~3, Fax : (86)-512-5746-9009

KCC (Guangzhou) Co.,Ltd. / No.9 North of the Doutang Street, Yonghe EconomicZone, Guangzhou 511356, P.R.ChinaTel : (86)-20-3222-1111, Fax : (86)-20-3222-2121, e-mail : [email protected]

KCC Shanghai OfficeRoom 1402, Block A, Far East International Plaza, No. 319 Xianxia RoadShanghai 200051, P.R.China / Tel : (86)-21-6235-1540, Fax : (86)-21-6278-6338e-mail : [email protected]