ITT Mirror Steering System Team P11565 Andrew Bishop Katie Hall Matt Manelis Ben Geiger Nurkanat...

-

Upload

kathlyn-hall -

Category

Documents

-

view

215 -

download

0

Transcript of ITT Mirror Steering System Team P11565 Andrew Bishop Katie Hall Matt Manelis Ben Geiger Nurkanat...

ITT Mirror Steering System Team P11565

Andrew BishopKatie Hall

Matt ManelisBen Geiger

Nurkanat Suttibayev

Meeting TimelineStart Time Topic of discussion

12:30 Review Project Goals12:35 Review Customer needs12:40 Over all System Design1:00 Voice Coil Design1:20 Mechanical Mounting Design1:40 Control System Design2:00 Sensor and Feedback Design2:10 Power Regulator Design2:20 Wrap up Discussion

Agenda

The mission of this project is to design and build a mirror steering system that can outperform commercially available systems in terms of Power Consumption.

This project will provide appropriate documentation that can be utilized by future senior design teams for further refinement.

Project Goals

The mirror steering system is a device that controls the angle of a mirror in two dimensions.

This device is used in directing optical devices at the mirror and aiming the mirror at an object located a far distance away.

The tilting of the mirror is achieved by the use of actuators, which push and pull the mirror into different locations.

Project Description

High Interaction between Mechanical and Electrical Designs which creates more design challenges

The goal is to compete with and do better than commercially available designs

The chance to work hands on with a design outside of our previous experiences.

Project Appeal

Customer Needs

Importance Ranking:9 – These needs have the highest importance and will be the main focus of the project3 – These needs are somewhat important and will be the secondary focus of the project if time allows1 – These needs are not as important as the rest of the needs and will only be focused on if the main and secondary needs have been satisfied

Target Specs

Importance Ranking:9 – These needs have the highest importance and will be the main focus of the project3 – These needs are somewhat important and will be the secondary focus of the project if time allows1 – These needs are not as important as the rest of the needs and will only be focused on if the main and secondary needs have been satisfied

System Design

2 Voice coils and 1 sensor Per Axis

Flexure Spring Mounting

PID Controller with VCCS Stage

Underhung Voice Coil

Complete System Model

PID controller to ensure system stability and settling time.

The Trans-conductance (voltage converted to current) stage can be modeled as an attenuation.

The voice coil is also modeled as a gain stage. PID controller is being tuned

Voice Coil

The basics of the voice coil is a device that uses current flow through a loop of wire and opposes a magnetic field to produce a force in single direction (positive or negative).

It is the heart of the system and everything was based off of the force and dimensions of the Vc for a given input current.

The final design included 2 different voice coils, both with a 20mm outer diameter, one being 32mm tall, the other being about 22mm tall

The 22mm tall VC has a higher magnetic field of .33T field in the gap area, the taller one having .38T field.

Height not being too much of an issue for these gave us the choice to use the stronger field, and so giving more force for a given current.

Voice Coil Continued

Main assembly:- Waffle mirror (provided by ITT) attached to mirror mount by RTV adhesive- Flexure spring that allows system range of motion- Stem that connects the flexure to the top face of electronics box- Four actuators connected to mirror mount that will push and pull on mirror mount with generated force

Mechanical Design

Mirror Mount- CN8 (Size): The surface area of the mount is large enough to fit the flexure, voice coil contact point, and sensors, while not exceeding the diameter of the mirror- CN13 (Feasibility): The thickness is a standard value that can easily be purchased in stock (0.16’’)- ES3 (Modulus of Elasticity): Material must be stiff enough to withstand the forces and stresses imposed on part (6061 Aluminum)

Relating Design to Needs/Specs

To determine the displacement and stresses of the model, Finite Element Analysis is required

SolidWorks/COSMOS software used for FEA Two types of analyses performed

- Mirror and Flexure Structure- Electronics Box

Finite Element Analysis

To perform this analysis, the model is first constrained on the bottom face

To simulate actuators acting in one axis, an upward force of 0.105 lbf is applied at one actuator, and a downward force of 0.105 lbf is applied at the other actuator

To simulate actuators in two axes, two additional forces are added to the model at the other actuators

Mirror and Flexure FEA Setup

Mirror and Flexure FEA Results

One axis simulation- Displacement: 0.0587 in- Angle: 2.24º- Max Stress: 8350 psi- FOS: 4.78

Displacement

von Mises Stress

Factor of Safety

Mirror and Flexure FEA Results

Two axes simulation- Displacement: 0.0825 in- Angle: 3.15º- Max Stress: 10296 psi- FOS: 3.87

Displacement

von Mises Stress

Factor of Safety

To perform this analysis, the model is first constrained on the bottom face

The total weight of the components is summed, and applied on the top surface of the box

Extra weight is added to simulate a worst case scenario (total force = 5lbs)

Electrical Box FEA Setup

Electrical Box FEA Results

Results:- Displacement: 1.37e-5 in- Max Stress: 64.4 psi- FOS: 619

Displacement

von Mises Stress

Factor of Safety

To determine the spring constant of the flexure, varying forces were applied to the mount, and displacement was measured for each data set

A graph was generated to show the Force and Displacement relationship

The slope of the line is equal to the spring constant

Simulated spring constant equal to 626.8 N/m, or 3.58 lbf/in

Determining Spring Constant

Flexure Spring Design

Modeled as seen on McMaster’s website

Specific dimensions not given, so spring constant is not known

Plan on purchasing part, and testing to determine k-value, otherwise, machine our own part

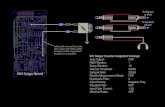

PID Controller

-+

V+

V-

U 1

O P 1 1 7 7

1

2

34

5

V 1

1 5 V d c

V 21 5 V d c

V _ C M D1 0 V d c

0

0

R 11 0 k

R 21 k

-+

V+

V-

U 2

O P 1 1 7 7

1

2

34

5

-+

V+

V-

U 3

O P 1 1 7 7

1

2

34

5

-+

V+

V-

U 4

O P 1 1 7 7

1

2

34

5

-+

V+

V-

U 5

O P 1 1 7 7

1

2

34

5

V _ F B0 V d c

R 1 3

. 9 k

R 3

1 k

C 2

. 1 n

R 4

1 k

R 5

1 k

C 1

1 n

R 7

1 k

R 9

1 k

R 1 0

1 k

R 1 1

1 1 0 K

R 1 2

1 k

R 1 71 k

V

V

Voltage Controlled Current Source

0

V 41 5 V d c

V 51 5 V d c

0

R _ I s e t2 5

U 8

O P A 5 4 7 / B B+1

-2 I L im

3V -

4

V +5

V o6

E / S7

R 2 1

2 kR 2 24 k

0

R 2 31 0 0

I

L 14 2 0 u H

1

2

Theta X +

Theta X -

-+

V+

V-

U 6

O P 1 7 7

1

2

34

5

-+

V+

V-

U 7

O P 1 7 7

1

2

34

5

R 8

1 0 k

R 1 4

1 0 k

R 1 5

1 k

R 1 81 0 k

R 1 92 5

V_V_CMD

0V 1V 2V 3V 4V 5V 6V 7V 8V 9V 10VV(U1:34) V(U5:34) -I(R19)

-12

-8

-4

0

4

8

12

(10.000,-10.000)

(10.000,9.578)

(10.000,145.345m)

Sensor Design

The sensor is based on the idea of a varying capacitance by using 2 metal plates close to each other

One is stationary while the other moves with the mirror moves.

As the plate moves the capacitance changes and changed the impedance of the circuit.

An Impedance converter creates an equivalent resistance.

A Wheatstone bridge circuit is used to find the variation of the impedance in terms of a voltage.

The voltage VG Is then supplied back to the control circuitry to use as feedback.

Power Regulator

IN

ADJ

OUT

U 2

L M 3 3 7 K

1

2

3

V 1

A C = 6TR A N =

D C = 2 4

V 2

A C = 6TR A N =

D C = -2 4R 15 0 0

R 25 . 6 3 k

R 35 0 0

R 45 . 3 6 k

0

C 1. 1 u

C 21 0 0 u

C 3. 1 u

C 41 5 0 u

U 3L M 3 1 7 K

I N2

O U T3

AD

J1

V

V

Frequency

10mHz 100mHz 1.0Hz 10Hz 100Hz 1.0KHz 10KHz 100KHz 1.0MHzV(U3:OUT) V(U2:19)

0V

50mV

100mV

150mV

(362.611,141.542m)

(1.6033K,6.0046m)

Pre-assembly and construction test plan: Makes sure that customer needs and engineering specs are met in pre-

assembly stage Serves as a quality control procedure, in order to eliminate defects at early

stage Mistake proofing Example: testing PCB, voice coil functionality, measuring important part

dimensions.

Final product test plan Shows if all the customer needs and specs met by final product Displays if there are functionality issues that needs to be eliminated prior

delivery Examples: testing slew rate, settling time, power consumption, tilt range.

Test Plan

Engr. Spec. #

Task (description)Unit of

MeasureMarginal

ValueComments/Status

ES4, ES5 Testing mirror settling time ms 60 ±5

ES6 Testing mirror speed (slew rate) rad/sec >50

ES8 Tilt range (max range of angle tilt can move) degrees 4.5 ±.5

N/A (QC purpose) Movement in X-axis NA NA

N/A (QC purpose) Movement in Y-axis NA NA

N/A (QC purpose) Movement in X and Y axis NA Na

N/A (QC purpose)

Movement flexibility (ability to draw geometrical shape)

NA NA

CN5, CN6 Testing steering accuracy/precision TBD TBD

ES15 Testing Signal to noise ratio dB 96 ±25

ES1 Testing total power consumption of the system W <10

Test Plan cont.

Final Product Testing Tasks

![Geiger 2011 Presentation[1]](https://static.fdocuments.us/doc/165x107/555e97f3d8b42a6d068b4d4c/geiger-2011-presentation1.jpg)