Katholieke Universiteit Leuven...viii Figure 3.1 Image of visual appearance of unheated (fresh) oil...

Transcript of Katholieke Universiteit Leuven...viii Figure 3.1 Image of visual appearance of unheated (fresh) oil...

i

Katholieke

Universiteit

Leuven

FACULTY OF BIOSCIENCE ENGINEERING

INTERUNIVERSITY PROGRAMME (IUPFOOD)

MASTER OF SCIENCE IN FOOD TECHNOLOGY

Major Food Science and Technology

Academic year 2014-2015

Heat Stability Evaluation of Oil-in-Water Emulsions Stabilized by Whey

Protein Isolate-Low Methoxyl Pectin Dry Heat Conjugates

by

Serveh Saeedi

Promotor: Prof. dr. ir. Paul Van der Meeren

Tutor: Arima Diah Setiowati

Master's dissertation submitted in partial fulfilment of the requirements

for the degree of Master of Science in Food Technology

i

Copyright

The author and promoter give the permission to consult and copy parts of this

work for personal use only. Any other use is under the limitations of copyrights

laws, more specifically it is obligatory to specify the source when using results

from this Master’s Dissertation.

Gent, August 2015

The promoter The author

Name: Prof. dr. ir. Paul Van Der Meeren Name: Serveh Saeedi

Signature: Signature:

ii

Dedication

I would like to lovingly dedicate this Master dissertation to my

parents. There is no doubt in my mind that without their continued

generosity, support and counsel I could not have completed this process.

iii

Acknowledgements

I would like to express my gratitude to Prof. Paul Van Der Meeren for giving

me the opportunity to work on this topic and his support and guidance throughout my

project. It is a great opportunity to study under his supervision and his support is

highly appreciated. My deepest sense of gratitude goes to Arima Diah Setiowati for

her invaluable support, academic advice and criticism during practical work and

writing of this master dissertation.

I also express my special thankfulness to my loving parents and family, for

their lofty love, constant support, motivation, and generosity. Special thanks go to my

sister and her family whose invaluable encouragements and support enabled me to

complete this work.

I would like to thank Arnout Declerck, Mathieu Balcaen and Quenten Denon

for their technical recommendations and support. My sincere thanks and appreciation

are also extended to all the staffs and research memberss of laboratory of Particle and

Interfacial Technology (PaInT).

Finally, my thanks go to all my friends and professors from the IUPFOOD

program in Gent and KULeuven universities. I would like to express my sincere

gratitude to all wonderful people I met during this master program.

iv

Table of Contents

Copyright …………………………………………………….................i

Dedication ………………………………………………………..….…ii

Acknowledgements ……………………………………………….…...iii

Table of contents …………………………………………………….....iv

List of Figures …………………………………………………...….…vii

List of Tables ………………………………………………….………..x

List of Abbreviations ………………………………………….……...xiii

Abstract ………………………………………………………………....1

Chapter 1: Literature Review...………………….………….….……...3

1.1. Introduction ……………………….……………………………...……………3

1.1.1. Overview ……………………………..……………………..….………...3

1.1.2. Research Objectives ……………..………………………….……….….4

1.2 Whey Protein ………………………………………………..…………...….....5

1.2.1 Whey Protein Components ……………..…………………………......6

1.2.1.1 β-Lactoglobulin …………………..……………………….……..6

1.2.1.2 α-Lactalbumin ………………………..………....………………8

1.2.1.3 Other Minor Proteins …………..…………..…………...………8

1.2.2 Whey Proteins Functional Properties ……………………….…….....9

1.3 Emulsions ………………………………………………..............…………....11

1.3.1 Emulsion Destabilization Mechanisms ……..………………..………12

1.3.2 Stabilization of Emulsions …………………..……………….……….15

1.4 Whey Protein as Emulsifier …………………………………..………….……16

1.4.1 Limiting Factors of WPI application in Emulsions ….......................18

v

1.5 Heat stability of WPI ………………………………………..…….…..………..18

1.5.1 Heat Induced Denaturation ………………...………….…….………19

1.5.2 Factors Influencing Heat Stability of WPI ……….……….………..21

1.5.3 Improvement of Heat Stability of Whey Protein Ingredients …..…23

1.6 protein-polysaccharide Conjugates via Covalent Bonding …………...…..…26

1.6.1 Mechanism of the conjugate formation ………………….….….…..27

1.6.2 Emulsifying Properties of Maillard Conjugates …………….……...29

1.6.3 Factors Influencing the Functionality of the Conjugate ………...…29

1.6.4 Studies on Heat Stability of Protein-Polysaccharide Conjugate ..…31

Chapter 2: Materials and Methods ……………………………..…....34

2.1. Materials ……………………………….……………………………………....34

2.2.Methods …………………………………………………………..…………….34

2.2.1. Whey Protein-Pectin Complex Formation …………………..…….34

2.2.2. Emulsion Preparation ………………………..………………..……35

2.2.3. Heat Stability Test of Emulsions …………….…………………….37

2.2.4. Emulsion Stability Test ………………………….…….….…..……39

2.2.5. Viscosity Measurement …………………………….………..….….41

2.2.6. Particle Size Measurement ……………………………..….…..…..42

2.2.7. Light Microscopic Observation ……………………………….…..43

2.2.8. Protein Load ………………………………….……………….…....43

2.2.9. Pectin Load ………………………………….…………………...…45

Chapter 3: Results and Discussion …………………………………. 47

3.1. Visual observation ……………………………….…………….…..………....47

3.2. Droplet size ………………………………………………….……………...... 49

3.3. Viscosity ……………………………………………………….…….……..…61

3.4. Emulsion Stability Analysis ………………………………….….……..……68

3.5. Protein Load ……………………………………………………..……..……74

vi

3.6. Pectin Load ……………………………………………….………..…….….79

Chapter 4: Conclusion ………………………………..…………….83

Chapter 5: References ………………………………………………87

vii

List of Figures

Figure 1.1 Schematic figures of emulsions. a. oil in water emulsion (O/W); b.

water in oil emulsion (W/O); c. Water in oil in water double emulsion

(W/O/W); d. Oil in water in Oil double emulsion (O/W/W) ………12

Figure 1.2 Schematic representation of common instability mechanism in food

emulsions; flocculation, coalescence, Ostwald ripening, creaming and

phase separation …………………….…………………………..……14

Figure 1.3 Mechanism of emulsion stabilization by proteins through (A)

electrostatic repulsion and (B) steric stabilization. Red dots are

hydrophobic parts of protein molecules positioned at the oil phase

(Lam and Nickerson, 2013) ……………………….…..……………17

Figure 2.1

Schematic presentation of setup for heat treatment ………………….38

Figure 2.2 Schematic illustration of the operational principle of the LUMIfuge

…………………………………………………………………...……39

Figure 2.3 Schematic presentation of front tracking method of transmission

profile with trigger value of 20% ……………………………….….. 40

Figure 2.4 Standard Curve for pectin measurement ………………………..……46

viii

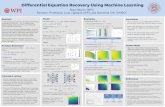

Figure 3.1

Image of visual appearance of unheated (fresh) oil-in-water emulsion

(10% w/w) stabilized with 0.5% WPI (A), dry heated WPI day 8 (B),

and WPI-LMP conjugate (ratio 2:1) day 8 (C), at pH 5.0.

…………………………………………………………….…………47

Figure 3.2 Image of visual appearance of oil-in-water emulsion (10% w/w)

stabilized with 0.5% WPI, dry heated WPI, and WPI-LMP conjugates (

2:1), day 4 at pH 5.0 with NaCl, after heat treatment at 80°C for 10 and

20 min. ……………………………………………………………...48

Figure 3.3 Comparison of visual appearance of oil-in-water emulsion (10% w/w)

stabilized with 0.5% WPI, at pH 5.0 and pH 6.5, and emulsion

stabilized with WPI-LMP conjugate (2:1), day 0 and day 8, at pH 5.0

with NaCl, after heat treatment at 80°C for 20

min…………………………………………………………………..49

Figure 3.4 The mean volume-weighted droplet size, d43, of oil in water emulsion

(10% w/w oil), containing 0.5% (w/w) WPI and WPI-LMP, incubated

for 8 days at pH 6.5 and 5.0 in the absence and presence of 30 mM

NaCl, and corresponding micrograph of the emulsions containing WPI

(right) and WPI-LMP (D8) (left) at pH 5.0.

………………………………………………………………………51

Figure 3.5 Droplet size distribution curves of an oil-in-water emulsion (10% w/w

sunflower oil) stabilized with a 0.5% (w/w) WPI heat treated at 80°C

for 0, 10 and 20 min at pH 6.5 with NaCl. The micrograph image

shows WPI stabilized emulsions at pH 6.5 unheated (left) and heated

for 20 min (right) ……………………………………………………54

Figure 3.6 Changes in average droplet size, d43 , of oil in water emulsions (10%

w/w oil), stabilized with 0.5% (w/w) WPI, dry heated WPI (D4) or

WPI-LMP conjugates (D4), after heating at 80 °c for 10 and 20 min, at

pH 6.5 ………………………………………………………………56

ix

Figure 3.7 Comparison of droplet size distribution curves of oil-in-water

emulsions (10%w/w) stabilized with non-incubated and incubated (4, 8

and 16 days) WPI-LMP, unheated and heated at 80°C for 20 min at pH

6.5. ……………………………………………………………………57

Figure 3.8 Changes in average droplet size, d43, of oil in water emulsions (10%

w/w oil), stabilized with 0.5% (w/w) WPI-LMP conjugate (D0), after

heating at 80 °C for 10 and 20 min, at pH 6.5 and 5.0, with or without

NaCl. ……………………………………………………………..…58

Figure 3.9 Droplet size distribution curves of oil-in-water emulsions (10% w/w)

stabilized with a 0.5% (w/w) WPI, heat treated at 80°C for 0 and 10

min, with size distribution curve and the corresponding micrograph of

the heated emulsions after dispersion in 1% SDS at pH 6.5 (left : 10

min , right: 20 min). ……………………………………..……….….59

Figure 3.10 Viscosity profile of oil in water emulsion (10% o/w sunflower oil),

stabilized with 0.5% (w/w) WPI, dry heated WPI (D8) and WPI-LMP

conjugate (D0) , at pH 6.5 after heat treatment at 80 °C for 10 and 20

min………………………………………….……….………………64

Figure 3.11

Viscosity profile of oil in water emulsion (10% w/w sunflower oil),

stabilized with 0.5% (w/w) WPI-LMP conjugate, incubated for 4, 8 and

16 days, at pH 6.5 and 5.0, with and without NaCl, before and after

heat treatment at 80 °C for 10 and 20 min.

………………………….……………………………………………66

x

Figure 3.12 Evolution of transmission profile of an oil in water emulsion (10% w/w

oil), stabilized with 0.5% (w/w) WPI (A), and WPI-LMP conjugate

(2:1) (B), at pH 5.0. …………………………………………………69

Figure 3.13 Comparison of front tracking results of emulsions (10% w/w oil),

stabilized with 0.5% (w/w) WPI (A), and WPI-LMP conjugate (2:1),

incubated for 4days, at pH5.0 with 30mM NaCl. …..….………..70

Figure 3.14 Comparison of creaming rate (mm/day) of emulsions (10% w/w oil)

stabilized with 0.5% (w/w) WPI, dry heated WPI and WPI-LMP

conjugate (2:1), incubated for 16 days, containing 30 mM NaCl, at pH

6.5 ……………………………………………………………………71

Figure 3.15 Comparison of creaming rate (mm/day) of emulsions (10% w/w oil)

stabilized with 0.5% (w/w) WPI and WPI-LMP conjugate (2:1),

incubated for 4, 8 and 16 days, at pH 5.0 containing 30 mM NaCl,

heated at 80°C for 0,10 and 20min. ………………………..………73

Figure 3.16 Protein load (kg/m2) of oil in water emulsions (10% w/w sunflower

oil), stabilized with 0.5% (w/w) WPI, and WPI-LMP conjugate (2:1),

unincubated and incubated for 8 days, heated for 0 and 20min at 80 °C

at pH6.5 and 5.0. ..................................................................................78

xi

List of tables

Table 2.1

Emulsions names and codes ………………………………………… 37

Table 3.1 Average Droplet Size d43 (µm) of oil in water emulsion (10% w/w oil),

stabilized with 0.5% (w/w) WPI, dry heated WPI and WPI-LMP

conjugates, unincubated (Day 0) and incubated for 4, 8 and 16 days, at

pH 6.5 and 5.0, in the presence of 30 mM and 0 mM NaCl,

homogenized at 560 bar for 2 minutes and temperature of 50 oC.

……………………………………………………………………….….50

Table 3.2 Effect of heating at 80°c for 10 and 20 min on the mean volume-weighted

particle size, d 43 , of oil in water emulsions (10%w/w) containing 0.5%

(w/w)WPI, dry heated WPI and WPI-LMP conjugate (2:1) , non-

incubated and incubated for 4, 8 and 16 days at pH 6.5.

……………………………………………………………………………5

3

Table 3.3 Table.3.3. Effect of heating at 80°c for 10 and 20 min on the mean

volume-weighted particle size, d 43 (µm), of oil in water emulsions

(10%w/w) containing 0.5% (w/w)WPI and WPI-LMP conjugate (ratio

2:1) , non-incubated and incubated for 4, 8 and 16 days at pH 5.0, with

and without NaCl.

……………………………………………………………………..55

Table 3.5 Viscosity of oil in water emulsion (mPa.s) (10% w/w sunflower oil),

stabilized with 0.5% (w/w) WPI, dry heated WPI and WPI-LMP

conjugate, at pH 6.5 and 5.0, with and without NaCl.

……….………………….61

Table 3.6 Effect of heating at 80°C for 10 and 20 min on consistency index of oil in

xii

water emulsions (10%w/w) containing 0.5% (w/w) WPIand WPI-LMP

conjugates (2:1) non-incubated and incubated for 8 and 16 days at pH 5.0

with and without NaCl.

…………………………………………………..62

Table 3.7 Creaming rate (mm/day) (LUMiFuge, 3000 rpm, 1 hr) of o/w emulsions

(10% w/w oil) stabilized with 0.5% (w/w) WPI and WPI-LMP conjugate

(2:1), containing 30 mM NaCl, at pH 6.5 and 5.0. …………………….69

Table 3.8 Amount of protein (μg/ml) in aqueous phase, serum phase and adsorbed

on oil droplets of heated and unheated oil in water emulsion (10% w/w

sunflower oil), stabilized with 0.5% (w/w) WPI, and WPI-LMP conjugate

(2:1), unincubated and incubated for 8 days, at pH 6.5 and 5.0.

.....................................................................................................................7

5

Table 3.9 Table 3.9. Amount of adsorbed protein (%) on oil droplets, ɸ32, and

protein load (kg/m2) of heated and unheated oil in water emulsion (10%

w/w sunflower oil), stabilized with 0.5% (w/w) WPI, and WPI-LMP

conjugate (2:1), unincubated and incubated for 8 days, at pH 6.5 and 5.0.

......................................................................................................................

76

Table

3.10

Amount of pectin(mg/100ml) in aqueous phase, serum phase and

adsorbed on oil droplets of heated and unheated oil in water emulsion

(10% w/w sunflower oil), stabilized with 0.5% (w/w) WPI-LMP

conjugates (2:1), unincubated and incubated for 8 days, at pH 6.5 and 5.0.

……………..…80

Table

3.11

Amount of adsorbed pectin (%) on oil droplets, ɸ32, and pectin load

(kg/m2) of heated and unheated oil in water emulsion (10% w/w

sunflower oil), stabilized with 0.5% (w/w) WPI-LMP conjugate (2:1),

unincubated and incubated for 8 days, at pH 6.5 and 5.0.

………………………………….80

xiii

List of Abbreviations

AO Alginate oligosaccharide

BSA Bovine serum albumin

CMC Carboxymethyl cellulose

DX Dextran

EA Emulsion activity

ES Emulsion stability

IEP Isoelectric point

Ig Immunoglobulin

LMP Low methoxyl pectin

PGWP Partially glycosylated whey protein isolate

SBPI Soybean protein isolate

WPI Whey protein isolate

WPC Whey protein concentrate

WPH Whey protein hydrolysate

WPN Whey protein nanoparticle

1

Abstract

The effect of covalent Maillard conjugates of whey protein isolate (WPI) and

Low Methoxyl pectin (LMP) on the emulsifying properties of WPI and the heat

stability of oil-in-water emulsions (O/W), containing 10 % (w/w) of sunflower oil and

0.5 % of WPI or conjugates were investigated as a function of pH (6.5 and 5.0) and

incubation time of the conjugates. WPI-LMP conjugates were prepared by dry heating

of a mixture of WPI and LMP at 60°C for time periods of 0, 4, 8 and 16 days. In a

similar way, whey protein isolate was dry heated without pectin, for comparison. The

properties of the emulsions stabilized by WPI-LMP conjugates, dry heated WPI and

WPI alone were compared before and after heat treatment in an oil bath of 80 °C for

10 and 20 min.

At pH 5.0 without and with salt (30 mM), emulsions containing dry heated

WPI and WPI alone exhibited flocculation, creaming and phase separation, while

emulsions containing WPI-LMP conjugates were stable against flocculation and

creaming. On the other hand, at pH 6.5, the emulsions stabilized by WPI-LMP

conjugates, dry heated WPI, and WPI alone were more stable and homogenous.

Upon heat treatment, emulsions stabilized by dry heated WPI, WPI alone, and

WPI-LMP conjugates (day 0) exhibited extensive flocculation at both pH 5.0 and 6.5.

Both the average droplet size and viscosity of these heated emulsions increased and

shear thinning behavior was observed. On the other hand, emulsions stabilized by

WPI-LMP conjugates which were incubated for 4, 8, and 16 days showed no

aggregation and flocculation. Correspondingly, there was no visible change in the

droplet size distribution and viscosity of the emulsions containing WPI-LMP

conjugates obtained by dry heating for 4, 8, and 16 days.

The observed results demonstrated that conjugation improved the emulsifying

properties and heat stability of WPI stabilized emulsions. The main reason for

improved stability of whey protein by conjugation with pectin is that covalent

2

bonding with pectin enhances the steric stabilization forces as a result of the presence

of the hydrophilic polysaccharide moiety which acts between protein layers adsorbed

at the surface and inhibits heat-induced aggregation of the droplets. Moreover,

conjugation with pectin increases the surface hydrophilicity of the oil droplets which

reduce droplet-droplet hydrophobic interactions and improves the stability against

aggregation, coalescence, and creaming.

3

Chapter 1: Literature Review

1.1. Introduction

1.1.1. Overview

Nowadays, whey protein products are increasingly used for a variety of

nutritional and functional applications in food products. Some of the applications

include sport beverages, liquid meat replacements, ice cream, salad dressing, bakery

products, infant foods and various other dairy products [Fitzsimons et al., 2007;

Jovanović et al., 2005]. One of the promising applications is the use of whey protein

as an emulsifier in oil in water (O/W) emulsions [Jovanović et al., 2005]. However,

the main challenge of whey protein application is heat-induced denaturation of whey

proteins which decreases their solubility and limits their application in food products,

particularly in emulsions [Demetriades et al., 1997a; Euston et al., 2000]. Heat

treatment can affect the structure and solubility of whey proteins, leading to

aggregation and precipitation of the whey proteins and destabilization of whey

protein stabilized emulsions [Sliwinski et al., 2003]. Therefore, the stability of whey

proteins during thermal processing is of utmost importance for product quality and

functionality.

Several methods for modification of whey proteins and improving their

functionality have been proposed [Akhtar and Dickinson, 2003; 2007; Ashokkumar et

al., 2009; Chandrapala et al., 2011; Gentes et al., 2010; Jimenez-Castano et al., 2007;

Asylbek Kulmyrzaev et al., 2000a; Lorenzen, 2007; Mishra et al., 2001; Sağlam et al.,

2013]. Whey proteins have been modified by means of conjugation with

polysaccharides via covalent bonding which follows the path of Maillard reaction

[Akhtar and Dickinson, 2003; 2007; Kika et al., 2007; Mishra et al., 2001; N

Neirynck et al., 2004]. These conjugates have been reported to improve the functional

properties, including solubility [Akhtar and Dickinson, 2003; Mishra et al., 2001; N.

Neirynck et al., 2004] and emulsifying properties [Akhtar and Dickinson, 2007; Kika

4

et al., 2007; Mishra et al., 2001; N Neirynck et al., 2004], foaming properties [Mishra

et al., 2001], as well as thermal stability of whey proteins [Jimenez-Castano et al.,

2007; G Liu and Zhong, 2013].

1.1.2. Research Objective

In this work, we aimed to improve the heat stability of whey protein-stabilized

oil in water (O/W) emulsions by replacing whey protein with whey protein-pectin

conjugates made by dry heating under controlled temperature and relative humidity as

well as evaluating the heat stability. We hypothesized that these conjugates would

exhibit improved emulsification activity and thermal stability compared to the WPI

alone. In this research, the effects of the incubation time, pH and low concentration of

salt on the emulsion properties and thermal stability of whey protein-pectin

conjugates were evaluated.

5

1.2. Whey Protein

Whey is the residual fluid of the cheese and casein manufacturing industry,

after almost complete removal of casein [Smithers, 2008]. Whey proteins are

nitrogenous compounds representing 18-20% of the total milk nitrogen content

which are recovered from milk serum or whey after precipitation of casein at pH 4.6

and a temperature of 20 °C by the action of chymosin or acid [Eigel et al., 1984].

Whey proteins exist as compact, globular proteins in their native state [Lee et al.,

1992]. They have high solubility as a result of the large number of surface hydrophilic

residues. However, they are highly sensitive to heat induced denaturation and

polymerization leading to the decrease of their solubility [Lee et al., 1992].

Different types of whey protein products are commercially available, for

instance whey protein concentrate, whey protein isolate and whey protein hydrolysate.

The important products are whey protein concentrates (WPC) and whey protein

isolates (WPI). WPC contains protein in the range of 34-80% with a low level of fat

and cholesterol and a greater amount of bioactive compounds and lactose, while WPI

contains more than 90% protein and lower levels of fat, lactose and bioactive

compounds [Gangurde et al., 2011].

WPI are obtained by two processing methods, namely ion-exchange (IE)

chromatography followed by ultrafiltration, and membrane filtration (MF) in which

microfiltration is followed by ultrafiltration-diafiltration [T Wang and Lucey, 2003].

Retentates obtained from the filtration process are then spray dried after further

concentration. Differences in total composition and in protein fractions have been

reported between the two isolation processes as well as between different

manufacturers [T Wang and Lucey, 2003].WPI obtained by microfiltration (MF) is

known to contain more glycomacropeptides and a lower concentration of β-

lactoglobulin than that obtained by ion-exchange [T Wang and Lucey, 2003].

Whey proteins can also be furthered processed by partial hydrolysis under

controlled conditions resulting in hydrolyzed whey proteins (HWP). This makes HWP

6

easily absorbed in the gut and suitable for development of infant products [Jovanović

et al., 2005].

1.2.1. Whey Protein Components

Whey proteins are primarily mixtures of β-lactoglobulin ( β-Lg), α-

lactalbumine (α-Lac), bovine serum albumin (BSA) and immunoglobuline (Ig) which

constitute 60%, 22%, 5.5% and 9% of the total whey protein, respectively [Bryant

and McClements, 1998]. Other minor fractions of whey proteins are proteose peptone,

lactoferrin, lactoperoxidase and lysozyme [De Wit, 1998].

1.2.1.1. β-Lactoglobulin

The major component of whey protein is β-lactoglobulin, and thereby its

properties impart great importance in the functionality and thermal behavior of whey

protein ingredients [Vardhanabhuti and Foegeding, 2008]. β-lactoglobulin has seven

genetic variants; among them, variant A and B are the most abundant variants which

are different from each other only in two amino acids [Cayot and Lorient, 1997; Eigel

et al., 1984]. Variant A is the most negatively charged at the pH of milk (6.6) [Cayot

and Lorient, 1997].

β-lactoglobulin is a small molecule with a molecular mass of about 18.3 kDa

and is soluble in dilute salt solutions [Kontopidis et al., 2004]. It represents more than

50% of the total whey proteins and 12 % of total milk proteins [Fox and McSweeney,

2003]. Its primary structure consists of 162 amino acid residues with one free thiol

group (C121) and two disulfide bonds (C106-C119 and C66-C160) [Hoffmann and

van Mil, 1999].The secondary and tertiary structure of β-lactoglobulin consist of 43-

50% of β-sheet, 10-15% of α helix and 15-20% of β-turn [Cayot and Lorient, 1997].

The monomeric form of β-lactoglobulin is conical, and forms a so-called calyx

or β-barrel with a hydrophobic pocket that can bind vitamin A and fatty acids (Cayot

& Lorient, 1997). The monomeric form appears at a pH below 3, while at room

temperature and pH between 5 and 7, it is present as a dimer constituted of two

identical subunits; by increasing the temperature, the equilibrium is changed to the

7

monomeric form [deWit and Klarenbeek, 1984; Kontopidis et al., 2004;

Vardhanabhuti and Foegeding, 2008]. This dimer transition to monomer is a

prerequisite for aggregation by heat [Hoffmann and van Mil, 1999].

It is known that β-lactoglobulin dissociation and aggregation are influenced by

pH, temperature, salt and protein concentration [Hoffmann and van Mil, 1999].

Heating β-lactoglobulin at 40°C induces a small reversible conformational change

[deWit and Klarenbeek, 1984], while heating at above 50°C induces irreversible

conformational changes in β-lactoglobulin during which buried hydrophobic and

thiol groups of the native protein become exposed. This exposure leads to sulphydril-

disulphide interaction with β-lactoglobulin itself or other thiol-containing proteins,

while the secondary structure is retained, and it is called as molten globule state

[deWit and Klarenbeek, 1984; Vardhanabhuti and Foegeding, 2008].

Therefore the thiol groups of β-lactoglobulin play an essential role in thermal

destabilization of whey protein stabilized emulsions. The exposed thiol group in the

newly formed monomers can form disulfide linkages by thiol/disulfide exchange

reactions. The C66-160 disulfide of β-lactoglobulin is the main disulfide involved in

the intermolecular exchange reaction due to its location on the external loop, whereas

the other disulfide bond, buried in the structure, is less prone to the intermolecular

exchange reaction [Hoffmann and van Mil, 1999].

In addition to the covalent disulfide bonds, non covalent interactions including

hydrophobic, ionic and Van der Waals also play a role in the β-lactoglobulin

aggregation process [Hoffmann and van Mil, 1999]. The β-lactoglobulin association

properties are pH-dependent. The dimer form is present at pH 5-8 and associates to

octamers at pH 3-5. On the other hand, the monomeric form exists at extreme pH

values (i.e. either below 2, or above 8). At pH values above 9, β-lactoglobulin will

undergo reversible denaturation [Cayot and Lorient, 1997].

8

1.2.1.2. α-Lactalbumin

α-lactalbumin is the second most dominant and the smallest whey protein

component with a molecular mass of about 14.2 kDa [Cayot and Lorient, 1997]. It

represents about 20% of the total whey proteins and about 3.5% of the total milk

proteins. It consists of 123 amino acid residues and four disulfide bridges. It has no

free thiol group and as a result, α-lactalbumin is known as the most heat resistant of

the whey protein components [deWit and Klarenbeek, 1984]. In addition, α-

lactalbumin has a calcium binding site, which promotes the heat stability and the

recovery of its native conformation (Cayot & Lorient, 1997).

The secondary structure of α-lactalbumin consists of two main domains of the

native molecule, namely α-helix (30%) and β-sheet (9%), which are connected by

calcium. The great flexibility and recovery of the native conformation of α-

lactalbumin is not only due to its Ca2+ binding properties but also due to the low

amount of ordered secondary structure [Cayot and Lorient, 1997]. By releasing

calcium at a pH below 4, flexible apo-α-lactalbumin is formed which is highly prone

to proteolysis (Cayot & Lorient, 1997).

Upon heating of α-lactalbumin up to 77°C and subsequent cooling, 90% of the

conformational change is reversible, whereas upon heating at 95°C for 15 min, 40%

of the changes are reversible [Vardhanabhuti and Foegeding, 2008]. The C6-C120

disulfide bond of α-lactalbumin is the most active disulfide group involved in

aggregation reactions due to its position at the surface of the protein [Wijayanti et al.,

2014]. α-lactalbumin is highly water soluble even at its isoelectric point due to the

presence of a high amount of hydrophilic groups, which leads to its incapability to

precipitate from milk at the isoelectric point [Swaisgood, 1982].

1.2.1.3. Other Minor Proteins

Bovine serum albumin (BSA) of milk is physically and immunologically

similar to blood serum albumin [Eigel et al., 1984]. BSA has 582 amino acid residues

with a molecular weight of about 66 kDa. It has 17 intramolecular disulfide bonds and

9

one free sulfhydryl group [Eigel et al., 1984]. Serum albumin constitutes of three

major domains which are different in hydrophobicity, net charge and ligand binding

sites [Eigel et al., 1984]. BSA can act as a carrier of nonpolar fatty acids in the blood

circulatory system [deWit and Klarenbeek, 1984]. It has been pointed out that fatty

acids provide stabilization of BSA against heat denaturation [deWit and Klarenbeek,

1984]. Furthermore, BSA is a well-known whey protein for its gelling properties.

During gelation of BSA, the amount of β-sheet, which is very low in the native

molecule, increases while the amount of the α-helix decreases. This transition is

particularly critical in the gelation of BSA [Wijayanti et al., 2014].

The other minor proteins present in whey proteins are Immunoglobulins which

are glycoproteins with antibody properties [Cayot and Lorient, 1997]. IgG, IgA and

IgM are the main Immunoglobulins in bovine milk and whey [deWit and Klarenbeek,

1984] . The most heat sensitive Immunoglobulin is IgM, whereas the most heat

resistant type is IgG [Sweeney and Fox, 2013]. In spite of the higher denaturation

temperature compared to β-lactoglobulin and α-lactalbumine, the presence of BSA

will reduce the heat stability of Immunoglobulins due to the interaction of the free

thiol group of BSA with Immunoglobulins [Cayot and Lorient, 1997].

1.2.2. Whey Proteins Functional Properties

Having unique properties, whey proteins have received most attention for their

versatile functionality and excellent nutritional value [Bryant and McClements, 1998;

De Wit, 1998; Jovanović et al., 2005; Smithers, 2008]. Whey proteins are recognized

nutritionally superior to other common dietary proteins due to their high amount of

essential amino acids and branched chain and sulphur amino acids, as well as their

high biological value (BV) and digestibility compared to other protein sources

[Smithers, 2008].

Moreover, whey proteins contain biologically active proteins and peptides

proper for medicinal application. Evidences about anti-cancer effects of lactoferrin,

lactoperoxidase and serum albumin have been found in some studies [Bounous et al.,

1991; Gill and Cross, 2000]. Anti-infectivity of immunoglobulins, antithrombotic

10

effects of glycomacropeptides and antimicrobial effects of lactoferrin have also been

reported [Farnaud and Evans, 2003; Hernández-Ledesma et al., 2006; Mehra et al.,

2006; Smithers, 2008].

Along with physiological benefits, whey proteins possess inherent functional

and sensory characteristics. The functional properties of whey proteins include

gelling, emulsification, foaming, water binding, solubility and viscosity, which

enable whey proteins to be used in various food products by taking advantage of one

or several functional properties for each application [Foegeding et al., 2002; Xiong,

1992]. As a gelling agent, WPI is useful for designing and improving textural

properties of various foods, such as dairy, meat and bakery products [Jovanović et al.,

2005]. Based on how the gels are prepared, they can be divided into heat induced gels

and cold set gels [Jovanović et al., 2005].

The functional properties of whey proteins are related not only to their

structure but also to their processing conditions [Bryant and McClements, 1998].

Intrinsic physiological properties of native proteins such as their amino acid

composition and their sequence, the ratio of hydrophobicity to hydrophilicity, charge

distribution, and flexibility influence the functional properties of whey proteins. In

addition, external factors such as processing conditions, isolation methods,

protein content, pH, temperature and ionic strength, as well as the interaction

with other food ingredients will also influence the functional properties of whey

proteins by changing their conformation [J Kinsella and Whitehead, 1989].

The most important functional property of whey protein is its high solubility

over a wide range of pH conditions, which is a principal prerequisite for its

functional properties such as emulsification [J E Kinsella et al., 1986]. In general,

whey proteins are soluble in the pH range of 2 – 9 [Damodaran et al., 2007]. The

solubility of proteins depends on their water binding capacity and physical state

[Damodaran, 1997]. The amount of water bound to the protein is a function of

intrinsic factors such as protein composition, number of exposed polar groups,

conformation, and surface polarity, as well as external factors such as pH, temperature

and ionic strength [J E Kinsella and Morr, 1984].

11

Moreover, protein solubility is governed by two main interactions, namely

hydrophobic and ionic interaction. Hydrophobic interaction decreases the solubility

by promoting protein-protein interaction, while ionic interactions enhance the

solubility by promoting protein-solvent interaction [Damodaran et al., 2007].

Solubility of whey proteins, even at their isoelectric point, is due to a large ratio of

surface hydrophilic to hydrophobic residues. By extensive heat treatment, the

solubility of whey proteins shifts to a minimum due to the rise of the surface

hydrophobicity as a result of protein unfolding [J Kinsella and Whitehead, 1989].

Whey proteins are widely known for their superior emulsification properties.

Having an amphiphilic structure and surface activity, whey proteins have the ability to

readily adsorb at the oil-water interface, reduce the interfacial tension at the oil and

water interface, and also form an interfacial membrane around oil droplets preventing

destabilization of the emulsion [J E Kinsella et al., 1986].

1.3. Emulsions

An emulsion is a mixture of two immiscible liquids in which one of the liquids

(called the dispersed phase) is dispersed in the other one (called the continuous

phase)[D J McClements, 2007]. The average diameter of the dispersed phase droplets

is in the range of 0.1 to 100 µm [Lam and Nickerson, 2013]. In the food industry,

typical emulsions are either oil in water (O/W), in which oil droplets are dispersed in

an aqueous phase, e.g. milk, ice-cream, and mayonnaise, or water in oil (W/O) which

consist of water droplets dispersed in an oil phase, such as butter and margarine. In

addition, multiple emulsions such as water-oil-water (W/O/W) or oil-water-oil

(O/W/O) can be made in advanced systems [Lam and Nickerson, 2013; D J

McClements, 2007].

Emulsions are formed by a homogenization process by which intense

mechanical shear is exerted using a homogenizer, a high pressure valve homogenizer,

a microfluidizer or an ultrasonic homogenizer [Lam and Nickerson, 2013; D J

McClements, 2007]. The force applied during homogenization breaks down fat

droplets into small sizes and prevents fat droplet separation.

12

Fig. 1.1. Schematic figures of emulsions. a. oil in water emulsion (O/W); b. water in

oil emulsion (W/O); c. Water in oil in water double emulsion (W/O/W); d. Oil in

water in Oil double emulsion (O/W/W)

1.3.1. Emulsion Destabilization Mechanisms

Emulsions are very prone to destabilization due to their high interfacial area

[Badolato et al., 2008]. Since food emulsions are lyophilic colloidal dispersions, the

contact between oil and water molecules, which leads to an increase in the interfacial

tension between dispersed and continuous phase and in the free energy of the system,

is unfavorable. As a result, emulsions are thermodynamically unstable and separation

of the two phases of an emulsion occurs for minimizing the interfacial contact area

and free energy of the system [Damodaran, 2005]. Various physiochemical

mechanisms such as gravitational separation (creaming and sedimentation),

flocculation, coalescence, partial coalescence and Ostwald ripening can cause

instability of food emulsions [D J Mcclements, 2007].

Gravitational separation is due to the density difference between the

continuous phase and the dispersed phase or oil droplets. Two types of gravitational

separation include creaming and sedimentation. Since oil droplets have a lower

density than the continuous phase (water), they rise to the top of the emulsion in oil-

in-water (O/W) emulsions and lead to creaming. In the case of water-in-oil (W/O)

a b

c d

Oil

Water

13

emulsions, the water droplets move downward leading to sedimentation.Nevertheless,

creaming is a reversible process [Damodaran, 2005; D J McClements, 2007].

On the other hand, in aggregation two or more oil droplets come close to each

other and form an aggregate due to the Brownian motion [Fredrick et al., 2010]. The

structure and properties of the flocks or aggregates is a function of the net interparticle

force and the oil volume fraction [Damodaran, 2005; D J McClements, 2007]. A weak

flock with a low number of droplets can be formed at low oil volume with weak

attraction forces. The principal non covalent interactions in the aggregation are Van

der Waals attraction and electrostatic and steric repulsion. If aggregates disintegrate

by gentle mechanical force (stirring), it is called flocculation, which is a reversible

process. On the other hand, coagulation requires a stronger force to disrupt the

aggregates [Fredrick et al., 2010].

When small oil droplets are in close contact for a long period of time, they

may merge together and form a single larger droplet; this phenomenon is called

coalescence [Badolato et al., 2008]. Consequently, creamed or aggregated emulsions

are more susceptible to coalescence in which there is only a thin film of continuous

phase between the droplets [Fredrick et al., 2010]. Partial coalescence occurs when

two or more partly crystalline droplets merge together in which solid crystals from

one droplet penetrate into the liquid part of the other droplet, and as a result,

aggregate whereby an irregular shape is formed [D J McClements, 2007].

Another instability mechanism is Ostwald ripening, which involves growth of

larger droplets due to the diffusion of molecules of the dispersed phase from small

droplets to the larger ones through capillary forces [Fredrick et al., 2010].Therefore

the particle size distribution of the emulsion shifts to the bigger size during

coalescence and Ostwald ripening, while it remains unchanged during gravitational

separation and aggregation [Badolato et al., 2008].

Interrelations between physiochemical instability mechanisms have been

pointed out. Instability due to flocculation and coalescence promote instability to

gravitational separation like creaming and sedimentation due to the increase in

14

particle size. Furthermore, the close vicinity of the particles for a long period due to

gravitational separation or flocculation promotes coalescence [D J McClements,

2007]. A schematic diagram of the most common instability mechanisms and their

interrelation has been given in Fig.1.2

Fig.1.2 Schematic representation of common instability mechanism in food emulsions;

flocculation, coalescence, Ostwald ripening, creaming and phase separation [Chung

and McClements, 2014].

Emulsion stability can also be influenced by environmental stress, including

homogenization, thermal processing, chilling, freezing, drying and mechanical

agitation, as well as by the aqueous phase composition such as pH, ionic strength and

presence of surfactants, sugar and biopolymers [D J McClements, 2004].

Emulsions stabilized with proteins are highly sensitive to the pH and ionic

strength [Asylbek Kulmyrzaev et al., 2000b]. They tend to flocculate at pH values

close to the isoelectric point of the adsorbed proteins due to the low electrostatic

repulsion between the droplets which is not strong enough to overcome the various

15

attractive interactions, e.g., van der Waals and hydrophobic interactions. Moreover,

the presence of minerals can promote flocculation by screening of the electrostatic

interaction through binding to the oppositely charged groups on the surface of the

emulsion droplets. This effect is highly influenced by the type of salt, ion valency and

solubility [AA Kulmyrzaev and Schubert, 2004]. Multivalent ions are more effective

in screening electrostatic interactions compared to monovalent ions.

Furthermore, emulsion sensitivity to ions is higher near the isoelectric point

of the proteins [Asylbek Kulmyrzaev et al., 2000b]. If the amount of emulsifier is not

sufficient to completely cover the interface of the system, a gap between the

interfacial membranes surrounding the droplets will appear, which leads to droplet

coalescence when these gaps come into close contact [D J McClements, 2004].

1.3.2. Stabilization of Emulsions

“Emulsion stability” refers to the ability of an emulsion to remain unchanged

in its physiochemical properties over the time-scale of observation [D J McClements,

2007]. To prepare a kinetically stable emulsion, over a time period, it is necessary to

use an emulsifier to minimize the interfacial tension between the continuous phase

and the dispersed phase [Fredrick et al., 2010].

Emulsifiers are surface active materials consisting of both a hydrophilic head

and a hydrophobic tail adsorbed at the interface in a way that the hydrophobic part is

oriented to the oil and the hydrophilic part is exposed to the aqueous phase.

Consequently, the emulsifier prevents droplet aggregation by reducing the interfacial

tension. Moreover, it helps in disruption of the emulsion droplets and formation of

smaller droplets during homogenization [Dickinson, 2003]. Emulsifier molecules are

either low molecular weight synthetic (e.g. Tween surfactants) or natural (e.g. egg

lecithin) surfactants, or macromolecules such as proteins [Dickinson, 2009].

Besides emulsifiers, hydrocolloids, which act as thickening agents or gelling

agents, are also able to stabilize emulsions through either enhancing the viscosity of

16

the continuous phase (thickening agent) or forming a gel network within the

continuous phase. In both cases the droplet movement is lowered and thus

aggregation is slowed down or prevented [D J McClements, 2007]. However, at low

concentrations, hydrocolloids can destabilize emulsions through either depletion

flocculation induced by non-adsorbing polysaccharides or bridging flocculation by

weakly adsorbed polysaccharides [Dickinson, 2009].

1.4. Whey Protein as Emulsifier

Whey proteins have a potential for being effective emulsifiers through their

amphiphilic nature and film forming abilities [Lam and Nickerson, 2013].The

adsorbed protein molecules undergo some level of unfolding, exposing the buried

hydrophobic amino acids to the surface. They align themselves at the surface in a

way that the hydrophobic amino acids are exposed to the oil phase, while

hydrophilic amino acids point to the aqueous phase [Dickinson, 1999].

Generally, proteins are less surface active than smaller molecular weight

surfactants due to their complex structural properties and conformational

constraints which hinder the protein to properly orient the hydrophilic and

hydrophobic groups at the interface [Damodaran, 2005]. On the other hand, protein-

stabilized emulsions are generally more stable than those stabilized by small

surfactants due to the pronounced surface rheological properties of proteins and the

formation of a viscoelastic layer around the oil droplets [Dickinson, 1999].

Furthermore, as compared to caseins, whey proteins are less surface active due to

their rigid globular structure, but they have a pronounced solubility and they can

readily adsorb at the oil droplet surface and form a stable layer around oil droplets

[Leman et al., 1989].

Whey protein adsorption onto the oil droplet surface is selective and it

depends on pH, ionic strength, temperature, and protein concentration. The pH

dependency of whey protein adsorption indicates that the conformational changes of

17

the protein and the effective hydrophobicity are pH dependent [Yamaachi et al.,

1980]. β-lactoglobulin adsorbs more readily at alkaline pH conditions, compared to

other whey proteins because of molecular expansion in this pH range, while α-

lactalbumin conformational changes occur more easily in the acidic pH range due to

the loss of bound calcium in acidic conditions [Yamauchi et al., 1980].

Fig.1.3 Mechanism of emulsion stabilization by proteins through (A) electrostatic

repulsion and (B) steric stabilization. Red dots are hydrophobic parts of protein

molecules positioned at the oil phase [Lam and Nickerson, 2013].

A viscoelastic layer can be provided through non covalent interaction between

adjacent adsorbed protein, for instance by polymerization at the interface involving

sulfhydryl-disulfide interchange reactions in the presence of amino acids containing

sulfhydryl and disulfide group [Dickinson and Matsumura, 1991]. These interactions

help the proteins to be adsorbed to the surface irreversibly and provide resistance

against mechanical stresses. Furthermore, the adsorbed proteins at the surface offer

electrostatic and steric stabilization preventing droplet aggregation and coalescence

(Fig.1.3) [Lam and Nickerson, 2013].

18

1.4.1. Limiting Factors of WPI Application in Emulsions

Whey proteins are less sensitive to pH and they can be used over a wider

range of pH than caseins. However, whey proteins are heat labile globular proteins

which unfold and aggregate upon heating at temperatures above their denaturation

temperature, leading to destabilization of whey protein-stabilized emulsions and

aggregation of oil droplets [Sliwinski et al., 2003]. Moreover, common heat

treatments such as preheating, pasteurization and sterilization are commonly applied

to foods containing whey protein ingredients to increase the safety and shelf life of the

product [deWit and Klarenbeek, 1984]. These heat treatments change the native state

of globular whey proteins by various mechanisms, such as denaturation, aggregation

and flocculation, leading to emulsion destabilization. Therefore, it is of vital

importance to obtain a comprehensive knowledge of the whey protein unfolding and

aggregation mechanisms to be able to optimize the processing conditions and develop

techniques to modify the whey protein properties in order to attain their maximum

functional and nutritional properties.

1.5. Heat Stability of WPI

Whey proteins are globular proteins with a tertiary structure stabilized by

disulfide bonds between the cysteine residues [D McClements et al., 1993].

Thermodynamically, the native structure of the whey proteins is the most stable

conformation formed under physiological conditions. This native structure is

stabilized by non-covalent forces including hydrogen bonding, as well as

hydrophobic, van der Waals and electrostatic interactions, while the structural

integrity of extracellular proteins is maintained by covalent disulfide bonding

[Damodaran et al., 2007]. Changes in environmental factors can influence these

interactions, leading to an alteration in the protein conformation. Heat treatment is one

of the factors which can affect the conformation of whey protein and cause

denaturation and loss of solubility, which can implicate a loss of protein functionality

[J Kinsella and Whitehead, 1989].

19

1.5.1. Heat Induced Denaturation

Protein denaturation is referred to as the change in spatial arrangement of the

polypeptide chain or a modification in the secondary, tertiary or quaternary structure

of the protein, without breaking the backbone of the peptide bonds in the primary

structure. Denaturation of globular proteins will lead to aggregation which can

influence their solubility and functionality [Damodaran et al., 2007; Mulvihill and

Donovan, 1987].

During thermal processing, heat-induced denaturation occurs which can be

either reversible or irreversible [deWit and Klarenbeek, 1984]. Reversible

denaturation of the protein structure involves a partial loss of the tertiary structure

which takes place at a temperature up to 60°C [deWit and Klarenbeek, 1984]. On the

other hand, heating above the denaturation temperature leads to irreversible

denaturation of the protein in which unfolded protein molecules further associate

through intermolecular interaction, mainly by intermolecular disulfide bonds, to form

aggregates [deWit and Klarenbeek, 1984]. Therefore, denaturation or unfolding of

proteins leading to the exposure of reactive groups, such as hydrophobic or sulfhydryl

groups, is a prerequisite for protein aggregation which involves further cross-links of

denatured proteins and is followed by precipitation (i.e. formation of insoluble

aggregates), coagulation (i.e. formation of soluble aggregates) or gelation of the

protein. In a coagulum and a precipitate, protein molecules randomly interact, while

in a gel an ordered three dimensional structure can be seen [Damodaran et al., 2007].

At the initial stages of aggregation, various interactions in proteins lead to the

formation of small oligomers that can persist at low protein concentration and

associate into monodispersed primary aggregates when their concentration exceeds a

critical value [Durand et al., 2002]. The Critical association concentration (CAC) is

the concentration above which small oligomers form large aggregates. Furthermore,

by increasing the protein concentration, the primary monodispersed aggregates

associate into larger polydisperse self-similar aggregates or a gel [Nicolai et al.,

2011].

20

In addition to the covalent intermolecular disulfide bonds, non-covalent

interactions such as ionic, van der Waals, and hydrophobic are also involved in the

protein aggregation process. The contribution of non-covalent bonding in aggregation

and gelation processes is determined by the environmental conditions, such as pH,

temperature and salt concentration. Electrostatic interactions play an important role in

protein precipitation at the isoelectric point [Hoffmann and van Mil, 1997]. The role

of non-covalent interactions in aggregation of β-lactoglobulin is more significant at

higher temperatures [Vardhanabhuti and Foegeding, 2008].

Thermal stability of proteins refers to the ability of proteins to maintain their

biologically active native state, and survive heat processing without detrimental

changes, such as increased turbidity, increased viscosity, phase separation,

precipitation or gelation [Vardhanabhuti and Foegeding, 2008]. The thermal

denaturation behavior of whey proteins reflects the collective response of the

component proteins. β-lactoglobulin and α-lactalbumin are the predominant whey

proteins. So, they contribute significantly to the thermal stability of whey protein

ingredients; particularly β-lactoglobulin plays a key role [Cayot and Lorient, 1997].

β-lactoglobulin is mainly present as a non-covalently bound dimer at ambient

temperature and neutral pH. However, it dissociates into monomers at higher

temperatures [Nicolai et al., 2011]. Upon further heating to above 50°C, β-

lactoglobulin undergoes reversible conformational changes including a partial loss or

change of the ternary structure. In this state, known as the molten globule state,

proteins are not completely unfolded and their native secondary structure is preserved

while some hydrophobic and thiol groups are exposed. Consequently, the free thiol

groups in the modified monomers can induce thiol/disulfide exchange reactions and

formation of aggregates [Hoffmann and van Mil, 1997; Nicolai et al., 2011;

Vardhanabhuti and Foegeding, 2008]. It was reported that heat treatment of β-

lactoglobulin at 80 °C resulted in a change in the secondary conformation, i.e. a

decrease in the α-helix content and a corresponding increase in the random coil

content [Kim et al., 2005]. Moreover, an increase in surface hydrophobicity, protein

flexibility and surface rheological properties was observed during heat treatment [Kim

et al., 2005].

21

A kinetic model based on radical-addition polymerization reactions for

denaturation and aggregation of β-lactoglobulin in low ionic strength conditions at

neutral pH was proposed [Roefs and Kruif, 1994]. The main reaction steps are

initiation, propagation and termination, and the free thiol group acts as a radical in this

process. The initiation step occurs when a folded native dimer of β-lactoglobulin

unfolds and exposes its free thiol group. In the propagation step, the reactive thiol

group reacts with one of the two intramolecular disulfide bonds of a nonreactive β-

lactoglobulin molecule and forms an intermolecular disulfide bond and releases a new

reactive free thiol group. The propagation leads to the formation of linearly linked

aggregates (polymerization). The polymerization reaction stops in the termination step

when a polymer is formed between two reactive intermediates without a reactive thiol

group [Roefs and Kruif, 1994].

1.5.2. Factors Influencing Heat Stability of WPI

The effects of heat are greatly influenced by pH, ionic strength, the rate of

heating, the protein concentration and the presence of lactose [deWit and Klarenbeek,

1984]. Moreover, the amino acid composition and sequence also influence the

structure and thermal behavior of whey proteins. The protein concentration, and the

number of reactive amino acids per molecule such as half-cystin (cys/2) and lysine-

residues are influential characteristics during heat treatments [deWit and Klarenbeek,

1984].

The thermal denaturation temperature of the three major whey proteins, β-

lactoglobulin, α-lactalbumin, and bovine serum albumin is around 78, 62, and 64°C,

respectively, while the isoelectric point of β-lactoglobulin, α-lactalbumin, and bovine

serum albumin is 5.2, 4.8-5.1, and 4.8-5.1, respectively [Bryant and McClements,

1998].

β-lactoglobulin, the most abundant whey protein, mainly defines the heat

behavior of whey proteins [Hoffmann and van Mil, 1997]. It is highly sensitive to heat

treatments due to the presence of free thiol groups involving intra and intermolecular

22

disulfide interactions. Numerous studies have focused on the role of the thiol group of

β-lactoglobulin in heat induced aggregation and gelation.

In spite of its low denaturation temperature, α-lactalbumin is described as the

most heat-stable whey protein due to the lack of free thiol group as compared to β-

lactoglobulin and BSA. α-lactalbumin tends to aggregate slowly compared to β-

lactoglobulin. However, it will readily aggregate in the presence of β-lactoglobulin

and BSA [Wijayanti et al., 2014]. α-lactalbumin is the only whey protein which is

able to renature after heating [Mulvihill and Donovan, 1987]. The thermal behavior of

α-lactalbumin is influenced by some factors, such as the presence of calcium,

temperature, ionic strength and the degree of purity [Vardhanabhuti and Foegeding,

2008].

During heat treatment, the denaturation rate of β-lactoglobulin and α-

lactalbumin is influenced by temperature, protein concentration, pH and ionic

strength [Nicolai et al., 2011]. The extent of these parameters influencing the

denaturation rate can be varied depending on the values of the other parameters. The

temperature dependency of the depletion rate of β-lactoglobulin and α-lactalbumin

can be described by the Arrhenius equation in which the depletion rate increased by

increasing temperatures above the critical temperature (90°C for β-lactoglobulin) due

to the reduction of the activation energy (Ea) [Nicolai et al., 2011].

The effect of pH on the denaturation and aggregation of β-lactoglobulin at

65°C was investigated [Hoffmann and van Mil, 1999]. It was found that the

denaturation of β-lactoglobulin was enhanced by increasing the protein concentration

and pH from 6 to 8 at 65°C.

The native β-lactoglobulin solution is stable against aggregation due to the

long range electrostatic repulsion except at a pH close to the isoelectric point, where

aggregation occurs at room temperature. Around the iso-electric point, proteins

contain the same amount of negative and positive charges and aggregation occurs due

to the interaction between opposite charges [Majhi et al., 2006]. Moreover, an

increasing ionic strength leads to an increase in the denaturation rate around neutral

23

pH, in which the effect is higher for multivalent ions such as CaCl2 than for NaCl

[Croguennec et al., 2003].

The size and the number of the aggregates formed during heat treatment

change with the heating conditions, the protein concentration , the pH and the type

and concentration of added salt [Mehalebi et al., 2008; Nicolai et al., 2011]. The rate

of aggregation increases exponentially with increasing temperature, especially at high

protein concentration which leads to precipitation of large amounts of protein. The

size and amount of the aggregates increases with heating time until a steady state is

obtained. Moreover, the size of the aggregates increases by increasing the protein

concentration until above its critical concentration (Cg) at which a gel is formed

[Durand et al., 2002].

This critical concentration depends on the type of protein and other factors,

such as ionic strength and pH. The rate of aggregation reaches a maximum at the

isoelectric point (IEP), in which the electrostatic repulsion is minimum, and it

decreases when the pH is increased or decreased away from the IEP. As it was

mentioned previously, salt addition also promotes the rate of aggregation by screening

the electrostatic interactions [Mehalebi et al., 2008; Nicolai et al., 2011].

1.5.3. Improvement of Heat Stability of Whey Protein Ingredients

Based on the literature studies, whey protein isolate has the potential to be a

good emulsifier. However, the applications of whey protein isolate are limited due to

its low heat stability. To overcome this problem, some research has been performed in

order to increase the heat stability of whey proteins.

The improvement of the functional properties, particularly the heat stability, of

proteins can be performed through physical, chemical, enzymatic and genetic

modification [Damodaran, 2005]. Physical modification of proteins can be performed

by partial denaturation of the proteins or protein unfolding which can be achieved by

exposing the proteins either to heat or to hydrostatic pressure under controlled heating

and shear conditions. Partial denaturation increases the surface hydrophobicity of the

24

proteins, which increases their solubility, functionality and heat stability. The main

drawback of this method is that the partial denaturation cannot be defined as an exact

value and partially denatured proteins are highly susceptible to many parameters such

as protein concentration, heating and shearing rate, pH, ionic strength and presence of

other food components. Furthermore, high partial denaturation can lead to

aggregation of the proteins, thereby decreasing the protein solubility and functionality

[Damodaran, 2005].

Soluble whey protein aggregate formation has been found to be an effective

method for modification of the whey protein functional properties and thermal

stability [K Ryan et al., 2012; K N Ryan et al., 2013]. Whey protein soluble

aggregates are intermediates between monomer proteins and an insoluble gel network

or precipitate which are formed by heating whey proteins at a concentration below

their critical gelling concentration under proper condition of pH, salt concentration,

protein concentration, heating time and temperature [McSwiney et al., 1994; K N

Ryan et al., 2013]. [K Ryan et al., 2012] proposed that whey protein soluble

aggregates with a high charge, a small size, a more compact structure, and a low

surface hydrophobicity are resistant to added salt and heat in beverage applications.

Microencapsulation is another method for producing heat stable whey proteins

[Zhang and Zhong, 2009; 2010]. Thermal pretreatment at 90 °C for 20 min was

applied to WPI solutions in nanometer-sized micelles of water/oil microemulsions to

form a whey protein nanoparticle (WPN) which improved the heat stability of WPI

due to irreversible physical and chemical bonds during pretreatment [Zhang and

Zhong, 2010]. Furthermore, [Zhang and Zhong, 2009] reported that cross-linking of

WPI by transglutaminase, before incorporation in the microemulsion or within the

microemulsion, before heat treatment enhances the thermal stability of WPN.

EDTA and trisodium citrate as chelating agents were used to improve the heat

stability of whey protein stabilized emulsions containing CaCl2 [Keowmaneechai and

McClements, 2006]. Since calcium is present in commercial whey protein products

and as it contributes in whey protein aggregation, using mineral chelating agents,

25

which bind calcium, is a proper method for improving the heat stability of WPI

stabilized emulsions.

Another method for improving the protein functionality and heat stability is

enzymatic modification. The most applicable enzymatic method that has been

reported is hydrolysis and polymerization. Partial enzymatic hydrolysis of proteins

using proteases such as pepsin and trypsin, as well as controlled polymerization of

protein by transglutaminase, which catalyses homopolymerization of proteins, can

improve their functional properties [Damodaran, 2005]. The transglutaminase enzyme

(TGase) has been applied for improving the thermal stability of whey proteins through

formation of covalent cross-links between reactive proteins [Truong et al., 2004; W

Wang et al., 2012; Zhong et al., 2013]. Before the cross-linking reaction, the whey

proteins should be unfolded to expose the enzyme-targeted sites. Therefore,

denaturation of whey proteins by heat or by addition of reducing agent such as DDT

before incubation with TGase can increase the cross-linking reaction [Tang and Ma,

2007]. It has been reported that preheating of WPI prior to treatment with TGase

improved the heat stability of WPI solution [Zhong et al., 2013].

Chemical modification of proteins may improve their functional properties by

changing either the structure of the proteins at the secondary, tertiary and quaternary

levels, or the hydrophobic to hydrophilic ratio [Damodaran, 2005]. Some of the

chemical methods that have been reported include acylation, phosphorylation,

alkylation, sulfitolysis and the amino-carbonyl reaction. Based on nutritional and

safety considerations, among these methods, phosphorylation and amino-carbonyl

(Maillard reaction) methods are more advisable for application in the food products

[Damodaran, 2005]. In contrast to other chemical methods, the Maillard reaction is a

spontaneous and naturally occurring reaction. As a result, it can be safely

incorporated into the food system without using undesirable chemical catalysis

[Oliver et al., 2006]. Therefore, this method is more preferable for improving the heat

stability of whey proteins.

26

1.6. protein-polysaccharide Conjugates via Covalent Bonding

In recent decades, there has been a considerable effort in developing protein-

polysaccharide complexes through two process: (1) covalent bonding between the

reducing end of a polysaccharide and the amine group of a protein, produced by dry

heating of a protein and polysaccharide mixture under controlled temperature and

relative humidity [Akhtar and Dickinson, 2007; Aoki et al., 1999; Dickinson and

Semenova, 1992; Einhorn-Stoll et al., 2005; Kato et al., 1990; Kato et al., 1992; Kika

et al., 2007]; and (2) non-covalent or electrostatic complexes between positively

charged patches of the protein with the negative charges of the polysaccharide

carboxyl groups at pH values below the isoelectric point of the protein [Gentes et al.,

2010; Weinbreck et al., 2003; Zaleska and Tomasik, 2002]. Covalent protein-

polysaccharide hybrids have been recognized as more advantageous as they are more

stable towards changes in solution conditions, such as pH and ionic strength, and

retain their molecular integrity and solubility [Dickinson and Galazka, 1991].

Glycation of proteins via the Maillard reaction has an influence on the

functional properties of proteins by changing their charge, solvation and conformation

[Nakamura et al., 1994].The functional properties of the complex are remarkably

different from the original biopolymers [Akhtar and Dickinson, 2007]. Furthermore,

it has been proven that protein glycation during the early stages of the Maillard

reaction can dramatically improve the emulsifying activity of a protein [Akhtar and

Dickinson, 2003; Aoki et al., 1999; Dickinson and Galazka, 1991; Einhorn-Stoll et al.,

2005; Jourdain et al., 2008; Kato et al., 1990; Kato et al., 1992; Kika et al., 2007; N.

Neirynck et al., 2004], its foaming properties [Dickinson and Izgi, 1996; Mishra et al.,

2001], solubility [Akhtar and Dickinson, 2007; Katayama et al., 2002; Mishra et al.,

2001; N. Neirynck et al., 2004], antimicrobial activity [Takahashi et al., 2000] and

heat stability [Aoki et al., 1999; Diftis and Kiosseoglou, 2006; Hashemi et al., 2014;

Sato et al., 2003; Shu et al., 1996]. In addition, at advanced stages of the Maillard

reaction, the formation of compounds with antioxidant activity [Nakamura et al.,

1998], anticarcinogenic and antimutagenic properties [Hosono, 1997] have been

reported.

27

1.6.1. Mechanism of the conjugate formation

The formation of protein and polysaccharide conjugates follows the path of

the Maillard reaction. In general, the Maillard reaction can be divided into three

stages: early, intermediate (or advanced) and final stages [Jimenez-Castano et al.,

2007; J Liu et al., 2012; Oliver et al., 2006]. In an early stage of the Maillard reaction,

the carbonyl group of a reducing sugar condenses with the free amino group to form a

Schiff base with the release of water. Subsequently, the Schiff base cyclizes to the

corresponding N-glycosylamine. With aldoses as the initial reactant, an Amadori

product ( 1-amino-1-deoxy-2-ketose) is formed through Amadori rearrangement of

N-glycosylamine, and in case of ketoses, the Heyn’s product (2-amino-2-

deoxyaldose) is formed by Heyn’s rearrangement [Oliver et al., 2006]. Mostly, the ԑ-

amino group of the lysine residue in the proteins is the primary source of reactive

amino groups. However, the imidazole group of histidine, the indole group of

tryptophan, and the guanidine group of arginine residues can also take part in this

reaction, albeit to a lesser amount [Ames, 1998].

The intermediate stage of the Maillard reaction begins with degradation of

Amadori/Heyn’s products which includes various pathways depending on the pH of

the system. At a pH up to 7, it undergoes 1,2-enolization with the formation of

furfural or hydroxymethylfurfural (HMF). At pH values above 7, 2,3-enolization of

the Amadori products leads to the formation of reductones and a variety of fission

products [Jimenez-Castano et al., 2007; J Liu et al., 2012]. All these products are

highly reactive and they are involved in various transformation reactions such as

oxidation, cyclization, hydrolysis, fragmentation, free radical reaction, and so on.

Although some color is formed at the intermediate stage, color development mostly

occurs at the final stage of the Maillard reaction in which “Melanoidins” , highly

colored, water soluble, nitrogen-containing polymeric compounds, are produced

[Jimenez-Castano et al., 2007; J Liu et al., 2012] .

However, extensive glycation decreases the solubility of proteins due to the

cross-linking and polymerization which occur during the advanced and final stages of

the Maillard reaction [Oliver et al., 2006]. This reaction is partly due to the presence

28

of sugar-derived dicarbonyl compounds which can attach to two lysine residues via

their bifunctional groups leading to cross-linking of protein molecules [Oliver et al.,

2006]. Therefore, to obtain conjugates with improved functionality and minimum

color and flavor changes which are suitable for food application, it is necessary to

perform the Maillard reaction under carefully controlled conditions to prevent the

later stages of the Maillard reaction since this is undesirable [Oliver et al., 2006].

Consequently, a good understanding of the key reaction parameters influencing the

glycation and side reactions as well as their influence on the protein functionality is

important for the development of superior functional food ingredients. Furthermore,

the types and products of the Maillard reaction are influenced by the reaction

conditions such as temperature, time, pH, protein to carbohydrate ratio, relative

humidity, intrinsic characteristics of the reactant, as well as the presence of oxygen

and reaction inhibitors such as sulfur dioxide [Ames, 1998].

The Maillard reaction can take place either in wet conditions or in dry

conditions. The optimum aw for the Maillard reaction is between 0.5 and 0.8 [Oliver et

al., 2006]. The dry heating method involves lyophilization of the solution of a protein

and a reducing sugar, which is followed by equilibration and incubation to the desired

aw or RH under controlled temperature for a specific time. Maillard-type protein-

polysaccharide conjugates can be prepared by freeze-drying of the protein-

polysaccharide mixtures with various molar ratios of protein to polysaccharide and

subsequent storage of the dried mixtures at 60°C for a given period of time under

either 65% or 79% relative humidity in desiccators containing a saturated KI or KBr

solution, respectively [Kato, 2002].

From the industrial point of view, the dry reaction is more preferable than the

wet reaction [Oliver et al., 2006]. This is due to the fact that this method has a higher

reaction efficiency as it requires less space and time. Furthermore, the resulting

product is easier to be handled and stored and has a longer-term stability compared to

the liquid products obtained from the wet reaction. Moreover, in wet conditions there

is a possibility of growth of microorganisms [G Liu and Zhong, 2013].

29

1.6.2. Emulsifying Properties of Maillard Conjugates

It is well known that food macromolecules, such as proteins and

polysaccharides, play a significant role in the stability and structure of food

emulsions [Tolstoguzov, 1991]. Proteins have received most attention for their

emulsifying properties through their surface activity and film forming abilities

[Dickinson, 2009].On the other hand, hydrophilic high molecular weight

polysaccharides are well known as stabilizing agents through their

hydrophilicity, gelling and thickening properties [Dickinson and Semenova, 1992].

Both compounds can work simultaneously to stabilize oil in water emulsions by

forming a macromolecular barrier between the dispersed droplets in the aqueous

medium [Dickinson and Galazka, 1991].

Based on theoretical considerations, for a biopolymer to provide an ideal steric

stabilization, it is required to not only adsorb at the interface strongly, but it should be

highly soluble in the aqueous medium as well [Dickinson and Galazka, 1991].These

properties are present in the conjugate, in which upon addition of the conjugate, the

hydrophobic residue of the protein molecule are anchored into the oil droplets and the

hydrophilic saccharides attached to the protein bind water molecules around the oil

droplets. This leads to the formation of a thick layer around the oil droplets providing

steric stabilization, thereby preventing oil droplet coalescence. Therefore, making

hybrid biopolymers composed of both proteins and polysaccharides is an ideal

combination of the excellent emulsifying properties of proteins and the good

stabilizing ability of polysaccharides [Dickinson and Semenova, 1992].

1.6.3. Factors Influencing the Functionality of the Conjugate

One of the most important physiochemical properties influencing the

functional properties and heat stability of conjugates is the glycation extent which can

be changed by reaction conditions such as temperature, time and pH [J Liu et al.,

2012]. The reaction time is a critical factor influencing the functionality of the

protein-polysaccharide conjugates. After a certain time of heating, the emulsifying

properties (EP) are expected to reach a steady state. The time needed to reach this

30

condition differs depending on the reactant and reaction conditions:as an example,

globular proteins will need a longer time to form Maillard conjugates than other

proteins, because of their compact conformation [Oliver et al., 2006]. The early stages

of the Maillard reaction can improve the functional properties and solubility.

Accordingly, the heat stability increases as the solubility improves. On the other hand,

the advanced stages of the Maillard reaction lead to color formation and

polymerization which is detrimental to solubility and heat stability of the conjugates.

In this context, the reaction conditions should be selected in a way which restricts the

advanced stages of the reaction [J Liu et al., 2012].

One of the critical factors in the mechanism of increasing the emulsifying

properties of the protein-polysaccharide conjugates is the balance between

hydrophobic and hydrophilic parts [Oliver et al., 2006]. The initial protein-

carbohydrate mole ratio of the conjugate has a major influence on the emulsifying

properties of the complex. When the proportion of sugar reaches a certain maximum

value , the availability of the protein to adsorb at the interface will decrease, thereby

the EP also decreases [Oliver et al., 2006]. However, the presence of free or weakly

complexed polysaccharides in the protein-polysaccharide composite should be

avoided since this leads to emulsion instability through depletion flocculation and

bridging flocculation, respectively [Dickinson and Galazka, 1991].

The type of carbohydrate and its molecular weight is another factor which