MADURAI KAMARAJ UNIVERSITY (University with Potential for ...

KAMARAJ COLLEGE OF ENGINEERING AND TECHNOLOGY - course outcomes... · Web viewwith various...

Transcript of KAMARAJ COLLEGE OF ENGINEERING AND TECHNOLOGY - course outcomes... · Web viewwith various...

DEPARTMENT OF MECHANCIAL ENGINEERING

COURSE OUTCOMES

1

TECHNICAL ENGLISH-I

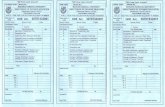

Subject code: HS6151Course Outcomes

CO CO- Statements Learning LevelC101.1 Demonstrate proper grammar usage K3

C101.2 Comprehend technical and non-technical passages in English. K2C101.3 Apply Verbal reasoning with contextual knowledge. K3C101.4 Interpret the data given in graphical representations. K2C101.5 Use formal and informal communication effectively. K3

Courses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

Tec

hnic

al E

nglis

h-I

C101.

1 (K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C101.

2 (K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C101.

3 (K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C101.

4 (K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C101.

5 (K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

2.6 1.6 1 1 - 2.6 3 2.6 - - 2.6 1 3 1

2

ENGINEERING MATHEMATICS-I

Subject code: MA6151Course Outcomes

CO CO- Statements Learning LevelC102.1 Apply the basic concepts of Matrices to solve problems in electronics. K3

C102.2 Make use of the concept of infinite series in analyzing questions in Signals & Systems.

K3

C102.3 Utilize the knowledge of differential calculus and curvature in Satellite Communication

K3

C102.4 Derive the various circuit parameters using the knowledge of calculus of several integrals.

K3

C102.5 Formulate and Solve the concepts of field theory using multiple integrals

K2

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

Eng

inee

ring

Mat

hs-I

C102.1

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C102.2

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C102.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C102.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C102.5

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

2.8 1.8 1 1 0 2.8 3 2.8 0 0 2.8 1 3 1

3

ENGINEERING PHYSICS-I

Subject code: PH6151Course Outcomes

CO CO- Statements Learning LevelC103.1 Outline the crystal, its crystallographic arrangement of atoms

including the packing density and crystal growth techniques.K2

C103.2 Make use of the elastic & thermal properties of the material to predict the behaviour of materials when the heat/pressure is applied.

K3

C103.3 Apply the fundamental principles of physics to solve problems related to classical , quantum mechanics and analyse the micro structure of materials using SEM and TEM.

K3

C103.4 Demonstrate the generation of ultrasonic waves and its application in NDT and Sonogram.

K2

C103.5 Summarize the different types of LASER, its production and utilization in various disciplines and also explain the various types, principle and application of optical fibre.

K2

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

Eng

inee

ring

Phy

sics

-I

C103.1

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C103.2

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C103.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C103.4

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C103.5

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C103 2.4 1.4 1 1 2.4 3 2.4 - - 2.4 1 3 1

4

ENGINEERING CHEMISTRY-I

Subject code: CY6151Course Outcomes

CO CO- Statements Learning LevelC104.1 Identify the types of polymers and state their applications K3

C104.2 Relate the thermodynamic laws to various real time problems K2

C104.3 Outline the photo physical processes and explain the principle behind various analytical techniques

K3

C104.4 Define the phase rule and recall the purpose and significance of alloys.

K1

C104.5 Explain the properties and applications of nano materials K2

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

Eng

inee

ring

Che

mis

try-

I

C104.1

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C104.2

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C104.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C104.4

(K1) 1 - - - - 1 2 1 - - 2 - 1 -

C104.5

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C104 2.2 1.5 1 1 - 2.2 2.8 2.2 - - 2.4 1 2.6 1

5

COMPUTER PROGRAMMING

Subject code:GE6151Course Outcomes

CO CO- Statements Learning LevelC105.1 Explain the knowledge gained in Computer fundamentals. K2

C105.2 Illustrate algorithms using flow charts and pseudo codes for solving problems using computer.

K2

C105.3 Experiment with fundamentals of C Programming Basics. K3

C105.4 Build skills on writing simple C Programs. K3

C105.5 Model customized solution for solving real world problems using C. K3

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

CO

MPU

TE

R P

RO

GR

AM

MIN

G

C105.1

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C105.2

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C105.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C105.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C105.5

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C105 2.6 1.6 1 1 2.6 3 2.6 - - 2.6 1 3 1

6

ENGINEERING GRAPHICS

Subject code: GE6152Course Outcomes

CO CO- Statements Learning LevelC106.1 Contrast simple curves like parabola , hyperbola, involute, cycloid

etc. and practice the various projections of simple objects.K3

C106.2 Develop the projection of points, straight lines and planes K3

C106.3 Construct the projection of solids K3

C106.4 Model the development of surfaces and section of solids K3

C106.5 Solve the isometric and perspective drawings K3

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

Eng

g. G

raph

ics

C106.1

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C106.2

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C106.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C106.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C106.5

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C106 3 2 1 1 3 3 3 - - 3 1 3 1

7

COMPUTER PRACTICES LABSubject code:GE6161Course Outcomes

CO CO- Statements Learning LevelC107.1 Apply good programming design methods for program development. K3

C107.2 Illustrate algorithms using flow charts and pseudo codes for solving problems using computer.

K2

C107.3 Model and implement C programs for simple applications. K3

C107.4 Demonstrate recursive programs. K3

C107.5 Model customized solution for solving real world problems using C. K3

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

Com

pute

r Pr

actic

e L

ab

C107.1

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C107.2

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C107.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C107.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C107.5

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

2.8 1.8 1 1 2.8 3 2.8 - - 2.8 1 3 1

8

ENGINEERING PRACTICES LAB

Subject code: GE6162Course Outcomes

CO CO- Statements Learning LevelC108.1 Identify the various components used in plumbing and carpentry

works and Develop various types of welding joints like butt, lap and tee joints

K3

C108.2 Experiment with various machining operations in a lathe like simple turning, drilling, taper turning, sheet metal etc

K3

C108.3 Demonstrate the working of logic gates and rectifier circuits K2

C108.4 Model simple circuits using soldering practice K3

C108.5 Illustrate the various types of wiring and also measure the energy and resistance of any equipment.

K3

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

EPL

C108.1

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C108.2

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C108.3

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C108.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C108.5

(K2) 3 2 1 1 - 3 3 3 - - 3 1 3 1

2.8 1.8 1 1 2.8 3 2.8 - - 2.8 1 3 1

9

PHYSICS & CHEMISTRY LAB-I

Subject code: GE6163Course Outcomes

CO CO- Statements Learning LevelC109.1 Find the size of the microscopic particles with the help of laser and

determine the acceptance angle in an optical fiber. K3

C109.2 Solve the elastic property (Young’s modulus) of the materials using non uniform bending method and find the velocity & compressibility of ultrasonic wave in liquid media.

K3

C109.3 Find the wavelength of different colours present in polychromatic light source using grating and measure the thermal conductivity of the bad conductors like card board and glass.

K3

C109.4 Infer quantity of sample by volumetric method K3

C109.5 Infer the concentration of the samples with help of various instruments.

K3

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

Phys

ics &

Che

mis

try

Lab

-I

C109.1

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C109.2

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C109.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C109.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C109.5

(K2) 3 2 1 1 - 3 3 3 - - 3 1 3 1

3 2 1 1 3 3 3 - - 3 1 3 1

10

TECHNICAL ENGLISH-II (common for all programmes)

Subject code: HS6251Course Outcomes

CO CO- Statements Learning LevelC110.1 Recall the concepts of English grammar and its linguistic features. K1

C110.2 Comprehend the passages by familiarizing them with different types of reading strategies.

K2

C110.3 Describe effectively for situations in academic contexts. K2C110.4 Write for situations in workplace contexts. Differentiate written

communication in formal and informal situations.K3

C110.5 Prepare reports, proposals etc using relevant materials. K3

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

TE

CH

NIC

AL

EN

GL

ISH

-II

C110.1

(K1) 1 - - - - 1 2 1 - - 1 - 1 -

C110.2

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C110.3

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C110.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C110.5

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

2.2 1.5 1 1 - 2.2 2.8 2.2 - - 2.2 1 2.6 1

11

ENGINEERING MATHEMATICS-II

(Common for all programmes)Subject code: MA6251Course Outcomes

CO CO- Statements Learning LevelC111.1 Apply the concepts of vector calculus in building equations in

engineeringK3

C111.2 Solve Ordinary Differential Equations analytically and numerically K3

C111.3 Apply the concept of Laplace Transforms in solving linear ODE of second order with constant coefficients

K3

C111.4 Construct the analytic function and transform complex functions from one plane to another plane graphically

K3

C111.5 Apply complex integration to evaluate real integrals K3

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

EN

GIN

EE

RIN

G M

AT

HS-

II

C111.1

(K3)3 2 1 1 - 3 3 3 - - 3 1 3 1

C111.2

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C111.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C111.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C111.5

(K3) 2 1 - - - 2 3 2 - - 2 - 3 -

2.8 1.8 1 1 0 2.8 3 2.8 0 0 2.8 1 3 1

12

ENGINEERING PHYSICS-II

Subject code: PH6251Course Outcomes

CO CO- Statements Learning LevelC112.1 Demonstrate the thermal and electrical conductivity of the material ,

carrier concentration in metals from density of energy states.K2

C112.2 Compute the carrier concentration, electrical conductivity and band gap of intrinsic and extrinsic (P and N) type semiconducting materials and also Hall effect

K3

C112.3 Compare Dia, Para and Ferro magnetic materials and its application K3

C112.4 Illustrate the polarization mechanism and local field in dielectric materials.

K2

C112.5 construct the modern engineering materials such as metallic glass, SMA and Nano materials for industrial and medical uses.

K3

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

EN

GIN

EE

RIN

G P

HY

SIC

S-II

C112.1

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C112.2

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C112.3

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C112.4

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C112.5

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C112 2.6 1.6 1 1 - 2.6 3 2.6 - - 2.6 1 3 113

ENGINEERING CHEMISTRY-II

Subject code: CY6251Course Outcomes

CO CO- Statements Learning LevelC113.1 Explain the various process of removing the hardness of water. K2

C113.2 Identify and solve the problems of corrosion through the basic knowledge of EMF series

K3

C113.3 Outline the operating principles and the reaction mechanisms of batteries and fuel cells

K2

C113.4 Make use of the knowledge of synthesis and applications of engineering materials

K3

C113.5 Classify the types of the fuels and calculate its calorific value and efficiency

K2

Cour-ses CO

Program out comesProgram

Specific out-comes

PO1

(K3)

PO2

(K4)

PO3

(K5)

PO4

(K5)

PO5

(K6)

PO6

(K3)

PO7

(K2)

PO8

(K3)

PO9

(A3)

PO10

(A3)

PO11

(K3)

PO12

(A5, K5)

PSO1

(K3)

PSO2

(A3, K5)

EN

GIN

EE

RIN

G C

HE

MIS

TR

Y-I

I

C113.1

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C113.2

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C113.3

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C113.4

(K3) 3 2 1 1 - 3 3 3 - - 3 1 3 1

C113.5

(K2) 2 1 - - - 2 3 2 - - 2 - 3 -

C104 2.4 1.4 1 1 2.4 3 2.4 - - 2.4 1 3 1

14

Basic Electrical and Electronics EngineeringSubject Code: GE6252

COURSE CODE COURSE OUTCOME

C114.1Explain the usage of construction material and proper selection of construction materials.

C114.2

Interpret the building components.

C114.3Explain the working principle of various kinds of power plants.

C114.4Explain the concept of IC engine construction and its types.

C114.5Describe the working principle of Refrigeration and Air conditioning systems.

CO-PO MAPPING

C114 PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

C114.12 1 - - - - 2 2 - - - - 3 3

C114.22 1 - - - - 2 2 - - - - 3 3

C114.32 1 - - - 2 3 2 1 1 2 - 1 -

C114.42 1 - - - 2 3 2 1 1 2 - 1 -

C114.52 1 - - - 2 3 2 1 1 2 - 1 -

15

Engineering MechanicsSubject Code: GE6253

COURSE CODE COURSE OUTCOME

C115.1 Apply basic engineering principles such as laws of mechanics and vector calculus for solving problems related to particles at rest.

C115.2 Identify the various reactive forces and couples for equilibrium of rigid bodies using free body diagram

C115.3 Determine the various section properties (Centroid, Moment of Inertia, Product Moment of Inertia and Mass moment of Inertia ) for simple and composite sections

C115.4 Solve simple problems related to dynamics of particles

C115.5 Calculate the frictional forces on sliding & Rolling bodies and problems related to Rigid body dynamics

CO-PO MAPPING

C115 PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

C115.1 3 3 1 1 - 3 2 1 2 - - 1 1 1

C115.2 3 2 1 1 - 3 2 1 2 - - 1 1 1

C115.3 2 1 - - - 2 3 1 - - - - - -

C115.4 3 2 1 1 - 3 2 1 2 - - 1 1 1

C115.5 2 1 - - - 2 3 1 - - - - - -

16

Computer Aided Drafting and Modeling Laboratory

Subject Code: GE6261

COURSE CODE COURSE OUTCOME

C116.1Understand the basic tools and commands available in CAD software package.

C116.2Apply the drawing commands for drafting Planes, curves, trusses etc.,

C116.3Apply the drawing commands to draft solid elements like prism, pyramid, cylinder and cone.

C116.4Apply the drawing tools for drafting sectional views of solids and isometric projection of objects.

C116.5Create 3D models of simple objects and obtain 2D multi view drawings from 3D object

CO-PO MAPPING

C116 PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

C116.1 2 - - - - 1 2 1 1 1 1 2 1 1

C116.2 3 2 - - - 3 3 3 3 3 2 2 2 2

C116.3 3 2 - - - 3 3 3 3 3 2 2 2 2

C116.4 3 2 - - - 3 3 3 3 3 2 2 2 2

C116.5 3 3 3 3 3 3 3 3 3 3 2 2 2 2

17

Physics and Chemistry Laboratory – II

Subject code: GE 6262

COURSE CODE COURSE OUTCOME

C117.1The students will identify the size of the microscopic particles with the help of laser and the acceptance angle in an optical fiber.

C117.2

The students will apply the concepts of the elastic property (Young’s modulus) of the materials using non uniform bending method and compressibility of ultrasonic wave in liquid media.

C117.3

The students will identify the wavelength of different colors present in polychromatic light source using grating and the thermal conductivity of the bad conductors like card board

C117.4The students will be able to quantitatively analyze the sample by volumetric method

C117.5The students will be able to find the concentration of the samples with help of various instruments.

CO-PO MAPPING

C117 PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

C117.1 3 2 - - - - - 2 - - 3 - 2 1

C117.2 3 2 - - - - - 2 - - 3 - 1 1

C117.3 3 2 - - - - - 2 - - 3 - 2 1

C117.4 3 - 1 3 2 - - - - - - 2 3 1

C117.5 3 - 1 3 2 - - - - - - 3 3 1

18

Sub Code : MA 6351 Class & Year : II - Year MechSub Name : Transforms and partial differential equations Course Code : C201

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Construct the Fourier series for periodic functions and for function with discrete data ( using Harmonic Analysis)

K2- Understand

CO 2Solve problems in Fluid Mechanics, Electromagnetic theory, Quantum Mechanics and other fields which involves Partial differential equations.

K3- Apply

CO 3 Explain the integral transforms - Fourier, Fourier Sine and Cosine and its properties.

K3- Apply

CO4

Classify and solve the initial and boundary value problems arising in engineering problems like wave equation, heat flow equation (one dimensional and two dimensional) by Fourier series.

K3- Apply

CO5 Analyze the continuous-time and discrete-time signals and systems using Z transforms

K4- Analyse

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - - - - - - - - 1 -CO 2 3 2 1 1 - - - - - - - - 1 -CO 3 2 2 1 1 - - - - - - - - 1 -CO4 3 2 1 1 - - - - - - - - 2 -CO5 3 3 2 2 - - - - - - - - 2 -

2.8 2.2 1.2 1.2 - - - - - - - - 1.4 -

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

19

Sub Code : CE 6306 Class & Year : II - Year MechSub Name : Strength of Materials Course Code : C202

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Interpret the stress, strain and deformation of solids under the axial loads.

K3

CO 2Draw shear force, bending moment and induced stresses in cantilever, simply supported and over hanging beam under the transverse loads.

K3

CO 3 Explain stresses developed in shaft and springs due to tor-sion.

K2

CO4Identify deformation behaviors of cantilever, simply supported and over hanging beams under the transverse loads.

K2

CO5 Explain stresses induced in thin, thick cylinders and spherical shells.

K2

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 - 1 -CO 2 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 3 2 1 - - - 2 3 2 1 1 2 - 1 -CO4 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO5 2 1 - - - 2 3 2 1 1 2 - 1 -

2.4 1.4 1 1 - 2.4 3 2.4 1.4 1.4 2.4 - 1.4 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

20

Sub Code : ME6301 Class & Year : II - Year MechSub Name : ENGINEERING THERMODYNAMICS Course Code : C203

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1Apply the basic concepts, zeroth law and first law of thermo-dynamics in open and closed systems for both steady and un-steady flow processes.

K3- Apply

CO 2 Apply the concepts of second law of thermodynamics and availability in source and finite bodies.

K3- Apply

CO 3 Apply the thermodynamic properties of steam in steam cy-cles

K3- Apply

CO4 Describe the thermodynamic relations in real and ideal gas. K2- Understand

CO5 Apply the concepts gas mixtures and psychrometry in ther-modynamic problems.

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 3 3 3 2 2 3 1 2 1CO 2 3 2 1 1 - 3 3 3 2 2 3 1 2 1CO 3 3 2 1 1 - 3 3 3 2 2 3 1 2 1CO4 3 2 - - - 2 3 2 1 1 2 1 1 -CO5 3 2 1 1 - 3 3 3 2 2 3 2 2 1

3 2 1 1 - 2.8 3 2.8 1.8 1.8 2.8 1.2 1.8 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

21

Sub Code : CE6451 Class & Year : II - Year MechSub Name : FLUID MECHANICS & MACHINERY Course Code : C204

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Understand the fundamental properties of fluids and law of conservation of mass, momentum, energy concepts.

K2- Understand

CO 2Apply the boundary layer concept for the problems related to flow of fluids and Reynolds Number concept for the flow through pipes

K3- Apply

CO 3 Develop the prototype using the concept of Dimensional analysis and model analysis.

K3- Apply

CO4Calculate the efficiency, construct the characteristic curves of a centrifugal pump and understand the working principle of reciprocating pump.

K3- Apply

CO5 Calculate the efficiencies of Pelton, Francis, Kaplan turbines and construct the characteristic curves

K4- Analyse

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 - 1 -CO 2 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 3 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO4 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO5 3 2 1 1 - 3 3 3 2 2 3 - 2 1

2.8 1.8 1 1 - 2.8 3 2.8 1.8 1.8 2.8 - 1.8 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

22

Sub Code : ME 6302 Class & Year : II - Year MechSub Name : Manufacturing Technology - I Course Code : C205

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Students will be able to understand the principles and tech-niques of casting and to determine their suitability

K2- Understand

CO 2 Students will be able to classify the welding processes and make simple joints using metals

K3- Apply

CO 3Students will be able to fabricate metals with different shapes using various forming processes like Forging/Rolling/Extru-sion/Drawing

K4- Analyse

CO4Students will be able to design various forms of sheet metal using special forming processes (Rubber Pad forming/Explosive forming)

K4- Analyse

CO5Students will be able to identify the manufacturing process and application of plastics for producing simple products (Poly Bags/Bottles)

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 3 - 1 1 - - 3 - 1 - - -CO 2 3 2 3 1 1 1 - 2 2 - 3 3 3 2CO 3 3 3 3 - 3 2 - - 2 - 1 - 1 -CO4 3 3 2 - 3 3 - 3 1 - 2 - 1 -CO5 3 2 3 2 2 - - 3 3 2 3 3 3 2

3 2.4 2.8 1.5 2 1.7 - 2.7 2.2 2 2 3 2 2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

23

Sub Code : EE6351 Class & Year : II - Year MechSub Name : Electrical drive and control Course Code : C206

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 To predict the electric drives for different applications. K2- Understand

CO 2 To comprehend the operation and performance of DC and AC motors

K3- Apply

CO 3 To predict the different type of starters for motors K3- ApplyCO4 To comprehend the speed control methods for dc motors K3- ApplyCO5 To comprehend the speed control methods for ac motors K4- Analyse

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 1 3 3 2 2 3 - 2 1CO 2 2 1 - - - 2 3 2 1 1 2 - 1 -CO 3 3 2 1 1 - 1 3 3 2 2 3 - 2 1CO4 2 1 - - - 2 3 2 1 1 2 - 1 -CO5 2 1 - - - 2 3 2 1 1 2 - 1 -

2.4 1.4 1 1 - 1.6 3 2.4 1.4 1.4 2.4 - 1.4 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

24

Sub Code : ME 6311 Class & Year : II - Year MechSub Name : Manufacturing Technology Laboratory – I Course Code : C213

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Equip with the practical knowledge required in the core in-dustries.

K2- Understand

CO 2 Demonstrate various machine tools. K2- Understand

CO 3Practice the various operations such as taper and eccentric turning, boring, knurling, internal and external thread cutting in lathe.

K3- Apply

CO4 Perform the operations using milling and shaping machines. K3- ApplyCO5 Practice green sand moulding and welding K4- Analyse

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 3 3 - 1 2 - 3 - 3CO 2 3 2 1 1 - 3 3 - 1 2 - 2 - 3CO 3 3 2 1 1 - 3 3 1 3 - 3 2 1 3CO4 3 2 1 1 - 3 3 1 3 - 3 2 1 3CO5 3 2 1 1 - 3 3 1 1 - 3 1 1 3

3 2 1 1 - 3 3 1 1.8 2 3 2 1 3

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

25

Sub Code : CE6461 Class & Year : II - Year MechSub Name : Fluid Mechanics & Machinery Lab Course Code : C214

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Experiment with the given Orifice meter, venturimeter and find the Coefficient of discharge

K2- Understand

CO 2 Make use of the given set of pipes and find the friction fac-tor, Co-efficient of Friction

K3- Apply

CO 3 Experiment with the given centrifugal pump, reciprocating pump, gear pump and Construct the characteristic curves

K3- Apply

CO4 Experiment with the given Pelton wheel, Francis turbine, Kaplan turbine and Construct the characteristic curves

K3- Apply

CO5 Make use of the given Rotameter and find the rate of flow. K4- Analyse

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 2 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 3 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO4 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO5 3 2 1 1 - 3 3 3 2 2 3 - 2 1

3 2 1 1 - 3 3 3 2 2 3 - 2 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

26

Sub Code : EE6365 Class & Year : II - Year MechSub Name : Electrical Engineering Lab Course Code : C215

COURSE OUTCOMES (COs):

Upon completion of the course,

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 "Get a basic idea of the advanced specialized topics related to this field like, AC Machines."

K2- Understand

CO 2Choose their future career in the field of manufacturing, test-ing and control applications of D.C Electrical motors and transformers.

K3- Apply

CO 3 Do projects related to automation of control of machineries with the basics of conventional techniques studied.

K3- Apply

CO4 Improve the performance of machineries by rectifying its drawbacks and also implement that on real time applications.

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 2 2 - - 1 1 1 1 2 3 1 1CO 2 3 2 2 2 - - 1 1 1 1 2 3 1 1CO 3 3 2 2 2 - - 1 1 1 1 2 3 1 1CO4 3 2 2 2 - - 1 1 1 1 2 3 1 1CO5 - - - - - - - - - - - - - -

3 2 2 2 - - 1 1 1 1 2 3 1 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

27

Sub Code : MA6452 Class & Year : II - Year MechSub Name : Statistics and Numerical Methods Course Code : C207

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Compute numerical solutions to system of linear equations, transcendental equations and Eigen value problems

K2- Understand

CO 2Construct a polynomial from a set of tabulated values using Interpolation and find numerical values of differentiation and integration.

K3- Apply

CO 3 Solve the Ordinary differential equation numerically K3- Apply

CO4 Analyze the level of significance of samples using testing of hypothesis techniques

K4- Analyse

CO5 Apply the ANOVA techniques to obtain maximum informa-tion with minimum cost and labour

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - - - - - - - - 2 1CO 2 3 2 1 1 - - - - - - - - 2 1CO 3 3 2 1 1 - - - - - - - - 2 1CO4 3 3 2 2 - - - - - - - - 3 2CO5 3 2 1 1 - - - - - - - - 2 1

3 2.2 1.2 1.2 - - - - - - - - 2.2 1.2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

28

Sub Code : ME 6401 Class & Year : II - Year MechSub Name : KINEMATICS OF MACHINERY Course Code : C208

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Discuss the basic components and layout of linkages in the assembly of a Machine

K2- Understand

CO 2 Implement the kinematic linkages with respect to displace-ment, velocity, and acceleration at any point

K3- Apply

CO 3 Illustrate cam mechanisms for specified motions K3- Apply

CO4 Explain the basic concepts of toothed gearing and kinematics of gear trains

K2- Understand

CO5 Discuss the basic concepts of friction in motion transmission systems such as clutches and brakes

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 1 1 1 2 1 1 1CO 2 3 2 1 1 - 3 3 3 2 2 3 2 2 2CO 3 3 2 1 1 - 3 3 3 2 2 3 2 2 2CO4 3 1 - - - 2 3 2 1 1 2 1 1 1CO5 3 1 - - - 2 3 2 1 1 2 1 1 1

2.8 1.4 1 1 - 2.4 3 2.2 1.4 1.4 2.4 1.4 1.4 1.4

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

29

Sub Code : ME 6402 Class & Year : II - Year MechSub Name : Manufacturing Technology-II Course Code : C209

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1Describe the fundamentals of theory of metal cutting, chip formation mechanism, various cutting tool materials, cutting fluids, tool wear and tool life.

K2- Understand

CO 2 Understand metal removal processes in conventional, semi-automatic and automatic lathe machines.

K2- Understand

CO 3Comprehend the basic concepts of reciprocating machine tool, shaper and other machines like milling, and gear cut-ting.

K2- Understand

CO4 Explain the essentials of various abrasive processes. K2- Understand

CO5 Demonstrate the elements of NC machine tools, and write manual part program.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 - - - - 1 3 1 1 - 1 2 2 1CO 2 3 2 - - - 3 3 1 1 - 3 1 1 3CO 3 3 2 - - - 3 3 1 1 - 3 1 1 2CO4 3 2 - - - 3 3 1 1 - 3 1 1 1CO5 2 - - - - 2 3 1 1 - 2 2 2 3

2.6 2 - - - 2.4 3 1 1 - 2.4 1.4 1.4 2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

30

Sub Code : ME6403 Class & Year : II - Year MechSub Name : Engineering Materials & Metallurgy Course Code : C210

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1Describe the phase diagram (eutectic, eutectoid, peritectic, and peritectoid reactions), Fe-C diagram and Microstructure of alloys.

K2- Understand

CO 2 Explain the different heat treatment processes such as anneal-ing, normalizing, hardening and tempering of steel.

K2- Understand

CO 3 Discuss the various ferrous and non-ferrous materials. K2- Understand

CO4 Illustrate the non-metallic materials such as polymers, ceramics and composites with their applications.

K2- Understand

CO5 Practice the testing of mechanical properties and its deforma-tion mechanism.

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 - - - - 2 3 2 1 - 2 1 1 2CO 2 2 - - - - 2 3 2 1 - 2 2 2 2CO 3 2 - - - - 2 3 2 1 - 2 1 3 2CO4 3 1 - - - 3 3 2 1 - 3 1 2 2CO5 3 1 - - - 3 3 2 1 - 3 3 3 3

2.4 1 - - - 2.4 3 2 1 - 2.4 1.6 2.2 2.2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

31

Sub Code : GE 6351 Class & Year : II - Year MechSub Name : Environmental Science and Engineering Course Code : C211

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Understand the importance of Ecosystem and Biodiversity to the Environment.

K2- Understand

CO 2 Recognize pollution control norms and waste management Techniques.

K3- Apply

CO 3 Realize the resources available in earth’s interior and surface and get knowledge to protect the natural resources

K3- Apply

CO4 Understand the importance of environmental and social issues by assessing its impact on the human world.

K2- Understand

CO5Aware of Human population, Family welfare programme, human rights, HIV / AIDS and women and Child welfare in their adolescence period.

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 - 2 1 - 1 3 2 1 3 - - - - 2CO 2 1 1 3 3 3 3 1 3 1 3 2 1 1 1CO 3 1 - 3 - 2 3 2 3 2 3 - 3 1 -CO4 - - 2 2 - 3 3 - 2 2 3 2 - -CO5 - 3 - - 1 3 3 - 3 2 - - - 3

1 2 2.2 2.5 1.7 3 2.2 2.3 2.2 2.5 2.5 2 1 2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

32

Sub Code : ME6404 Class & Year : II - Year MechSub Name : THERMAL ENGINEERING Course Code : C212

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Apply the concepts, laws and methodologies from the first course in thermodynamics in gas power cycles

K3- Apply

CO 2 Understand the various types of IC engines and their perfor-mance calculations

K2- Understand

CO 3 Apply the thermodynamic concepts in nozzles, turbines K3- Apply

CO4 Apply the basic thermodynamic concepts to calculate efficiencies for different types of compressors

K3- Apply

CO5 Apply the thermodynamic concepts in refrigerator and air-conditioner in various working conditions

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 2 1 1 2 2 2 - 2 2CO 2 2 1 - - - 1 2 - 1 1 1 - 1 1CO 3 3 2 1 1 - 2 1 1 2 2 2 - 2 2CO4 3 2 1 1 - 2 1 1 2 2 2 - 2 2CO5 3 2 1 1 - 2 1 1 2 2 2 - 2 2

2.8 1.8 1 1 - 1.8 1.2 1 1.8 1.8 1.8 - 1.8 1.8

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

33

Sub Code : ME 6411 Class & Year : II - Year MechSub Name : Manufacturing Technology Laboratory – I I Course Code : C216

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Describe various machining operations in special purpose machines.

K2- Understand

CO 2Demonstrate various special purpose machines such as verti-cal and horizontal milling, grinding and gear hobbing ma-chines.

K2- Understand

CO 3 Operate different machine tools such as horizontal milling and gear hobbing machines to manufacture gears.

K3- Apply

CO4 Employ different machine tools such as surface and cylindrical grinding machines for finishing operations.

K3- Apply

CO5 Interpret CNC part programming. K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 - - - - - - 3 - 1 2 - 3 - 3CO 2 3 2 1 1 - 3 3 - 1 2 - - - 3CO 3 3 2 1 1 - 3 3 1 3 - 3 2 2 3CO4 3 2 1 1 - 3 3 1 3 - 3 2 - 3CO5 3 - - - - 3 3 - 1 1 - - - 3

3 2 1 1 - 3 3 1 1.8 1.6 3 2.3 2 3

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

34

Sub Code : ME 6412 Class & Year : II - Year MechSub Name : Thermal Engineering Lab - I Course Code : C217

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Recognize the valve Timing and Port Timing diagrams. K3- Apply

CO 2 Analyze the performance test, heat balance test and retarda-tion test on Diesel Engine.

K4- Analyze

CO 3 Test the efficiency of multi-cylinder Petrol Engine by con-ducting Morse Test.

K3- Apply

CO4 Identify the flash point and fire point of various fuels / lubricants.

K3- Apply

CO5 Examine the performance and energy balance test on steam turbine / steam generator.

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - - - 2 3 2 - - 1 1CO 2 3 3 2 2 1 2 3 2 3 2 - 3 3 3CO 3 3 3 2 2 1 1 3 2 3 2 - 3 3 3CO4 2 1 - - - 3 - 2 3 2 - 2 1 1CO5 3 3 2 2 1 3 3 2 3 2 - 3 3 3

2.6 2.2 2 2 1 2.2 3 2 3 2 - 2.7 2.2 2.2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

35

Sub Code : CE 6411 Class & Year : II - Year MechSub Name : Strength of Materials lab Course Code : C218

COURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Assess the real life problems in engineering. K3- ApplyCO 2 Propose solutions for the industrial problems. K2- Understand

CO 3 Evaluate the effectiveness of their design and fabrication project for the welfare of the society.

K5- Evaluate

CO4

Analyse the fundamentals of contemporary manufacturing systems including materials, manufacturing process, product and process control, Computer integrated manufacturing and quality.

K4- Analyse

CO5 Practice team work skill for decision making. K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 - 2 3 - -CO 2 3 2 1 1 - 3 3 3 2 1 3 3 1 1CO 3 3 3 2 2 1 3 3 3 2 1 3 3 2 2CO4 3 2 1 1 - 3 3 3 2 1 3 3 1 1CO5 3 3 2 2 1 3 3 3 2 1 3 3 2 2

2.8 2.2 1.5 1.5 1 2.8 3 2.8 1.8 1 2.8 3 1.5 1.5

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

36

Sub Code : ME6501 Class & Year : III - Year MechSub Name : Computer Aided Design Course Code : C301

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Implement the fundamentals of Computer Graphics in CAD by any programming language.

K2- Understand

CO 2 Create a solid modelling by any technique. K3- ApplyCO 3 Apply the various visual realism algorithms in CAD. K3- ApplyCO4 Design and evaluate assembly models. K3- Apply

CO5 Apply the various CAD standards and CAD neutral files in complex models.

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 3 3 2 - - - - 2 2 - 3 1 -CO 2 1 2 3 2 3 - - - 2 2 - 3 2 3CO 3 2 2 2 1 3 - - - 1 2 - 3 2 3CO4 3 3 3 3 3 - - - 2 3 2 3 3 3CO5 3 3 2 3 3 - - - 1 3 2 3 - 2

2 3 3 2 3 - - - 2 2 1 3 2 2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

37

Sub Code : ME6502 Class & Year : III - Year MechSub Name : Heat and Mass Transfer Course Code : C302

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Apply the concepts of conduction under steady state, tran-sient heat transfer and extended surfaces.

K3- Apply

CO 2 Apply the concepts of free and forced convection through hydrodynamic and thermal boundary layer.

K3- Apply

CO 3 Solve the problems on phase change heat transfer and types of heat exchanger.

K3- Apply

CO4 Illustrate the concept of black body and grey body radiation. K3- ApplyCO5 Describe the basic concepts of mass transfer and its types. K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 2 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 3 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO4 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO5 2 1 - - - 2 3 2 1 1 2 - 1 -

2.8 1.8 1 1 - 2.8 3 2.8 1.8 1.8 2.8 - 1.8 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

38

Sub Code : ME6503 Class & Year : III - Year MechSub Name : Design of Machine Elements Course Code : C303

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1Describe the various steps involved in the design process, identification of the steady stresses and variable stresses in machine members.

K2- Understand

CO 2 To calculate the design parameters of Shafts, keys and cou-plings.

K3- Apply

CO 3 Design the threaded fasteners, bolt, knuckle joint, cotter joint, welded joint and riveted joint.

K3- Apply

CO4 Design the various types of springs and to examine the Flywheels.

K3- Apply

CO5 Develop the design of sliding contact and selection of rolling contact bearing for machine members.

K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 - - -CO 2 3 2 1 1 - 3 3 3 2 2 3 - 1 1CO 3 3 2 1 1 - 3 3 3 2 2 3 - 1 1CO4 3 2 1 1 - 3 3 3 2 2 3 - 1 1CO5 3 2 1 1 - 3 3 3 2 2 3 - 1 1

2.8 1.8 1 1 - 2.8 3 2.8 1.8 1.8 2.8 - 1 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

39

Sub Code : ME 6504 Class & Year : III - Year Mechub Name : Metrology and Measurements Course Code : C304

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Explain the different types of measurement technologies K2- UnderstandCO 2 Classify the linear and angular measurements K3- ApplyCO 3 Discuss about advances in metrology K2- Understand

CO4Explain the form measurements to measure the thread parameters, gear elements, surface finish, straightnees, flatness and roundness.

K2- Understand

CO5Discuss the basic principles and various methods of measur-ing force, power, flow, and temperature and familiarize with calibration and reliability

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 - 1 2 - 1 -CO 2 2 1 - - - 2 3 2 1 1 2 - 1 -CO 3 2 1 - - - 2 3 2 1 1 2 - 1 -CO4 2 1 - - - 2 3 2 1 1 2 - 1 -CO5 2 1 - - - 2 3 2 1 2 2 - 1 -

2 1 - - - 2 3 2 1 1.2 2 - 1 -

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

40

Sub Code : ME 6505 Class & Year : III - Year MechSub Name : Dynamics of Machines Course Code : C305

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Discuss the force and motion analysis of components sub-jected to external forces.

K2- Understand

CO 2 Explain the undesirable effects of unbalanced forces in recip-rocating and rotary machine components.

K2- Understand

CO 3 Calculate the natural frequencies for undamped and damped vibrating systems.

K3- Apply

CO4 Solve problem on effect of harmonic disturbances, support motion and vibration isolation

K3- Apply

CO5 Explain the principles in mechanisms used for speed control and stability control.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 - - 2 3 3 2CO 2 2 1 - - - 2 3 2 - 2 2 3 2 2CO 3 3 3 2 2 1 3 3 3 - 1 3 3 2 1CO4 3 3 2 2 1 3 3 3 - - 3 3 2 2CO5 2 1 - - - 2 3 2 - - 2 3 3 2

2.4 1.8 2 2 1 2.4 3 2.4 - 1.5 2.4 3 2.4 1.8

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

41

Sub Code : GE6075 Class & Year : III - Year MechSub Name : Professional Ethics in Engineering Course Code : C306

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Summarizes the various Morals, Values, Ethics, Integrity and other Human Values

K2- Understand

CO 2 Examine the Senses of Engineering, its related Theories and Models of Professional Roles

K2- Understand

CO 3 Apply the Codes of Ethics for various Engineering Experi-mentation in Design and Manufacturing

K3- Apply

CO4 Examine the various Risk, Safety, and Risk Benefit Analysis for a Product/Service in an Organization

K2- Understand

CO5Explain the Various Global Issues in Ethics and Review the Responsibilities and Rights of Professionals and Employees in an Organization

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 - - - - - 2 3 2 1 1 2 - - -CO 2 - - - - - 2 3 2 1 1 2 - 1 -CO 3 - - - - - 3 3 3 2 2 3 - 2 1CO4 - - - - - 2 3 2 1 1 2 - 1 -CO5 - - - - 1 2 3 2 2 1 2 - 2 1

- - - - 1 2.2 3 2.2 1.4 1.2 2.2 - 1.5 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

Sub Code : ME6511 Class & Year : III - Year Mech

42

Sub Name : Dynamics Laboratory Course Code : C313

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Students can able to analyze the kinematics principles of gears, mechanisms, cam profile.

K4- Analyze

CO 2 Students will be able to understand the mass moment of iner-tia of flywheel and turn table apparatus.

K2- Understand

CO 3 Students can be able gain hands on experience in motorized gyroscopic effect, couple, whirling of shaft &governors.

K3- Apply

CO4 Students will be able to analyze the balancing of rotary and reciprocating masses.

K4- Analyze

CO5Students can be able gain hands on experience to determine the frequency of free and forced vibration, torsional vibration and transverse vibration for shaft and spring.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 - 1 -CO 2 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 3 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO4 3 3 2 2 1 3 3 3 3 3 3 1 3 2CO5 3 2 1 1 - 3 3 3 2 2 3 - 2 1

2.8 2 1.2 1.2 1 2.8 3 2.8 2 2 2.8 1 2 1.2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

Sub Code : ME6512 Class & Year : III - Year MechSub Name : Thermal Engineering Lab - II Course Code : C314

43

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1Analyze the thermal conductivity using guarded plate appa-ratus, pipe insulation using lagged pipe apparatus, composite wall and insulating powder.

K4- Analyze

CO 2 Examine the heat transfer coefficient under natural convec-tion, forced convection and pin-fin apparatus.

K2- Understand

CO 3 Interpret the Stefan – Boltzmann constant and the emissivity of a grey surface.

K3- Apply

CO4 Identify the effectiveness of Parallel / counter flow heat exchanger.

K4- Analyze

CO5 Examine the COP of a refrigeration system and efficiency of a reciprocating air compressor.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 2 3 2 2 2 2 - 2 2CO 2 3 2 1 1 - 2 3 2 2 2 2 - 2 2CO 3 3 2 1 1 - 2 3 2 2 2 2 - 2 2CO4 2 1 - - - 1 2 1 1 1 1 - 1 1CO5 3 2 1 1 - 2 3 2 2 2 2 - 2 2

2.8 1.8 1 1 - 1.8 2.8 1.8 1.8 1.8 1.8 - 1.8 1.8

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

44

Sub Code : ME 6513 Class & Year : III - Year MechSub Name : Metrology and Measurements Lab Course Code : C315

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1Understand the fundamental principles of measuring tech-niques by practicing exercises on various measuring instru-ments.

K2- Understand

CO 2 Measure the various dimensions of linear and angular com-ponents.

K2- Understand

CO 3 Apply projection techniques to measure the parameters of thread and gear.

K3- Apply

CO4 Interpret shear force and moment induced in a cantilever beam at different values of load.

K4- Analyze

CO5 Compare the temperature of a fluid using thermocouple and thermometer.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 1 - - - 2 3 2 2 2 2 - - -CO 2 3 2 1 1 - 3 3 3 3 3 3 1 1 1CO 3 3 2 1 1 - 3 3 3 3 3 3 1 1 1CO4 2 2 1 1 - 3 3 3 3 3 3 1 1 1CO5 3 2 1 1 - 3 3 3 3 3 3 1 1 1

2.8 1.8 1 1 - 2.8 3 2.8 2.8 2.8 2.8 1 1 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

45

Sub Code : ME6601 Class & Year : III - Year MechSub Name : Design of Tranmission Systems Course Code : C307

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Students able to Select the flexible elements such as V-Belts flat belts, ropes, chains for power transmission.

K2- Understand

CO 2 Students able to calculate the design parameters of spur gear and helical gears.

K2- Understand

CO 3 Students able to Design the bevel worm, and helical gears used in transmission systems.

K3- Apply

CO4 Students able to Develop the design the constant speed and variable speed gear boxes.

K4- Analyze

CO5 Students able to Create the design of cams, clutches and Brakes.

K4- Analyze

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 3 2 2 1 3 3 3 3 3 3 1 2 2CO 2 3 2 1 1 - 3 3 3 2 2 3 - 1 1CO 3 3 2 1 1 - 3 3 3 2 2 3 - 1 1CO4 3 2 1 1 - 3 3 3 2 2 3 - 1 1CO5 3 2 1 1 - 3 3 3 2 2 3 - 1 1

3 2.2 1.2 1.2 1 3 3 3 2.2 2.2 3 1 1.2 1.2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

46

Sub Code : MG6851 Class & Year : III - Year MechSub Name : Principles of Management Course Code : C308

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Summarizes the various Morals, Values, Ethics, Integrity and other Human Values

K2- Understand

CO 2 Examine the Senses of Engineering, its related Theories and Models of Professional Roles

K2- Understand

CO 3 Apply the Codes of Ethics for various Engineering Experi-mentation in Design and Manufacturing

K3- Apply

CO4 Examine the various Risk, Safety, and Risk Benefit Analysis for a Product/Service in an Organization

K4- Analyze

CO5Explain the Various Global Issues in Ethics and Review the Responsibilities and Rights of Professionals and Employees in an Organization

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 2 2 2 - 1 -CO 2 2 1 1 - - 2 3 2 2 2 2 - 1 -CO 3 2 1 1 - - 2 3 2 2 2 2 - 1 -CO4 2 1 - - - 2 3 2 2 2 2 - 1 -CO5 2 1 - - - 2 3 2 2 2 2 - 1 -

2 1 1 - - 2 3 2 2 2 2 - 1 -

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

47

Sub Code : ME 6602 Class & Year : III - Year MechSub Name : Automobile Engineering Course Code : C309

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Discuss different types of automobiles and the usage of dif-ferent materials in vehicle construction.

K2- Understand

CO 2 Explain the working of injection and ignition system, tur-bocharger, emission control methods and Euro/BS norms.

K2- Understand

CO 3 Explain the working of clutch, gear box and differential units.

K2- Understand

CO4 Discuss the types and applications of steering, suspension and brake systems of automobiles.

K2- Understand

CO5 Explain the engine modifications required while using alter-nate fuels.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 2 2 2 - - -CO 2 2 1 - - - 2 3 2 2 2 2 - - -CO 3 2 1 - - - 2 3 2 2 2 2 - - -CO4 2 1 - - - 2 3 2 2 2 2 - - -CO5 2 1 - - - 2 3 2 2 2 2 - - -

2 1 - - - 2 3 2 2 2 2 - - -

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

48

Sub Code : ME 6603 Class & Year : III - Year MechSub Name : Finite Element Analysis Course Code : C310

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Explain the FEA formulation of Boundary Value Problems. K2- UnderstandCO 2 Solve 1D FEA Simple Problems. K3- ApplyCO 3 Explain the 2D Finite Element Analysis. K2- Understand

CO4 Discuss the application of Heat Transfer & Fluid Mechanics in FEA.

K2- Understand

CO5 Analyze the iso-parametric elements and complex dynamic analysis problems in FEA.

K4- Analyze

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 1 - 1 2 3 2 - - 2 3 1 1CO 2 3 3 2 2 2 3 3 3 - - 3 3 2 2CO 3 2 1 2 - 1 2 3 2 - - 2 3 3 2CO4 2 1 2 - 1 2 3 2 2 - 2 3 3 3CO5 3 3 2 2 2 3 3 3 2 - 3 3 2 3

2.4 1.8 1.8 2 1.4 2.4 3 2.4 2 - 2.4 3 2.2 2.2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

49

Sub Code : ME 6604 Class & Year : III - Year MechSub Name : Gas Dynamics & Jet Propulsion Course Code : C311

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Apply the mass, momentum and energy conservation princi-ples to Nozzles and Diffusers.

K3- Apply

CO 2 Solve flow through constant area duct problems based on the concept of Fanno flow and Rayleigh flow.

K3- Apply

CO 3 Apply the Normal & Oblique Shock concepts to find the variation of flow parameters.

K3- Apply

CO4 Explain the working principle and performance of aircraft Engines.

K2- Understand

CO5 Explain the working principle and performance of rocket propulsion systems.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 2 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 3 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO4 2 1 - - - 2 3 2 1 1 1 - 1 -CO5 2 1 - - - 2 3 2 1 1 1 - 1 -

2.6 1.6 1 1 - 2.6 3 2.6 1.6 1.6 2.2 - 1.6 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

Sub Code : ME 6003 Class & Year : III - Year Mech

50

Sub Name : Unconventional Machining Processes Course Code : C312

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Identify the different types of unconventional processes and their limitations.

K2- Understand

CO 2 Discuss the mechanical energy-based machining processes and material removal rate characteristics.

K2- Understand

CO 3 Describe the electrical energy-based machining processes and influencing parameters.

K2- Understand

CO4 Discuss the chemical and electro chemical energy-based machining processes and their parameters.

K2- Understand

CO5 Explain the thermal energy-based machining processes and control techniques.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 - 1 1CO 2 2 1 - 1 - 2 3 2 1 1 2 - 1 1CO 3 2 1 - 1 - 2 3 2 1 1 2 - 1 1CO4 2 1 - 1 - 2 3 2 1 1 2 - 1 1CO5 2 1 - 1 - 2 3 2 1 1 2 - 1 1

2 1 - 1 - 2 3 2 1 1 2 - 1 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

51

Sub Code : ME 6611 Class & Year : III - Year MechSub Name : CAD/CAM Lab Course Code : C316

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Implement 3D modelling features for the basic exercises by using 3D modeling software.

K3- Apply

CO 2 Create an assembly for the machine components by using 3D modelling software

K3- Apply

CO 3 Produce a machine component by using CNC Machining centers

K4- Analyze

CO4 Generate toolpath simulation and machine codes for a machine component by using CAM Software

K3- Apply

CO5 Summarize the application of Electric Discharge Machining, Wire cut EDM and Rapid Prototyping

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 3 3 2 3 1 - 1 - 1 - 3 3 3CO 2 3 3 3 3 3 1 - 1 2 2 - 3 3 3CO 3 3 3 3 3 1 2 1 1 2 3 - 3 3 3CO4 3 3 3 3 3 1 - 1 - 1 - 3 3 3CO5 3 3 1 1 - - - - 1 1 - 3 1 1

3 3 2.6 2.4 2.5 1.2 1 1 1.6 1.6 - 3 2.6 2.6

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

52

Sub Code : ME 6612 Class & Year : III - Year MechSub Name : Design & Fabrication Project Course Code : C317

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Identify, select the need based potential problem related to engineering.

K2- Understand

CO 2 Develop the solution by Applying the design principles K3- ApplyCO 3 Create the design model and find solution K3- Apply

CO4 Develop the detailed design in Manufacturing aspect by preparing the bill of materials and cost estimation.

K4- Analyze

CO5 Fabrication of the model and implementation / Testing K6- Create

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 3 2 2 1 3 3 3 3 3 3 1 3 3CO 2 3 3 2 2 1 3 3 3 3 3 3 1 3 3CO 3 3 3 3 3 2 3 3 3 3 3 3 3 3 3CO4 3 3 2 2 1 3 3 3 3 3 3 1 3 3CO5 3 3 3 3 2 3 3 3 3 3 3 3 3 3

3 3 2.4 2.4 1.4 3 3 3 3 3 3 1.8 3 3

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

53

Sub Code : GE6674 Class & Year : III - Year MechSub Name : Communication Skills - Laboratory Based Course Code : C318

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Develop their communicative competence in English with specific reference to speaking and listening

K2- Understand

CO 2 Prepare a power point presentation on the given technical topic

K3- Apply

CO 3 Apply the usage of English grammar to answer verbal ability questions in competitive examinations

K3- Apply

CO4 Demonstrate their ability to communicate effectively in interviews

K2- Understand

CO5 Infer the varied applications of the softskills K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 - - - - - - - - - 2 - - 1 -CO 2 - - - - - - - - - 2 - - 1 -CO 3 - - - - - - - - - 2 - - 1 -CO4 - - - - - - - - - 2 - - 1 -CO5 - - - - - - - - - 2 - - 1 -

- - - - - - - - - 2 - - 1 -

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

54

Sub Code : ME 6701 Class & Year : IV - Year MechSub Name : Powerplant Engineering Course Code : C401

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Explain the basics of Thermal Power Plant and the working principle of various accessories

K2- Understand

CO 2 Describe about the various diesel, gas turbine and combined cycle power plants.

K2- Understand

CO 3 Describe production of electricity using Nuclear energy and various types Nuclear reactors

K2- Understand

CO4 Explain method of generating power from renewable energies like hydro, wind, solar, biomass etc.

K2- Understand

CO5 Analyse about the energy, economic and environmental is-sues of power plants

K4- Analyze

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 - - - 2 3 2 1 1 2 1 1 -CO 2 3 2 - - - 2 3 2 1 1 2 1 1 -CO 3 3 2 - - - 2 3 2 1 1 2 1 1 -CO4 3 2 - - - 2 3 2 1 1 2 1 1 -CO5 3 2 - - - 2 3 2 1 1 2 1 1 -

3 2 - - - 2 3 2 1 1 2 1 1 -

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

55

Sub Code : ME 6702 Class & Year : IV - Year MechSub Name : MECHATRONICS Course Code : C402

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1To understand the basic concepts of mechatronics system and different types of sensors and transducers used in mechatron-ics system.

K2- Understand

CO 2 To study the architecture of 8085 microprocessor and 8051 microcontrollers.

K2- Understand

CO 3 To study the different programmable peripheral interfaces. K2- UnderstandCO4 To study the architecture of PLC and its programming. K2- Understand

CO5To study the different types of actuators used in mechatron-ics system and various stages in the design process with ex-amples.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 2 1 1 - 1 3 3 2 2 3 - 2 2CO 2 2 1 - - - 2 3 2 1 1 2 - 1 1CO 3 3 2 1 1 - 1 3 3 2 2 3 - 2 2CO4 2 1 - - - 2 3 2 1 1 2 - 2 2CO5 2 1 - - - 2 3 2 1 1 2 - 1 1

2.4 1.4 1 1 - 1.6 3 2.4 1.4 1.4 2.4 - 1.6 1.6

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

56

Sub Code : ME 6703 Class & Year : IV - Year MechSub Name : CIM Systems Course Code : C403

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1

Explain the concepts and computerised elements of Com-puter Integrated Manufacturing(CIM) along with the contem-porary manufacturing strategies such as Lean Production and Just-In-Time Production

K2- Understand

CO 2Discuss the usage of computers in Production Planning & Control and develop automated process plans using Com-puter Aided Process Planning (CAPP)

K2- Understand

CO 3Describe the concept of Group Technology, Identification of Part Families and Quantitative analysis in Cellular Manufac-turing Systems

K2- Understand

CO4

Explain the components, applications, benefits and Quantitative analysis in Flexible Manufacturing System(FMS) by enhancing the usage of Automated Guided Vehicle System (AGVS) in CIM

K2- Understand

CO5Discuss about Robot Anatomy, Robot Control systems, In-dustrial Robot Applications, Robot Part Programming, Robot Accuracy and Repeatability

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 2 - - - 1 - 1 - - 2 2 1 2CO 2 3 2 1 - 1 2 - 2 - - 2 - 1 1CO 3 2 2 2 - - 2 - 2 1 - 2 1 2 1CO4 2 1 - - - 2 - 2 2 - 2 2 3 2CO5 2 2 1 - 1 2 1 - - - 3 2 3 3

2.2 1.8 1.3 - 1 1.8 1 1.7 1.5 - 2.2 1.7 2 1.8

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

Sub Code : GE 6757 Class & Year : IV - Year Mech

57

Sub Name : Total Quality Management Course Code : C404

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 To know the basic concepts, definitions of Total Quality management.

K2- Understand

CO 2 To gain knowledge about the TQM principles like customer satisfaction, leadership, continuous process improvement etc.

K2- Understand

CO 3 To know about the TQM tool- Management tool, sixsigma, Benchmarking, QFD and TPM.

K2- Understand

CO4 To understand the Quality systems-ISO 9000:2000, QS9000-ISO 14000 and Quality auditing.

K2- Understand

CO5 Case studies of TQM implementation in manufacturing and service sector including IT.

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 1 1 1CO 2 2 1 - - - 2 3 2 1 1 2 1 1 1CO 3 3 2 1 1 1 3 3 3 2 2 3 2 2 2CO4 2 1 - - 1 2 3 2 1 1 2 1 1 1CO5 2 1 - - - 2 3 2 1 1 2 1 1 1

2.2 1.2 1 1 1 2.2 3 2.2 1.2 1.2 2.2 1.2 1.2 1.2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

58

Sub Code : ME6005 Class & Year : IV - Year MechSub Name : Process Planning and Cost Estimation Course Code : C405

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Explain the procedure for process planning K2- Understand

CO 2 Describe the concepts of documentation for process planning & Economic analysis

K2- Understand

CO 3 Summarize the procedure for cost estimation and costing of the product

K2- Understand

CO4 Apply the procedure for estimating the cost of different machining operations

K3- Apply

CO5 Demonstrate the procedure for calculating machining time of given component

K4- Analyze

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 1 - -CO 2 2 1 - - - 2 3 2 1 1 2 1 1 -CO 3 2 1 - - - 2 3 2 1 1 2 1 1 -CO4 3 2 1 1 - 3 3 3 2 2 3 1 2 1CO5 3 2 1 1 - 3 3 3 2 2 3 1 2 1

2.4 1.4 1 1 - 2.4 3 2.4 1.4 1.4 2.4 1 1.5 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

59

Sub Code : ME6012 Class & Year : IV - Year MechSub Name : Maintenance Engineering Course Code : C406

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1Explain the Principles and Importance of Maintenance Plan-ning, Reliability and also the factors affecting Machine Availability.

K2- Understand

CO 2 Discuss the Principles of Maintenance Schedule and Repair Schedule for machineries.

K2- Understand

CO 3Describe the Condition monitoring techniques and instru-ments on both On-Load and Off-Load Testing of machiner-ies.

K2- Understand

CO4 Predict the Failure modes and Repair Methods for basic machine elements.

K2- Understand

CO5 Express the repair methods for material handling equipments. K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 1 - -CO 2 2 1 - - - 2 3 2 1 1 2 1 1 -CO 3 2 1 - - - 2 3 2 1 1 2 1 1 -CO4 3 2 1 1 - 3 3 3 2 2 3 1 2 1CO5 3 2 1 1 - 3 3 3 2 2 3 1 2 1

2.4 1.4 1 1 - 2.4 3 2.4 1.4 1.4 2.4 1 1.5 1

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

60

Sub Code : ME6711 Class & Year : IV - Year MechSub Name : Simulation and Analysis Laboratory Course Code : C410

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1Evaluate the stress analysis of one dimensional structural problems using analysis software and compare it to an ana-lytical solutions.

K5- Evaluate

CO 2Evaluate the stress analysis of one dimensional structural problems using analysis software and compare it to an ana-lytical solutions.

K5- Evaluate

CO 3 Resolve the heat transfer analysis for a given problem using analysis software

K4- Analyze

CO4 Execute the dynamic analysis for a given structural problem using analysis software

K3- Apply

CO5 Simulate a mechanism using Multibody Dynamic Software. K3- Apply

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 3 3 3 2 3 3 3 1 2 3 3 3 3CO 2 3 3 2 2 1 3 3 3 1 2 3 3 3 3CO 3 3 3 2 2 1 3 3 3 1 2 3 3 3 3CO4 3 3 2 2 1 3 3 3 1 2 3 3 3 3CO5 3 3 2 2 1 3 3 3 1 2 3 3 3 3

3 3 2.2 2.2 1.2 3 3 3 1 2 3 3 3 3

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

61

Sub Code : ME6712 Class & Year : IV - Year MechSub Name : Mechatronics Lab Course Code : C411

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 To interpret the architecture, addressing mode and instruction set of microprocessor and microcontroller

K2- Understand

CO 2 To construct basic arithmetic and logical operation programs using microprocessor

K3- Apply

CO 3 To construct simple interfacing programs using 8085 K3- ApplyCO4 To compare a force, pressure, velocity of Pneumatic piston K5- Evaluate

CO5 To design the cylinder sequencing circuits by appropriate software

K2- Understand

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 2 1 - - - 2 3 2 1 1 2 - 1 -CO 2 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO 3 3 2 1 1 - 3 3 3 2 2 3 - 2 1CO4 2 1 - - - 2 3 2 1 1 2 - 1 -CO5 3 3 2 2 1 3 3 3 3 3 3 1 3 2

2.6 1.8 1.3 1.3 1 2.6 3 2.6 1.8 1.8 2.6 1 1.8 1.3

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

62

Sub Code : ME6713 Class & Year : IV - Year MechSub Name : Comprehension Course Code : C412

ICOURSE OUTCOMES (COs):

Upon completion of the course, students will be able to

CO No. Course Outcome K/Bloom’s Taxonomy Level

CO 1 Identify the knowledge of the students in Engineering me-chanics of solids and fluids.

K2- Understand

CO 2 Examine the student’s ability in the aspects of Kinematics and Dynamics of machines.

K2- Understand

CO 3 Interpret the skills of the students in basic concepts of Manu-facturing technology. .

K3- Apply

CO4 Test the understanding of the students in Thermodynamics and .Thermal Engineering.

K3- Apply

CO5 Analyse the efficiency of the students in Managerial and Leadership qualities..

K4- Analyze

Table 1: Mapping of COs Vs POs/PSOs

Course Programme Outcomes

Outcomes PO1 PO2 PO3 PO4 PO5 PO6 PO7 PO8 PO9 PO10 PO11 PO12 PSO1 PSO2

CO 1 3 3 3 3 2 3 3 3 2 2 3 3 2 3CO 2 3 3 3 3 3 3 3 3 2 2 3 3 3 3CO 3 3 3 3 3 2 3 3 2 1 2 3 2 2 2CO4 3 3 2 2 1 3 3 1 1 2 1 2 1 1CO5 3 2 1 1 - 3 3 3 1 2 3 2 - -

3 2.8 2.4 2.4 2 3 3 2.4 1.4 2 2.6 2.4 2 2.2

1: Slight (Low) 2: Moderate (Medium) 3: Substantial (High)

63