IS 9020 (B) (2002): Power Threshers - Safety … of power thresher. 2 REFERENCES 2.1 The following...

Transcript of IS 9020 (B) (2002): Power Threshers - Safety … of power thresher. 2 REFERENCES 2.1 The following...

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to information for citizens to secure access to information under the control of public authorities, in order to promote transparency and accountability in the working of every public authority, and whereas the attached publication of the Bureau of Indian Standards is of particular interest to the public, particularly disadvantaged communities and those engaged in the pursuit of education and knowledge, the attached public safety standard is made available to promote the timely dissemination of this information in an accurate manner to the public.

इंटरनेट मानक

“!ान $ एक न' भारत का +नम-ण”Satyanarayan Gangaram Pitroda

“Invent a New India Using Knowledge”

“प0रा1 को छोड न' 5 तरफ”Jawaharlal Nehru

“Step Out From the Old to the New”

“जान1 का अ+धकार, जी1 का अ+धकार”Mazdoor Kisan Shakti Sangathan

“The Right to Information, The Right to Live”

“!ान एक ऐसा खजाना > जो कभी च0राया नहB जा सकता है”Bhartṛhari—Nītiśatakam

“Knowledge is such a treasure which cannot be stolen”

“Invent a New India Using Knowledge”

है”ह”ह

IS 9020 (B) (2002): Power Threshers - SafetyRequirements(BI-LINGUAL) [FAD 21: Farm Implements andMachinery]

mfqwlS 9020:2002

(%mfVBilingual)[* 9129:1979* Wd’W 10618:1983

ai13ifa7wTma\~][SupersedingIS9120:1979andIS 10618:19;3]

‘w7mkTJ?m7

?TfRWRm-@ ~?fh(tr?R)— ~?n m @?Tlq( Waiy@9w’r)

Indian Standard

POWER THRESHERS — SAFETYREQUIREMENTS

( First Revision)

W&fRWICS 65.060.50

c3$TTTq32002

Wla-4mvqfimmmFr,9m13’? ?llF~wJf

* m 110002

0 BIS 2002

BUREAU OF IN DIAN STANDARDSMANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

,.

m/sqwtnber 2002 ~ & Price Group 6

i)

ii)

iii)

iv)

IS 9020:2002

‘wwkTm7z-

?ll% m ‘T@ ~?fh (a?R) — TJRIT m W%TTq

( ~.!ll?m)

Indian Standard

POWER THRESHERS — SAFETYREQUIREMENTS

( First Revision)

lmiw

‘2TiR-4

-..

1 SCOPE

1.1 This Indian Standard specifies the safetyrequirements of power thresher.

2 REFERENCES

2.1 The following Indian Standards containprevisions which through reference in this text,constitute provision of this standard. At the time ofpublication, the editions indicated were valid. Allstandards are subject to revision and parties toagreements based on this standard are encouraged toinvestigate the possibility of applying the most recenteditions of the standards indkated- below:

[S No.

210:1993

816:1969

1363 (Part 1):1992

1363 (Part 2):1992

1363 (Part 3):1992

1364 (Part 1):1992

Title

Grey iron castingsrevision)

~out-th

Code of practice for use of metalarc welding for general construc-tion in mild steel (/lrst revision)

Hexagon head bolts, screws andnuts of product grade C : Part 1Hexagon head bolts

Hexagon head bolts, screws andnuts of product grade C : Part 2Hexagon head screws

Hexagon head bolts, screws andnuts of product grade C : Part 3Hexagon nuts

Hexagon head bolts, screws andnuts of product grades A and B:Part 1 Hexagon head bolts

1

1S 9020:2002

*m

?* IS No. Title

1364 (9TFT2): WqRR*q3ik**~?ti 1364(Part 2): Hexagon head bolts, screws and

1992 Q1-iiitFq ~(w)* z:$rPT2 1992 nuts of product grades A and B:

q?fl’d~~ Part 2 Hexagon head screws

1364 (WJT3) : 3WFIt3q@17~*~?fht 1364(Part 3): Hexagon head bolts, screws and

1992 mti=ikq ~(h)&t7w:wr3 1992 nuts of product grades A and B:

q?wti= Part 3 Hexagon nuts

1364 (W 4) : WllKik3q&’R~*~?fPi 1364(Part 4): Hexagon head bolts, screws and

1992 fi=Rz, ~(ti)*w:$TFT4 1992 nuts of product grades A and B:

~?fl’dtitiw (m) Part 4 Hexagon thin nuts (cham-fered)

1364 (WT 5) : EFR*q&k**~?fFf 1364(Part5): Hexagon head bolts, screws and

1992 m-ii*, ~(ti)*w:mT5 1992 nuts of product grades A and B:

m?ti*~(WF@@@ Part 5 Hexagon head screws (un-chamfered)

1691 : 1980 @6ii’6T&R~wH+lm 1691:1980 Cast iron and mild steel flat pulleys

m (~flWl) (second revision)

1891 (WT 1): %@i$+~dlTYiT&tT3&TFR

1994 @:wJTlwFrl=rmf*m

* (Zh17y?tkm-)

1929 : 1982 m~m+ftrqmrfmi

m+ft$Z(12*15~=WlT)

(m@@+’)1977 : 1996 lmFIT*&mf%mmmT

m (~mm2062 : 1992 mrT=q@mKtit*ftTqm(#f77

W-2292 : 1974 mmwti*mim(w7r

me2293 : 1974 fm-?fPi m’f&rTmff@i+i(QmT

mm2494 (Wl):V-@ 3hf@FF%Rifti~ThT

1994 Tfwv-wq: wrlwmrmitwr

@ (~@ml)

2637 : 1991 s@r?cmiR +ttFR*, xiFrwh

ditT$Frm (m@w’)

1891 (Part 1): Conveyor and elevator textile1994 belting : Part 1 General purpose

belting (fiiurth revision)

1929:1982 Hot forged steel rivets for hot clos-ing (12 to 36 mm diameter) (firsrrevision)

1977:1996 Low tensile structural steels (thirdrevision)

2062:1992 Steel for general structural purpose~ourfh revision)

2292:1974 Taper keys and keyways (firstrevision)

2293:1974 Gib-head keys and keyways @rstrevision)

2494 (Part 1): V-belts — Endless V-belts for1994 industrial purposes : Part 1

General purpose belts (secondrevision)

2585:1968 Black square bolts and nuts (diarange 6 to 39 mm) and black squarescrews (dia range 6 to 24 mm) (firstrevision)

2591:1982 Dimensions for hot rolled steelbars for threaded components(second revision)

2637:1991 Steel roller chains Type S and Cattachments and chain wheels (@rrevision)

2693:1989 Power transmission — Bush typeflexible couplings (second revision)

--- -“

2998: 1982 ?ti (* -) + ftF! W@ 2998:1982 Cold forged steel rivets for cold

ti?(WIH &R&(l#16f%$t closing (1 to 16 mm diameter) (first

am) (WTwyl??wl)revision)

2

IS 9020:2002

*W3138 : 1966

3142 : 1993

4454 (m 1) :

1981

4454 (w-P12) :

1975

4773 : 1979

5669 : 1987

5932 : 1970

7461 (WT 1) :

1993

7461 (WJ12) :

1993

7461 (WJT3) :

1993

8132 : 1999

9019 : 1979

?tki%q4FFzaT 7-3m @J?r)-31=a#Ff

IS No.

3138:1966

3142:1993

4454 (Part 1) :1981

4454 (Part 2) :1975

4773:1979

5669:1987

5932:1970

7461 (Part 1):1993

7461 (Part 2):1993

7461 (Part 3):1993

8132:1999

9019:1979

Title

Hexagonal bolts and nuts

Pulleys — V grooved pulleys forendless V-belts sections Z, A, B,C, D and E and endless wedgebelts sections SPZ, SPA, SPB andSPC (second revision)

Steel wires for cold formedsprings: Part 1Patented and colddrawn steel wires — Unalloyed(second revision)

Steel wires for cold formedsprings : Part 2 Oil hardened andtempered spring steel wire andvalve spring wire — Unalloyed(fht revision)

Plumber blocks for rolling bear-ings (first revision)

General plan of boundarydimensions for radial rolling bear-ings (/W revision)Boundary dimensions for thrustball bearings with flat seats

General plan of boundarydimensions for tapered roller bear-ings : Part 1 Single row bearings(second revision)General plan of boundarydimensions for tapered rollerbearings : Part 2 Double rowbearings (second revision)General plan of boundarydimensions for tapered roller bear-i~gs: Part 3 Flanged cups (secondrevision)Tractors and machinery foragriculture and forestry, poweredlawn and garden equipment —Operator’s manuals — Contentand presentation (second revision)Code of practice for installation,operation and preventive main-tenance of power threshers

3 TERMINOLOGY

3.0 For the purpose of this standard in addition tothe definition given in IS 9826, the following defini-tions shall apply.

3.1 Prime Mover

A power source used for operating the thresher, suchas electric motor, tractor or stationary engine etc.

-----

+“-4IS 9020:2002

3.2 Transmission System

Any shaft, wheel, drum, pulley, system of pulleys,coupling, clutch, driving belt and chain or otherappliance or device by which the motion of a primemover is transmitted to or received by the powerthresher and its any component.

4 MATERIALS

4.1 Material for construction of different componentsshall be selected from those given in COI3 of Table1. The material should, as for as possible, conform tothe Indian Standards given in COI4 of Table 1.

Table 1 Material Used for Various Parts ofPower Thresher

m. $TPIWwf W14 Ti’?’Mlw-dkrm3 sl Name of Part Material Ref to IndianNo. Standards

(2) (3) (4)(3) (4)(1)

FrameShaft

Concave

Threshing drum Mildsteel 1S2062orBlower 1s 1977

Sieve

Beater arm

Fly wheel Cast iron 1s210Pulley Castiron 1s210

Mildsteel 1S2062or1S1977

0ii)

W&H 2062 31’tWf iii)

%S-?4’m W&W 1977 iv)

v)vi)

vii)

miim WF$!w210 viii)

mm W@qi 210 ix)

@ iflwrdwl mm W&H 2062 or x) Transport wheel

W@!731977

mm WI’RW21O

Wgm -

xi) M Tl=hm W1’&W2591

xii) @ (WT$?RT) Whm W&W 2591

Cast iron 1s210Pneumaticwheel —

xi) Beater Carbonsteel 1S2591xii) Spikes Carbon steel IS 2591

----

.,

4.2 Material for various components of differenttypes of feeding systems are given in Annex A.

4.3 The bearings, plumber blocks, keys, belts and

*Wmw7tr4@ *twymF?R7rrRqIWm pulleys, chain, rivets and bolts shall conform to

*WT%f*@*a@?l relevant Indian Standards. A list of such standards isgiven below. .

~–- 1929 @7* 2998 I 4.3.1 Rivets — IS 1929 and IS 2998.

G%?’—M&H 1363 ($lFf 1, 2 ?r?k 3), * 4.3.2 Bolts — IS 1363 (Parts 1, 2 and 3), IS 1364

4.3.1

4.3.2

1364 (~ 1 # 5), W&H 2585 ~ & 31381

@–3_TE@jH 2494 (WTl)l

*W—* 1891 (WJT1)1

@–W#QIT 1691 &1’T31T@fT31421

*–*2292C$$731Ti& 22931

(Parts 1 to 5), IS 2585 and IS 3138.

4.3.3 4.3.3

4.3.4

4.3.5

4.3.6

4

Belts — IS 2494 (Part 1).

Conveyor Belt — IS 1891 (Part 1).

Pulley — IS 1691 and IS 3142.

Key — IS 2292 and IS 2293.

4.3.4

4.3.5

4.3.6

)., r

. A

IS 9020:2002

4.3.7 Bearing and Block — IS 7461 (Parts 1 to 3),IS 4773, IS 5669 and IS 5932.

5 GENERAL REQUIREMENTS

5.1 Fastening connections between differentcomponents shall be made in such a way that theywill not get loosened due to vibration or suchother forces as may occur during normal operation.5.2 The thresher shall be so designed that generalmaintenance, inch.dhg cleaning, replacement ofparts can be done without damage to the componentsor danger to the operator.

5.3 Proper arrangements for lubrication of movingcomponents shall be provided. All points requiringfrequent lubrication shall be easily accessible. In caseof bearings where these are inaccessible or in anhazardous position and require frequent lubrication,the means of lubrication shall be located in anaccessible position and the lubricant piped into thebearing.5.4 Bearings shall be adequately protected againstthe ingress of dust.5.5 In case the prime mover is to be mounted on thethresher, a protective cover shall be provided toprevent it from dust or straw falling on it and to ensureoperator’s safety.5.6 Provisions shall be made for tightening of thebelts.5.7 Threshing drum shall be statically balanced.

5.8 Provision for easy adjustments of concaveclearance, airflow rate, screen pitch, sieve speed,eccentricity of shaking mechanism, sieve clearance,etc, should be made.

5.9 Provision for easy transportation of the thresherand towing with the tractor shall be provided.

5.10 Each thresher shall be provided with ano~rator’s manual. (see IS 8132 and IS 9019) inHindi or English or any other vernacular language.

5.11 All the required tools for operation,maintenance and adjustment of various componentsof the thresher shall be supplied by themanufacturers.5.12 The thresher shall be run idle (without load) forat least 5 minutes at the specified speed of threshingcylinder to check the following:

a)

b)

c)

c

There shall not be any undue knocking orrattling sound,

Drive belts shall not slip frequently,

Fan shall run without any significant vibra-tions,

Y--

,..-

d) Sieve shall oscillate smoothly, and

e) Thresher shall not vibrate unusually.

6 GUARDING OF TRANSMISSION SYSTEM

6.1 Guards shall be provided on all moving parts ofthe thresher to prevent accidental contact of personsor parts of clothing being caught. In case of PTOdriven threshers guards shall be provided on the PTOshaft.

6.2 The guards shall be made of blind sheets of mildsteel (see IS 2062) having a minimum thickness of1.6 mm.

6.3 The guards shall be so designed as not to hinderin easy adjustment, servicing and operation of thethresher.

6.4 All guards shrdl be either permanently attachedor firmly secured to prevent their removal withoutthe aid of tools. The servicing and adjustments shouldbe possible without complete removal of the guatds.

7 FEEDING SYSTEMS

7.1 The feeding system in power threshers shall beof the following types and shall conform to therequirements given in Annex A.

a) Chute,

b) Hopper,

c) Conveyor, and

d) Feed roller.

7.1.1 The recommended feeding system for varioustypes of threshers are given in Table 2 for guidance.

Table 2 Recommended Feeding Systems

S1No. Type of Thresher Type of Feeding Systems(1) (2) (3)

i) Hammermilltype Chute

ii) Drumy type do

iii) Chaff-cutter type Feed roller with chute or conveyor

iv) Spiketoothtype Chute,hopperor conveyor

V) Rasp-bar type do

NOTE — Hopperand conveyor in spike tcmth type threshersshould normally he used if the power rating is 7.5 kW or more.

W1’aalaafam

8 WORKMANSHIP AND FINISH

8.1 Welding used for joining different componentsshould be done in accordance with IS 816.

6

,.=----’

.J

.

.,,

I

Is 9020:2002

.

i

8.2 The components shall be free from rust andshall have protective coating to prevent corrosion andsurface deterioration in transit and storage.

8.3 The components should be free from pits, burrsand other defects that may be detrimental for their use.

9 MARKING

9.1 Each thresher shall be marked with thefollowing particulars:

a)

b)

c)

d)

e)

M~nufacturer’s name and his recognized trade-mark, if any;

Model number

Batch or code number, or S1No. if any;

Power rating, kW; and

Revolutions per minute of the threshing drumand its direction of rotation.

9.2 Each thresher shall be fitted with a label/platecontaining cautionary notices written in vernacularlanguage and their pictorial representation as givenin Annex B.

9.3 BIS Certification Marking

Each thresher may also be marked with the StandardMark.

9.3.1 The use of the Standard Mark is governed bythe provisions of the Bureau of Indian Standards Act,1986 and the Rules and Regulations madethereunder. The details of conditions under whichthe Iicence for the use of the Standard Mark may begmnted to manufacturers or producers may beobtained from the Bureau of Indian Standards.

,-

7

IS 9020:2002

WJitT‘w

-n--

(-4.2 & 7.1)

*?T?* m***

ANNEX A

(Clauses 4.2 and 7.1)

REQUIREMENTS FOR FEEDING SYSTEMS OF POWER THRESHERS

T-1 .2 m

T-1.3 m

ai. u.m-w~w T ?#$m-Wlm, fam m m fw F@

(1) (2) (3) (4) (5) (6)

i) 3.7 500 200 50 125

ii) 5.5 550 200 60 175

iii) 7.5 600 220 60 190

iv) 11 &’)T31f@5 650 220 60 200

A-1 FEEDING CHUTE

A-1.l Material

Mild steel sheet (see IS 2062) shall be used in themanufacture of the feeding chute. The thickness ofsheet shall not be less than 1.6 mm.

A-1.2 Shape

The shape of the chute shall be as shown in Fig. 1.

A-1.3 Dimensions

A-1.3.1 The total length of chute, length of coveredportion (see B and Din Fig. 1) shall be 900 mm, Minand 450 mm, Min respectively. The angle of lift ofcovered portion (see ~ Fig. 1) shall be between 10°to 30°. However, the length of the covered portionof chute for chaff-cutter type thresher shall not be lessthan 550 mm.

A-1.3.2 Other dimensions, when read in conjunctionwith Fig. 1, for feeding chute of hammer mill type,drummy type and chaff-cutter type threshers ofvarious power ratings are given in Table 3 forguidance.

Table 3 Recommended Dimensions of Chute forHammer Mill, Drummy and Chaff-Cutter Type

Threshers

S1 Size of the Prime A c E FNo. Mover for mm mm mm mm

the Thresher, kW(1) (2) (3) (4) (5) (6)

i) 3.7 500 2tXl 50 125

ii) 5.5 550 2(K) 60 175

iii) 7.5 600 220 60 190

iv) 11 and above 650 220 60 200

A-1.3.3 Other dimensions, when read in conjunctionwith Fig. 1 for chute of spike-tooth cylinder typethresher of various power ratings are given inTable 4 for guidance.

,.. --’

,

.,

8

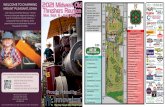

FIG. 1 AN IMPROVED FEEDING CHUTE

COVERED PORTION —?61 @ll W

T–A

+–B@?-c8–D+–E

Is 9020:2002

1A

,.---’

,

9

IS 9020:2002

alRFK14wl%K gyRRlwzlwiM?aa**

m@fkrwnq

(WW%-1.3.3)

Table 4 Recommended Dimensions for Chute forSpike Tooth Cylinder Type Threshers

(Clause A-1.3.3)

*.!aTmqT? ail c’ at .#TJTLamfi17, fm7fm$tiwiwr @Ffr

(1) (2) (3) (4) (5) (6)

i) 3.7 440 350 60 190

ii) 5.5 480 400 60 190iii) 7.5 540 480 60 190

iv) 11 ** 590 530 60 210

S1 Size of the Prime A c E FNo. Mover for Threaber

kW mm mm mm mm(1) (2) (3) (4) (5) (6)O 3.7 350 60 190

ii) 5.5 4s0 400 60 190iii) 7.5 540 4s0 60 190

iv) 11 and above 590 530 60 210

A-1.4 Other Requirements

A-1.4.1 To facilitate easy and smooth feeding of thecrop during operation, the feeding chute shall beproperly mounted on the thresher. In the mountedposition, angle ct (see Fig. 1) shall be kept as unde~

a) For hammer-mill and drummy-type threshers— 10° to 15°

b) For chaff-cutter type threshers — o“ to 5°

c) For spike tooth type threshers — 10° to 15°

A-1.4.2 No sharp edges shall be provided on thefeeding chute.A-1.4.3 The covered portion of the chute shall berigidly attached and shall not be able to be detachedwithout cutting.A-1.4.4 The feeding chute shall be so fixed with thethresher that it is not possible to remove it easily.

A-2 FEEDING HOPPER

A-2.1 Material

A-2.LI Hopper — Mild steel sheet (see IS 2062)shall be used. The thickness of the sheet shall not beless than 1.6 mm.A-2.1.2 Star Wheels — Cast iron (seeIS210) shall beused.

A-2.13 Star Wheel Shafi — Mild steel rod (seeIS 2062) shall be used.

A-2.2 Shape

The sliapeof the hopper unit shall be as shown in Fig. 2.

A-2.3 Dimensions

A-2.3.1 The dimension A in Fig. 2 shall be 400 mmmore than the length of the threshing cylinder and shallbe declared by the manufacturer.

A-2.3.2 The thickness of sheet for the hopper shall be1.6 mm.

A-2.3.3 ‘fhedimensionsofrhehopperandstarwheelswhenA inconjunctionwithFig.2 shallbe as giveninTable5.

10

IS 9020:2002 +-4

1

~M~

f

FEEDING HOPPER

. -----

LT~R~s~l~G cyL~~ogR

*2 w’TJ’ri$m$mTJT

FIG.2 DETAILS OF FEEDING HOPPER

STAR WHEEL SHAIT

FEEDING HOPPER

S+AR WHEEL

THRESHING CYLINDER

a —G

71:

m —Lw —M

11

IS 9020:2002

*5m3fklzr?**wlPl

(7?W6-2.3.3)

T--”-

T. *. it?rl * far! G? ?/7 3? imtiwrx

mq??=l WWwm f5

m, Eli?l’1 Mmmmmm mm

(1) (2) (3) (4) (5) (6) (7) (8) (9) (lo)

i) 7.5 900 180 340 425 280 45 20 50

ii) 11 900 200 370 500 280 45 20 50

iii) 15 925 220 400 535 280 45 20 50

iv) 18.7 &R C@l’T 950 240 430 565 280 45 20 50

m-mw*m* 7.5hw**mm*aw%*%l

Table 5 Dimensions of Hopper and Star Wheel(Clause A-2.3.3)

S1 Size of the Prime B c D E F G H aNo. Mover for Thresher Min Min Min Min *5

kW mm mm mm mm mm mm mm deg(1) (2) (3) (4) (5) (6) (7) (8) (9) (lo)

i) 7.5 900 180 340 75 280 45 20 50ii) 11 900 200 370 500 280 45 20 50

iii) 15 925 220 400 535 280 45 20 50iv) 18.7 and above 950 240 430 565 280 45 20 50

NOTE — Hopperfeedingsystem is normally used with the threshers of 7.5 kW or more power ratings.

A-2.3.4 Mounting Dimensions

A-2.3.4.1 The feed hopper shall be built as an integralpart of the thresher.

A-2.3.4.2 The Iw&ationof the star wheels in relationto hopper sides (see J in Fig. 2) shall be 75 mm. Thecentre to centre dkmce of two star wheels (see K inFig. 2) shall be 220 mm.

A-2.3.4.3 The fixation of star wheel shaft in hopper(see L in Fig. 2) and fixation of star wheel in relationto centre of threshing cylinder (see M in Fig. 2) shallbe 350 mm and 450 mm respectively.

A-2.4 Other Requirements

A-2.4.1 The hopper shall be attached on the top of thethreshing cylinder or on the side. If it is attached onthe sides a feed regulating shaft shall be provided andit shall be operated at a speed of 25 to 55 rpm.

A-2.4.2 No shaxp edges shall be provided in hopperor on star wheels.

A-2.4.3 The casting shall be smooth and shall not beporous.

!\\.’

.“

1.‘.

‘w’,,

j

.----

12

IS 9020:2002-_+-a—.

3-2.5 W ~ ~ WIW 3R JiW17& W @ W A-2.5 Other types of feeding mechanisms may also

wd-J-rmmrrwTJTammTJTg&*lmT be used with feeding hoppem. A typical shape of the

**qm-m3a4hHl~hhopper unit with feed roller type feeding meehanism

Zi’WW7@i7@Tf R!R*mmwis shown in Fig. 3. The material and dimensionalrequirement of feed roller type feeding mechanism are

T-2.5.1 @7 =-2.5.2 ti ~ @ %I given in A-2.5.1 and A-2.5.2.

m

FEEDING HOPPER

o

THRESHINGCYLINDER

FIG.3 DETAILS.OFFEEDINGHOPPERWITHFEEDROLLER

mm. FEEDINGHOPPER-WJrm. FEED ROLLER

v m —FC: 77 —G?ft-c $ —J8—D ‘# —K$–E m —L

T-2.5.1 W@ A-2.5.1 Material

@’W,~~~W~%@~~@ The material for the construction of hopper, feed

d$wTtis’wT3(W&W2062@)~*~Wl ~~2062)rollers and feed roller shaft shall be of mild steel (see

13

,-----

IS 9020:2002

L ‘

9 t%

=-2.5.2 3TRiT4 A-2.5.2 Dimensions

3-2.5.2.1 f?H2~~m~wTwTA~@%I’@~?R A-2.5.2.1 The dimensions A in Fig. 2A shall be

@i m @ FFS!T$~ 400 m - * ~ ~ @Ommmorethant helengthofthet hreshingcylinder

-mm* Gilqland shall be declared by the manufacturer.

T-2.5.2.2 ‘df47 ~ ~ !WJt5 ~ @ 7il?7 ~ WJT A-2.5.2.2 Thethickness ofsheet forhopper shall be

~1.6~~1 1.6 mm, Min.

%-2.5.2.3 %T 3 ~f?_@ll!TIT#w ?hW_Wh$ A-2.5.2.3 The dimensions of the hopper and feed

3TRiT4Hlft$%T 6tif@71q TTr#i&3F@R#l rollers when read in conjunction with Fig. 3 shall beas given in Table 6.

O 15 740 150 545 560 300 100 15 55

ii) 26.3 900 200 560 570 300 100 15 55

iii) 37.3 925 230 570 580 300 100 15 55

Table 6 Dimensions of Hopper and Feed Roller(Clause A-2.5.2.3)

sl Size of the Prime B c D E F G HNo. Mover for Thresher, kW

cr.Min Mill Min Min *5mm mm mm mm

(1)mm mm mm

(2) (3)deg

(4) (5) (6) (7) (8) (9) (lo)i) 15 740 150 545 560 300 100 15 55

ii) 26.3 900 200 560 570 300 100 15 55iii) 37.5 925 230 570 580 300 100 15 55

NOTE — Hoppr feeding system with feed roller type feeding mechanism is normally used with thresher of 15 kW or morepower ratings.

%-2.5.2.4 ~ ~ W ~ &i17~ * %5 & A-2.5.2.4 The feed hopper shall be built as an integral

matiml part of the thresher.

A-2.5.2.5 The location of the feed rollers in relationto hopper sides (see J in Fig. 3) shall be 90 mm. Thecentre to centre distance of two feed roller rods (seeKin Fig. 3) shall be 355 mm.

A-2.5.2.6 The fixation of feed roller in hopper (see Lin Fig. 3) and fixation of feed roller in relation tocentre of threshing cylinder (see M in Fig. 3) shallbe 125 mm and 450 mm respectively.

A-2.5.2.7 No sharp edges shall be provided in hopperor on feed rollers.

A-3 POSITIVE FEED ROLLERS WITHCONVEYOR OR CHUTE

14

T-3.1.3

T-3.1.4

3+3.1.5

3-3.1.6

l)i%jl

T-3.1.7

%-3.1.8

T-3.1.9

a7FFi5-?ki’T-aad FilFT(wl&w210@)l

?iw?k77- Raal Fit3r(371fqH 210at$l

%’7JT?k’7- @FilFr(*210w)l

FF?wl&’T -&lwnH[*4454(wr

W*–~W(ti2062~l

*-za7iftiFr (@wr210t@l

@77@aT-@*(*21012@l

IS 9020:2002

A-3.O The system is used on a chaff-cutter typethresher. It comprises a feed pressing roller, twocorrugated feed rollers and a feeding chute orconveyor with power transmission system. For thistype of threshers with power ratings, of 15 kW ormore, a feed reversing mechanism is recommended.It comprises a gearbox, a clutch lever and two joiningshafts with universal joints (see Fig. 4), In somethreshem fast and loose pulleys to cut-off thedrive to the upper and lower feed rollers are also used.In the feeding system with feed reversing mechanism,if the hand of an operator gets entrapped, the clutchlever is pressed by his hand or shoulder and the driveto the feed roller is cut-off in the neutral position orthe direction of the upper and lower feed rollexs isreversed.

A-3.1 Material

A-3.1.1 Chute — The chute shall be made of mildsteel sheet (see IS 2062) having thickness of not lessthan 1.6 mm.

A-3.1.2 Conveyor— Canvass or rubber [see IS 1891(Part 1)] or steel slats (see IS 2062).

A-3.1.3

A-3.L4

A-3.1.5

A-3.1.6

Driving Roller — Cast iron (see IS 210).

Pressing Roller — Cast iron (see IS 210).

Feed Rollers — Cast iron (seeIS210).

Tension Spring — Spring steel [see IS 4454(Part l)].

A-3.1.7 Clutch Lever — Mild steel (see IS 2062).

A-3.1.8 Gears — Cast iron (see IS 210).

A-3.1.9 Gear Box — Cast iron (see IS 210) or mildsteel (see IS 2062).

A-3.1.1O Gear Shajl — Mild steel (see IS 2062).

A-3.2 Shape

The shape of feeding system with feed reversingmechanism used for chaff-cutter type threshers isshown in Fig. 4.

A-3.3 Dimensions

A-3.3.1 If chute is used, the dimensions shall be asgiven in A-1.3.1 and A-1.3.2 and the arrangementshould be as shown in Fig. 5.

A-3.3.2 If conveyor is used, the length of centre tocentre distance of conveyor rollers (see A in Fig. 4)shall be minimum of 1200 mm. Minimum of450 mm of length of conveyor at feed inlet side shallbe covered.

15

Is 9020:2002

,,9

It /-TENSION SPRING

-A * I1: 1! ;L--IL,-. --f

m4 =n%-zT$’? $t?17*fw*m@

FIG.4 FEEDREVERSINGDEVICEFORCHAFF-CUTTERTYPETHRESHERS

BEVEL PIN1ON

BEVEL GEAR

REVERSE GEAR

FEED REVERSING DEVICE

CLUTCH GEAR

UNIVERSAL JOINTSHA~CLUTCHLEVERCONSTANT MESH GEAR

FORWARD GEAR

TENS1ON SPRING

FEED REVERSING ROLLER

CANVASS FEED CONVEYOR

UPPER FEED ROLLER

LOWER FEED ROLLER

THRESHING CYLINDER

CHOPPING BLADES

DRIVING ROLLER

‘., .

IS 9020:2002

m$tm Frf@Rif4%l*5 wwiiz7zr?Jfit? 17timwdwafyfkTwJrm

.M1dimensions in millimetres.

FIG. 5 SAFE FEEDING CHUTE USED ON A CHAFF-CTJITER TYPE THRESHER

m – Min

fPJfa$lm’G’FRTwm-l173mrWmTr?l

A-3.4 Feed Reversing Device

A-3.4.1 Functioning of Device (see Fig. 6)

Pinion ‘A’ receives the drive from the main shaft ofthe thresher by means of chain and sprocket. Pinion‘A’ meshes with bevel gear ‘B’ which is mounted ona counter shaft. On the same shaft a spur pinion ‘G’is mounted which slides on splines with the help ofa hand lever. When pinion ‘G’ meshes with the gear‘F’ on the lower feed shaft, the lower feed rollerrevolves in clockwise direction and the upper feedroller in anti-clockwise direction. This is the feed-inposition.

A-3.4.1.1 When pinion ‘G’ is meshed with gear ‘C’,the direction of rotation of the upper and lower rollersis revemed. In other words, the upper roller rotates inclockwise and the lower roller in anti-clockwisedirection. This is the reversed or feedback positionand the material being fed moves out instead ofmoving into the threshing chamber.

A-3.4.1.2 The third position is when pinion ‘G’ doesnot mesh either with gear ‘F or ‘C’. This is theneutral position. The lever to slide pinion ‘G’ can beactuated by hand or foot or shoulder.

I

17

IS 9020:2002

FORWARD SPEED REVERSE SPEED

*PATH OF TRAVEL OF THE POWER

~ ROTATION OF GEARS AND SHAFTS

FIG. 6 POWER TRANSMISSION THROUGH FEED REVERSING SYSTEM FORCHAFF-CUITERTHRESHER@@ — UPPERSHA~ T–AzfiWQ?7g# — COUNTER SHAFT 8–B=flmqi — DRIVESHAFT #l-cmql — LOWER SHAfW D* ti — FORWARDSPEED ::E~m ~ — REVERSESPEED —

7–;

+PATtf OF TRAVEL OF THE POWER + ?lf% %t * %t f%fTl

G ROTATION OF GEARS AND SHAFTS G @ * W * ~ * f??n

3-3.4.1.3 W ~ ~ WJjF ~ ~ _ -7 % A-3.4.1.3 The details of gears in this system shall be

RWTW31 as given in Table 7.

i71RlTf7*w@8JqYFwwm Table 7 Details of Gears in the Feed ReversingMechanism

mu. mwi#TfaifmlJl aK@Rim7FPTla S1 Type of Gear/ Designation Shaft on whicham No. Pinion Mounted

(1) (2) (3) (4)(1) (2) (3) (4)

i) *+IUT q %allwva’ta?nqi~ O Bevel gear A Splined shaft on main shaft

ii) @ * -- (@) ii) do B Counter shaft

iii) WTm 7$t r$K3WqTW iii) Spur pinion c Counter shaft

iv) ~ * a GQ?tmm@f iv) Spur gear D Upper feed roller shaft

vi) @ w f%fr$’TcJTtlaT@ vi) do F Lower feed roller shaft

vii) * * $ %?TlWqT6RTfT?11’W vii) Bevel gear G Splined shaft on main shaft

18

IS 9020:2002

A-3.4.2 Functioning of Device (see Fig. 7)

If the roller handle is put in backward direction, bevelgear ‘A’ which is mounted on splined shaft receivesthe drive from main shaft. The main shaft movingin anti-clockwise direction will rotate bevel gear‘A’ also in anti-clockwise direction. Bevel gear ‘A’meshes with bevel gear ‘B’ which is mounted on acounter shaft, having at other end a pinion ‘C’. Thiswill rotate bevel gear ‘B counter shaft and pinion‘C’ in clockwise direction. Gear ‘D’ meshes withpinion ‘C’ and rotates in anti-clockwise direction.Gears ‘D’ and ‘E are on the same shaft, hence thedirection of rotation of ‘E’ would also be the same.Gears ‘E’ and ‘F mounted on upper and lower feedroller shafts respectively, mesh with each othentherefore the gear ‘F’ rotates in clockwise direction.The direction of rotation of upper and lower feedrollers would be the same as that of gears ‘E’ and ‘F’.This is the feed-in position.

A-3.4.2.1 If the roller handle is put in forwarddirection, bevel gear ‘G’, which is mounted onsplined shaft, receives the drive from main shaft andmoves in anti-clockwise direction. Bevel gear’ G’meshes with bevel gear ‘B’. The bevel gear ‘B’,counter shaft and pinion ‘C’ will rotate inanti-clockwise direction. This will ultimately lead tothe rotation of lower feed roller in anti-clockwisedirection. This is the reversed or feedback positionand the material being fed moves out instead ofmoving into the threshing chamber.

A-3.4.2.2 In case the roller handle is kept in centralposition, feed-revecsing mechanism will not operate.This is the neutral position.

A-3.5 Where conveyor feeding system is notprovided in a chaff-cutter type thresher nor thechute is covered from top, a second set (secondaryset) of feed rollers shall be placed at 200 to 300 mmaxial distance to assist feeding of the crop to theprimary set of feed rollers. The top roller (which isidle, that is, not driven positively) of the second set ofthe rollers shall have moderate axial grooves and aspring control to let the hand be withdrawn withoutinjury before the hand gets to the second set of rollers.

A-3.6 Other Requirements

A-3.6.1 All the sharp edges shall be avoided.

A-3.6.2 Castings shall be smooth and shall not beporous.

A-3.6.3 The shifting of gear shall lx easy and smooth.

19

Is 9020:2002 k---%

+ ‘F

(Ip) — —i?’

j\9 ‘“R

/ROLLER SHAFT

//

REVERSE M

4+

,

. F’ r-b

_ or————————————.7 7

_._. — .—. —

FORWARD MOTIONOIRECTION OF

ROTATIONOFMAIN 5HAFT

*

I_.___ .—. — .—. —

COUNTER SHAFT

HANDLE1

~rUPPERFEEOROI.LER

,41RECTIONOF ROTArlONOF MAIN SHAFT—

I-:

‘p t . .~*-----;

I,

I[n : is “

t–-– –— ---- —--—-i1,

——L_--_–-_;

?F

~--- &

@’+

@-+-

@+

F

[ LOWER FEED ROLLER ~LOWER RoLLER SHAFT

ROLLERSHAFr mm –

HANDLE WW-Z7$J8 —

ROLLERSHA~Mm

LEVERTtr8WJrh I

sPLINEDSHAFr3iT88Fi7y8 —

REVERSEMOTION%Ri$lm@ —

FORWARDMOTIONmwihw.

DIRECTION OF MAIN SHAFT

MAIN SHAFT

COUNI13R SHAFr

ROLLER HANDLE

UPPER FEED ROLLER

UPPER ROLLER SHAFT

LOWER ROLLER SHAFT

LOWER FEED ROLLER

*7 m-W3-Wl_Wam~w*M@*~~

FIG.7 WORKINGOFFEEDREVERSINGMECHANISMFORCHAFF-CUITER TYPE THRESHER

20

. A

T-4.1.1

3-4.1.2

ai-4.l.3

?i’-4.l.4

IS 9020:2002

A-4 CONVEYOR FEEDING SYSTEM

A-4.O Conveyor system is generally used with spiketooth or rasp-bar type threshers of power ratings of5.5 kW or higher.

A-4.1 Material

A-4.1.1

A-4.1.2

A-4.1.3

A-4.1.4

Conveyor — Rubber [see IS 1891(Part 1)].

Fenders — Mild steel (see IS 2062).

Conveyor Roller — Cast iron (see IS 210).

Cover — Mild steel sheet (see IS 2062)having thickness of 1.6 mm, Min. ‘

A-4.2 Shape

The shape of a conveyor system is given in Fig. 8.

A-4.3 Dimensions

A-4.3.1 The centre to centre distance of conveyorroller (see A in Fig. 8), shall be minimum of1000 mm.

A-4.3.2 The length of covered portion of conveyorshall be minimum of600 mm.

A-4.4 Other Requirements

A-4.4.1 All the sharp edges shall be avoided.

A-4.4.2 Castings shall be smooth and shall not beporous.

RASP /-CYLINDER.-Lvv EFt-1 BIIR> /

FENDER

–CONVEYOR

\\

ROLLER

1----- A ~

+=37 — FtZNt)ER m — COVER

w h — CONVEYORROLLER Iwm — RASPt3AR

m — CONEYOR — CYLINDER

r—A

~8%W17~it?17&ftP79RQl~tim

FIG.8 ARRANGEMENT FORFEEDINGCONVEYOR FORRASP-BAR TYPE THRESHER

21

-..-.$4

‘ j

I

-----

Farm Implements and Machinery Sectional Committee, FAD 59

FOREWORD

This Indian Standard (First Revision) was adopted by the Bureau of Indian Standards, after the draft finalizedby the Farm Implements and Machinery Sectional Committee had been approved by the Food and AgricultureDivision Council.

Mechanization of the threshing operations in the country also brought in its wake a chain of accidents tofalm workers resulting in their temporary or permanent disability. This brought to the fore the need forsome immediate measures to safeguard the farm workers against avoidable accidents be it due to any of thevulnerable factors of machine, man, etc. As a number of reports of many farm workers specially the younglosing their limbs poured in, the urgency to provide for safety provisions in the threshers became morepronounced.

Punjab Agricultural University, Ludhiana conducted a survey on the accidents during the wheat threshingseason of 1976. 294 cases were examined and it was observed that the factors responsible for accidentsare as under:

Factors of Accidents Percentagea) Human 72.9b) Machine 12.9c) Crop 9.0

d) Situational 5.2

This standard covers the safety aspects relating to the accidents arising out of machine factor. Human, cropand situational factors have been covered in IS 9019: 1979 ‘Code practice for installation, operation andpreventive maintenance of power threshers’. This standard was first published in 1979.

This revision has been taken up due to foliowing reasons:

i) To incorporate, modifications suggested in Amendments No. 1 to 4;

ii) To incorporate the material requirements for various components of power thresheu

iii) To incorporate requirements given in IS 9129: 1979. ‘Technical requirements for safe feedingsystems for power threshers’ and IS 10618 : 1983 ‘Pictorial representation for cautionarynotices for power threshers’ to make the standard comprehensive and user friendly as these IndianStandards were complementary to the earlier one; and

iv) To up-date the standard.

In the preparation of this standard, considerable assistance has been received from Punjab AgriculturalUniversity, Ludhiana.

For the purpose of deciding whether a particular requirement of this standard is complied with, the finalvalue, observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordancewith 1S2: 1960 ‘Rules for rounding off numerical values (revised)’. The number of significant places retainedin the rounded off value should be the same as that of the specified value in this standard.

Bureau of Indian Standards

B1S is a statutory institution established under the Bureau of Jndian Standards Act, 1986 to promoteharmonious development of the activities of standardization, marking and quality certification of goodsand attending to connected matters in the country.

Copyright

B]S has the copyright of all its publications. No part of these publications may be reproduced in any form

without the prior permission in writing of BIS. This does not preclude the free use, in the course ofimplementing the standard, of necessary details, such as symbols and sizes, type or grade designations.Enquiries relating to copyright be addressed to the Director (Publication’s), BIS.

Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewedperiodically; a standard along with amendments is reaffirmed when such review indicates that no changes areneedecl; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standardsshould ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of‘BIS Catalogue’ and ‘Standards: Monthly Additions’.

This Indian Standard has been developed from Doc : No. FAD59(1060).

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF lNDIAN STANDARDS

Headquarters :

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telegrams : ManaksansthaTelephones :3230131,3233375,323 9402 (Common to all offices)

Regional Offices: Telephone

Central :

Eastern :

Northern :

Southern :

Western :

Manak Bhavan, 9 Bahadur Shah Zafar Marg

{

3237617NEW DELHI 110002 3233841

1/14 C.LT. Scheme VII M, V. I. P. Road, Kankurgachi

{

3378499,3378561KOLKATA 700054 3378626,3379120

SCO 335-336, Sector 34-A, CHANDIGARH 160022

{

603843602025

C.I.T. Campus, IV Cross Road, CHENNAI 600113

{

2541216,25414422542519,25413 15

Manakalaya, E9 MIDC, Marol, Andheri (East) ~83292 95,8327858

J

\

MUMBAi 400093 ~8327891, 8327892

Branches : AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. FARIDABAD.GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR. LUCKNOW. NAGPUR.NALAGARH. PATNA. PUNE. RAJKOT. THIRUVANANTHAPURAM. VISAKHAPATNAM.

Printedat Pmbhat Offset Psess, New Delhi-2