j O'NEILL CONTENTION IIB

Transcript of j O'NEILL CONTENTION IIB

,. ._ - - _ ._ _ _ .. . __. _ _ _ _ . . _ . .

!

I-

!

: OTESTIMONY OF THOMAS C. BORDINE,

j CONCERNINGO'NEILL CONTENTION IIB

The following testimony is a response to O'Neill [

4

Contention II-B which states:.

The licensee's plan is deficient in failingi

to discuss the environmental hazards aasociated

with small to' medium leaks of radioactive water'

from the expanded spent fuel pool.4

The contention assumes that small to medium leaks-

of radioactive water from the expanded spent fuel pool can

pose a hazard to the environment. However, analysis of all,

I) potential leakage paths from the expanded spent fuel pool

shows that all contaminated water'either remains within con-i

tainment or is automatically processed through the plant's

radwaste system. None of the water can be released in an un-

|controlled manner to the environment and such leaks therefore

do not pose an environmental hazard.4

All leakage paths can be grouped into one of two j

:i

categories: those from the. pool itself and those from con-

necting systems. I shall first address leakage p6ths from-

the pool itself.;

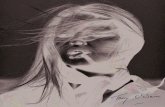

Figure 1 depicts the spent fuel pool and related-

structures. The spent fuel pool consists of a concrete

structure lined with a stainless steel plate.- The interior'

L O '

8110130520 8110052

P3R ADOCK 05000155--

LT- PDR..

%

- - , . -m - - , m a , e - a -g ,- , , -m, , . - -, . - - - <gn x y ,--ne.g ,,,-ww--gn..r,ynpnewrv/v y ,gw- --v,- , g s-

. -

-2-1

|

'- of the pool is rectangular in shape; its dimensions are:*

'l

length 26 feet, width 20 feet, and depth 29 feet. The

concrete pool floor is over 6 feet thick. The stainless

steel pool liner is 3/16 inch thick; there is a gap of 1/2

inches maximum (typical 1/16 inch) between the liner and the

concrete pool structure. Stainless steel channels known as

monitoring trenches are imbedded between the stainless steel

liner and the concrete pool structure. These trenches

connect to eight stainless steel pipes 3/8 inch in diameter

known as drain tubes. The drain tubes are enclosed within

the concrete floor of the spent fuel pool. They extend

vertically through the concrete beneath the pool for a ,

distance of approximately 15 feet and terminate in manually

operated valves positioned over an open sample basin located

in the room directly beneath the pool floor. The basin drain

pipe connects to piping which extends to the containment sump.

Sump run time is monitored and logged to provide data for

Technical Specifications requirements associated with leakage

limits.

The stainless steel pool liner prevents any direct'

leak from the spent fuel pool so long as its integrity is

maintained. Such a leak therefore could result only from an

accident that would puncture the liner. An event that would

have this effect is the drop into the pool of the 15-ton

O4

- - - -- - - - - - . y -- _ y ,, ,

-3-

()<

cobalt cask or the 7-1/2-ton treat II cask. Safe practices

exist to prohibit such accidents; however, assuming a cask

accident such that the cask strikes the bottom of the pool

directly, the liner integrity might be lost..

Since cask movement is limited to the southwest

corner of the pool, a credible liner punctu.re would most

likely occur in this area. Regardless of the location of

the puncture, however, the result will be the same: pool

water will seep between the liner and concrete pool floor

into the monitoring trenches. The leak chase system willi

funnel the leaked water from the monitoring trenches to the

(~g drain tubes and collect and hold it at one or more of theV

eight valves at the sample basin beneath the floor. Figure

2 represents a detail of this leak collection system.

Unless these valves are opened manually, the leaked water

will remain in the drain tubes. If the valves are opened,

the water will flow into the sample basin and from there

into the containment sump from which it will be processed

through the liquid radweste system.

The only other possible leakage path from the pool

itself is condencation or seepage through the concrete pool,

1/ Ruptura of the concrete pool floor as a result of acask drop is not considered credibile; in any case,

_

however, a leak resulting from such an accident wouldnot be a "small to h.edium leak" within the scope ofthis contention and therefore is not addressed here.gg

U

. . . - .-. .

-4-

floor following the postulated liner puncture. Before

' 1974 the pool was operated without the stainless liner.

Operating experience dating from that period showed that

very small amounts of moisture, amounting to a few drops,

collected on the underside of the concrete pool floor. It

is believed that this moisture was due to condensation

rather than pool leakage; nonetheless, even if it were

leakage and even if it should form in much greater amounts,

all such water is collected by the floor drains in the room

|below the pool and flows to the enclosure sump. The enclosure

dirty sump collects and transfers the water to the waste

|receiver tanks. The water is eventually processed through-

radwaste and reused as appropriate. Thus no direct leakage

from the pool could reach the environment and therefore

poses no environmental hazard.

The second category of leakage paths comprises

piping systems that connect with the spent fuel pool. There

are three such systems:

a. Spent Fuel Pool Cooling System (SFPCS)

Piping,

b. Deminerlized Water Systerm Piping, and

2/ Evaporation of the water in the pool might also beconsidered a leak. This subject is discussed in mytestimony submitted in response to O'Neill Conten-

| tion IIC.

};

I

L

- . - . . , . - , - - , ,

- -

|

-5-

c. Treated Waste Piping.

The Spent Fuel Pool Cooling System piping is

located entirely within containment. The piping forms a

loop, the inlet end of which feeds water into the pool and

the outlet end of which draws water from the surge tank

adj:tcent to the pool. Water from the spent fuel pool flows

across a weir and into the surge tank. Then the SFPCS pumps

draw water by suction from the surge-tank through the fuel

pool " sock" filter. No direct piping connection to the pool

exists on the suction end of the SFPCS. A pipe failure in

the SFPCS will result in the draining of the surge tank,

fuel pool filter tank and lines. Fuel pool level will not)

fall below the concrete weir, which is the normal water,

level, as a result of any pipe failure in the SFPCS. In

case of pipe failures in the SFPCS or any other intercon-

nected piping systems, an anti-siphon provision in the

makeup line inlet to the pool prevents the water from siphon-

ing out of the pool. Therefore, no pipe failures can allow

the fuel pool water to be drained, pumped or siphoned out.

A pipe failure in the SFPCS which drained the

surge tank, fuel pool filter tank, asscciated piping and

fuel pool water above the level of the concrete weir could

3/ In addition, a spent fuel pool drain line was originallyprovided in the plant design. However, during in-stallation of the spent fuel pool liner, this drain

(,s) was plugged and no penetration or provision for drainingthe pool was provided through the liner.

Y

.. . . _ _ _. _ - . . . - _ _ . __ _. __ _ . . _

,

f

i1 -6-!i

i

(h release approximately 6,000 gallons of water. Any leakedia

j water would be collected by the floor drains and thence flow,

to the enclosure sump. The capacity of the waste receiver,

tanks is more than adequate to accommodate the leaked water.t

j The demineralized water system piping and the

ij treated waste piping are not connected directly to the spentij fuel pool. They are both located partly inside and partly;

outside containment. Their only connection to the pool isj

!, by means of one connection between the demineralized water

! system piping and the spent fuel pool cooling system piping5

and one connection between the treated waste piping and the

! (}- cooling system piping. These connections are identified in

Figure 3.!

l The purpose of these connections is to~obtain

i inlet water to the SFPCS from either the Treated Wastet

System or the Demineralized Water System. Because-water;

i from both of these systems is flowing into containment when

the pumps are running, not out of it, a pipeline break in

) either system could not result in a release of spent fuel: 1/

pool water to the environment. When the pumps are not'

running, in addition to those check valves identified on'

i Figure 3, both systems have an additional check valve toi! prohibit back-flow. There is also a control valve and aIit

f/. The siphon break in the makeup line inlet preventsO. 'the siphoning of water from the pool to radwaste

through'the treated waste supply line.

,

.-w< , ,,we , , , , - , . , , - n-, - - - r

.. . . - . . - -_ . . . .--

;;

J

-7-i

!

|- ()j manually-operated valve on both systems that can be utilized:

to isolate SFPCS water from the systems..

j At one time the connection between the SFPCS andi

the demineralized water system constitu'ad a possible,

leakage path for water from the spent fuel pool. An in-1' cident occurred in 1978 in which a check valvc failure at

this junction permitted undetected contamination of the

demineralized water system. This was the incident reportedi

by Consumers Power Company on September 15, 1978 (LER #RO-

78-32, attached as Exhibit 1) and subsequently identified by:

| Mr. O'Neill during the special prehearing conference. The

(]) incident reported in the LER involved the removal of demin-

eralized water from the site in bottles. It.was later

determined that this demineralized water had been contaminated

with spent fuel pool water by leakage through the check

valve at the containment boundary. This 2-inch check valve

was repaired and tested, and manual valves VSFP-20 and VSFP-

27, which connect ';he SFPCS to the demineralized water

system, are now placed under lock control, so that recurrence

i of this leakage is not possible. Periodic testing of the

demineralized water is now being conducted to detect contam-

ination and radiological clearance practices for removal of

material from the site have been revised to preclude recur-.

rence of any environmental hazard associated with the inci-

! dent.!,

r

i.

I- - _ - - - .. - - - - . . - - . . . . - , . . . . , , ._, ,.

. . -- - - . - _ - .. - . . - -

-3-

4

C:)| Similar leakage paths through connections from

the SFPCS to the treated waste system exist; however, treated

] wastewater is radioactive. The activity of the treated !

wastewater may be more or less than the spent fuel pool

water depending upon the source of the water from radwaste4f

or in the waste hold tanks at the time of the postulated t

backflow. Contamination of treated wastewater from the

spent fuel pool is therefore irrelevant and would not pose;

any hazard to the environment. Treated waste is handled

under applicable plant procedures which reflect the require'

ments of Title 10 of the Code of Federal Regulations Part 20'

and Part 100. Backflow would ultimately return the water to|

}radwaste. Detection of this occurrence could be identified

by increasing levels of water in the waste hold tanks or de-

creasing levels oi water in the spent fuel pool surge tank

or unexplained increases or decre'ses in radioactivity of

|either system.

t

The two other incidents identified by Mr. O'Neill2/

during the special prehearing conference and previously.

reported by Licensee in LERs RO-78-33 and RO-79-23, attachedi

5/ In a letter to Licensee' counsel, received on April 7,1980, Mr. O'Neill referred to a fourth LER allegedlyrelating to a small to medium release of water from the'

pool or connected systems.~ He stated that the eventi occurred on October 19, 1979 and was reported by

Licensee on March 7, 1979. At least one of these datesis clearly inaccurate, since the alleged report pre-

, ( dates the alleged event. Licensee has searched itsfiles for any corresponding LER from 1979 or 1980 buthas found nothing.

| . ___ __ - , _ _ . _ _ . _ _ _ . _ _ _ . .~._. _.,

m

-9- !

.

4

(:)as Exhibits 2 and 3, both involved excessive leakage de-'

4

tected during routine leak rate tests of valve CV/4027,known as the reactor and fuel pit drain valve. This 2-inch

..ivalve is on a line which junctions upstream with a drain

line from the clean-up demineralizer system and a drain line

from the spent fuel pool surge tank and the spent fuel pool,

cooling system. Any leakage of spent fuel pool water from

the SFPCS through this line, assuming failure of the redun-;;

dant valves, goes directly to the liquid radwaste system and

cannot escape to the environment. The valve CV/4027 in fact

is used to periodically recycle the spent fuel pool water to

{} radwaste to purify it by reducing suspended solids. Subse-

quent corrective action taken by Consumers Power Company re-

lated to these LERs is discussed in my testimony submitted

in response to Licensing Board Question No. 1.

My analysis has shown that regardless of the1

leakage path, all small to medium leaks either directly from

the spent fuel pool or from connected piping systems will

either remain within the containment building or will

be processed through the liquid radwaste system. Those

collected through the floor drains into the containment sump

will ultimately be processed as radwaste and reused as

appropriate. Because no small to medium leaks from the,

spent fuel pool can result in uncontrolled releases to the-

environment, they do not pose any environmental hazard.J

_ _ _ _ . ,

_

;

Oj! REACTOR BLDG.

l.

I

i~ ^

REFUELING FLDOR EL.632 -o^-i .,

-;

, ,

v 's 'N' d _ _. i_,|. c _

.v,,T~~~ ~~T , , , o' . 6 of U_ c ,_:

s._ y . ,- .. ; ,

.' I,1 gg.I i , i

" ~ l I | | i: ' . ' . " .EL s? f'. 0" I | | g

'*y*.' .

,-

| g g il_ 'g **- ..

9' ;d |' I - I

fI SPENT FUEL~ ~

_O M2Wtaj226:::' ..Ar' - - ~*

;L 9--t- 3 @ I | -- POOL? *

d Sg| I .-

g6I ..o.c.

'

I i. j i, ,

*;

- ... .. y,

i ! . . I e i i .. _c s . .*. j . i 1 ; i L_, E L. 6 02'- l" j . |-.' '$ '

--

,

|*' '

I } g ,EL.6C O' e *' *a , ,p_ ,

.g y q ; p . .. .-_____ ..

. ,

'k p_'.L _ I_q f" FUEL PIT H.E.8'

*__

'. || | | %'- -

.

I N EL S8 5'- 6"i EL. 5 55' C"' _ _,__ J .J l.

s *z, . - _q.

. | . .,.| |5 Ig i Contai ment I CONTROL ROD CRIVE*-

I p_ ) Sur. s | . PUMPS 4*.

''= EL. 575'-6"..

.5 \ iI .. ,w. m. . ; . . . - I 7;,,. ..,

,_ l

,

I e.

... .

....

,, t... i. . . .-....

.

FIGURE - 1 East-West Section Tarough Reactor Building||

| Bordine Testimony on O'Neill Contention IIB

|

||

.

O

Stat.RWTOR 44*2.D a .olS*WGLL, LCautxtNG SLL frArJoe fg. Opnas vRCouO RUSES

(We,Was 4\ \ .

. . . * 6 . '/ oo }s \) .

*=*N.'

ziawia , \~

sQT Tt,.3,'

if ..

, . , , . .- ~.

--

'

[CD JNEf 73| '. Wg I

'

'

Cu,*.tw og '; j 'g!,,mm

EQtrAL . ~_ | z;..

i

*'l

_J ). . _ . . -- - - - -

1 ./ .. '' '0

'| f/|. EX/fr. d * SCerLD JO[ J S. P/PE.\ r

(.,

% 1

|% 1 *-

|' [. ' .l'f~) . .. .

a- - i .

.-..

*) 4:7 7.SiAB% E'; EL. 595' G *

4

TW. s rs co.Es a(DiMEN!/.'US 70,, <o

EWT CtrLO , g*ggy,ggocy poppyngAN GR Epsing fr*YD)

$)*CtC21 VALvf J$ BCDY? J.'JriENED E NC2-7yp

r , , , , , ,

i valve EACM Lluf(EJ LM AA/JTof.*L 2Z:'2 X23*a.Y JSELED /Cn Au A 14

* * )~~%|.

C svsfrutruftAML.VL'

Z.*e F. AW C-/ f;RA.x:t c s *eese r' % .

5:p',.!*"|g. LwlC&$1 URTION)b $. YC 40TO*4LA a ., p.

111:cyns;;,?nxsaws--

,,_

SPENT FUEL POOL

LEAY, COLLECTION SYSTEM

bt/ FIGURE - 2

Bordine Tastimony on O'Neill Contention II3

SPENT FUEL ~ POOL CONNECTING SYSTEMS

SIPHON WEIR (

O 'ae**REFUELING /

SHIELD TANK /___ _ _'C>G_ _ J. ~ ~ --

e _ __ _

SURGE_ _

__

TANKSPENTf _A | FUEL' '

;P0OL

v

! OC)C :v '--DC DQ--"| FILTER

n" '

DRAIN -

(REMOVED) | [ TANKn

l 0)<=

|-t>c = -

3_ XX X |

1REATED_ L___

E>6--X 'M 2

2 N/VSFP "

FUEL PIT PUNPS305 VSFP \

DENIN 20C)GM C>< 'M M'

' :'

WATER y3ppsos

o o en_ _

[><

X,

C>G- -

W==

HEAT EXCHANGERSD A N L NE "

& RAD WASTE

.

XoD 0>G--:

Bordine Testimony on O'Neill Contention IIB

FIGURE #3-

-_ _

:

I*

1

'

Exhibit 1 *

) Bordine Testimony on O'NeillBIG ROCit POINT PLANT

I Contention I7.BU.S.IduCLEAft Aseut ATORY CORA.etSSeoM

spec Pomas Msi

LICENSEE EVENT REPORTfF TF1j

I I l@ etsAss ramt on Tves Au, neousaso imponuAviom,

cowTmotstocic: pj i l@

l u l T ln l u l pl 1.I@l,.n I n l 10 I_n l nl .ff n l I n In .l@l a l 1I l l 1I l l,

- -..

; . .. uc . Coo..

15R019 I 11117 lo @l 110 |1I of 7 I9l@| cowi"'**y" @l 01 51 01 1101115 = 75 aspant oars se

j Q es e eve =v oAve,. oocast u .es si.

evan rcasenwrion AmoPnosAetscosessousaces@f automatie isolatioa valvan inthe remetorf| During routir.e leak rate tests o -

o I

l and fuel pit drain line, valve Cv/4027 .whibited1.=1,s.. 'nf Ar, ,111414 e.

;

[ rensi 1ruP h.)of ch. 14=fe A f4==A <= t-, 5. e--- 1

f I car min. which ir in .we am !redundant valve CV/4117 was operable and thus containment inteerity was

o ij"

v.na, e A 4. u n 7R 1t1 enA

E I maintained. Similar 1.mkmee of thfn valvh= h..n

f

E I AO-15-75 dated 6 /in /7'i . f-

ei

IIvi@ @.1@ ['@**

.||||||2.'cE'." *^"J' .u.c"." ,' ** *^

11 L kr

lsJ.u)@ trJ@ laJ@[l**Tod"" "?;"|" "*||*" 'j

O EID;

m-,I. ""ia"','.*

' *.

@ ,",t, .,,o 7 I 91 l--J 10 121 31 W L.t.l JJ.< .g;I = n= =

.h Mouns 22 hM*

aan ACTuntaFOR sus. surPu- _

|@ Og [@ 10101 0| u l p. @ (jg@ (A,j@ | B 12 1910|@P 7AER

.e .: as 4. .

as

cAusa casenwTION ANo CoRREC'MVS AcT1oNs l1 Investigation revealed that the seatine surface needed to be samebined to

ioj 'war.r

i reduce the disc contact area to provide tinht shut-off ennabf14 ev-, ,th. ===e i

g gaats vill be installed on both valves durine a fueurnnema.-

Renortabilftv in hag p

fg g as machined and a valve retest was satisfactory.

I

I E I on Tech Soec 6.9.2b(2)RT

D.geovte?00$Cn.m0m h

'bu'? OTMSRSTATWE @ | Os"sC"CQ )| Annual Surveillance Test"

Is Powt4N/A

{ Q |Gj@ |0 l 010 l@lLOCAftouormeLgAsth

OFACTtvtT. d' ng Asa LaAsa I I NA| NAI t s

_

'

pens.o gL tu .m*$ @ }u . .

E I 01 d 01@LI1@l NA"

"* n. .t' J a I'- * *

[email protected] @u ..lNA ee

i e, . . n u

1t OS #T1

L7J@lr.

88' .

54Ac uSE oNLY j..

3 8 9 to

I fffIIIIIIIIIIpusu

L, .yj'el NA .., o,,, ,

!

'' - - - _ _ , _ . _ . _ _ , ,_, "^ ~' ''' - - - . - . . _ _ . , _ _ __ _

1

I

l

^h consumers

a Power g !g g company

Q 1' C'TybU[U

.. .,., .... _ ... ..~ .....~..... _ ..~,... _ . m .c ...........

October 10, 1979

.

Mr James G KepplerOffice of Inspection and Enforce =entRegion IIIUS Nuclear Reg 11atory Comission4

799 Roosevelt BoadGlen Ellyn, IL 60137

DOCKET 50-155 - LICENSE DPR-6 -BIG ROC 5' POINT PLANT - LICENSEEEVENT '.iPCRT 79-23: AUTCMATICISOLATION VALVES IN REACICR ANDFUEL PIT DRAIN LINE

The attached Lice see Event Report (79-23) is submitted in accordance with gTechnical Specification 6.9 2.b(2). W

/David P Hof than (Signed)

David P HoffmanAssistant Nuclear Licensing Administrator

CC: Director, Office of Nuclear Reactor RegulationDirector, Office of Inspection and Enforcement

'

;

-

O '

.

._ _ _ - _ __ _ . _._ _ _ _ _ - - - - _ _ - - - - -

*

Exhibit 2 " Update Report - Previous Report Date 9/15/78"l

Bordine Testimony on9O'Neill Contention IIB

'

BIG ROCK POININne eoman me u.s.Nuctsan naoutATonY commission17 m

LICENSEE EVENT REPORT

coNTnot sLocc: | I | | l l e@l trosAss rmNT on Tves Att amouineo moonesATiomi

I Mli I B IR IP | 1 l@u| 0 l 01- 10101010101- 10| 01@al 4l11 ill! 11@ -ee ucs seacoot i. ucsau umeen as uca a un m

con ,

R s%o LLJ@l ol 5101 -10111515 Gl 0181 Il91718 |@l1101216171 8@1es el oocasT =unseam S # eve =T DATs 78 75 At*oRToats se

EVENT DESCalPTioN ANs PaoSASLE con $tousNCas hITTD | Failure, betwen 7/26/78 and 8/19/78, of the check valve providing contain g

g iment integrity in the 2" demineralized water line to containment contrib- tluted to radioactive contamination of the plant domineralized water system. I.

E ITwenty-five gallons of this water was removed from the plant by employees. Ioe IContainment integrity was established on 8/21/78 and evaluation on 8/23/78

f5TO Irevealed that no undue health hazard exists for any emiloyees or the pub- g

m.nsi Ilic. Check valve failure is repetitive. See RO-77-31 dated 8/25/77. |' '' "

'We" *^#! 3 31st w l CIO LEj@ W@ IV I AI L I VI El XI@ .Es@ =p 'o@

vaco o ew coos .(m)O ' * *, d.. " "m"I aced *"c' W ""**"

O ,,2 0."= @I L--J 1013121 M LOL3J px pt GJ22 23 34 24 37 3 m 12-

M =# o't % W:"@@gJ@ p@ pJ@ ] 01010g|

a"verTTt;' ,em '"sur m 3.** = e.a *ou.. s.

I pJ@ ,L,EJ@ LAJ@ | LI 31010l@cAuse osscnierson Ano conasenvr Actions @

,,

s i t o i |The check valve was repaired e t 9/5/78. Containment integrity had been es-t

E Itablished by valv h on 8/21/78 when the check valve defect became susneet.1|Reportab111ty is based on T/S 6.9.2.b.(2). Inadequate survey per 10CFR20.-ti

g |201 resulted in unnonitored removal of vacer from the site and revised ad- iIministrative contrels are being isolemented to prevent recurrence. I

i 4

'W[ BJ@| Trending of Sample Resul(fs32)

; s no van ofuen TATUS o o.eCoveRY oteCairfio=[E,,,J @ |0|8 10l@lN/A |i s

I, a 4,,,, g,,, is n . .e se

l .074 Millicurie @ | tocatio= w astaan @I

A LL,j @o orasLease(fJ@ Masaetace an .v7 oe acTivin 'o

| Carried Off-Site bv Emplovees I,

l '

' ' masona'deneon '' " "oescairfio=(af

Iwuimen wn

@ | 01 Ol 01@[gj@l N/A |' ' es.so et' ze, a =

esscaieTio=@=uneen

10101Ol@lN/A Ia e

' * ,,

oe oa,o " a,'o naciuTv g ",,

O-@ [Zj@l N/A |

.

- e i-se

_

,,,yf"C,',",c,,,,,,, @ NaC USE oNLY

LlJ.a1 LIJ@l Local Press Release Issued on 8/23/78 I IIIIIIIIti!II; ee se es u esi

#

_ _ _ . _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ -- - _ . . . - _ . _ . . . , _ - . , _ _ . _ _ . . _ _ _ _ . . _ _ _ , _ _ _ , . . _ _ _ _ _ . . _ , . . -

*.

: - ".,

4N,(p) consumersh j Power g

company

0General Omces 212 W: .t uchigan Avenue.Jacksors Michigan 49201. Area Code 017 788-0500

October 26, 1978

Mr James G KepplerOffice of Inspection and EnforcementRegion IIIUS Nuclear Regulatory Co==ission799 Roosevelt RoadGlen Ellyn, E 60137

DOCKET 50-155 - LICENSE DPR-6 -BIG ROCK PODIT PLANT - UPDA'ED

1 LICENSEE EVENT REPORTS RO-78-31, g78-32, 78-35, 78-36, 78-37

| Attached are five updated event reports (RO-78-31, 78-32, 78-35, 78-36 r_nd78-37). These updated reports are submitted to correct coding errors madein the original submittals. In addition, the description of off-site re-lease of radioactivity and the attachment to event report RO-78-32 havebeen revised. Changes are noted by vertical lines in the margin.

Item number 17 on reports 78-31, 35, 36 and 37 has not been completed asdescribed in NUREG-Ol61, " Instructions for Preparation of Data Entry Sheetsfor Licensee Event Report File". This item has been completed as in theattached in accordance with a request from Begion III personnel to correcterrors in the original Jubmittal.

David A Bixel (Signed)

David A BixelNuclear Licensing Ad=inistrator

- CC: Director, Office of Nuclear Reactor RegulationDirector, Office of Inspection and Enforcement

O

.- . .. -- __ _ __--_--________ ___ - __

,-,

'

Exhibit 3,

BIG ROCK POIttr. .

Bordine Testimony on

QPomm388 O'Neill Contention IIB u.s.muetsad neoutarony conomismon

LICENSEE EVENT REPORT |

.@cowinot stoex: 1 I I i 1 | l sposass paint on tres att nuovinen moonmanom

), .

%. I Mll I B l R I P l 11@,l 0 | 0 |- 10 | 0 | 010 | 01-| 0| 0 |@a( 4 | 1| 111[ 1| g ;,. _. oo. .. . - - m 1, .,

,

Q ,",','*,",, QIO | 510 |-|0 |115 I 5 Q 0 | 812 |9 I 7 I 8 @l 0 t 912 I717 |8 l@'

ei ooca., u. e m .v. = oar. = m a oarear.; eveur ossenemon Amo Pnosasts consecueness Cio

g iDuring reutine leak rate tests of automatic containment isolation valves in ,

o Ithe reactor and fuel pit drain line, Valve CV/4027 exhibited excessive leak-t

. I age as defined by T/S 3.7(b). The redundant valve CV/4117 had been leak Io

3 | tested the same day and it was maintaued closed until the integrity of CV/jo I 4027 was established following ratesting on 8/29/78. Prior failure report- |

'Ied as A0-l'5-75 in letter of 6/10/75.* Io 7

r.m i 1' '* "

'."o"o." 'i'#! cJ.***

[1],,p,,j @ , [gj@ [f,,J@ | V i A | L l V I E l X l@ .Mo.@@ .

co o . Jnu.:

| o .

O'

'O."c. J~ " " "

= ~=i" =' ~

~~-

#M M, h-l I O f 3 I3 I % I0131 @ p h_ , , ,; C ." Tut! o!!!s'Er *E"J' @ *MMW .;"*J "||"Ju*r io.T, .J'" o",T.,,*.

%[@ [@ |,7 j @ a ul 0101010 | |,,Hj@ [ N,,j@ (fj@ lB|2|9iOl@m = .i . . . .cAuss ossenwrio= Ano conneenve ntions Q27

o I The valve and einincr were flushed viehnue disassembly and the leakage te:st i

g I repeated satisfactorily. Foreign material it the valve may have prevented ii adequate seating. The valve was tested again satisfactorily on 9/11/78. ,,

g | Reportable based on T/S 6.9.2.b.(2) . g

EI ,I

'| *W cm..n.v.no @ o W..E mesov.avonen rio., @'

. 3.on.a

E .g(,IJ @ l0l810l@l N/A f [B,,,j@lRoutineTesting |u u =, = .| 1 g ,,

m o o...,,,,

L,g,j @ [,z_J@l NAro. ,i.rv @ ) - o. . @

-

<

| NA |i .,,,

i -._je ..o, . ,,_,,,, g

- - -_ ,

| 01010 |@[zj@| NA |i >' ' '

o l' ,',i.a.c. rio @- ="

u. u101010 l@l NA |i .

O E E t>J 8' y ..aury g' *

E o.oa,o"g

; "^ ' '

'

d, ho,,@"'

'**''* noe use ontvi NA i i,i,iii ,,,,i I. u e,.. o

>, ..

l

__ _ - ~ . - - - . . __ . - - - - , , - - , - -- --- - - - - ~ - - - - -|

I|

. .

,

!y 1.'. aj egg -

s n CORSum8f5@ 'j Power O'

-

L. f Company l& r , ;~,, | d) |

o.a.r., ome..: sim w..e usem .n 4..nu.. s.c2.on, wieme.n .eaoi . 4r.. coa. eir 7ss.oeeo

Septe=ber 27, 1978.

Mr James G Keppler,

Office of Inspection and EnforcementRegion IIIUS Nuclear Regulatory Co==ission799 Roosevelt ReadGlen Ellyn, IL 60137

DOCKET 50-155 - LICEISE DFR-6 - gBIG ROCK POEIT - LICENSEE EVENT REPORTS

,

RO-78-33 CONTAINMCIT ISOLATION VALVES78-34 RDS - BATTERY A - IcW SGna

Attached are two event reports which are reportable under Technical Specifi-

cation Section 6.9 2b.

David A Bixel (Signed)

David A BixelNuclear LiceLaing Ad=inistrator

CC: Director, Office of Nuclear Reactor RegulicionDirector, Office of Inspection an'1 Enforcement

i

~

.

.

1

_ _ _ _ _ _ _ . _ _ . _ - - . _ _ _ _ - _ - _ _ - - - - - -

. _ -

.

) ) ^

O'NEILL CONTENTION IIC

; A. THE CONTENTION

Licensee's plan, which provides for makeup waterf

j to replace water being lost from the pool at rates of

up to 200 gallons per minute, is deficient because it

does not consider the impact of the lost water on health

I and safety or on the environment.

B. MATERIAL FACTS AS TO WHICH THERE IS NO GENUINEISSUE TO BE HEARD

|1. The maximum makeup capacity needed to replace water

i/~(_)/ lost from the expanded spent fuel pool is 11 gallons

,

|Per minute. (Bordine Testimony, p.1).

2. The 200 gallon per minute capacity of the fire sys-

tem, which is available as a backup supply to re-

place water lost from the pool, was designed forfire-related purposes, not for pool water loss.

(Bordine Testimony, p.2).

3. The maximum water-loss rate of 11 gpm represents

the rate at which pool water would evaporate during

pool boiling, assuming the unlikely event that both

spent fuel pool cooling loops failed to operateduring the peak heating period when a full core of j

\i| reactor fuel had been off-loaded into the expanded

|

(-) pocl. (Bordine Testimony, p.2).|

| ("'T- I,

1

|4

{

_#

|1

-2-

m( )''

4. Any water lost from the pool through evaporation

would condense and flow to the enclosure sump.

(Bordine Testimony, p.2).

5. The 50 gpm capacity of the enclosure sump is more

than adequate to accommodate an 11 gpm boil-off

rate. (Bordine Testimony, p.2).

6. Water lost from the pool would remain within con-

tainment and would not reach the environment.

(Bordine Testimony, p.3).

C. DISCUSSION

r^3 The testimony of Thomas C. Bordine shows that Mr.V

O'Neill's contention is based on a misinterpretation of

the Licensee's " Spent Fuel Rack Addition Description and

Sate? 3 Analysis" submitted to the NRC Staff on April 23,

1979. This document indicated that the fire systems

provide a secondary backup supply of water to replenish

any water lost from the spent fuel pool up to 200 gal-

lons per minute. The 200 gpm figure, however, merely

reflects the capacity of the fire systems, and was de-

signed for fire-related purposes, not for the rat.e at

which water could be lost from the fuel pool.

In fact, the maximum makeup capacity needed for the

spent fuel pool was also calculated by the Licensee in

the Description and Safety Analysis; these calculations j,_6

bk |

1

.. , _ _ - _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

-3

() show that the maximum makeup capacity needed is 11

gallons per minute. This figure reflects the maximum

evaporation rate from the pool, assuming a failure of

both spent fuel pool cooling loops immediately follow-

ing discharge of a full core of fuel to the spent fuelpool. The NRC Staff's May 15, 1981 Safety Evaluation

Report also cupports the 11 gpm figure.

The 11 gpm of water lost from the pool would remain

within the containment enclosure. Upon condensation it

would be collected in the enclosure sump and procesced

through the liquid radwaste system.

No factual issue has been raised by Intervenor

O'Neill which controverts the facts established in theAffidavit of Mr. Thomas C. Bordine, and accordingly,Licensee is entitled to summary disposition on the Con-

tention as a matter of law.

.

Ou.

-

G

STATE OF MICHIGAN )) SS.

- COUNTY OF JACKSON )v

UNITED STATES OF AMERICA -

NUCLEAR REGULATORY COMMISSION

. BEFORE THE ATOMIC SAFETY AND LICENSING BOARD

IN THE MATTER OF )CONSUMERS POWER COMPANY ) Docket No. 50-155 OLA(Big Rock Point Nuclear Plant) ) (Spent Fuel Pool Expansion)

AFFIDAVIT OF THOMAS C. BORDINE

My name is Thomas C. Bordine. My business address

is 1945 W. Parnall Road, Jackson, Michigan. I am employed

by Consumers Power Company as a Staff Licensing Engineer for

) the Big Rock Point Plant. I have a Bachelor of Science

Degree in Mechanical Engineering from Wayne State University,

Detroit. I joined Consumers Power Company in the Gas Engineer-

ing Department of the Livonia, Michigan district office in

June 1967 and remained at that Jocation until December 1975

(excepting two years military leave in 1968-1970). My

primary responsibilities as Systems Planning Designer included

directing the updating of the Gas Network Flow Analysis, as

well as the formulation of proposed system networks. In

January of 1976, I transferred to the Big Rock Point Plant,

- Charlevoix, Michigan as Quality Assurance Engineer. In that

capacity, my responsibilities as a staff member of the site

Quality Assurance Depar tment included conducting QA Program

Audits and Surveillances; performing quality reviews of

procedures, design and procurement documents; and monitoring'

and performing final close-out reviews of the site corrective

action system documents.

.- _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

-2-

In June 1977, I was assigned the position of,,

('N Quality Assurance Superintendent, Big Rock Point Plant.Q)

My responsibilities included organizing and directing the_

activities of the Plant Quality Assurance and Quality

Control staff; providing assistance to the plant technical.

staff to more effectively implement the QA Program; analyz-

ing the effectiveness of the QA Program and recommending

program improvements to QA Department Management; reporting

the status of QA Program implementation at the plant to QA

Department Management; and representing the QA Program and

QA Department to the NRC I/E Branch personnel. During my

assignment at Big Rock, I also participated in and com-

pleted, in April 1980, an administrative certification

(~') program for Senior Reactor Operator Equivalency. The'

program included extensive training in plant systems, con-

trols and licensing requirements as well as reactor start-up

qualification at the General Electric Boiling Water Reactor

Simulator.

In August 1980, I was assigned to work at the

Institute of Nuclear Power Operations, Atlanta, Georgia in

a one-year on-loan capacity. My primary responsibility at

the Institute was to establish a process for the development

and coordination of nuclear operations management criteria..

Since August 1981, I have been assigned as Big Rock Point i

Staff Licensing Engineer at the Corporate Office in Jackson, |- |

Michigan. I am responsible for the coordination and response

of licensing activities related to the Big Rock Point Plant

which include the spent fuel expansion project.

-3-

I am the author of the documents entitled "Testi-

mcny of Thomas C. Bordine Concerning O'Neill Contention

II-B", " Testimony of Thomas C. Bordine Concerning O'Neill

Contention II-C", and " Testimony of Thomas C. Bordine

- Concerning Licensing Board Question No. 1". I believe that

my educational background and work experience qualifies me

to respond to thora contentions and question. Where state-

ments of fact are made in this testimony, they are based on

my personal knowledge. Where results of calculations

performed by Consumers Power Company are discussed, I have

personally reviewed and verified the calculations.

I swear that this affidavit and the testimony

( ) attached hereto are true and correct, to the best of my

knowledge and belief.

fa ~.

JNM -. C v0

Thomas C. Bordine

SUBSCRIBED AND SWORN TObefore me this 2nd dayof October 1981.,

d~/Ad Y Y(Ut'/2s'4/Y' Notaff FublicJacksen County, MichiganMy Commission expires March 26, 1983

.

-